By Dorothy Crouch Contributing Writer

Fashion is moving forward from thinking of responsible, sustainable apparel development as a goal that pulls only from nature. Minimally processed natural materials and production practices that rely on cleaner output with fewer negative environmental impacts are foundational components of making sustainable clothing. Moving forward, the industry will rely on scientific discoveries and technological innovation to push through boundaries and enhance the capabilities of nature. Brands and designers are working with partners who have explored how science and technology can keep fashion clean and honest and have brought about the innovations that have promoted progress in apparel sustainability. Fashion is becoming smarter, more agile and technologically advanced from farm to sales floor thanks to brands and designers who are taking greater responsibility and their partners, who are developing innovation that supports an evolution toward sustainable apparel-making processes.

Sustainability page 4

By Dorothy Crouch Contributing Writer

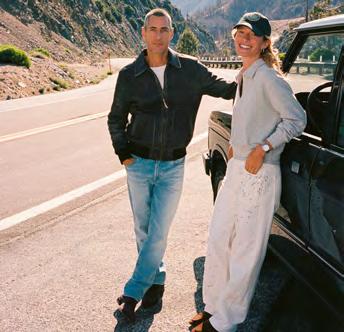

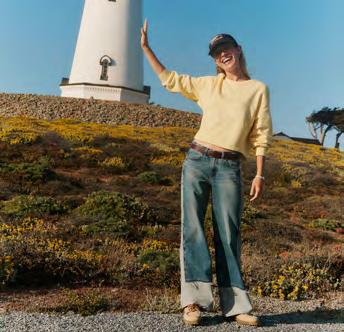

Designers at Southern California denim and knitwear brand AG Jeans have been proud of the brand’s Golden State heritage since the label’s founding in 2001. They now highlight the region’s allure with the brand’s Spring 2026 Park Pass collection, which features imagery of a stylish road trip through a selection of the state’s national parks: Yosemite, the Channel Islands and Joshua Tree. The brand has pursued more-responsible denim and apparel making over the years through practices that include water-saving initiatives, ozone and laser technologies, responsible fibers, and solar power, all of which contribute to land preservation and environmental protection. ➥ AG Jeans page 3

Los Angeles–based Pacsun continues to steer youth culture as it celebrated the debut of “The Youth Report by Pacsun” and Pacsun Youth Advisory Council during its inaugural Pacsun Purpose Partner Summit, held Sept. 18 at Rolling Greens in downtown Los Angeles. The event highlighted Gen Z and Gen Alpha voices, community and purpose, drawing more than 300 experts in fashion, media, wellness, sports and entertainment, in addition to next-gen creators.

“The Youth Report” was developed in partnership with GlobalData through feedback from more than 6,000 respondents ages 11–24. This complimentary resource was created as an annual report to guide brand decision-makers, educators and those who shape culture as they learn the priorities and influences that drive young consumers.

“Pacsun has adopted a stewardship role toward young people—this is why we designed ‘The Youth Report’ as an open resource to provide meaningful takeaways that help others engage, uplift and celebrate these generations and honor their voices,” said Brieane Olson, CEO of Pacsun.

Recent initiatives—including the launches of “The Youth Report by Pacsun,” Pacsun Youth Advisory Council, Pacsun Purpose Partner Summit and second NFL x ALEALI MAY collection—illustrate the brand’s commitment to understanding Gen Z and Gen Alpha.

Pacsun also launched its Youth Advisory Council, which comprises Gen-Z and Gen-Alpha creators who will work with the

brand’s executives on product strategy, creative campaigns and cultural initiatives during 2025 and 2026. The group’s members— Anna Sitar, Anais and Mirabelle Lee, Jabari and Malik Williams, Life.w.Bex, Mark Aoki, Melody Hurd, Shea Durazzo, Sienna Lewis, Teala Dunn, and Valera Djordjevic—will gain professional development through quarterly mentorship sessions, creative workshops and brand activations, while they also influence Pacsun’s future.

These initiatives launched on the heels of the release of Pacsun’s second NFL x ALEALI MAY collection. The limited-edition collection was designed and styled by Los Angeles native Aleali May and speaks to Pacsun’s understanding of sports and athletes as major influences in youth culture, fashion and style.

The collection launched Sept. 16 in Pacsun stores and online with T-shirts retailing at $45 and hoodies priced at $80, both in sizes S–XL.

“What excites me about this collection is showing how sports energy translates into streetwear that people want to live in,” said May.—Dorothy

Crouch

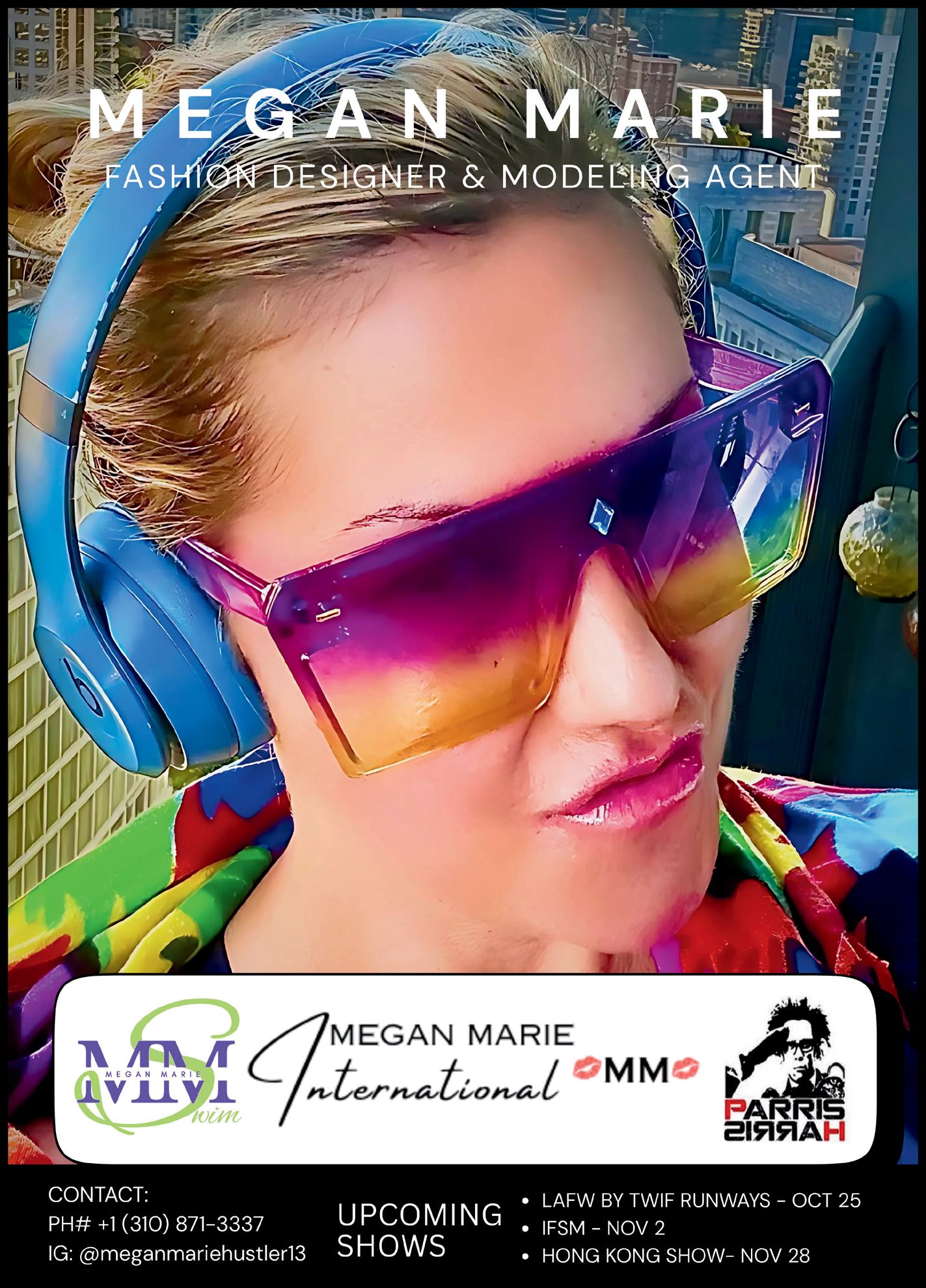

Los Angeles–headquartered design house and manufacturer ARGYLE Haus of Apparel has launched its Fashion Incubator as a program that provides comprehensive domestic planning, development, production and promotion for emerging brands. The program connects brands and designers with a single partner through all steps, including technical design, patternmaking, sampling, e-commerce build-out, content development and public-relations support.

Incubator relationships with ARGYLE Haus of Apparel allow brands to grow do-

mestically, which affords timely communication during sampling and production processes at locations that are easily accessible. The company’s showroom is located in The New Mart in downtown Los Angeles’ fashion district, while its manufacturing facility is in the San Fernando Valley. As it serves its partners through its domestic facilities, ARGYLE Haus of Apparel offers accountability through all stages, affording peace of mind to brand founders and designers as they build their businesses.

“We built the Incubator to give serious

Design house and manufacturer ARGYLE Haus of Apparel affords partners of its recently launched Fashion Incubator program a domestic resource through its downtown Los Angeles showroom and San Fernando Valley factory.

founders a real alternative to the trial-anderror journey,” said Houman Salem, CEO of ARGYLE Haus of Apparel. “As one of the leading clothing manufacturers in the U.S.A.—and among the most experienced clothing manufacturers in Los Angeles—we bring every discipline under one roof: design, development, production, digital and investor relations. The focus on execution, right here in our L.A. factory, lets brands move from idea to market with confidence.”

ARGYLE Haus of Apparel notes that it has supported the launch of more than 1,000 clothing brands during its 11 years in business, boasting capabilities for both smallrun and larger production. The company has manufactured for clients focused on athleticwear, lingerie, menswear, outerwear, readyto-wear, streetwear, swimwear, uniforms and womenswear. ARGYLE Haus of Apparel’s portfolio includes NSA Swim, Ebbets Field Flannels, Elemiints, Free People, VKTRE Moto Company, Scout Goods, TITOV, Fia Green, Activ Intimates, Inner Thread and The Loop Running Supply Co —D.C.

Messe Frankfurt is expanding its Home Textiles Sourcing footprint to Los Angeles in 2026. The show will be co-located with Texworld Los Angeles and Apparel Sourcing Los Angeles July 21–23 at the California Market Center in the city’s downtown fashion district. Home Textiles Sourcing provides attendees with options in home fabrics and finished soft goods in categories including bedding, bath, table, floor coverings and decorative accessories. “The West Coast is not only a hub for apparel and fashion innovation but also for home and lifestyle markets,” said Jennifer Bacon, vice president of fashion and apparel at Messe Frankfurt Inc. “By uniting these three shows under one roof, we’re offering a sourcing experience that supports the full spectrum of buyer needs.”

White Oak Commercial Finance will support sustainable growth of Lulu’s Fashion Lounge, LLC, through a $20 million ABL Revolver Facility with a $5 million uncommitted accordion and $1 million sublimit for letters of credit. Los Angeles–based Lulu’s was founded in 1996 and transitioned to an exclusively e-commerce platform in 2008. “We are pleased to work with Lulu’s as it enters this next phase of growth,” said Matt DeBernardo, managing director at White Oak. “This transaction underscores our cross-sector abilities to deliver fast, flexible and tailored financing solutions to support middle-market businesses.”

Circulose has partnered with Jilin Chemical Fiber for the exclusive marketing and sale of viscose filament yarn made with Circulose. The 2026–2028 partnership centers on Jilin’s Jirecell viscose filament yarn, which blends 30 percent Circulose and 70 percent wood pulp. As production scales, Circulose and Jilin aim to increase Jirecell’s recycled content to 50 percent. Jilin has pledged to increase the volumes of the Circulose it purchases annually, and any of the pulp not used during production will be blended across the viscose company’s fiber portfolio. “We have been working with Circulose for many years, and we have full confidence in its performance and market potential,” said Jin DongJie, general manager of Jilin “With this commitment, we are proud to set a global benchmark for textile circularity. Together with Circulose we will lead the industry toward a future where recycled fibers are the norm.”

Artistic Milliners has acquired a majority stake in Cone Denim from Elevate Textiles. Karachi, Pakistan–headquartered Artistic Milliners will operate independently of the 130-yearold Greensboro, N.C.–based Cone Denim, which will offer fully vertical end-to-end solutions. This deal reflects an expansion that brings the Artistic Milliners–Cone Denim reach to Parras and Yecapixtla, Mexico; Jiaxing, China; and Los Angeles. “Cone Denim will preserve its unique identity while continuing to drive its own business strategy. Our goal is to collaborate closely with the Cone Denim team, building on the legacy and achievements of more than 130 years,” said Murtaza Ahmed and Omer Ahmed of Artistic Milliners in a joint statement. Cone Denim will be led by Steve Maggard, the company’s president, as a standalone portfolio company under Artistic Milliners.

While the Spring 2026 collection celebrates California’s natural beauty, it also focuses on sustainable approaches to apparel making, which has been a tenet of AG since its founding. AG describes the collection as “embracing the spirit of the American West and the transformative journeys that unfold there.” AG remains proudly Californian in this moment as the brand moves into 2026.

Park Pass’s first delivery reflects Yosemite National Park, located in Northern California’s Sierra Nevada and famous for its giant sequoia trees. The white tones of the mountains are reflected in pieces such as the Sawtelle Button-Down and Saige Wide Leg Crop in Powder and the Embellished Billie in Opal Radiance. Pine colors of Yosemite’s trees inspired pieces such as the Blake Crew Shirt in Deep Alpine. Camper chic takes on an authentic twist with the Adam Jacket in Natural Oak and the Chels Turtleneck and Sanna Knee-Length Short in Khaki Sand.

AG heads off to the Southern California coast to The Channel Islands National Park— which includes Anacapa, Santa Cruz, Santa

Rosa, San Miguel and Santa Barbara—for its second road-trip drop. Sailor stripes and utilitarian notes informed the design direction for pieces such as the Danny Long-Sleeved Shirt in Navy/Natural Stripe, Century Short and Pant in Sulfur Spruce Green and Roselle Shirt in Sunlight Yellow.

The AG road trip concludes at Joshua Tree National Park primarily located in southeastern California’s Mojave Desert. AG pulled inspiration from the park’s towering rocks and clay hues. Pieces in this third delivery include the Sawtelle Button-Down in Desert Plaid Grey Multi, Scarlet Cami in Yucca Shadow, Sadie Crew in Heather Grey and Mercer Pant.

Denim in the Park Pass collection includes the Thalia knee-length short and Adria and Stella pants. New denim fits include the Billie relaxed straight leg, Sydney midrise stovepipe and Quinn low-rise skinny. Women’s bottoms range in size from 23 to 33, and retail pricing ranges from $158 to $695, while tops are sized XS–XL and priced $68–$325. The AG Jeans Spring 2026 Park Pass collection will be available in stores and online at agjeans.com, and goes live Feb. 5. —Dorothy Crouch

California Apparel News asked apparel sustainability experts: How are companies blending nature with technological tools to advance sustainable progress in fashion?

Daren Abney Executive Director

U.S. Cotton Trust Protocol

Fashion brands are going beyond trendy buzzwords to embrace sustainability, leveraging partnerships between nature and technology, beginning with practices right where the cotton fiber for our clothes begins—on the farm.

Precision agriculture tools like GPS and variable-rate application technologies were adopted on 91 percent of Trust Protocol growers’ fields based on soil type, plant needs and rainfall. Growers also continue to adopt regenerative agriculture practices, which focus on restoring and enhancing soil health and ecosystem vitality. Adding cover crops after harvest, for example, helps prevent soil erosion, improves water-quality infiltration and contributes to carbon sequestration. Promoting biodiversity above and below ground through practices like setting aside land for conservation areas can benefit important beneficial insects such as pollinators and increase soil microbes, which enhance ecosystem resilience and natural pest control.

The Trust Protocol acts as a tool to verify these on-farm efforts, measuring outcomes like improved soil health, and translates them into aggregated, quantifiable data. This empowers brands to move beyond broad sustainability claims, backing them up with proof.

This is further advanced through a new pilot to bring Trust Protocol Regenerative Cotton to market via a Field Partner Program created to meet the growing brand demand for regenerative cotton. It’s verification process combines field visits with satellite imagery to formally recognize growers’ regenerative practices.

This comprehensive approach provides fashion brands with more than just sustainable cotton; it gives them access to verifiable data that prove how technology is being used to actively support the environment.

Jaffar Ali Manager of Digital Marketing and Communication

Sapphire Finishing Mills

Fashion’s real progress comes when natural materials and modern tools work together. Fibers like cotton, linen, hemp and Tencel offer renewability, while technology makes them smarter. 3D design reduces sampling waste, new dyeing methods save water, and advanced weaving adds durability without heavy synthetics.

But materials and processes are only part of

the story. The industry is also being measured against Scope 1, 2 and 3 emissions, energy use, and transparency across the chain. At Sapphire Finishing Mills, we’ve taken that seriously by rethinking how we power our facilities, treat water and source energy. For us, compliance isn’t a box to tick, it’s a way to move toward more-responsible manufacturing, cutting impact at the source while still creating fabrics and apparel people want to live in. That balance of nature, technology, and responsibility is how we see endless possibilities taking shape.

Mary Ankeny Vice President, Product Development and Implementation Operations Cotton Incorporated

Sustainable prog-ress in fashion is being driven by technology that enhances rather than replaces nature’s own circular systems with cotton, providing powerful examples throughout the product life cycle.

At the manufacturing level, innovation is tackling the use of harmful forever chemicals. New research supported by Cotton Incorporated shows how technology can transform cottonseed oil, a natural coproduct, into a high-performance, sustainable fabric finish. This process creates an alternative to formaldehyde and PFAS using a part of the cotton plant itself to make fabrics water-repellent plus wrinkle- and oil-resistant. The research shows the potential to replace petroleum-based and formaldehyde-containing chemicals in common textile finishes.

This synergy extends to the very end of a garment’s life. Another recent report shows how a special high-tech composting process can turn cotton textile waste into a powerful climate solution. It breaks down almost all of the cotton and produces two valuable outputs: first, a pure form of CO2 that is far easier and more efficient to capture and store permanently, and second, a high-quality compost that can be used to enrich farmland. In short, it turns old cotton clothing into a way to actively keep carbon from the atmosphere.

By using technology to unlock the full potential of a natural fiber like cotton from the start by creating textile products and processes from the entire plant to capturing carbon from textile waste at the end, the industry is building a truly circular model for fashion.

SPONSORED BY FUNCTIONAL FABRIC FAIR—POWERED BY PERFORMANCE DAYS

Kerry Bannigan Co-Founder UN Fashion & Lifestyle Network President of the Board PVBLIC Foundation

At the United Nations Fashion and Lifestyle Network we see members reimagining materials and processes, where the convergence of nature and technology is shaping one of the most powerful frontiers in sustainable fashion. This approach goes beyond reducing harm and instead fosters regenerative solutions that align fashion with planetary health.

TômTex, for example, uses biofabrication to transform mushrooms and waste streams into leather-like textiles, offering scalable alternatives to resource-intensive materials. Banofi Leather upcycles banana-crop waste into durable fabrics, demonstrating how agricultural by-products can become highvalue inputs. Cellsense contributes to this movement with smart bio-based sensors that monitor fabric performance and life cycle, extending product longevity and reducing waste. EcoaTEX applies ecological processing methods that conserve water and reduce chemicals, bridging natural efficiencies with technical precision.

At the 80th United Nations General Assembly, the Network highlighted these innovations, showing how creativity, culture and science can accelerate the transition to a circular fashion system. Additionally, Network member Mara Hoffman emphasized that circularity must be embedded at the moment of design, with responsibility woven into creativity from the start. These examples illustrate that blending nature with technology is not a trend but a pathway to systemic transformation.

Oya Barlas Bingul Senior Manager, Business Development and Marketing TextiMag

The fashion industry is under increasing pressure to reduce its footprint while still delivering performance and creativity. What encourages me is how many companies are now turning to nature for inspiration and pairing it with technological tools to make genuine progress on sustainability.

Nature has always been an innovator. From the self-cleaning properties of lotus leaves to minerals that absorb odors, biological processes offer solutions that are both efficient and resourceful. Translating these mechanisms into textiles can extend garment life, reduce care requirements and minimize environmental impact.

This is where I see real potential: innovations that don’t simply claim sustainability but embed it into everyday use. TextiMag, for

example, draws on natural mineral adsorption to neutralize odors without added chemicals. By reducing the need for frequent washing, it helps conserve water and energy while keeping garments fresher for longer. It’s a small shift with a measurable effect and exactly the kind of practical sustainability the industry needs.

Blending biology with technology isn’t about short-term fixes or marketing slogans; it’s about rethinking how textiles are designed, used and cared for. It means respecting nature’s limits, learning from its strengths and scaling solutions through innovation.

For me, this is where sustainable progress in fashion truly lies—at the intersection of natural intelligence and human ingenuity, where performance and responsibility can move forward together.

Karen Beattie Global Director of Product Management Polartec

Companies are advancing sustainable progress in fashion by blending nature-inspired materials with cutting-edge technology. Polartec, a distinguished Milliken brand, uses plant-based and recycled fibers—like Biolon nylon from renewable sources and fabrics made from post-consumer plastic bottles—to reduce environmental impact. Our technical innovations, such as Power Air insulation, minimize microfiber shedding in home laundering, and our barrier technologies enable designing for circularity. By designing products for durability and circularity and eliminating harmful chemicals ahead of regulations, we’re setting new standards for manufacturing processes designed with sustainability in mind. This holistic approach—combining natural resources and advanced science—helps create high-performance textiles that support a more sustainability-minded future for fashion.

At UNIFI, we continuously innovate with a focus on environmental sustainability and product performance. Through the REPREVE platform, we have the world’s most recognizable brands of environmentally preferred fibers and insulation. Reusing waste as the raw material, REPREVE polyester has avoided over 1.47 billion kilograms of greenhouse-gas emissions and conserved more than 7.2 billion gallons of water versus virgin polyester products. This empowers our protection of our natural resources.

Recently, UNIFI launched a new plantbased technology, A.M.Y. Peppermint, a

➥ Sustainability page 6

NOVEMBER NOVEMBER

DAY 0 SUSTAINABILITY WORKSHOP EXHIBIT HALL & EXPERT TALKS 11 12–13

OREGON CONVENTION CENTER PORTLAND, OR

INNOVATION WITHOUT LIMITS. A COMMUNITY MOVING TEXTILES FORWARD—TOGETHER.

Discover what’s next in performance textiles at Functional Fabric Fair Fall in Portland, OR. Join us for a curated sourcing event connecting you with top suppliers, industry leaders, and brands driving the future of activewear, outdoor gear, and performance fashion.

NOVEMBER 11: DAY 0 SUSTAINABILITY WORKSHOP | NOVEMBER 12–13: EXHIBIT HALL & EXPERT TALKS

Explore 12 essential fabric categories curated by a jury of textile experts, and experience the season’s most innovative materials—up close and firsthand.

Discover cutting-edge products before they launch and get an exclusive first look at breakthrough materials and technologies shaping the future of performance textiles.

Engage with industry leaders through dynamic sessions that spotlight the latest trends, innovations, and sustainability practices driving outdoor and active textile design.

How are companies blending nature with technological tools to advance sustainable progress in fashion?

naturally deodorizing yarn engineered for long-lasting freshness. The latest innovation, which can be combined with our REPREVE polyester, delivers built-in odor control using sustainably sourced peppermint oil, offering a botanical alternative to traditional antimicrobial treatments for textiles.

Laura Corna Sales Manager

NextPrinting

In our vision, nature is not simply a tool. It is an ecosystem to be preserved, a finite resource that demands responsibility. That is why, at NextPrinting, we harness technological progress to minimize our impact on the environment and on natural resources. For us, combining nature and technology means beginning with the selection of the most sustainable materials, choosing efficient processes, and developing solutions that reduce waste and consumption throughout the entire supply chain.

Our digital fabric-printing technology makes it possible to achieve highly realistic visual effects while using significantly less water, energy and chemicals than conventional methods. We work with certified yarns and fabrics—GOTS, GRS, FSC—and promote flexible, on-demand production that prevents overproduction and gives value to every piece. Digital printing enables brands to design, test and produce collections more quickly, creatively and responsibly, aligning production with real market needs. This approach reduces waste, strengthens traceability and integrates sustainability and aesthetics into a single coherent vision.

Paola Corna Chief Financial Officer, Sustainability and Human Resources Manager ACM

Technology is becoming increasingly accessible to small and mediumsized enterprises and, thanks to growing digitalization, companies like ACM can now make use of tools that were once the exclusive domain of large industries. Energy-management software, resource-monitoring platforms and predictive systems help optimize consumption, lower operating costs and improve production efficiency. Low-impact technologies applied to logistics, design and customization also reduce waste and allow production to be adapted to actual demand, supporting a more circular model. The future of sustainability is closely linked to technological innovation. Essential solutions such as artificial intelligence and the Internet of Things enable the introduction of smart sensors and automated processes for real-time consumption monitoring, ensuring greater accuracy and timeliness in operational decisions.

At the same time, collective awareness of the importance of social and environmental responsibility is increasing, pushing the fashion industry toward production models that

are more ethical, transparent and efficient. In this context, ACM stands out for its concrete and forward-looking approach. As early as the 1990s, the company implemented a complete water-treatment and recycling system, achieved energy independence through solar power systems and obtained certifications such as GRS and WeImpactIndex. On the creative side, it experiments with natural, regenerated and recycled materials, promoting an aesthetic that highlights waste and resources while respecting the environment.

Eric Davidson Director, North America Brands and Retail

Fashion is leveraging nature and technological advancements today, and our new bio-derived LYCRA EcoMade fiber is a great example of this shift. Instead of relying on fossil fuels, we’re using dent corn—mostly grown in Iowa—as the starting point and fermentation as the key technology. It’s a smart and sustainable way to blend nature and science.

What’s exciting is that this approach lets us replace a finite resource with something renewable, and we expect it could cut greenhouse-gas emissions by up to 44 percent, all while keeping the same stretch and shape retention people love in LYCRA fiber.

As more consumers look for sustainable options, we’re helping the industry move toward renewable inputs by offering transparency around where our raw materials come from. Our bio-derived fiber works seamlessly with existing fabrics and processes—no need to reengineer anything. It’s already compatible with our performance fiber products like LYCRA ADAPTIV and LYCRA XTRA LIFE.

From farm to fashion, bio-derived LYCRA EcoMade fiber is a compelling example of how natural inputs like corn and cutting-edge biotechnology can come together to help drive sustainable innovation at scale.

Naia Renew is a circular fiber sourced from 60 percent sustainably sourced wood pulp and 40 percent GRS-certified recycled content. By combining renewable inputs with advanced recycling, it shows that circular fashion can be both scalable and traceable, meeting environmental and performance standards. To further reduce reliance on virgin resources, we developed Naia Renew ES, a fiber sourced from 60 percent certified-recycled content, including 40 percent hard-to-recycle waste materials transformed through molecular recycling and 20 percent certified-recycled cellulose combined with 40 percent sustainably sourced wood pulp.

This innovative material offers a luxurious alternative to silk with a significantly lower carbon footprint, making it ideal for premium applications. Through our partnership with TextileGenesis, we embed digital traceability

across the value chain, giving brands and retailers verified insight into material origin and sustainability performance.

Naia fibers are produced in a closedloop system with safe and environmentally sound chemical use and are backed by third-party certifications such as OEKOTEX STANDARD 100 and TÜV AUSTRIA for biodegradability and compostability. By combining renewable sourcing, circular inputs and digital traceability, Naia empowers brands to deliver fashion that honors both people and the planet.

Betsy Franjola President, BFF Studio Founder, PREFACE Chief Executive Officer, Hocking Hills Garment Center

At BFF Studio, we’re seeing a dynamic blend of nature and technology driving sustainable innovation in fashion. Cellulosic fibers like Tencel and Naia offer performance benefits such as absorption and moisture movement, while new developments layer in botanicals like mint, ginger and aloe to harness their natural antimicrobial, cooling or warming effects. These advancements show how science and nature can work together to create textiles that are not only more sustainable but also deliver enhanced function and comfort for the wearer.

Marcelo Guimarães Founder Fashinnovation

The future of fashion is in the connection—nature and technology working side by side.

At Fashinnovation, we see this happening every day, from AI tools that reduce overproduction to biodegradable fabrics grown in labs. Fashion brands are using digital design to avoid waste before the first thread is even cut. Others are using blockchain to trace natural fibers back to farmers, ensuring fair practices and real transparency. But real progress happens when tech doesn’t replace nature, it protects it. Sustainability is no longer a trend. It’s the new standard. And tech is helping us scale what’s natural, local and circular on a global level. One innovation at a time.

Jan Hilger Head of Business Unit Textiles and Apparel

Livinguard Technologies AG

Livinguard Technologies uses microencapsulation of nature-based active ingredients such as essential oils and herbal extracts that are then released in a controlled manner over time through friction and diffusion. This approach provides similar functional performance and durability as established alternatives but through safer, more-natural ingredients.

The goal of Livinguard is to empower con-

SPONSORED BY FUNCTIONAL FABRIC FAIR—POWERED BY PERFORMANCE DAYS

sumers to make every moment carefree and every choice responsible. The brand’s promise of “Feel better. Do better” highlights this unique value proposition of providing lasting value-added functionality through technologies that make more-responsible choices for consumers effortless. Livinguard’s portfolio of nature-inspired textile effects based on this technology include:

• Better Cool, which uses micro-encapsulated menthol-based actives;

• Better Repel, which relies on microencapsulated proprietary blends of citronella and herbal oils to provide insect repellence against mosquitos, bed bugs and mites;

• Better Scent, which uses micro-encapsulated natural ingredients like rose, citrus and clove; and

• Better Vitality, which offers controlled delivery over time of tailor-made formulations of natural-based active ingredients such as lavender, aloe vera, tea tree and vitamin E.

Algae and mushrooms create fantastic alternatives to plastics. Our increasing understanding of the negative health and environmental impacts of plastics in everything we wear and everything we place our food in has finally hit the mainstream. This is a great and amazing opportunity for innovation. It will also lead to a true circular economy when we have entrepreneurs, investors, companies and public entities that are starting to think about how to incorporate alternative and nature-based materials into the things we wear and use.

Some fantastic examples include companies like Vollbak, Sway and Algaeing, who use algae to make environmentally preferred fibers, packaging and natural dyes. To replace chemical-based inks, algae ink is used for clothing printing and other dye and printing needs. Other companies are looking into combining biopolymers with algae to make soft and highly breathable fabrics. In packaging, seaweed and algae are used to produce packaging that’s biodegradable and, in some cases, edible; think of sauce packets! Instead of petroleum-based plastics like Saran Wrap, algae films are used for food wraps or carrier bags so we can reduce microplastics getting into our food. Our future will be brighter when we incorporate naturebased solutions into technology that fuels our everyday outfits and meals.

Steve McCullough Event Vice President

Functional Fabric Fair

Companies are making real strides—mills and suppliers are turning to renewable and recycled materials like organic cotton hemp and biobased fibers while adopting tools that improve efficiency and reduce waste.

At Functional Fabric Fair, we see this accelerating each season. Through our partnership with the Future Fabrics Expo, we’re spotlighting the next generation of suppliers with breakthrough innovations like inkjet technol-

ogy powered by living fungi and bacteria that create regenerative, compostable print media; biomaterials forming textiles from plants cultivated in regenerated wetlands; enzymes capable of breaking down blended fibers into their original building blocks; and more. While these solutions represent different levels of commercial readiness, they collectively point to where the industry is heading.

Consumers expect products that perform while aligning with their values, and the industry is responding. From waterless dyeing to biodegradable fibers and textile recycling, the tools are here to scale responsible practices. The future of fashion lies in harnessing both nature and technology and working together to deliver performance and sustainability.

Emmanuelle Rienda

Creative Director

Ethical

Luxury Expert

Founder of Vegan Fashion Week

The future of fashion lies in a symbiosis between nature and technology. What we’re witnessing is not just material innovation but a cultural redefinition of luxury itself. Designers are drawing inspiration from natural systems while using AI, biofabrication and digital prototyping to radically

reduce waste and rethink production. At the same time, regenerative agriculture and plantbased alternatives remind us that true progress means giving back more than we take. When fashion aligns technological intelligence with the wisdom of ecosystems, we create beauty that is not only desirable but ethical and deeply relevant to the times we live in.

Dr. Anna Sammarco Senior Director of Business Development and Strategy Circulose

As climate urgency intensifies and overproduction continues to plague the industry, fashion’s sustainability efforts are at a critical crossroads. True transformation hinges on a shift away from linear, waste-heavy models toward fully circular systems that regenerate rather than deplete. Today, a new generation of innovators is blending nature-based solutions with technological tools to accelerate this change and reshape fashion from the inside out:

• Regenerated materials like Circulose convert worn-out cotton into cellulose pulp that can be spun into new fabric. The next-gen recycled textile material is available at industrial scale and already being adopted by major

brands like H&M, Zara and GANNI;

• Mycelium-based leathers, for example Forager by Ecovative, offer plastic- and animal-free alternatives grown from mushrooms;

• Seaweed-derived yarns and algaebased dyes developed by innovators like AlgiKnit and Colorifix are reducing environmental impact;

• AI-powered demand forecasting, 3Ddesign tools and digital sampling are helping brands design smarter and waste less;

• Blockchain and digital product passports via platforms like Eon and Provenance are powering transparency, enabling recycling and resale through traceable material identities; and

• Waterless dyeing innovations, including CO2 dyeing and digital pigment printing, are slashing water usage and chemical runoff.

Business models built around resale, rental, repair and product longevity through platforms like The RealReal, ThredUp and By Rotation are extending the life of clothing.

Circulose is proving that scalable circular materials are possible and that fashion is beginning to shift from extractive to regenerative, from wasteful to intelligent. The future of fashion won’t be simply sustainable; it will be circular, connected, and designed to evolve.

Andrea Venier Managing Director Officina39

In the collective imagination, chemistry is often perceived as being at odds with nature. Today, how- ever, thanks to a sustainable and innovative approach, chemical technologies can be a powerful ally in protecting the environment and human health. In the fashion industry in particular, the integration of science and nature is driving a profound shift toward more-responsible production processes. For years, Officina39 has been demonstrating that performance and ecology can coexist. A concrete example is ZeroPP|ALL.IN, the system developed by Officina39 to permanently replace the use of potassium permanganate, a toxic substance widely used in denim finishing to create vintage and corrosion effects at low cost.

Until now, finding a viable alternative had been a major challenge for the industry. Officina39 has finally developed a unique and innovative product that can be applied directly to raw garments, replacing PP from the very beginning of the process. This is not only about taking something away but also about

➥ Sustainability page 8

Breakthrough innovations that allow for tangible progress toward more-sustainable manufacturing practices are more vital than ever as the apparel industry faces mounting environmental challenges and increasing public scrutiny.

In this exclusive conversation, California Apparel News speaks with Sanjeev Swamy, founder and Chief Executive Officer of Livinguard Technologies. The Swiss materialsciences company is working on the forefront of innovation to shape a more sustainable future for textiles.

What do you perceive as the biggest environmental challenges in the textile industry today?

It is difficult to choose where to start—there are so many. First, the industry consumes absurd amounts of water. Furthermore, it is responsible for 20 percent of industrial wastewater. Moreover, the carbon footprint of the sector trumps emissions from even the aviation industry. Consumers washing clothes uses again unthinkable amounts of water and energy, and on top of that releases countless microfiber and microplastic particles into waterways. Finally, massive amounts of textiles land in the trash every year and continue to pollute the environment for centuries.

It sounds like it would be time to rethink how we produce and consume textiles. What is the holdup?

Livinguard EFD is an additive that enables sustainable saltfree dyeing of cellulose fabrics with significantly lower water and energy consumption. This innovative system has the potential to reduce energy and water consumption by up to 50 percent and drastically lower the chemical burden in the effluent. At the same time, the technology increases operational efficiency and the cost position of the manufacturers that adopt it.

solely count on consumers to reshape the industry through their demand but need technological innovations like those that we are working on.

What makes these solutions from Livinguard Technologies unique?

Sanjeev Swamy Livinguard Technologies Founder and Chief Executive Officer

It would be all our responsibility to change our purchasing behaviors and buy fewer clothes that are used longer. Unfortunately, the opposite is happening. Fast-fashion is booming. We produce more and cheaper textiles, which are worn less and discarded quicker. Hence, I don’t believe we can

Livinguard Better Fresh is a textile finishing chemistry that provides both wash-durable, biocide-free odor-control functionality while reducing the shedding of microfiber fragments by up to 80 percent. This solution allows brands to reduce the plastic pollution of their materials during the consumption phase at scale and cost efficiently. At the same time, the solution allows customers to adopt more-sustainable laundry practices as our powerful odorneutralization mechanism allows them to wear their clothes longer and wash less and at lower temperatures.

How are companies blending nature with technological tools to advance sustainable progress in fashion?

Sustainability Continued from page 7

rethinking the entire process. The innovation lies in a significant simplification that makes it possible to complete the entire workflow directly on raw garments with a single product, making the system more accessible, efficient and sustainable than ever. ZeroPP|ALL.IN is the outcome of scientific research, environmental responsibility and collaboration with brands and manufacturers.

It demonstrates that nature and technology can coexist and, more importantly, technology can serve as a means of protecting nature when guided by shared values and a sustainable vision of the future.

Matteo Vivolo Chief Sales Officer

Vivolo

All too often, unfortunately, sustainable innovations require significant capital investments upfront— for which there is no capital available. In other instances, they result in higher operating costs that cannot be absorbed by an industry that already now operates on razor-thin margins. Our approach to innovation stands out because we enable progress on sustainability in a minimally invasive, scalable, and cost-neutral or even costbeneficial way. All our technologies are drop-in solutions that are compatible with existing equipment and hence can be easily adopted at scale.

What drives you personally to take on such challenges?

I have two wonderful daughters living in India. As a father, I want to make sure the world they live in and the world many other daughters grow up in will be a better place. Livinguard therefore has a very clear mission— to use our technology platform to safeguard the well-being of people and the environment. With a mission as important as ours, giving up is simply never an option.

info@livinguard.com livinguard.com linkedin.com/company/livinguard-technologies

Fashion companies are adopting circular business models to advance sustainable progress. They are developing and using new materials that bring together the qualities of natural fibers with advanced technological processes. Production processes are being optimized to increase efficiency and reduce environmental impact by lowering water, energy and chemical use.

Artificial intelligence and machine learning, for example, analyze sales data to forecast demand with greater accuracy and help prevent overproduction, one of the industry’s biggest sustainability challenges. Companies are also investing in transparency and traceability through blockchain technology, which makes it possible to follow a product’s entire life cycle from raw material to finished garment. They also seek certifications that verify compliance with standards recognized nationally and internationally.

True innovation in the fashion industry lies in skillfully combining nature with technology, turning environmental challenges into opportunities for growth and progress. At Vivolo, we have been pursuing this opportunity for many years, beginning when President Luciano Vivolo cut patches from leather scraps to repair his eldest son’s tracksuit.

Kevin Vranes Chief Product Officer Worldly

Sustainability progress in fashion cannot be achieved through technology alone. Innovation must begin with an understanding of the natural systems on which our industry depends—from water basins that nourish cotton fields to the workers whose well-being is shaped by heat and climate.

If technology is built without considering the limits and needs of nature, we risk creating solutions that are efficient on paper but ineffective, or even harmful, in practice. True progress requires tools that preserve, protect and enhance the planet, ensuring that business growth aligns

SPONSORED BY FUNCTIONAL FABRIC FAIR—POWERED BY PERFORMANCE DAYS

with ecological and human resilience. This principle guided the creation of Worldly Axion, our new risk intelligence solution. It combines trusted facility-level sustainability data with insights from dozens of environmental datasets—including grid decarbonization rates, water stress and climate projections. By contextualizing supply-chain performance within nature’s realities, companies can focus on where action will have the greatest impact. For example, sourcing teams can see the regions that face water insecurity, where renewable energy is most available or how heat stress may affect worker productivity—and support supply-chain partners in those areas before those risks become disruptions.

This is how technology and nature must intersect, not as opposing forces but as partners. The future of fashion depends on innovation that recognizes the planet as its most critical stakeholder, ensuring that progress is measured not only by output but by the resilience and health of the natural systems that sustain us all.

David Williamson, PhD Chief Executive Officer Modern Meadow

As awareness of climate change intensifies, the fashion industry faces growing pressure to adopt more-sustainable practices. Yet many so-called sustainable materials require costly new infrastructure and often compromise on performance, beauty or scalability.

Modern Meadow is addressing this challenge head-on through advanced material science. The company has developed INNOVERA—a next-generation, leather-like biomaterial designed to make sustainability seamless for the fashion industry.

Inspired by bio-mimicry, INNOVERA emulates the structure of collagen—the protein responsible for leather’s strength and flexibility—using plant-based proteins, biopolymers and a textile backing made from recycled rubber sourced from end-of-life car tires. The result is a completely animal-free material that matches the performance of traditional leather yet is twice as strong, significantly lighter and luxuriously tactile in both look and feel.

With over 80 percent renewable carbon content and a design built for circularity, INNOVERA can be broken down and reused as feed stock to produce new material—supporting closed-loop production. Better yet, it is drop-in ready, enabling tanneries to integrate INNOVERA into existing workflows without new machinery or disruptive investment. This allows them to bypass resource-intensive steps while creating innovative, animal-free products across accessories, interiors and beyond.

With nature-inspired innovation at its core, Modern Meadow is helping fashion move forward—delivering sustainability without sacrificing style, function or emotional impact.

Responses have been edited for clarity and space.

* PRODUCT DEVELOPMENT & PATTERNMAKER *

Well established garment manufacturer based in LA downtown area is looking for following positions. We are a clothing manufacture for Men’s, Women’s, Missy, and Kids clothing. Need Garment Industry experience. Salary 60,000.00 – 70,000.00 depending on experience. Monday through Friday.

- PRODUCT DEVELOPMENT-

* Style Development, Tech Pack set up, style order package set up

* Customer communication Service

Fashion District

www.asherconcepts.com/

In 1991, Asher Fabric Concepts, based in Los Angeles, transformed the apparel industry by offering cutting-edge, high quality, “Made in U.S.A” knits for the contemporary fashion, swimwear, sportswear, sweater knits and loungewear markets. Since then, the company has become internationally known for its in-house system of vertically integrated machines that manufacture premium quality, knitted fabrications with and without spandex. Asher Fabric Concepts provides fabric development, knitting, dyeing, and finishing in addition to fabric print design and printing capabilities based on each customer’s needs. The company differentiates itself from the competition by offering proprietary textiles and by continually updating and innovating every aspect of textile design and production.

127 E. Ninth St. Los Angeles, CA 90015

(213) 627-0671, Fax: (213) 627-1187

www.newmart.net

In the heart of Los Angeles’ Fashion District

is the landmark New Mart Building. The showrooms of The New Mart represent the most exclusive and coveted contemporary lines from an international array of designers and manufacturers. The New Mart is unique in both architecture and style. The intimate setting creates a user-friendly experience for visitors. Each of its glass-fronted, uniquely designed showrooms provides a buying adventure that cannot be experienced at any other showroom destination. The New Mart is open year-round to the wholesale trade only and we host over 100 showrooms that carry over 500 collections.

www.texollini.com

From its very outset in 1989, Texollini was designed to be among the most technologically advanced knitting mills and fabric suppliers in America. Courtesy of a vertically integrated operation and a stretch-our-imaginationsand-ourselves approach to customer success, Texollini has rapidly grown to become one of the largest circular knitting mills in America and a leading worldwide supplier of Made in America stretch fabrics, including Lycra®, spandex and others. The Long Beach, Calif.–based company offer the very same edge to

it’s smaller fabric buyers in the areas of fabric development, circular knitting, fabric dyeing and finishing, print design and pigment printing that’s responsible for their large program fabric success with many of the most recognized brand names in the fashion business. Texollini continues to provide its customers with flexibility, time-saving experience, costcutting advice, deep market knowledge and, of course, a stretch fabric expertise no ordinary knitting mill, dye house, or printer can offer.

www.whiteoaksf.com

White Oak Commercial Finance, LLC (WOCF), formerly Capital Business Credit/Capital Factors, is a global financial products and services company providing credit facilities to middlemarket companies between $1 million and $30 million. WOCF’s solutions include assetbased lending, full-service factoring, invoice discounting, supply-chain financing, inventory financing, U.S. import/ export financing, trade credit-risk management, accountreceivables management, and credit and collections support. WOCF is an affiliate of White Oak Global Advisors, LLC, and its institutional clients.

www.alejandrasfashion.com

Alejandra’s Fashion provides the best factory direct apparel solutions for various recognized brands. The company works with corporate clients to convey the most astounding quality clothing and customer satisfaction delivering 100 percent American labor. With a production capacity of 35,000 items per weekly, Alejandra’s Fashion has a wide range of experience with simple through high-end garments. Where stringent approval processes exist that require extreme attention to details, Alejandra’s Fashion has an impressive and proven track record.

www.livinguard.com

Livinguard Technologies is a Swiss material-sciences company active in the textile industry and beyond. The company develops game-changing

* TNA, WIP set up with Approval records

* Problem solving to correction

- PATTERNMAKER: with experience on Style Cad System.

All Resumes are to be sent to: HR Department Attn: Rosa Garcia Email: hr@4goldengreen.com

textile finishings and processing aids that allow brands and manufacturers alike to radically decrease the environmental impact of their products and make meaningful progress toward their sustainability goals. Livinguard’s sustainable dyeing chemistries Livinguard +DYE and EFD reduce water and energy consumption in cellulose dyeing by up to 50 percent while improving operational efficiency. Livinguard Better Fresh is a leading biocide-free odorcontrol solution that at the same time reduces microfiber shedding by up to 80 percent.

www.functionalfabricfairfall25.com/ CaliforniaApparelNews

Functional Fabric Fair Fall takes over the Oregon Convention Center, Nov. 11–13— starting with the Day 0 Sustainability Workshop on Nov. 11, then shifting into two full days of exhibits and Expert Talks, Nov. 12–13. This high-energy sourcing event unites the most innovative performance textiles and sustainable solutions shaping the future of apparel, outdoor, and activewear. Curated for designers, product developers, and sourcing professionals, the fair showcases 300+ vetted exhibitors, delivering a powerful mix of trend insights, groundbreaking materials, and unmatched networking. Don’t miss the season’s ultimate destination to discover what’s next in performance fabrics—and join the community driving the textile industry forward.

www.ifjag.com

IFJAG trade shows feature fashion jewelry and accessories from around the world with over 100 manufacturers or direct importers showing exclusive designs to IFJAG’s unique venue of private showrooms which offer buyers a professional environment. The upcoming Las Vegas Show at a NEW HOTEL LOCATION — Embassy Suites By Hilton, Las Vegas Convention Center, 3600 Paradise Road, on Feb. 15–18,