Guide to German Med t ech Companies

Guide to German Medtech Companies Vol. 11

Published by: Knowbio GmbH

Jacobsenweg 61 13509 Berlin Germany

Tel. +49-30-264921-0 service@knowb.io www.knowb.io

Executive Producer: Christian Böhm

Production: Martina Willnow

Graphic Design: Michaela Reblin

Printed at: Druckhaus Sportflieger GmbH, Berlin

Pictures: www.istockphoto.com/Who_I_am/chana (cover); Fraunhofer Institute for Applied Polymer Sciences IAP, Potsdam (p. 7), Graphics: SPECTARIS Jahrbuch 2026, Die deutsche Medizintechnik-Industrie, facts and figures (p. 7-10) by Spectaris.de

This book is protected by copyright. All rights including those regarding translation, reprinting and reproduction reserved. No part of this book covered by the copyright hereon may be processed, reproduced, and proliferated in any form or by any means (graphic, electronic, or mechanical, including photocopying, recording, taping, or via information storage and retrieval systems, and the Internet).

© Knowbio GmbH, Berlin, 2026

ISBN: 978-3-928383-97-4

In recent years, the medical technology industry has struggled under the weight of regulatory and economic challenges, creating the impression that progress had slowed or even reversed. Despite these conditions, which seem to hinder innovation, the German medical technology industry is still the strongest in Europe. However, sales growth is slowing down, and companies find themselves caught between global and geopolitical disputes (tariffs) and massive technological catch-up efforts from Asia. The perceived strength of the industry could therefore be built on shaky foundations, and calls for politicians to finally take action have become increasingly desperate.

Fortunately, things now seem to be moving forward. Suddenly, medical technology is playing a central role in Germany’s high-tech agenda. At least, that was the message from Parliamentary State Secretary Matthias Hauer during the kickoff event for the MedTech Dialogue in November 2025 at the Federal Ministry of Health.

The Federal Chancellery is also actively involved in the process. Other participants come from the departments of health, economics, research and technology, and the medical technology industry. Together, they are drafting a strategy paper that summarises the results and will be submitted to the Federal Cabinet for approval.

The medical technology industry is represented by BVMed, SPECTARIS, VDGH and ZVEI. They are calling for “the courage to implement far-reaching and strategic reforms” in order to strengthen Germany’s competitiveness as a centre of innovation in medical technology. Some of their priorities have been known for years: reducing bureaucracy and deregulation, rapidly bringing innovations into standard care, expanding digital and AI-based care services, and utilising health data.

Is there now a chance that these demands will finally be heard and implemented? Industry associations are confident that the interdepartmental strategy process is the right way to strengthen Germany’s position as a leading medical technology location while ensuring high-quality healthcare for the population.

In 2026, the German Medtech Guide will continue to represent the sector at key national and international events, serving as both a snapshot of the industry’s current strengths and a reminder of what is at stake if structural challenges remain unaddressed.

Maren Kühr Editor

Christian Böhm Sales & Marketing

MD&M West Anaheim | 03.-05.02.2026 https://www.mdmwest.com/en/home.html

WHX Dubai Dubai | 09.-12.02.2026

https://www.worldhealthexpo.com/events/healthcare/dubai/en/home.html

WHX Labs Dubai | 10.-13.02.2026 https://www.worldhealthexpo.com/events/labs/dubai/en/home.html

Medical Technology UK Coventry | 11.-12.03.2026 https://www.medicaltechnologyuk.com/

Kimes Seoul | 19.-22.03.2026 https://kimes.kr/eng/

Pharma West Africa Lagos | 14.-16.04.2026 https://www.pharma-westafrica.com/home

expomed eurasia Istanbul | 16.-18.04.2026 https://expomedistanbul.com/en/

DMEA Berlin | 21.-23.04.2026 https://www.dmea.de/de/

GITEX Future Health Africa Casablanca | 04.-06.05.2026

https://gitexfuturehealth.com/home

MedtecLIVE Stuttgart | 05.-07.05.2026 https://www.medteclive.com/en

Hospitalar Sao Paulo | 19.-22.05.2026 https://www.hospitalar.com/en/home.html

Microtec Südwest Clusterkonferenz Baden-Baden | 19.-20.05.2026 https://www.microtec-suedwest.de/

CABSAT Dubai | 02.-04.06.2026 https://www.cabsat.com/

EPHJ Geneva | 16.-19.06.2026 https://ephj.ch/en/

WHX Miami Miami Beach | 17.-19.06.2026 https://www.worldhealthexpo.com/events/healthcare/miami/en/home.html

ebme Expo Coventry | 24.-25.06.2026

https://ebme-expo.com

Medical Technology Germany Ulm | 01.-02.07.2026 https://de.medicaltechnologygermany.com/

WHX Osaka Osaka | 02.-04.07.2026

https://www.worldhealthexpo.com/events/healthcare/japan/en/home.html

Medtech China Shanghai | 01.-03.09.2026

https://www.medtecchina.com/en-us/

Medical Technology Ireland Galway | 23.-24.09.2026 http://www.medicaltechnologyireland.com/

WHX Cape Town Capetown | 13.-15.10.2026

https://www.worldhealthexpo.com/events/healthcare/capetown/en/home.html

Medica Dusseldorf | 16.-19.11.2026

https://www.medica.de/

Compamed Dusseldorf | 16.-19.11.2026

https://www.compamed.de/

Formnext Frankfurt | 17.-20.11.2026

https://formnext.mesago.com/frankfurt/de.html

SPS Nuremberg | 24.-26.11.2026 https://sps.mesago.com/nuernberg/de.html

Few industrial sectors embody Germany’s blend of engineering excellence, scientific rigour and international competitiveness as clearly as medical technology. For more than a century, German manufacturers have shaped medical progress worldwide, from early imaging systems to today’s digitally enhanced diagnostics, surgical robotics and AI-enabled clinical tools. In 2024 and 2025 the industry once again demonstrated remarkable resilience: growing steadily despite global market turbulence, rising regulatory complexity, volatile supply chains and mounting geopolitical pressures, as the industry association SPECTARIS notes in its annual report (www.spectaris.de). At the same time, it faces one of the most challenging phases in its modern history –defined by new trade barriers, competing industrial strategies, raw-material dependencies and an accelerating shift towards localisation.

The sector guide of SPECTARIS describes the state of the German MedTech industry as it enters 2026: where it stands globally, what drives its strength, and which structural tensions increasingly shape its trajectory. It provides a sober assessment, but also a clear message: Germany’s medical-technology ecosystem remains one of the world’s strongest. Yet its future leadership will depend on political clarity, regulatory pragmatism and the ability of firms – especially SMEs – to adapt to a rapidly re-ordering global market. Some of the major topics of the report may help as an introduction to the sector´s status in Germany.

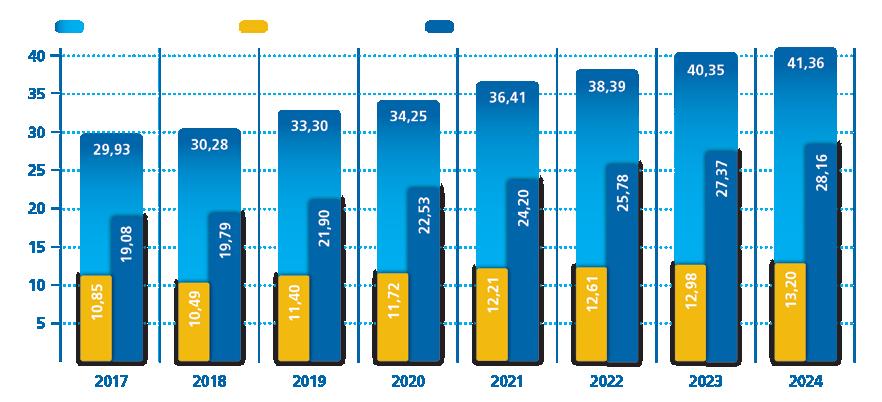

MedTech is fundamentally an export-driven sector. In 2024, German manufacturers generated EUR 41.36 billion in turnover, with EUR 28.16 billion – over two-thirds – earned abroad. Roughly 40 percent of exports flowed to EU markets, 20 percent to North America and 15 percent to Asia. The United States remained the single largest destination, with imports valued at more than EUR 5.7 billion. Meanwhile, exports to China – which have long been a growth driver – fell sharply by 14 percent to around EUR 2 billion.

The global outlook remained uneven. While demand in India increased by almost 12 percent and the Middle

East recorded growth of 17 percent, China’s more restrictive procurement policies and wider geopolitical frictions dampened market momentum. Even Africa, historically a smaller market, saw demand rise by 9.4 percent, suggesting that medical-technology needs are diversifying geographically.

Despite this international success, external pressures intensified. Geopolitical tensions, new trade regulations and shifting industrial policies have raised the cost and complexity of operating globally. The triangle of the United States, the European Union and China – once the backbone of globalisation – has become a focal point of protectionist competition. For a sector that relies on stable frameworks, open markets and predictable procurement rules, this shift creates significant uncertainty.

A major turning point came with the sharp escalation of US tariffs in 2025. Under “Section 232,” Washington imposed duties on a wide range of medical and pharmaceutical goods – fields traditionally spared from trade conflict. MedTech firms were already strained by higher tariffs on steel and aluminium earlier in the year, which directly increased production costs. By late 2025, EUmanufactured medical devices exported to the US faced tariffs of 15 percent, while American exporters enjoyed tariff-free access to the EU market. Parallel increases in steel and aluminium tariffs to 50 percent further amplified cost pressures.

controls and raw materials ... European and American industry associations jointly called for a return to the “zero-for-zero” principle, a longstanding agreement that ensured mutual tariff-free access for medical and pharmaceutical products. But for now, the principle remains suspended. Strains also rose in EU-China relations. In mid-2025, the EU applied the International Procurement Instrument (IPI) for the first time, excluding Chinese suppliers from high-value tenders in Europe due to discriminatory

procurement practices in China. Beijing responded in kind: EU companies were barred from tenders above EUR 5.3 million, and bids using more than 50 percent EU components were restricted. Only firms manufacturing locally in China remained exempt, effectively accelerating the global trend toward strategic localisation.

Trade barriers are no longer limited to tariffs or procurement restrictions. In 2025, China introduced stringent export controls on seven critical rare-earth elements – materials indispensable for MRI systems, sensors, high-precision actuators and other core MedTech applications. As China dominates roughly 90 percent of processing capacity and the vast majority of global production, these controls rapidly affected Western manufacturers. Prices spiked across several metals, and approval procedures for shipments became increasingly unpredictable. For German MedTech firms, the episode highlighted a deeper dependency: without diversified raw-material supply chains, technological leadership itself becomes vulnerable. At the same time, Russia-related export controls created additional complexity. A growing list of devices,

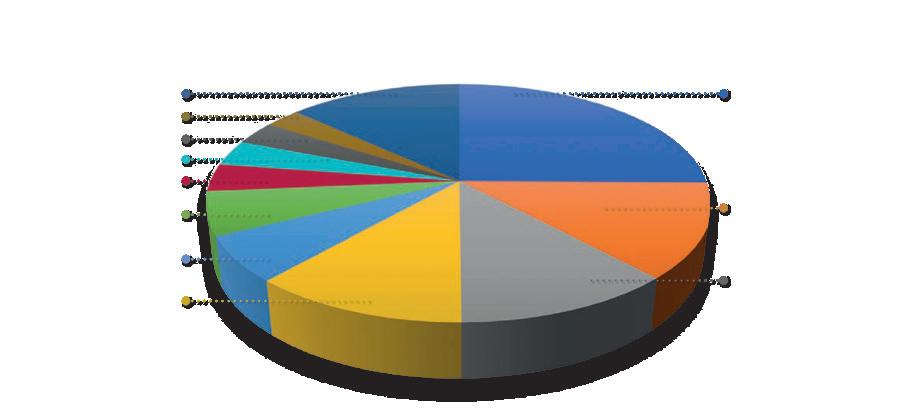

The European medical technology market by country

13.2% others

2.7% Poland

3.2% Austria

3.5% Belgium

3.8% Switzerland

5.9% The Netherlands

Spain

Italy

spare parts and components now requires individual export authorisation, even when used for humanitarian purposes. Processing times lengthened, and companies reported significant delays in servicing existing equipment in Russian hospitals.

These pressures have accelerated a trend that was already visible: localisation as a core pillar of international strategy. China continues to leverage its “Made in China 2025” and “Dual Circulation” strategies to require deeper local value creation from foreign suppliers. India and Indonesia, meanwhile, actively position themselves as alternative manufacturing hubs. India, supported by a potential EU-India free-trade agreement, offers tariff reductions and improved regulatory frameworks. Indonesia’s CEPA negotiations promise similar benefits, provided procurement restrictions – especially the ecatalogue system – are addressed.

For German manufacturers, establishing local production is no longer merely a cost-optimisation exercise. It is essential for preserving market access, controlling supply-chain risks and navigating compliance obliga -

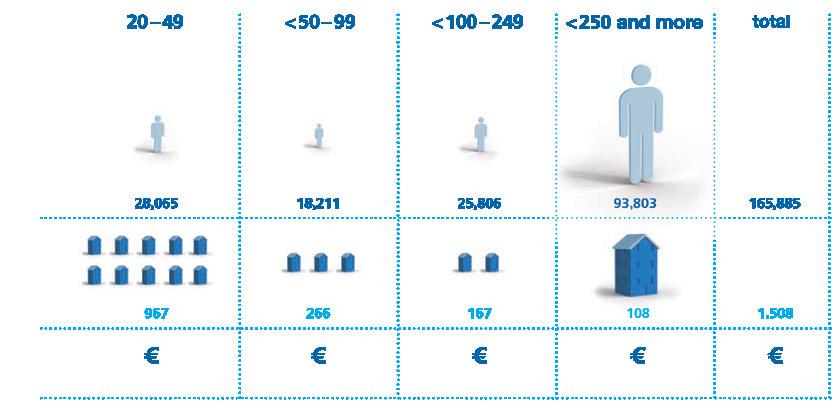

tions. Firms now restructure their customs, exportcontrol and logistics operations with a level of strategic attention once reserved for R&D and market development. Germany’s MedTech industry remains one of the most innovative in the world. With a research intensity of around nine percent, the sector continuously delivers breakthrough technologies – from minimally invasive surgical systems to advanced digital diagnostics. The workforce expanded to nearly 166,000 employees in 2024, underlining robust domestic capabilities.

Yet innovation is increasingly constrained by regulation. The European Medical Device Regulation (MDR) continues to impose burdens that disproportionately affect small and medium-sized enterprises, which form the backbone of the sector. Certification processes are slower and more expensive, delaying market entry. At the same time, the proposed ban on PFAS and similar high-performance materials threatens entire product categories, many of which have no viable technical alternatives. For manufacturers, this combination of administrative pressure and material uncertainty has become one

of the greatest structural challenges: one that requires political action rather than industry adaptation alone. Despite these hurdles, global demand for medical technology remains on a long-term growth trajectory. The consulting firm Frost & Sullivan forecasts annual global growth of 7 to 8 percent in the coming years, driven by demographic ageing, rising chronic disease burdens, growing healthcare investment in emerging markets and the rapid maturation of digital health ecosystems. A study by the FutureManagementGroup places MedTech among the ten most promising sectors for Germany’s economic future up to 2040, reinforcing its strategic importance for national competitiveness.

One of Germany’s greatest advantages remains its industrial structure. Alongside global leaders, the country hosts a dense network of medium-sized manufacturers – complemented by more than 9,500 micro-enterprises specialising in components, software and niche technologies. This decentralised ecosystem fosters resilience, flexibility and innovation. It enables rapid adapta-

tion to market shifts and encourages diversity in technological approaches.

Innovation evolves only with adaptation Stagnation is not an option. New times call for new action. In response to global fragmentation, companies increasingly treat resilience not as a crisis measure but as a strategic capability. They diversify supply chains, invest in digital transparency tools, build regional production sites and integrate trade-compliance expertise into their core operations. But resilience also requires governmental support: modern free-trade agreements, export-promotion initiatives and regulatory reforms that protect innovation rather than hinder it. And Berlin is understanding. As part of Germany’s Hightech Agenda, medical technology is moving centre stage. In late November, the Federal Ministry of Health convened its first cross-ministerial working group on MedTech and medical devices to develop a national strategy aimed at strengthening the industry and improving patient care. The process, supported by the Chancellery and involving all stakeholders, is expected to deliver a strategy paper for cabinet approval next year. Georg Kääb

Germany Trade & Invest (GTAI) is the international economic promotion agency of the Federal Republic of Germany. We provide German companies with a wide range of information and assistance to do business in markets abroad. We help international companies expand to Germany, strengthening the resilience of the German economy. Additionally, GTAI publicizes Germany as a business location in other countries and supports the internationalization of German regions undergoing structural change. We maintain a global presence and help bolster Germany as a business location in the long term with our expertise, services and assistance.

Understand Germany – for a successful investment

Germany is one of the most attractive business locations in the world. Here, investors will find an economic environment as stable as it is innovative. Germany Trade & Invest (GTAI) provides reliable and up-to-date information on all of the important questions concerning Germany as a business location.

Medical technology-specific information and support includes:

› Market research and industry reports

› Financing and incentives options

› Tax and legal information

› Regulatory and reimbursement information

› Matchmaking with industry and science

› Site selection

Readers of the Guide to German Medtech companies are invited to contact GTAI should they need any support on their way to becoming established in Germany. This publication is of great value to companies looking to find out who’s who in the German medical technology sector as well as seeking partners in Germany. GTAI’s expert team is ready to assist your search for joint-research and contract manufacturing-project candidates across the country.

German medical technology is cutting edge. Hundreds of companies – nearly all of them small or medium-sized – produce medical technology innovations across the entire spectrum of products. Many specialise in very specific fields of applications or types of products.

While these companies may focus on niche markets, they are often world market leaders in their respective fields. Moreover, they continuously strive to improve their existing products: one in three products on the market has been developed within the last three years, with companies investing around nine percent of turnover in R&D. Close cooperation between Germany’s manufacturers and hospitals, universities and a plethora of research institutes helps the country maintain its internationally unparalleled competitive edge. R&D projects in the medical technology sector can also count on numerous types of financial support in the form of grants, interestreduced loans, and special partnership programmes.

Germany is home to more than 30 medical technology cluster networks. Their goal is to achieve continuous innovation in R&D – as well as in manufacturing – by connecting companies, hospitals, universities, and other research institutions.

Dedicated cluster management teams help obtain funding for joint R&D projects, provide shared facilities, and organise educational training programmes for their members. A detailed overview of the cluster networks can be obtained from GTAI. Individual company requests are welcome.

For more information: Gabriel Flemming Deputy Director

Chemicals & Healthcare Germany Trade and Invest Friedrichstr. 60 10117 Berlin, Germany

Gabriel.Flemming@gtai.com → www.gtai.com

Germany stands as a global leader in the provision and export of healthcare products and services. The country’s innovative medical products consistently set international benchmarks for quality, safety, and reliability. German manufacturers and service providers across all health and life sciences sectors attract customers and partners worldwide, delivering leadership and innovation in healthcare.

To support this strong position, HEALTH MADE IN GERMANY is the official export initiative for the German healthcare industry. Established by the German Federal Ministry for Economic Affairs and Energy (BMWE), the initiative aims to promote the German healthcare sector internationally through networking and market insights.

HEALTH MADE IN GERMANY helps international companies and organisations to easily connect with German partners and suppliers in the healthcare industry. The initiative focuses on four major sectors active in the global medical market: pharmaceuticals, medical technology, medical biotechnology and digital healthcare. It works closely with 16 German industry associations and is part of BMWE’s MITTELSTAND GLOBAL umbrella programme supporting small and medium-sized enterprises.

HEALTH MADE IN GERMANY actively links international stakeholders to the German healthcare market by offering a wide range of services, including:

› We publish market briefs, detailed studies, and company directories across various sectors of the German healthcare industry – providing international companies with reliable, accessible information about the market and its key players.

› We offer free access to a comprehensive database of over 4,500 German healthcare companies, complete with detailed profiles and direct contacts, so international businesses can quickly identify potential suppliers and partners.

› We participate in leading healthcare trade fairs worldwide, organise networking events, and maintain

continuous dialogue with international health policymakers.

› We regularly update a calendar featuring the latest industry events in Germany and abroad.

Explore opportunities within the German healthcare industry and learn more at: www.health-made-in-germany.com

Our services help you find and connect with partners and suppliers across pharmaceuticals, medical technology, medical biotechnology, and digital healthcare. Contact us to discover how HEALTH MADE IN GERMANY can support your business goals.

HEALTH MADE IN GERMANY is implemented by Germany Trade & Invest, Germany’s economic development agency, on behalf of the Federal Ministry for Economic Affairs and Energy (BMWE).

Stefanie Zenk Deputy Director Medical Technology

HEALTH MADE IN GERMANY c/o Germany Trade and Invest Friedrichstr. 60 10117 Berlin, Germany

Stefanie.Zenk@gtai.de www.health-made-in-germany.com

SPECTARIS represents the interests of around 400 member companies in Germany, with four sectorspecific associations in the areas of medical technology, optical technologies, and analytical, biological, laboratory and consumer optics. Through its political activities, public relations, and industry marketing, the association gives its members a voice, formulates new responsibilities, and opens up new markets. This ensures the international competitiveness of German industry in these sectors.

Lobbying | Industry Marketing – SPECTARIS promotes industry interests through our communication channels in politics, economics, science, and the media.

Market Research | Statistics – SPECTARIS creates substantial economic advantages through its national, European, and global market reviews and industry data.

Technology Consultation | Research Promotion –SPECTARIS’ technological guidance guarantees access to monetary support programmes.

International Marketing | Promotion of Exports –SPECTARIS offers guidance on the global market and supports its members in securing international contacts.

In the medical technologies sector, SPECTARIS represents around 130 German capital goods and auxiliary aid companies who mostly produce high-tech products and have a pronounced export orientation. The member companies cover an extensive research and applications environment which includes medical products for diagnostic and surgery purposes, supply systems, and anesthesia and intensive care devices. The association also represents manufacturers of ophthalmic devices, large and small sterilisers, medical functional room equipment, respiratory home therapy, rehabilitation aids, and orthopedic technology.

The SPECTARIS trade association Medical Technology provides its members with support and information in various business areas and topics. In particular: financing, hygiene and processing, compliance, regulatory affairs, market access, research funding, and public affairs.

Global demand for German medical technology

› High significance of the European market: 40.0% of German medical technology exports go to countries within the European Union, a further 14.0% to the rest of Europe

› North America continues to be an important trade partner

› Demand is growing in Asia

› €41.4 billion turnover (2024), domestic turnover: €13.2 billion, overseas turnover: €28.2 billion

› European medical technology industry: >64,000 companies, €138 bn turnover, 550.000 employees

For more information: Marcus Kuhlmann

Head of Medical Technology Division

Phone +49-30-414021-17

Fax +49-30-414021-33

kuhlmann@spectaris.de

SPECTARIS. German Industry Association for Optics, Photonics, Analytical and Medical Technologies

Hannoversche Straße 19

10115 Berlin, Germany

→ www.spectaris.de

With 3,600 members, the VDMA is the largest network organisation and an important voice for the machinery and equipment manufacturing industry in Europe and Germany. The association represents the common economic, technical and scientific interests of this unique and diverse industry. The companies employ around 3 million people in Europe, more than 1.2 million of them in Germany. Mechanical and plant engineering represents a European turnover volume of around 870 billion euros.

In the VDMA, the fusion of machinery engineering and health technology is manifold and offers tremendous potential for the future. The VDMA HealthTech represents suppliers, manufacturers of production equipment, and all industry sectors active in the interdisciplinary field of medical technology within a joint platform. The health technology sector is especially focused on pooling the heterogeneous interests of its members and providing an information platform for companies, offering the opportunity to share and access relevant information.

With its huge network, VDMA HealthTech is in a position to recommend experts and to assist its members with fundamental issues. It offers market information for German and foreign markets, a comprehensive list of suppliers for the industry, standardisation activities and representation of political interests. Regular expert meetings and working groups provide information on various topics, including laws and regulations, production technology, components, and markets.

VDMA HealthTech addresses key challenges in healthcare, such as supply security, workforce shortages, and workplace attractiveness. Technological innovations like automation and AI alleviate pressure on professionals, enhance care quality, and increase efficiency. At the same time, VDMA HealthTech advocates regulatory simplifications, financial parity between humans and

machines, and new funding models. By promoting clear standards and sustainable solutions, it supports the widespread adoption of modern technologies. Collaboration between industry, research, and policy makers is essential to achieving these goals and ensuring a future-proof healthcare system.

Another important part of our activities is substantially supporting medical technology events through contentrelated or strategic partnerships and participation in national and international trade fairs: as a key supporter of the medical technology fair MedtecLIVE, through joint stands at Compamed, Altenpflege and med.Logistica, as well as at four German pavilions in the USA (MD&M West), Singapore (Medical Manufacturing Asia), China (Medtec China) and Ireland (Medical Technology Ireland).

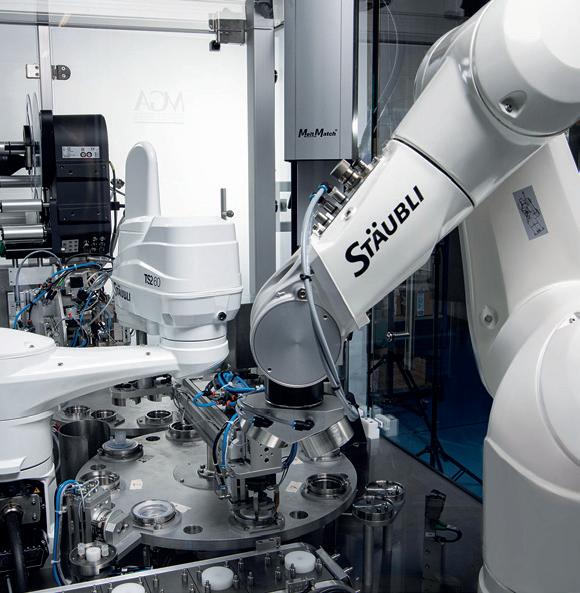

The latest initiative from VDMA HealthTech is the Smart Health Automation Summit. This event will bring together decision-makers, users, manufacturers, politicians and cost-bearers to discuss the potential and challenges of automation in healthcare. The conference will focus on automated systems, robotics and intelligent assistance technologies that are set to transform the future of healthcare.

For more information, contact: Diethelm Carius VDMA – HealthTech Lyoner Str. 18 60528 Frankfurt am Main diethelm.carius@vdma.eu → www.vdma.eu/healthtech

(emerged from the Forum MedTech Pharma e.V.)

Medical technology is one of the strongest research and development sectors. The resulting innovations have the potential to sustainably improve healthcare. In Germany, Bayern Innovativ's Health Innovation Network is the leading platform for networking innovation-driving players from industry, science and medical users. The network operates not only within Bavaria, but also beyond the Bavarian borders.

The Health Innovation Network at Bayern Innovativ is an independent, transdisciplinary network for innovations in the healthcare sector – including, in particular, healthcare and the industrial healthcare industry with the areas of medical technology, digital health and biotechnology/pharmaceuticals. The competencies of almost 200 partners from business, science, application and cost bearers are bundled here in an interdisciplinary innovation landscape and are in trustful exchange.

The Health Innovation Network

› identifies trends and picks up on trends and current topics along the entire value chain of the healthcare industry

› promotes cooperation

› initiates, supports and participates in projects

The Health Innovation Network acts as a dynamic driver of innovation, a source of inspiration and a reliable basis for networking, exchange, cooperation and knowledge transfer. In 2025 the focus of activites kann weg, falls es drinnen bleiben soll: In 2026 the focus of activities combine the relevant subjects of the industry. In addition, the aim is to create further synergies in the innovation landscape with other technology areas, to network intensively with them and thus to initiate and enable cross-industry innovations. The result is a strong market offering for the HEALTH ecosystem. Trend topics in the healthcare industry – such as digitalisation, artificial intelligence and robotics – can thus be explored in greater depth and new impetus for processes and products, as well as topics

such as approval and reimbursement, can be provided to players in the industry.

The Health Innovation Network‘s activities focus on the following key topics:

Technologies

› Digitalisation & artificial intelligence

› Care technologies & assistive products

› Minimally invasive therapy & robotics

› Manufacturing & value creation

› Innovative development & mechatronics

› Sustainability

› 4P Medicine

› Biotechnology / Pharmaceuticals

› Innovation management

› R&E strategies

› Quality management

› Regulation & approval

› Market, reimbursement & financing

› Business models

In cooperation with Medical Valley, the Health Innovation Network of Bayern Innovativ also operates the Bavarian Medical Technology Cluster, which strengthens and promotes the location with various barrier-free formats.

For more information: Bayern Innovativ Am Tullnaupark 8, 90402 Nürnberg gesundheit@bayern-innovativ.de → www.bayern-innovativ.de

Climate crisis, pandemics, digitalization, collapse of the healthcare system or demographic change: No matter what challenges await us in the future – microtechnology is part of the answer!

The IVAM Microtechnology Network unites people who are excited about key enabling technologies and the way these technologies shape our daily life and our future. As an international business network and technology marketing expert, IVAM creates trustful international connections between developers, manufacturers, and users of high-tech products. The focus is on small and medium-sized enterprises and their needs as well as on representation of their interests. IVAM was founded in 1995 and is one of the most experienced and efficient high-tech industry networks in Germany.

Microtechnology is the driver of ever-accelerating change

Microtechnology and related key enabling technologies like MEMS, nanotechnology, photonics, and advanced materials have significantly accelerated innovation in the late 20 th and early 21st century. These technologies have affected, improved, or fundamentally changed many areas of society, industry, and the economy –either by improving known products and processes or by triggering entirely new, previously unthought-of applications.

Many technologies that emerged in the 1990s, when IVAM started operating, have long since reached maturity. Consequently, technology suppliers today require support in marketing and finding customers. There is a growing need to access international markets. IVAM acts as a driver for innovation and offers well-founded orientation in the high-tech landscape and provides valuable know-how, e.g. through expert groups or studies on strategic questions concerning target markets, funding opportunities, application trends, or innovation management.

Medical technology has been the most profitable market for microtechnology suppliers in recent years. IVAM provides visibility to the technologies and products of its members: at international exhibitions and conferences as well as in virtual space via online meetings, online profiles, technical papers, blogs and podcasts, and other publications. Being found at the right time, in the right environment by the right customers: IVAM helps the sale of innovative high-tech products by supporting networking, contact building, and internationalisation, as well as supporting professionals on the career market.

IVAM has established joint trade fair areas at some of the most important medical supplier trade shows worldwide, such as COMPAMED (DE), MD&M West (US), Medical Manufacturing Asia, MMA, in Singapore, and China International Medical Equipment Fair, CMEF, (CN). In order to push business opportunities even further, IVAM arranges B2B meetings where innovative companies can exchange experience, discuss business ideas, and kick off joint projects.

For more information: IVAM Microtechnology Network Joseph-von-Fraunhofer-Str. 13 D-44227 Dortmund info@ivam.de → www.ivam.com

Baden-Württemberg is one of the leading locations in the medical technology sector. Its attractiveness reaches far beyond the country’s borders. The district of Tuttlingen alone counts a concentration of more than 400 enterprises of the sector. For this reason, the region is also known as the “World Centre of Medical Technology”. For many years, tradition and innovation have gone global from here.

Nonetheless the strongly regulated market and an intensely competitive environment raise permanent challenges for the sector. That is why a well-focused management of continuous advancement and an innovative network are an indispensable basis for long-term global success.

We are MedicalMountains: A cluster initiative for the medtech industry based in the heart of the World Centre of Medical Technology.

Shareholders of the MedicalMountains GmbH are the Schwarzwald-Baar-Heuberg Chamber of Commerce and Industry, the Tuttlingen District, the NMI Natural and Medical Sciences Institute at the University of Tübingen, the Surgical Mechanics Guild Baden-Württemberg, the Hahn Schickard Society for Applied Research, the Chamber of Crafts Constance and the city of Tuttlingen.

Our particular interest is to strengthen innovative capacity and long-term competitiveness, both for single companies as well as for the entire medical technology business cluster.

For this purpose we actively represent the interests of medtech enterprises on a political level, encourage innovation and technology transfer by directing work groups or R&D projects, organise training seminars and other informative events, and provide support for other service topics such as internationalisation or common marketing activities, amongst others.

MedicalMountains – more than

The companies of the cluster consist of more than 90% small businesses and mid-sized companies, making the importance of the network even more crucial now than ever before. The medical sector is experiencing constant change and increasing competition worldwide. For companies of any size, collaboration and exchange with regional partners brings immense knowledge and a lead in technology – as well as enhancing the appreciation of the location for the region itself. MedicalMountains brings order to this natural, mutual structure. Future-oriented, prudent management is the basis for effective, constructive and farsighted developments in medical technology.

In collaboration with a growing network of industry, research institutions and government policies, the cluster initiative MedicalMountains actively represents the interests of medtech enterprises. The focus of the cluster initiative is to promote growth, strengthen competitive advantages, and increase the sector’s international visibility even further. For this purpose MedicalMountains provides a platform for regular dialogue and technology transfer. It brings forward innovation by initiating directed project works, promotes qualification of specialised staff, and advises on subsidies or the opening up of new foreign markets. Our way of working is based on a close collaboration with the companies of our network.

For more information: Julia Steckeler

CEO MedicalMountains GmbH

Katharinenstr. 2

78532 Tuttlingen +49-7461-9697-21-2 steckeler@medicalmountains.de → www.medicalmountains.de

The Medical Valley European Metropolitan Region Nuremberg (EMN) Association is an internationally leading innovation ecosystem in the area of healthcare management. Highly specialised research institutions, international leaders, and many growing companies are active here. They cooperate closely with world-renowned health research institutions in order to jointly find solutions for the challenges of healthcare today and tomorrow. This extraordinary concentration of players, combined with the international market and competitive position of individual players, along with the unique infrastructures and services, allows ideas to be turned into products, processes, and services more quickly. The Medical Valley EMN currently has more than 260 members from business, science, healthcare, networks, and politics and has been contributing to the further development, coordination, and marketing of this ecosystem since 2007.

Selection of current projects: Health Care BY Your Side

Health Care BY Your Side (HCBYS) is an initiative that complements the Telematics Infrastructure Model Region Franconia (TI-Modellregion Franken). The aim is to easily integrate digital applications into everyday healthcare in order to offer patients more efficient healthcare. Providers from medicine, care, therapy, and other areas are also to be supported in this. Initiated by the Bavarian State Ministry of Health, Care and Prevention (StMGP), HCBYS aims to present digital solutions to stakeholders in the healthcare system as well as citizens and familiarise them with their practical use.

The basis for this is an examination of the status quo: How familiar are all those involved with digital applications at present? Where are the associated opportunities already being put to good use? Where is there still room for improvement? What questions urgently need to be addressed?

HCBYS actively involves citizens and service providers in the digital transformation of outpatient and inpatient medical, nursing, and therapeutic care facilities. The aim is to establish needs-oriented, practicable, effective, and safe healthcare that focuses on people.

In September 2023, Medical Valley, together with the consortium partners Bayern Innovativ Gesundheit and Monks – Ärzte im Netz, was awarded the contract by gematik GmbH to set up a telematics infrastructure (TI) model region in Franconia. The aim is to use TI applications and services that have already been rolled out, and those planned for the future, in day-to-day healthcare, in order to subsequently use the experience and knowledge gained there to improve the applications and services on the one hand, and to demonstrate how the applications and services can make an important contribution in a wide variety of healthcare scenarios on the other.

The Healthcare Hackathon Bavaria 2025 once more proved that Erlangen is a hub for digital health innovation, bringing together around 170 IT experts, healthcare professionals, students and founders. Over three days of intensive collaboration, interdisciplinary teams developed and presented forward-looking solutions addressing current challenges in healthcare, with a special focus on AI and the emerging field of Automotive Health.

After 48 hours of teamwork, innovative projects were showcased and awarded by a distinguished jury. Team SugarBeaters won first place in the AWS challenge with an AI-based approach to making complex health data more accessible and user-friendly. The hackathon once again demonstrated the power of interdisciplinary collaboration in driving innovation in healthcare and shaping solutions with real-world impact.

Don’t miss out on the Medical Valley Healthcare Hackathon Bayern 2026!

Medical Valley EMN e. V Marco Wendel

Phone: +49-176-32073960

E-mail: marco.wendel@medical-valley-emn.de

microTEC Südwest strengthens the competitiveness of the Medtech industry by transferring microsystems technologies into safe, high-performance medical applications. Around 100 members from industry, research and academia use the cluster to accelerate innovation, develop new products and increase international visibility.

The cluster focuses on Smart Health and Smart Production. Companies benefit from access to expert knowledge, cross-sector collaboration and high-quality networking that supports technology transfer, regulatory readiness and market adoption.

The expert groups bundle technological expertise and address key challenges at the intersection of Medtech and microsystems technology. Current topics discussed in recent meetings include:

› Digital Diagnostics and Artificial Intelligence in In-vitro-Diagnostics

› Microfluidics, Flexible Electronics and Manufacturing for Smart Implants and Medical Devices

› Cleaning, layer deposition, structurization and characterization of functional, biocompatible medical devices

Smart health and innovation transfer microTEC Südwest supports the development of advanced diagnostic and therapeutic solutions, including miniaturized systems, point-of-care platforms, surfaceengineered components and sensor-based medical devices. Close cooperation with leading research institutes strengthens innovation, safety and patient benefit.

microTEC Südwest invites Medtech professionals to actively participate in our Expert Groups. The groups offer direct access to specialists, current research topics and collaboration options for companies and research institutions. If you are interested in contributing your expertise or joining upcoming sessions, please contact us.

More about our last sessions: https://www.microtec-suedwest.de/fachgruppe-mikromedizintechnik-oberflächen-2025

https://www.microtec-suedwest.de/ fachgruppeivd-2025

We also welcome you to join the annual microTEC Cluster Conference, where industry, research and policy stakeholders meet to discuss new developments in microsystems technology and Medtech. www.microtec-suedwest.de/clusterkonferenz/

For more information:

Dr. Christine Neuy +49 761 38 69 09-12 christine.neuy@microtec-suedwest.de

microTEC Südwest e. V. Emmy-Noether-Str. 2 79110 Freiburg, Germany www.microtec-suedwest.de

Address/P.O. Box

Postal Code/City

Contact Person

Telephone

Founded (year)

Localization Services GmbH

Godesberger Allee 127

53175 Bonn

North-Rhine Westphalia

Michael Kemmann

+49-228-98226-0

+49-228-98226-15 adapt@adapt-localization.com www.adapt-localization.com 1999

ADAPT Localization Services – Your Partner for Multilingual Communication

Since the Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR) entered into force, documentation and translation requirements for medical products have become significantly more stringent across the European Union.

As a consequence, regulatory authorities and Notified Bodies pay closer attention to how manufacturers manage their translation and content creation processes — including the qualification and certification of service providers and the robustness of their Quality Management Systems (QMS). Partnering with an ISO 13485-certified supplier is key for manufacturers to demonstrate conformity and simplify their compliance workflows.

ADAPT Localization Services is a privately owned language service provider offering a comprehensive range of linguistic and technical services to support successful international market entry. Founded in 1999 and headquartered in Germany, ADAPT also operates offices in Sweden, Denmark, and Spain.

Our services include:

› Translation and Localisation – translation into all business languages, including software localisation and multilingual content adaptation.

› Technical Authoring and Editing – creation and structuring of technical and regulatory documentation.

› eLearning and Online Training Solutions – development and multilingual adaptation of digital training modules and compliance-related courses.

› UX Design and Information Architecture – design and structuring of user-centred, accessible, and compliant content across platforms and formats.

› Desktop Publishing and Multimedia Services – layout, graphics, and multimedia production, consistent across languages and media.

› Source Text Review and Optimisation – linguistic and structural optimisation to improve clarity, usability, and translatability.

As a leading provider of language solutions for the medical technology and life sciences industries, quality, reliability, and regulatory compliance are at the core of our operations. Our Quality Management System is based on ISO 14971/FMEA risk analysis principles and certified under:

› ISO 13485 – Quality Management System for medical devices

› ISO 17100 – Translation services

› ISO 18587 – Post-editing of machine translation

ADAPT specialises in the medical and life science industries and related technology sectors. Within these areas, we provide services for all content types, including

› user interfaces

› user manuals & user assistance

› instructions for use & training guides

› multimedia & eLearning

› marketing materials

› regulatory documentation.

Our integrated approach enables clients to maintain consistency, usability, and compliance across all languages, media, and markets.

While human expertise remains the heart of what we do, technology plays a key supporting role. Our technical infrastructure includes advanced translation and localisation platforms, powerful, AI-enabled QA tools, and a secure, user-friendly customer portal for data exchange and project management.

With more than 25 years of experience, ISO-certified processes, and deep industry expertise, ADAPT is the trusted partner for manufacturers seeking precise, compliant, and effective multilingual communication.

Name ›

Address/P.O. Box ›

Postal Code/City › State ›

Contact Person › Telephone › Email › Website › Social Media ›

Number of Employees › Founded (year) › Areas of Activity ›

Hermann Bantleon GmbH

Blaubeurer Straße 32 89077 Ulm

Baden-Wuerttemberg

Rainer Janz +49-731-3990-0 info@bantleon.de www.bantleon.de F I I

Ca. 260 1918

We advise our customers on site and create individual concepts. Our offer covers the entire process chain of the metalworking industry: from machining the workpiece to cleaning and packaging.

With this motto, we have been writing success stories for over 100 years. As a traditional top company in the region, we and our customers’ processes are always in motion. And if no suitable lubricant can be found, then we custom-make it ourselves!

We are Hermann Bantleon GmbH. The lubricant specialist from Ulm. A medium-sized company with approx. 250 employees. We advise our customers on site and create individual concepts. We have specialised in offering our customers holistic product and service concepts consisting of cooling lubricants, cleaning, and corrosion protection, as well as maintenance and care of the media used.

Annual Turnover ›

ca. €132m

Member of

It is precisely this holistic approach that demands close dialogue with customers, opens the way to innovations, and makes Bantleon a flexible and high-performance partner to industry. In the company’s own accredited laboratory, the specialists develop and analyse products with and for the customer.

Transparency and traceability, as well as complete documentation, reflect the reliability and high quality awareness of the Ulm-based development, production, and service company.

Today, medical technology primarily uses materials that are difficult to machine. In addition to medical steel, magnesium, and ceramics, these also include titanium and cobalt alloys. The advantages are primarily to be seen in their safe biocompatibility and high corrosion resistance.

Today, Bantleon offers a wide range of technologies in the field of water-miscible cooling lubricants, which have also proven their worth in the medical sector. Cooling lubricants with high reserve alkalinity enable very long service lives, even under adverse operating conditions. These technologies have proven their worth, for exam -

ple, in the machining of titanium, steel, and cast iron. In the field of light and non-ferrous metals manufacturing, technologies with moderate pH have proven their worth. Our many years of experience with boron-free and amine-free product strategies have been transferred here from development into reliable modern cooling lubricant solutions. In addition to application-specific cooling lubricant properties such as flushing and lubricating effects, foaming, and residue behaviour, technological suitability for the available water quality and the materials to be machined must also be considered. Skin compatibility is confirmed in Bantleon product development through dermatological testing.

As a partner to the medical industry, Bantleon naturally also offers lubricant solutions in the field of cutting and grinding oils, as well as minimum-quantity cooling lubricants. High performance, low consumption, good cleanability in the downstream process as well as low workplace pollution are relevant for the users.

The use of low-mist and low-evaporation base oils with very high lubricity have proven their worth here. Synergistically acting additive systems matched to the materials are an important success factor in the respective process.

In addition, Bantleon’s specialists work closely with our customers to develop optimised cleaning and packaging solutions. All according to the motto: “Through this collaboration, we jointly develop fluid technology and coordinate the processes, with monitoring by our specialist laboratory and fully traceable quality. This ensures the best possible solution and guarantees a satisfied customer.”

Certification status:

ISO 9001

ISO 14001

DIN EN ISO 21469

DIN EN ISO/IEC 17025

Bürkert Fluid Control Systems

Address/P.O. Box

Postal Code/City

Telephone

Fax

Website

Social Media

Number of Employees

Founded (year)

Areas of Activity

Christian-Bürkert-Straße 13–17

74653 Ingelfingen

Baden-Wuerttemberg

+49-7940-10-0

+49-7940-10-91204

info@burkert.com www.burkert.com

F I Q I

More than 3,700 1946

| Measuring, control and regulating systems for liquids and gases

| Components, customised systems, services and automation solutions

| Lab & analytical as well as medical & dental

| Solenoid valves, analytical valves, proportional valves and sensors

Annual Turnover

€667,3m (2024)

Member of

We make ideas flow.

At Bürkert, everything revolves around fluids. Whether it’s measuring, controlling or regulating – our fascination with everything that flows has driven Bürkert forward for eight decades. This passion is reflected in our continuous development of innovative products and tailored system solutions that are used in fluid technology applications the world over. We focus primarily on Lab & Analytical applications, the Food & Beverage and Pharma & Biotech industries, as well as on Hydrogen for the Energy sector. For these industries, we develop individual portfolios of components, system solutions and services (including digital services) that are precisely tailored to each of the various applications and requirements of our customers.

In vitro diagnostic: Precision, automation and increased throughput

The precision and accuracy of the analyses determine the diagnosis. At the same time, the speed and the space required for the device in the laboratory are essential for in vitro diagnostics due to the rapidly increasing need for tests.

Our systems are not just ideal for your applications for reasons of speed and compactness. Our extensive portfolio of media-separated valves has established itself as the benchmark in IVD fluidics over the past few decades. This makes Bürkert an experienced full-service provider in all processes of clinical diagnostics. In addition, we provide you with the documentation for our products and systems. Depending on the applicable medical regulations and guidelines, these can make it easier for you to apply for any approvals for your entire device.

More Information: www.burkert.com/in-vitro-diagnostics

Ventilators: Reliable, precise gas control If vital bodily functions, such as breathing, no longer work independently, patients are instructed to use ventilators. It can only be guaranteed that the patient is being supplied with sufficient oxygen when the device controls the supply of air and oxygen exactly. Adjustable gas concentrations are just as important as correct volume flow rates and pressure.

Collaboration with Bürkert will enable you to concentrate on user-friendliness and ventilation modes as a manufacturer. Our experts will support you with individual fluid technology in compact designs, solutions for mixing and controlling gases. Our experts rely on tried-andtested, individually combinable standard components in compact designs for this work. By doing this, we then reduce development costs for your requirement profile. We also contribute our expertise in digital data acquisition and processing.

More Information: www.burkert.com/respiratory

Dialysis: Highly integrated and cost-effective system solutions

As the prevalence of chronic kidney disease increases globally, so do the demands on modern dialysis devices: Patients expect functional reliability and comfort, the healthcare system increases cost pressures, manufacturers of dialysis devices strive to take advantage of market growth opportunities.

Bürkert is the ideal partner for the challenges involved in dialysis, thanks to its industry-specific portfolio covering all types of fluid handling (valves, sensors, pumps, controllers).

We offer you proven, innovative fluid systems that are also highly integrated and cost-effective – including multifunctional, compact application solutions to help you optimise and monitor processes, save space and increase functional reliability and operational safety.

More Information: www.burkert.com/dialysis

Name ›

Address/P.O. Box ›

Postal Code/City › State ›

Contact Person › Telephone › Email › Website › Social Media ›

Number of Employees › Founded (year) ›

Areas of Activity ›

Chips 4 Light GmbH

Am Kühlen Kasten 8 93161 Sinzing Bavaria

Dr. Wolfgang Huber

+49-9404-641330

Info@chips4light.com www.chips4light.com I I F >10

2010

| Industry: Position detection –encoders, sensors, light grids, safety barriers, distance measurement, triangulation, smoke detectors, mechanical engineering, robotics, gas analysis (CO 2 , oxygen)

| Medicine: dental, lighting, endoscopy, microscopy

| ToFL, LiDar, logistics (self-propelled robots) also distance measurement

| Research / development, colleges, universities, institutes

| Agriculture, horticulture

| Aerospace: lighting (ambient), route signals, position detection

| Railroad and signaling technology: lighting (ambience), route signals, position detection

| Maritime: Lighting (ambience)

| Data communication

| Automotive: Lighting (ambience)

| Consumer, niche lighting applications, wearables, bio - home medical

| Research projects

Member of

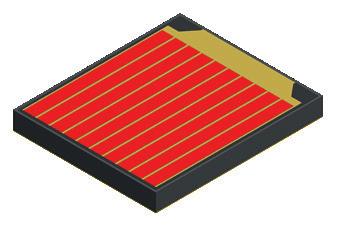

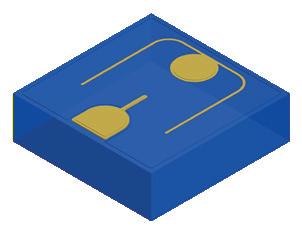

LED chips custom measured for precise requirements

We supply and integrate our specific light sources according to your requirements – whether as a standard solution or as a customized project.

Chips 4 Light supports companies that need customized optoelectronic components in a desired quantity, with long-term availability and individual specifications.

Our range includes high-quality LED chips, detector chips, LEDs and laser products across a broad spectrum in various performance classes from ultraviolet to infrared and also in white.

As extended services, we offer our customers the characterisation of laser diodes and the sorting of LED chips onto various carriers as well as long-term storage. Our products are particularly suitable for applications with a high demand for miniaturisation in sensor technology, industry, medicine and much more ... today and for tomorrow’s innovations. Wherever optical precision plays a role, we have the right lighting solution for you.

Developers of, for instance, precision sensors or medical devices are often looking for components with special properties. These are not always available on the market. Specific conditions, such as limited space and high ambient temperatures, make it difficult to use standard LED components. Pure LED semiconductor chips, in contrast to larger packed LED components, are often the only way to meet the customer’s requirements. Among other things, the bare die allows designs to be kept very small and to realize different functions on one board by combining several chip.

Chips 4 Light meets exactly these challenges with an extensive LED chip portfolio (synonymous LED bare dice or die). In addition to the opto semiconductor components, special high-tech equipment is needed to meet customer specific requirements. Chips 4 Light

has therefore also invested in “die sorters”, with which the single LED chip is sorted off the wafer and placed on different carriers as gel or waffle pack. In addition to the sorting service for small or sample quantities from the wafer, the company also offers its customers long-term storage of LED chips in waffle or gel packs.

LED chips can also be measured and sorted by individual optoelectronic parameters. The company also supports its customers in the production of prototypes.

Such precise work is delivered by the company not only in the LED and detector chips, but also for semiconductor laser diodes in the visible and infrared spectral range. A further service provided is the characterization of individual laser diodes according to specific performance parameters using a specially developed measuring station.

Thus, customers receive precisely measured laser diodes according to their desired specifications.

› Distribution of high-quality optoelectronic components: LED chips, LEDs and modules, laser diodes, photo detectors

› Design, development of customized LEDs and LED modules, laser modules outside the market standards

› Prototypes and small series production

› Services such as LED chip sorting and placing on different carriers

› Long-term storage of LED chips

› Offering small and medium quantities

› Laser diode characterization according to customer needs

› We realize your lighting application with our specific optoelectronic light sources

We are writing the future of light together with our customers!

Name ›

Address/P.O. Box ›

Postal Code/City › Country › Telephone › Email › Website › Social Media › Number of Employees › Founded (year) ›

Areas of Activity ›

Annual Turnover › Cicor Group

Gebenloostrasse 15 9552 Bronschhofen Switzerland +41-71-913-73-00 info@cicor.com www.cicor.com

4,600 worldwide 1966

| Engineering Services | Electronic Manufacturing Services | Precision Plastics | Hybrid Circuits

| Printed Circuit Boards | Printed Electronics | Power Supply | PCBA Prototyping Shop

CHF481m (2024)

We design and manufacture advanced electronic solutions that make the world a healthier, more connected and safer place.

Cicor is a global leader in the design and manufacturing of advanced electronic solutions. Serving the healthcare technology, industrial electronics and aerospace & defence sectors, our full-cycle approach combines engineering excellence with high-precision production to bring ideas to life. Together with our customers, we create electronics that make the world a healthier, more connected and safer place.

The rapid growth of innovative therapies such as cell and gene treatments and RNA-based drugs brings with it a number of challenges. They range from limited administration options and poor drug stability requiring costly cold-chain logistics, to high development costs, market acceptance hurdles and complex regulatory approvals.

Cicor helps overcome these obstacles with a comprehensive, end-to-end manufacturing service. We support customers from the first samples and pilot runs to full serial production, not only in PCB manufacturing, PCB assembly but also in the integration of housings, cables and other key components. Our cleanroom facilities ensure compliance with stringent medical standards, while our integrated approach streamlines supply chains, accelerates time-to-market and guarantees consistent quality.

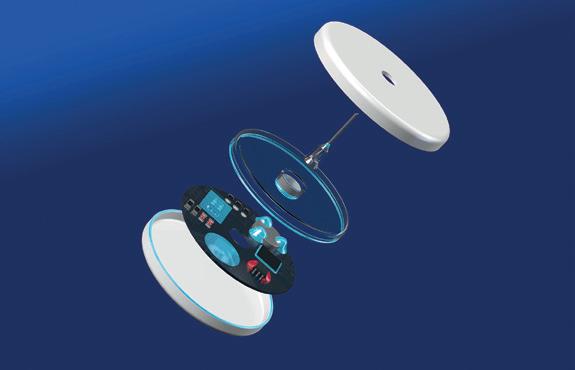

Implantable medical devices face demanding challenges, from biocompatibility and miniaturisation to long-term power management, secure wireless communication and strict regulatory requirements such as the MDR revision in Europe. Meeting expectations for safety, durability and data security further increases complexity.

Cicor addresses these needs with a multidisciplinary design team experienced in miniaturisation and active implantable medical devices (AIMDs). Our expertise in PCBs, microelectronic assembly and cleanroom manufacturing ensures the highest levels of precision,

safety and reliability. Customers also value Cicor’s ability to manufacture Class III medical devices, making us a trusted long-term partner in this highly specialised field.

The hearing aid industry is a high-mix, low-volume market that requires exceptional precision, advanced technology and trusted partners. Key challenges include miniaturisation, long battery life, seamless wireless integration, acoustic performance, personalisation and strict regulatory requirements.

Cicor has been a proven partner in hearing aid manufacturing since 2005, offering a one-stop shop that spans the full value chain — from PCBs, hybrid circuits and PCBA to tooling, moulding, painting and final assembly. With precision equipment designed for high-mix, lowvolume production and strategically located facilities in Europe and Asia, we help customers reduce lead times, optimise supply chains and ensure outstanding quality and cost efficiency.

Manufacturers of advanced medical devices must balance miniaturised product design, long development cycles, regulatory compliance and intense price pressure, while relying on capable and stable partners. Cicor acts as a full-lifecycle partner, from concept and V&V to prototyping and serial production. With strong expertise in IEC 60601-x, EN 62304 and international regulations, we ensure compliance and efficiency. By leveraging larger facilities in Vietnam and Romania, we deliver cost-effective production without compromising quality.

Representative projects demonstrate Cicor’s ability to retain technical know-how across changing development teams and deliver high-reliability devices that meet international safety standards, underlining our stability and long-term commitment.

Examples include defibrillators, image-based diagnostic systems, in vitro diagnostics, catheters, endoscopes and therapy devices, all requiring precision, regulatory compliance and long-term reliability.

Name ›

Address/P.O. Box ›

Postal Code/City › State ›

Contact Person › Telephone › Email › Website › Social Media ›

Straubinger Strasse 100 94447 Plattling Bavaria

Marcel Lavèn

+49-151-188-29-506

Number of Employees › Founded (year) › Areas of Activity › CSA Group Bayern GmbH

Marcel.Laven@csagroup.org www.csagroup.org F I

ca. 2,000 worldwide 1919

| Product Testing Inspection and Certification | Standards Development | Global Market Access

CSA Group is a global organisation dedicated to safety, social good, and sustainability. We are a leader in standards development and in the testing, inspection, and certification of products around the world including Canada, the U.S., Europe, and Asia.

Our areas of focus for testing, inspection, and certification services are the healthcare, industrial, home, and commercial industries.

Accredited as a National Certification Body (NCB) through the IECEE CB scheme and recognised by Authorities Having Jurisdiction (AHJ), we offer leading healthcare systems conformity assessment services, as well as testing and certification to leading international standards, such as IEC 60601-1, including the collateral standards and the applicable particular standards, and IEC 61010-1 with the applicable particular standards.

Our technical knowledge of medical electrical equipment and systems, and laboratory & measurement equipment, along with our knowledge of the compliance requirements in major world markets, work together to help you remove barriers to global market access.

CSA Group offers a comprehensive safety and compliance testing service offering. We offer testing and risk management evaluations throughout the product lifecycle and can offer tests for:

› Electrical safety

› Electromagnetic compatibility (EMC)

› Cybersecurity

› Interoperability

› Wireless applications

› Global market access

› Coexistence testing services

Member of

Medical electrical equipment and systems offer invaluable benefits but can also present great health and privacy risks through flawed design or malfunction. The experts at CSA Group can help you identify and resolve risks so you can safely and confidently go to market.

We provide standards, testing, and certification for a wide array of medical electrical equipment and systems for:

› Patient Monitoring

› Diagnostic lmaging

› Medical Robotic etc.

and products such as:

› CT Scanners

› lncubators etc.

Take advantage of CSA Group’s healthcare industry expertise to prepare your laboratory, control, and measurement equipment for the global market with fast and reliable services.

Laboratory and measurement equipment must meet demanding standards for precision and reliability. Trust CSA Group experts to help you identify and resolve flaws so you can confidently go to market.

We provide testing, certification, and standards solutions for a wide range of laboratory, control, and measurement equipment, such as:

› Centrifuges

› Autoclaves

› Mass Spectrometers

› In-vitro Diagnostic Equipment

› Multimeters

Address/P.O. Box

Postal Code/City

State

Telephone

Website

Social Media

Number of Employees

Founded (year)

Areas of Activity

Managing Director London | United Kingdom Andrew.Murray-Lyon@dcadvisory.com Name

Neue Mainzer Strasse 1

60311 Frankfurt am Main Hesse

+49-69-9720-040 enquiries@dcadvisory.com www.dcadvisory.com

I I 750+ 1902

DC Advisory’s global Healthcare team has extensive experience across a broad range of healthcare sub-sectors, with a track record in delivering results for clients, anywhere in the world.

Sub-sectors include: | Care & Services

| Healthcare IT & Supply Chain | Medtech & Life Sciences | Pharma

DC Advisory is an international investment bank committed to making a difference. Part of Daiwa Securities Group Inc., we offer access to over 750 professionals in 24 locations throughout Asia, Europe, and the US. Across 11 industry-focused teams, we offer tailored, independent advice on M&A, debt raisings and restructurings, private capital markets, secondary advisory, and access to unrivaled Asia investment knowledge.

Globally, DC Advisory has completed 80 Healthcare transactions since 2020. Selected notable transactions include:

› Isto Biologics, a portfolio company of Thompson Street Capital Partnes, on its majority stake sale to Keensight Capital

› Savanne Life Sciences on its majority investment in Franklin Biolabs

› Arlington Capital Partners and Riverpoint on the acquisition of CP Medical

› Blackstone on its acquisition of I`rom Group Co. Ltd

› Näder Holding on its €1.1bn debt financing to support buyback of shares from EQT

› Eurazeo on the sale of Peters Surgical to Advanced Medical Solutions Group plc

› A ltor Equity Partners on the acquisition of VTU Group

› c-Lecta on the sale of a majority stake to Kerry Group

Key contacts

Martin Moser

Managing Director Frankfurt am Main | Germany Martin.Moser@dcadvisory.com

Dr. Wolfgang Kazmierowski

Managing Director Frankfurt am Main | Germany Wolfgang.Kazmierowski@dcadvisory.com

Andrew Murray-Lyon

David Lyons

Managing Director Dublin | Ireland David.Lyons@dcadvisory.com

Joaquín Gonzalo

Managing Director Madrid | Spain Joaquin.Gonzalo@dcadvisory.com

Marzia Cormun Director Milan | Italy Marzia.Cormun@dcadvisory.com

Manish Gupta

Managing Director Chicago | United States Manish.Gupta@dcadvisory.com

Hector Torres

Managing Director Chicago | United States Hector.Torres@dcadvisory.com

Rich Blann

Managing Director New York | United States Richard.Blann@dcadvisory.com

Justin Balciunas

Managing Director Washington, D.C. | United States Justin.Balciunas@dcadvisory.com

Koki Kaita

Senior Managing Director Tokyo | Japan Koki.Kaita@dawia.co.jp

Shinta Niwa

Managing Director Tokyo | Japan Shinta.Niwa@daiwa.co.jp

Address/P.O. Box

Postal Code/City

State

Contact Person

Telephone

Elma Schmidbauer GmbH

Gottlieb-Daimler-Str. 17

78224 Singen

Baden-Wuerttemberg

Federica Fele

+49-7731-882-0 marketing@elma-ultrasonic.com www.elma-ultrasonic.com

F I Q

Number of Employees

Founded (year)

Collaborations

300 1948

l Medical Technology l Photonics l Laboratory l Health Care

l Fraunhofer Institut l Medical Mountains

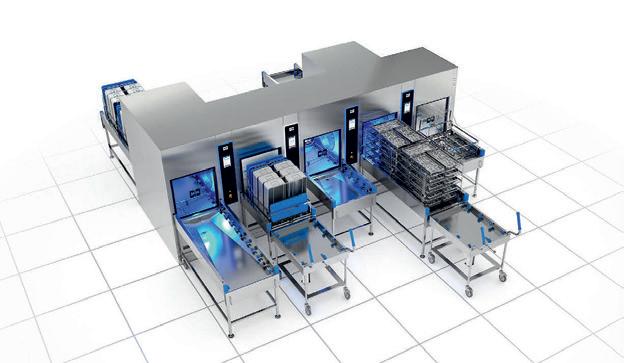

Elma Schmidbauer GmbH is leading in the field of industrial high-precision cleaning of products during their production or processing. Our expertise in medical technology is based on ultrasonic cleaning processes and steam cleaning technology. Thanks to many years of experience, innovative research and development, as well as industry-specific know-how, Elma supplies cutting-edge technology for a wide variety of cleaning applications in the medical technology and health care sectors.

The product portfolio ranges from ultrasonic and steam cleaning devices (also registered according to MDR (EU) 2017/745) to modular and customer-specific cleaning systems as well as suitable accessories. Our cleaning chemistry, developed in our own application laboratory and manufactured in-house, is perfectly matched to its cleaning tasks and thus solves even the most difficult challenges in pre-, intermediate, and final cleaning.

Highly qualified process engineers work together with our customers to develop individual process solutions for various cleaning tasks in our in-house process laboratory. This jointly developed cleaning process is basic to the design of the cleaning system. Tailor-made and depending on customer requirements, these cleaning system concepts also include calibration certificates, audit trail, bar code entry, and data logging. Of course, there are also individual accompanying documents such as FAT, HDS, SDS, FDS, IQ, and OQ for the qualification and validation of these cleaning systems.

Member of

Unconditional commitment to the highest quality standards is the foundation of Elma’s company philosophy. The consistent development of core competencies, the constant striving for improvement, and the constant focus on high customer satisfaction reflect the very high quality standards of Elma. Therefore, Elma is certified by DQS according to DIN EN ISO 13485:2016.

100% family-owned, today Elma employs about 290 people at several operation sites. The family business was founded in 1948 in Singen as a precision machine factory and is now being run in the third generation.

Name ›

Address/P.O. Box ›

Postal Code/City › State ›

Contact Person › Telephone › Email › Website › Social Media ›

Number of Employees › Founded (year) › Areas of Activity ›

FAULHABER Drive Systems

Faulhaberstraße 1

71101 Schönaich

Baden-Wuerttemberg

Kristina Wolff

+49-7031-638-0 marketing@faulhaber.com www.faulhaber.com F I I 2,000 1947

| Medical & Laboratory Equipment | Optics & Photonics | Robotics

Over the years since the company’s founding in 1947, drive specialist FAULHABER has repeatedly succeeded in using innovative products to develop new system solutions for a wide range of applications in many different markets. Laboratory automation and medical technology also benefit from the know-how that is today embedded into microdrives. In addition to the EN ISO 9001 and 14001 standards, FAULHABER is also specially certified for medical products according to EN ISO 13485.

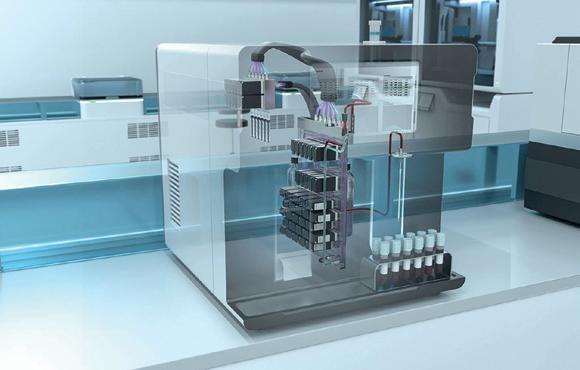

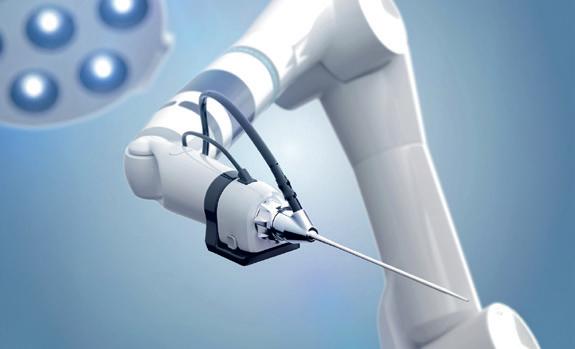

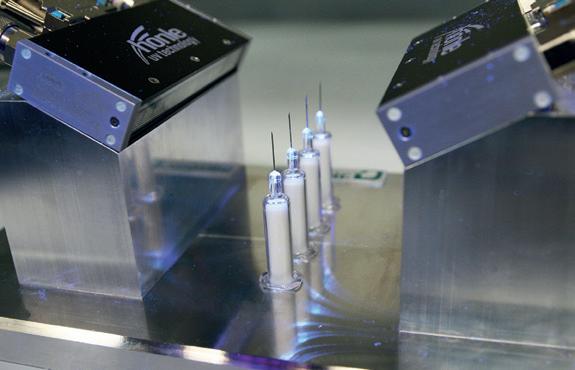

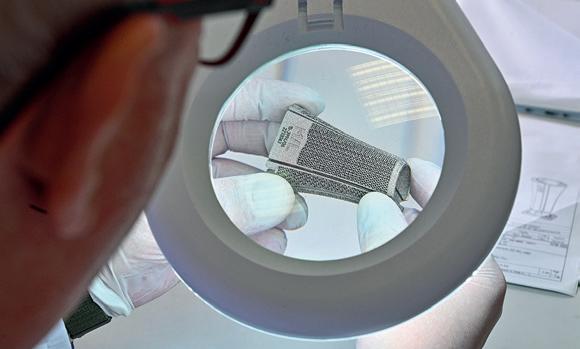

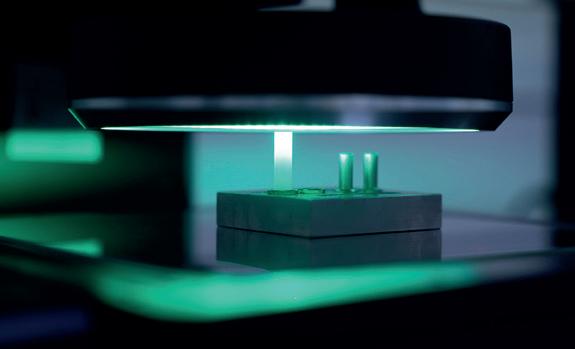

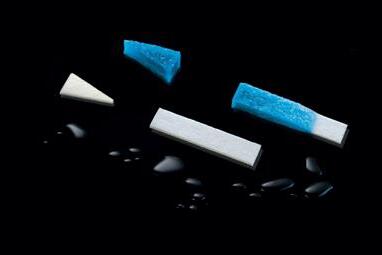

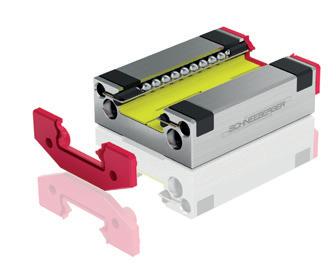

A lot can be learned about the efficacy of new drugs already in the laboratory. This can be significantly accelerated with automated systems for precise cell analysis. (Image 1) The process involves cameras and pipettes, which are moved by brushless DC servomotors with an integrated Motion Controller. They position with micrometer accuracy, are very compact, and they also work very reliably. Their low weight and volume is another advantage in terms of use in laboratories. The brushless DC servomotors with 4-pole technology deliver high torques and smooth running characteristics as well as low noise levels. The dynamically balanced rotor provides quiet, cogging-free operation. And as the data is processed right on the motor, there are no radiated interference signals during commutation, which are inevitable with long supply lines.

of

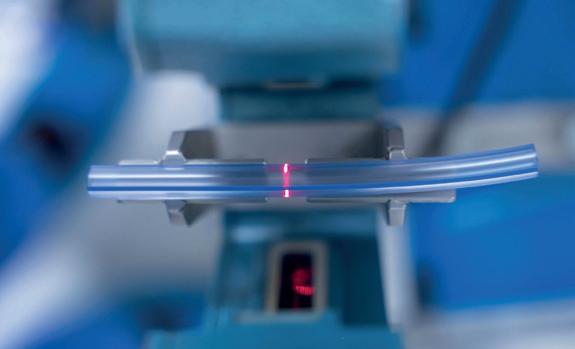

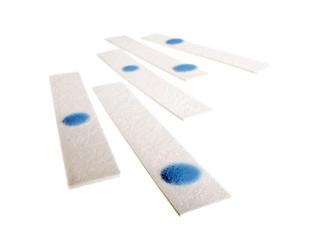

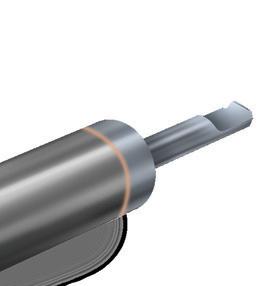

Studies predict that up to 50% of the population will be affected by pollen in the future. Possible symptoms range from hay fever and headaches to shortness of breath or anaphylactic shock. This makes it increasingly important to know when and which pollen are in the air and in what concentration. The standard instrument for this in many European countries is the so-called Burkard trap, in which pollen is collected and counted manually. But automated systems that aspire air and extract the pollen on specimen carriers can deliver results much faster (image 2). So-called pushers then move the specimens under a microscope for analysis (image 3).

These pushers are powered by DC-micromotors, which are well suited for fast start-stop operations thanks to graphite commutation.

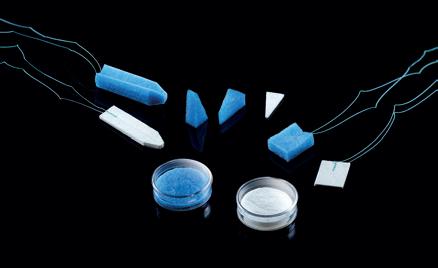

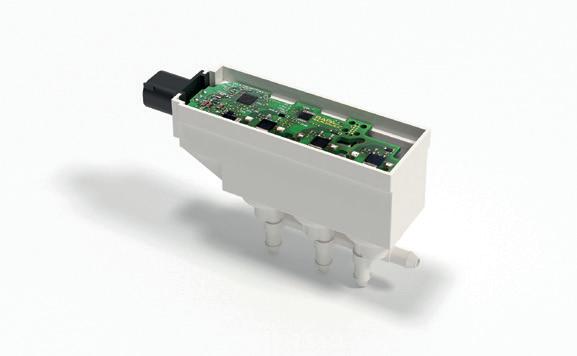

Since the beginning of the coronavirus crisis, the pharmaceutical industry and laboratories have been under pressure to realise the highest possible levels of automation. Miniaturised linear motor modules and axes open up new possibilities (image 4). Designed as a modular system, they are suitable for a wide range of single and multi-axis tasks in laboratory automation and the pharmaceutical industry. They are driven by small DC linear motors. These are not designed as classic “surface rotors” with carriages and guides. Instead, the forcer rod is guided within a 3-phase self-supporting coil. This design produces an exceptionally good relationship between linear force and current and high dynamics. In addition, there are no cogging torques, which makes the linear motors suitable for use in fast linear axes.

In modern laboratory operations, there is no way around the use of practical automation technology that relieves the employees from monotonous tasks and eliminates sources of errors. Fully automated sample distribution systems (image 5) ideally transport the samples directly to the corresponding analysis system and also handle other tasks: the route through the laboratory can be planned and optimised based on the identification of the sample after delivery, whereby many parameters can be taken into account, e.g., the type of container, the preparation, the filling level, and of course the sequence of the individual analysis steps. Brushless DC motors ensure that the sample transport systems accelerate, brake, or stop with pinpoint accuracy, e.g., in front of the analysis stations. They are designed for high reliability and a long service life; they can thus travel many kilometers in automatic distribution systems without wear being a concern. The same applies to motors that are used for pipetting, mixing, or stirring.

Name ›

Address/P.O. Box › Postal Code/City › State › Contact Person › Telephone

Website

Social Media

Number of Employees

Founded (year)

Areas of Activity ›

Gebr. Reinfurt GmbH & Co. KG

Niederhoferstraße 105

97222 Rimpar Bavaria

Team Healthcare

+49-9365-819-481

healthcare@grw.de www.grw.de

500

1942

Healthcare, Aerospace, Industry