In the life sciences industry, the digital revolution has arrived not with fanfare, but with quiet precision. It is transforming the way pharmaceutical and biotech companies design, construct and operate their facilities. At the centre of this transformation is ZETA, a globally operating end-to-end solution provider. that has evolved from pipe fitting to developing fully digital, data-driven production ecosystems for some of the world’s most complex manufacturing environments.

The company’s trajectory is remarkable. Fifteen years ago, ZETA was a modest business of around one hundred employees, primarily focused on piping and mechanical installation. Today, it is a global player with more than two thousand people and a reputation for advancing the digitalisation of pharmaceutical engineering. Its evolution has been shaped by a simple but powerful principle: everything in engineering, from concept to operation, should one day be seamlessly connected through data.

That belief has guided ZETA’s expansion into what it calls Digital Solutions,

a business line that integrates all disciplines of engineering into a single digital environment. It reflects a shift in the company’s mindset from building equipment to building intelligence.

The company’s journey into digitalisation began when one of its long-standing clients asked for more than physical delivery. They wanted ZETA to handle the full engineering scope of a facility, from design to automation. What started as an expansion of service quickly became a transformation in philosophy. ZETA’s leadership recognised that the future of engineering would rely on software as much as steel.

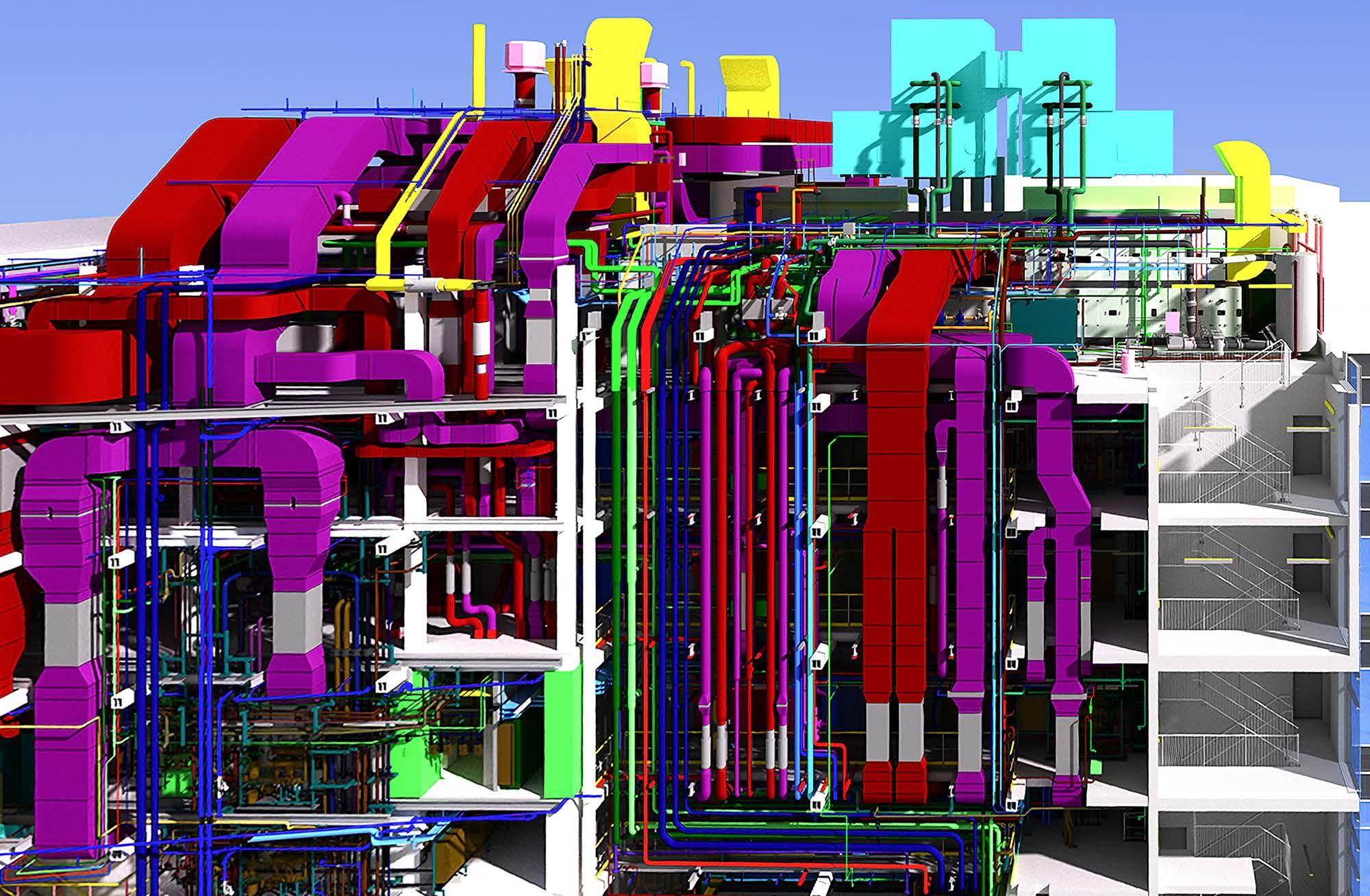

As digital systems advanced, the company began to merge its engineering, automation and design processes into one connected toolchain. Each discipline could now collaborate within the same environment, sharing information in real time and reducing the inefficiencies that had long existed between mechanical design, electrical planning and process automation. This approach became the foundation of ZETA’s integrated digital framework, an ecosystem where every

ZETA

PROJECT DIRECTED BY: RUPERT KAY

stage of a project contributes to a shared, living dataset.

Central to this framework is the digital twin: a virtual representation of a plant that mirrors both its physical structure and its operational logic. ZETA’s model combines two key elements. The first is the physical twin, which represents the layout, materials and equipment. The second is the procedural twin, which defines how the plant operates, from recipes to process parameters. Together, they form a complete digital replica of the facility.

This twin is not a static model, but an evolving intelligence that grows alongside the project. It allows ZETA and its clients to test, validate and optimise designs long before construction begins. Engineers can simulate entire processes, identify risks, and train operators using virtual or augmented reality environments. When the physical facility comes online, the operational data feeds back into the digital model, creating a continuous feedback loop for improvement.

The impact on project timelines and efficiency has been significant. In one recent case, ZETA delivered a biotech manufacturing site for a client facing a critical shortage of a life-saving product. With only three years of supply remaining, the company needed a new production facility designed, built and validated in record time. Using ZETA’s digital methods, the entire project was completed in twenty-four months.

Every element of that plant, from design to training, was developed within the digital environment. Data generated during engineering was reused for automation, commissioning and even workforce onboarding. Virtual reality simulations enabled 150 new employees to familiarise themselves with the facility before it was physically completed. The project demonstrated how digital tools can bridge the traditional gap between strategy and execution.

For the pharmaceutical and biotech

sectors, however, speed is only one side of the equation. Regulatory compliance remains an ever-present demand. ZETA’s systems are designed from the ground up to meet the stringent requirements of FDA and GMP environments, ensuring data integrity, traceability and validation. The company builds its solutions using proven industrial platforms such as Siemens COMOS and AVEVA E3D, which already incorporate features like audit trails, access controls and electronic signatures.

Yet Martin Mayer, Director Business Line Digital Solutions, and his team recognise that technology alone cannot deliver transformation. The real challenge lies in changing how people think and work. Within ZETA itself, the move toward digitalisation began with a major cultural shift. The company replaced isolated software tools with integrated workflows, introduced agile development methods, and encouraged engineers to think more like software designers. To complete the transformation, this toolchain was made available to the market as a service—independent of ZETA’s role as an

engineering partner in a project—marking a significant shift in its business model.

“Digital transformation starts with mindset,” Mayer has often said. Engineers needed to understand that their expertise remained vital, but that the tools for expressing it were changing. The company created a new internal division dedicated to software and IT, bringing together more than eighty specialists who now work on developing and refining its digital platforms. The result is a shared environment where process, mechanical and automation engineers can collaborate without barriers.

This integration has since extended to ZETA’s clients. Through secure cloudbased systems, project partners and suppliers can access a unified database, enabling true parallel engineering. Multiple disciplines can progress simultaneously while maintaining full visibility across design stages. This not only reduces delays but also enhances the overall quality of information, ensuring that data remains accurate and consistent throughout the project lifecycle.

Martin Mayer Director Business Line

Solutions

Modular production is reshaping life sciences manufacturing, and COPA-DATA’s zenon software platform stands at the forefront of this transformation. As drug development cycles shorten and regulatory demands increase, producers need scalable, repeatable processes that maintain quality across multiple sites. zenon’s flexible architecture enables modular production by standardizing control, visualization, and data handling into reusable building blocks via drag and drop.

By encapsulating recipes, equipment logic, and compliance checks into configurable modules, manufacturers can accelerate validation, reduce engineering effort, and deploy consistent production cells from bench to plant. For life sciences, where traceability and auditability are paramount, zenon integrates electronic batch records, alarm management, and secure historian functions to ensure data integrity while supporting rapid changeovers.

Beyond technical benefits, modularity improves organizational agility. Cross-functional teams can assemble validated modules without redesigning entire systems. COPA-DATA supports this shift with tools for versioning, role-based access, and standardized interfaces that simplify integration with 3rd party systems, such as PAS-X MES, classic MES, and building management systems.

Sustainability also gains from modular strategies: smaller, optimized units consume less energy and facilitate scalable capacity expansions without large capital expenditures. In a sector where responsiveness can dictate patient access, zenon’s approach helps manufacturers adapt to demand variability and regulatory updates more quickly.

The convergence of modular production and robust software platforms like COPA-DATA’s zenon creates a pragmatic path toward flexible, compliant, and efficient life sciences manufacturing. It’s not just about equipment – it’s about rethinking processes so innovation reaches patients faster and safer.

The advantages of this approach continue well beyond construction. All engineering data is harmonised and carried into the operational phase, forming the basis for predictive maintenance, performance analytics and continuous optimisation. The same digital twin that once served as a design tool becomes a living operational resource.

ZETA’s use of simulation and artificial intelligence further extends this capability. The company’s acquisition of the simulation specialist INOSIM has strengthened its ability to model complex production processes. These simulations allow teams to test different scenarios, from equipment configurations to energy efficiency strategies, supporting clients in balancing economic and environmental goals.

Artificial intelligence is also beginning to influence the way ZETA will design plants in the future. Instead of engineers manually drafting process diagrams and then extracting data from documents, AI

tools will soon enable the reverse: data will generate the documents automatically. This shift, currently being developed in partnership with Siemens, AVEVA and NVIDIA, represents a fundamental change in how engineering knowledge is captured and applied.

Mayer believes this transformation is essential if European industry is to remain globally competitive. The demand for efficiency, he argues, is growing faster than traditional methods can deliver. “We need to be at least fifty percent more efficient in the next five years,” he has remarked in other discussions. “Without embracing digital and AI, that will not be possible.”

The move toward modular and flexible manufacturing is another area where ZETA’s digital expertise is proving influential. By standardising design principles and creating reusable digital modules, the company is helping clients move away from one-off custom builds toward scalable, configurable systems.

This modular approach allows facilities to expand or adapt quickly, reducing costs and improving sustainability.

In practice, ZETA’s modular strategy is supported by automation standards such as MTP (Module Type Package), which enables different equipment units to communicate seamlessly within a common control system. The combination of standardisation, modularity and digitalisation has become the foundation of what Mayer calls “the smart building blocks of life sciences,” a system where digital design and physical flexibility meet.

Looking ahead, ZETA’s ambitions reach well beyond engineering. The company aims to position itself as a leading partner for digital transformation across the life sciences sector. In the short term, this means expanding from integrated engineering to integrated operations, with its digital platform evolving from a service into a product. The newly branded FrameWorks offering will serve as a scalable foundation for clients to manage their entire digital ecosystem.

In the longer term, ZETA’s focus lies in the emerging concept of Pharma 4.0, a fully connected, intelligent manufacturing landscape where AI, digital twins and modular production combine to create adaptable facilities capable of producing everything from niche therapies to largescale vaccines. Through partnerships with global technology leaders, ZETA is already developing AI-driven operational support tools that can assist human operators in real time.

Sustainability also plays a key role in this vision. By simulating energy use and material flow, ZETA’s digital systems allow clients to design processes that minimise waste and emissions. The company’s expertise in both engineering and software gives it a unique perspective on how digitalisation can accelerate decarbonisation across the sector.

Although ZETA’s digital reach is expanding globally, its strongest relationships remain in Europe, where its transformation story began. Many of its customers have witnessed its growth from traditional plant builder to digital pioneer. That trust, built over years of collaboration, is now helping the company lead a new era of partnership between physical and digital engineering.

The story of ZETA is, in many ways, a story about the future of the life sciences industry itself. It is a reminder that innovation does not always begin with disruption, but with evolution, the steady integration of technology, knowledge and purpose. As pharmaceutical manufacturing becomes more intelligent, sustainable and data-driven, ZETA stands as one of the organisations quietly shaping that transformation from within.

Digitalisation, in Mayer’s view, is not about replacing engineers, but empowering them. It is about using technology to extend human capability, connect disciplines and build smarter systems. The tools are changing, but the principle remains the same: excellence in engineering, guided by precision and imagination.

www.zeta.com