Spectrum Industrial is a British manufacturer with over 30 years experience of providing businesses with solutions to help identify, manage and reduce safety risks and hazards in the workplace.

Spectrum Industrial is a British manufacturer with over 30 years experience of providing businesses with solutions to help identify, manage and reduce safety risks and hazards in the workplace.

With three specialist companies, Centurion Europe, Spectrum Industrial, and Visual Group, we deliver best-in-class solutions across:

• Hardware & DIY • Safety signs & supplies • Visual communications

We offer far more than many realise: a wide, trusted product range backed by industry-leading customer support. Every employee and customer matters to us and that shows in everything we do.

More than products. Partners in progress.

Founded in 1984 as a sole trader, Centurion has grown into one of the UK’s largest distributors for DIY enthusiasts and trade professionals. From our 90,000 sq. ft Doncaster distribution centre, we stock over 27,000 products and ensure fast, reliable delivery. With over 40 years of experience serving retailers and builders’ merchants, we combine:

• ISO 9001:2015 and ISO 14001:2015 accreditation

• Top-quality, affordable products from our own brands and leading labels

• A robust quality management system that drives excellence across product, service, and team Centurion is committed to adding value, quality, reliability, and exceptional service, every time.

Your partner is health and safety solutions specialising in:

Safety Signage • Lockout Tagout Systems

Tagging Solutions • 6S Lean Manufacturing

Through Spectrum Services, we offer site surveys, custom designs, and expert support to strengthen your teams, sites, and safety culture. Our commitment to safety runs deep. Backed by up-to-date knowledge of legislation and decades of experience, we deliver more than products we deliver peace of mind. Partner with Spectrum for smarter, safer workplaces.

Signage that speaks. Service that delivers.

Visual Group is your trusted partner for stand out signage, from outdoor displays to indoor graphics. We design, produce, and install everything in-house at our Doncaster facility, combining cutting-edge technology with hands-on expertise. We collaborate closely with clients, encouraging input at every stage to ensure your vision comes to life.

As a proud, community-focused business, we’re passionate about quality and committed to sustainability, from sourcing to final delivery. Whatever the scale, we deliver signage that makes an impact.

UK manufacturer

Experts in signage

Site surveys

1000’s of standard stock

Fast delivery

Bespoke customer brochures

Dedicated account manager

Technical support and advice

Branded signage

Experts in Lockout Tagout

Committed to CSR

Bespoke design and manufacturing

ISO Accredited

Our digital flatbed printers use the very latest technology to enable us to print extremely high quality graphics onto substrates up to 3m x 2m. Using the latest hardware and software, these machines combine both speed and quality and provide the ultimate in flexibility.

With multiple machines available these are ideal for printing one-off high quality prints through to production runs of many thousands.

Our state of the art digital cutters use optical recognition software to accurately cut a range of materials. We utilise various different cutting methods available depending on the substrate to be cut, from hightensile strength knife blades through to diamond cut routers and oscillating blades. The substrates are placed on a tough cut-resistant conveyor bed to increase productivity and ease the job of the operator. This is the ideal partner to our digital print machines.

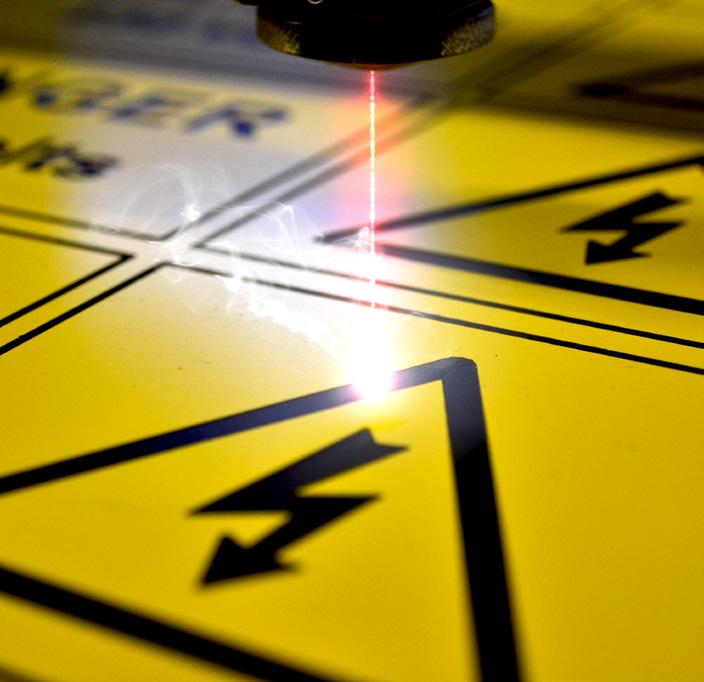

We have multiple laser machines on-site providing us with the ability to cut or engrave various materials. Vector artwork is imported and the computer carefully controls the position and power of the laser to cut or engrave materials as required. Different laser types are needed for different materials and the accuracy provided exceeds router based cutting or engraving.

All permanent road signs must be manufactured by an audited and registered company by law, and have the appropriate labelling attached to the reverse. As manufacturers we are fully accredited to the relevant standards. The UKCA (UK Conformity Assessed) marking is a new UK product marking that is used for goods being placed on the market in Great Britain (England, Wales and Scotland). All permanent roads signs manufactured for installation within Great Britain will be supplied with a UKCA Mark, whereas signs destined for the European market will have the CE Mark.

TAGGING INSPECTION

We have been safety sign experts for more than 30 years and are one of the UK’s largest manufacturers of ISO 7010 compliant safety signs. You can feel confident that any sign you order from us will fully comply with the latest legislation. Our state-of-the-art production facility is based in Doncaster, South Yorkshire. This is where our highly-skilled team manufactures our products using the latest digital printing technology. As well as thousands of ‘off the shelf’ products ready to ship the very same day we have a custom department and can assist with one off jobs or bespoke branded brochures.

Safety signs are essential in any environment as they communicate warnings, instructions and guidelines that help prevent accidents and ensure the well-being of individuals. Health and Safety signs can be broken down into the following categories, as specified by British and European standards. Safety Signage

A site survey can be an essential tool to help in identifying risks, ensuring compliance, and promoting a safe working environment. Our advisory service can help mitigate these risks with the correct tools and equipment, advice on implementation and procedures to ensure long term safety goals are achieved.

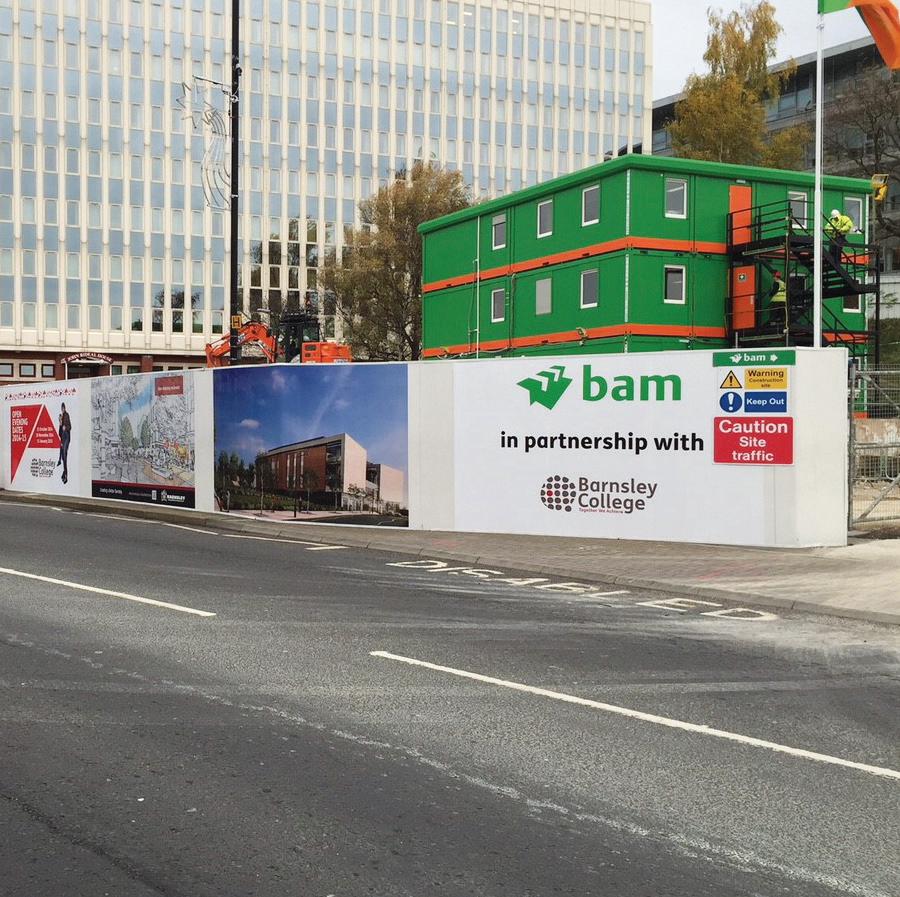

Our sign manufacturing team has many years of experience designing, producing and installing signage worldwide. From the smallest one-off sign, large hoarding boards or print runs of thousands, we can be depended upon to provide a fast and efficient service.

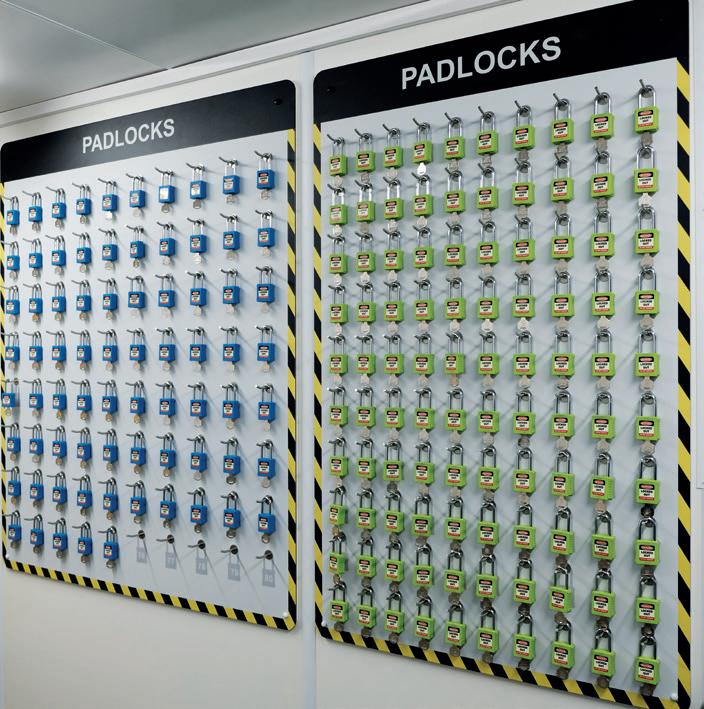

The process and procedure used to ensure that machinery, moving parts and energy sources that are in need of maintenance or cleaning, are effectively isolated so safe work can commence. The process also includes the safe practice of re-energising the machine once the work has been completed, allowing production to continue.

The main application of LOTOTO is locating, identifying and isolating single or multiple points of hazard that could harm employees if the hazard was to re-energise, shift via stored energy or be overridden manually or otherwise.

Major industries are adopting the LOTOTO process due to the awareness and associated real-life risks. It is now being recognised as best practice for safety management in quarries, oil & gas, heavy manufacturing, food processing plants and more. Sectors such as renewable energy, waste and large retail companies are beginning to apply company-wide procedures utilising LOTOTO to ensure employee and operative safety with a structured and controlled procedural method.

We offer hundreds of specialised products ensuring we have a suitable solution for all isolation points.

Our dedicated team is ready to assist you in selecting the appropriate equipment for your specific requirements.

Tagging systems are a useful way of ensuring those who need to access to equipment know that it has been inspected and is safe to use. They also can act as records to help ensure that the equipment inspection procedures and maintenance are kept up to date.

The working at height regulations requires the inspection of scaffolding and ladders from which a person might fall 2 metres or more and the issue of a report by a competent person. Ladder and Scaffolding tags are types of safety inspection tags that are attached to the equipment to indicate whether it is safe to use and therefore prevent accidents.

Tagging systems are a useful way of ensuring those who need to access scaffolding or ladders know that it has been inspected and is safe to use and they can act as records to help ensure that the equipment inspection procedures and maintenance are kept up to date.

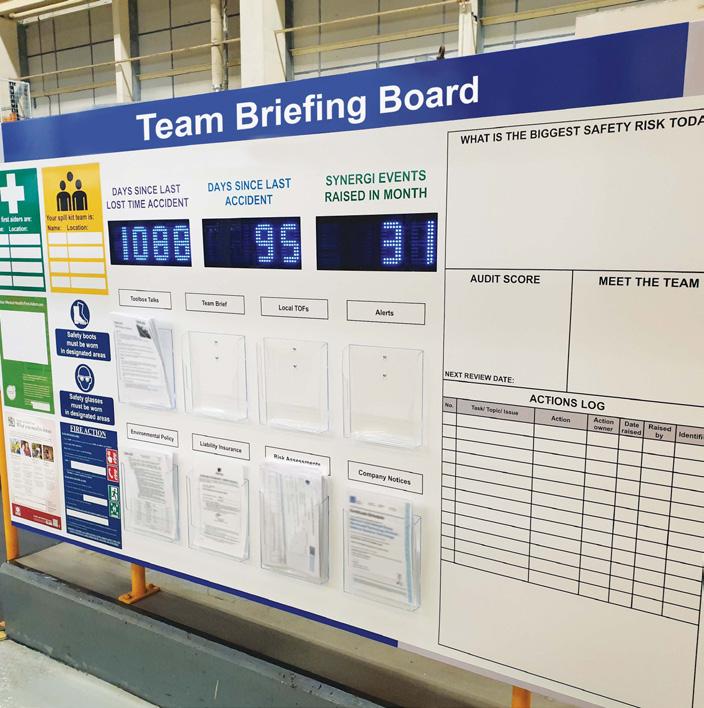

A methodology focused on improving workplace efficiency and safety through a systematic approach. By implementing 6S, organisations can reduce waste, enhance productivity, and create a safer, more organised work environment. Cleaning Stations provide ideal colour coded storage solutions for tools and hygiene equipment.

A tidy, organised workplace allows work to be carried out efficiently and effectively. Using shadow boards as part of a 6S lean programme are an effective visual management tool to keep any shop floor or workshop in order all year round.

By providing a dedicated area for anything from cleaning equipment, tools and machinery parts they ensure everything can be easily located and should never get lost. Encourage your customers to de-clutter and start thinking about their work environment and how Shadow boards are a simple tool to help in commercial and industrial environments.