Bevananda was established in 1995 to provide solutions to frequently occurring disasters such as floods, landslides, earthquakes, etc.

Bevananda provides quality products for solutions to these issues, both in the form of mitigation, repair, or soil maintenance such as:

BEVA Gabion® (Wire Gabions);

BEVA Greenett® (Erosion Control Blanket);

BEVA GreenMatt® (Erosion Control Blanket);

BEVA Welded Gabion®;

BEVA Welded Sand Gabion®; BEVA Geosynthetics®

All Bevananda products are manufactured in-house using state-of-the-art technology machines and are certified with Indonesian National Standards (SNI) as well as having TKDN (Domestic Component Level) certification with a

To ensure the quality of production outcomes, services, and the sustainability of the surrounding environment, Bevananda has an Independent Laboratory facility that complies with established standards from pre- to

ISO 14001:2015 Environmental Management System

ISO 45001:2018 Occupational Health and Safety Management System

is our motto, supported by an experienced technical team, making Bevananda a One-Stop Solution Company that can provide consultative services for every infrastructure project you handle.

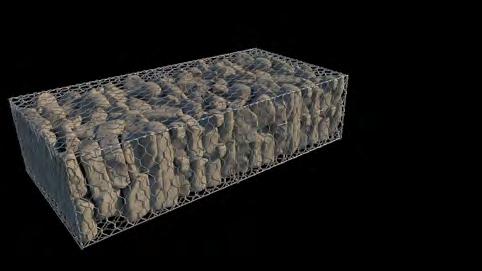

BEVA Gabion® is a permanent construction material is flexible, permeable, easy to install in various environmental conditions, and environmentally friendly. It is used in applications such as retaining structures, road reinforcement, slope stabilization, bridge protection, riverbank protection, groynes, weirs, and more.

BEVA Gabion® is made from thick galvanized wire and PVC-coated galvanized wire produced with advanced technology machines. It has obtained SNI certification, TKDN certification, and is listed on the LKPP E-Catalog Portal.

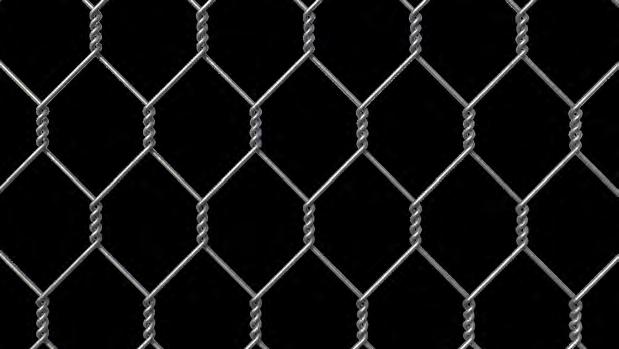

The wire mesh gabion box consists of rectangular units made by double-twisted weaving. The double twisted woven wire, formed into hexagonal holes, is a result of soft annealed thick galvanized wire according to SNI standard No. 03-6145-1999 (Gabion Wire).

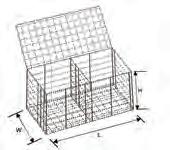

The mesh panels are reinforced along all edges with larger diameter wire to strengthen the construction. The size of the gabion box can be customized as needed and can be divided into cells by installing diaphragms, which serve to reinforce the gabion structure and make connections easier, more precise, and stronger.

These diaphragms are made of the same hexagonal mesh as the gabion box itself and are tied or connected to the base panel of the gabion box. Galvanized wire mesh gabions must comply with SNI No. 03-0090-1999 (Galvanized Wire Mesh Gabions)

similar to galvanized gabions, but the wire material of this type of gabion is first coated with a PVC (Polyvinyl Chloride) sheath continuously. This PVC coating provides additional protection against corrosion and enhances the wire's resistance to environmental influences, making it particularly suitable for use in marine/coastal environments or polluted environments.

Diaphragms in PVC-coated gabions strengthen them when subjected to continuous pressure caused by wave movement, high water velocity, etc. Galvanized wire mesh gabions with PVC coating must comply with SNI No. 03-3046-1992 for both gabion wire and PVC-coated gabions

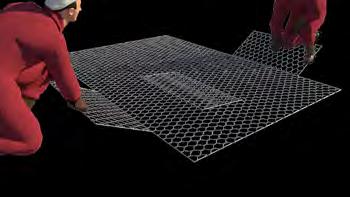

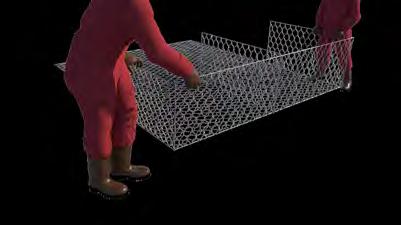

Take wire tie pieces, then tie them on each side of the gabion to form a box. Tie using a combination of ties as shown in the picture.

4.

Tie the gabions together according to the the gabions to the them together according positions.

The gabion structure can be built quickly and economically in all conditions and is highly suitable for stabilizing slopes in mountainous areas and in regions with unstable soil

Mechanically Stabilized Earth Retaining Walls;

Gully Control, Water Velocity Reduction Structures;

Landscape Architecture Elements (such as benches,

• Easy, fast implementation, and creating harmony with the surrounding environment;

• A cost-effective alternative to concrete structures and stone masonry;

• Enhances slope stability as it acts as a massive gravity wall and has high tensile strength due to its wire mesh construction;

• Can reduce horizontal deformations and soil settlement in extreme conditions or unstable soil areas;

• Has a relatively long construction lifespan due to the galvanized or PVC-coated wire;

• High-quality end result and a more aesthetic appearance.

together by tying them previous method. Bring the work location and tie according to the planned

5.

After placing the gabions in their positions, and before filling them, straighten the sides of the gabions using a simple straightening tool, using a wooden board to maintain their straightness.

6.

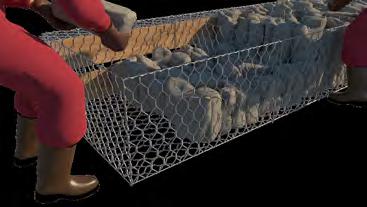

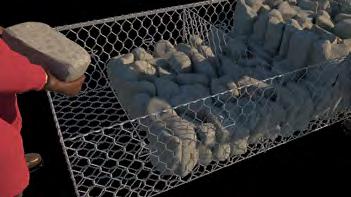

Fill the gabion with stones halfway. Install reinforcing wires and refill until it is full, leaving 3-5 cm above the height of the gabion box.

Remember: Do not fill the gabion directly to the top, fill it gradually per section.

Close the top part of the gabion according to its folds and tie it. Repeat the same process for the other gabions. 7.

H (M)

2.0 x 1.0 x 0.5

3.0 x 1.0 x 0.5

4.0 x 1.0 x 0.5

3.0 x 1.5 x 0.5

Specifications are subject to change when necessary. Special orders can be made according to requirements. Tolerance for box dimensions (width, height, length) is 5%.

Tailed Gabion

2.0 x 1.0 x 0.5

3.0 x 1.0 x 0.5

4.0 x 1.0 x 0.5

3.0

Quality Management ISO 9001:2015 with approval from the National Accreditation Committee (KAN) Quality Standard: SNI 03-0090-1999 and SNI 03-3046-1992 (LS Pro Ministry of Industry of the Republic of Indonesia) 6.0 x

SNI NO. 03-0090-1999

Minimum tensile strength 41 kgf/mm2

• • • Box dimensions (length, width, height) tolerance ± 5.0% For PVC-coated gabions, salt spray test for 500 hours.

Mesh size 80x100 mm or 100x120 mm with double twist Diaphragms every 1 meter in length

JARING

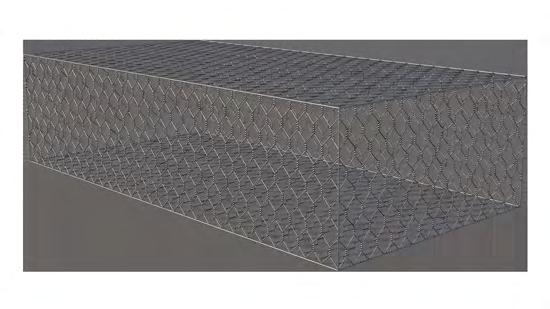

BEVA® Welded Gabion (Bronjong Jaring Kawat Baja Las /JKBL) is a square-shaped wire gabion made from parallel rows and intersecting wire columns as its column holes, fabricated using welding methods rather than weaving, resulting in high tensile strength. Its raw material wire consists of low carbon steel wire with a zinc + aluminum coating aimed to protect the core wire for better rust resistance.

BEVA® Welded Gabion (JKBL Gabion) is manufactured using European machine technology, ensuring the highest quality. This product has obtained SNI certification, and its production process is based on ISO Quality Management Standard 9001:2015. BEVA® Welded Gabion already has SNI certification and TKDN (Domestic Component Level) certificate with a sufficiently high value.

APPLICATIONS OF WELDED GABION STRUCTURES

Similar to BEVA Gabion® Hexagonal Weave, welded gabion structures can also be built quickly and economically in all conditions. They are highly suitable for architectural designs, especially as walls and boundary fences, or as retaining wall structures in infrastructure projects.

ADVANTAGES OF USING WELDED GABION STRUCTURES

• Easy and fast implementation, creating harmony with the surrounding environment;

• A low-cost alternative to concrete structures and stone masonry;

• More resistant to corrosion, as it is made from low-carbon steel wire with a 90% zinc and 10% aluminum coating;

• High tensile strength wire makes the gabion shape more rigid, sturdy, and precise;

• High-quality end result and a more aesthetic appearance.

Welded Box Gabions are designed based on the principle of gravity retaining walls. The strength of the wire mesh helps to withstand the forces generated by the unstable soil mass.

Class 2 Zinc-Aluminum Coated Steel Wire or Heavy Galvanized Steel Wire

Class 2 Zinc-Aluminum Coated Steel Wire or Heavy Galvanized Steel Wire Specifications are subject to change when necessary. Special orders can be made according to requirements

with 10% Al

with 10% Al

with 10% Al

50x50mm ± 3mm

75x75mm ± 3mm

100x100mm ± 3mm

50x50mm ± 4mm

75x75mm ± 4mm 100x100mm ± 4mm 50x50mm ± 5mm

± 5mm

± 5mm

50x50mm ± 3mm

75x75mm ± 3mm

100x100mm ± 3mm

50x50mm ± 4mm

75x75mm ± 4mm

100x100mm ± 4mm

50x50mm ± 5mm

75x75mm ± 5mm

100x100mm ± 5mm

•Box Dimensions (length, width, height) tolerance ± 3.0%

•Diaphragms every 1 meter in length

•Quality Management ISO 9001:2015 approved by the National Accreditation Committee (KAN)

•Quality Standards: SNI 03-3750-1995, SNI 03-0090-1999, SNI 9039:2021, and SNI 9168:2023 (Registered with the Ministry of Industry of the Republic of Indonesia)

•ISO 45001:2018 Occupational Health and Safety Management System

•ISO 14001:2015 Environmental Management System

• • Woven Wire

Selvedge Wire

Mesh

Tensile Strength

SNI

Galvanized

3mm

4mm

80mm x 100mm & 100mm x 120mm

Min. 41 kgf/mm2

03-0090-1999

Min. 275 gr/m2

2,7mm-3,8mm

3,4mm-4,6mm

80mm x 100mm & 100mm x 120mm

Min. 41 kgf/mm2

03-3046-1992

Min. 260 gr/m2

3mm

4mm

80mm x 100mm & 100mm x 120mm

Min. 41 kgf/mm2

9168 : 2023

Kelas 3 : 230 gr/m2

Supported by experienced technical support.

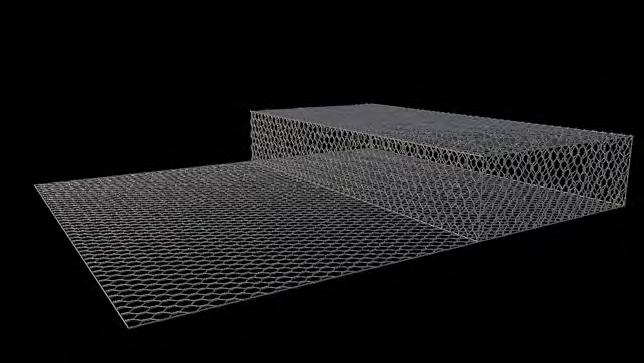

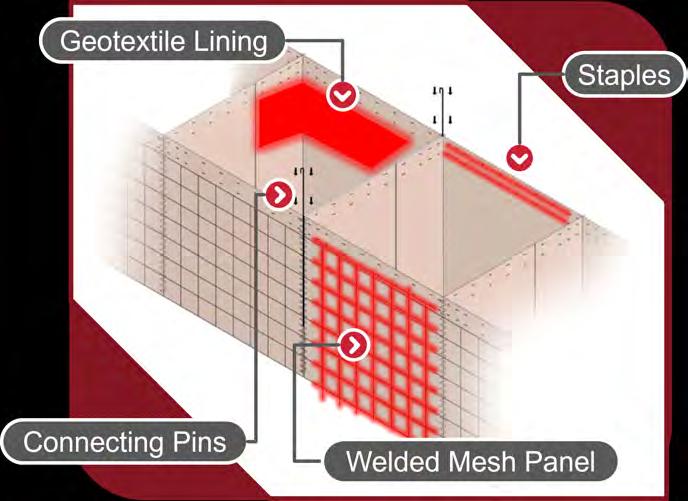

BEVA Welded Sand Gabion® consisting of a multilayered framework of Welded Wire Gabion (JKBL) with a zinc + aluminum coating aimed to protect the core wire from corrosion. The inner part of this sand gabion box is lined with anti-UV geotextile to provide excellent field durability.

BEVA® Welded Sand Gabion® serves as a flood-retaining embankment, with a strong and user-friendly system. This product greatly aids processes requiring faster completion or those of emergency response nature. BEVA gabions are more efficient and durable compared to other types of products and do not require special equipment for installation.

This product has a load resistance of 2700 kPa per box system or equivalent to a 135 m high embankment proper installation, flood retaining embankments based on BEVA® Welded Sand Gabion® can withstand for a long time, making it suitable as an alternative flood preparedness product. Sand as the filling material is readily available from the surrounding environment. This product is also listed on the LKPP E-catalogue portal.

Advantages of BEVA® Welded Sand Gabion®

•More resistant to rust thanks to the zinc + aluminum 10% coating

•Non-woven geotextile layer that is thicker (300 grams) and UV-resistant, with 2 types available: Polypropylene and Polyester Filament

•It has a load resistance of 2700 kPa per 1 box of the system or equivalent to a 135 meter high embankment

gr/m2 w/ 10% Al

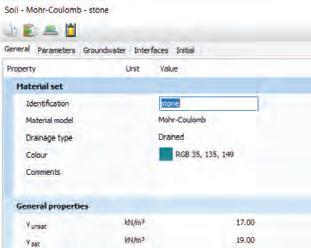

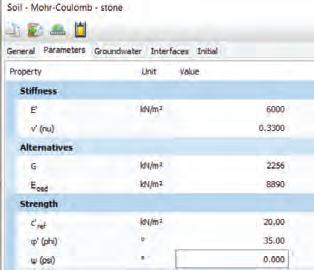

Optimum Vertical Load = 2700 kPa

500 kPa

Deformed mesh |u| (Scaled up 0.500 times) (Time 2.000 day)

Maximum value = 0.05628 m (at Node 431)

2000 kPa

Deformed mesh |u| (Scaled up 0.200 times) (Time 4.000 day)

Maximum value = 0.2250 m (at Node 92)

A load of 2700 kPa is equivalent to a load of 135m high embankment.

Based on numerical results, to achieve a maximum strain of 30% for 1 unit of Welded Wire Mesh Gabion (JKBL) ZINC+Alum, the optimum load obtained is 2700 kPa.

100 kPa

Deformed mesh |u| (Scaled up 5.00 times) (Time 1.000 day)

Maximum value = 0.01125 m (at Node 7703)

1000 kPa

Deformed mesh |u| (Scaled up 0.500 times) (Time 3.000 day)

Maximum value = 0.1125 m (at Node 464)

4000 kPa

Deformed mesh |u| (Scaled up 0.100 times) (Time 5.000 day)

Maximum value = 0.4500 m (at Node 7975)

Geosynthetics are synthetic products used to stabilize land.

Non-Woven Geosynthetics are made from various material options such as continuous filament (LS) polyester, where the resulting fibers are not interrupted in the manufacturing process, resulting in a stronger geosynthetic compared to typical PET non-woven. Polypropylene (PP) offers finer characteristics, greater strength, and thickness compared to other non-wovens, and it comes at a more competitive price compared to both PET non-woven and continuous filament. Meanwhile, polyester (PET) is the most affordable and best option in its class.

Non-Woven Polypropylene (PP)

Polymer Polypropylene

ASTM D 5261Gr/sqm

Colour

Tensile Strength

ASTM D 4595kN/m

White

Grab Strength

Tear Strength

Elongation at Break Puncture Resistance

ASTM D 4595%

ASTM D 4632N

ASTM D 4533N

ASTM D 4833N

Non-Woven Polyester (PET)

ASTM D 5261Gr/sqm

Colour

Tensile Strength

Elongation at Break

Grab Strength

Tear Strength

Puncture Resistance

ASTM D 4595kN/m

ASTM D 4595%

ASTM D 4632N

ASTM D 4533N

ASTM D 4833N

Polyester White

271,7290,4322,7322,7550,3579,8 830,9888,8

Woven geosynthetics are made from polypropylene fiber raw materials with the addition of UV-resistant materials, resulting in strong tensile strength and high stability. The way this product works is as a membrane effect (relying on tensile strength), thus reducing the occurrence of local settlement (differential settlement) due to soft/peaty subsoil.

Woven geosynthetics are recommended for use as a stabilizing material for soft or damaged subsoils. This type of geosynthetics has higher tensile strength compared to non-woven geosynthetics (approximately twice as much for the same gram weight or weight per m2).

Woven Polypropylene (PP)

ASTM D 4595kN/m

ASTM D 4595%

Geomat is a material made from high-density polyethylene (HDPE) with a three-dimensional structure used for erosion protection and slope protection. with BEVA Greenett® double-twisted hexagonal steel wire mesh sheets and can be planted with plants using hydroseeding or tamping methods, thus forming natural vegetation and strengthening the soil structure. This material supports long-term reinforcement and has erosion resistance that can withstand water scouring on the soil surface.

3.2 kN

1.8 kN

Other Specification

Other Specification

Geomembrane is one type of geosynthetic made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE) coated with anti-UV material, making it usable for years.

Geomembranes do not leach into water and do not contain harmful substances, thus maintaining the condition and quality of water. They also have waterproof properties (impermeable), capable of containing water or various other liquids, making them suitable for use in projects such as reservoir construction, ponds, landfill sites, and water management installations.

Properties

Polymer

Thickness (Avg.)

Thickness (min.)

Density (avg.)

Tensile

Strength at Break

Elongation at Break

Tear Resistance (Avg.)

Test Method

ASTM D 5199

ASTM D 5199

ASTM D 1505

ASTM D 6693

D 6693

D 1004

Roll

Area

Geogrid is made from high-quality polypropylene (PP) that is integrally formed and specifically designed to stabilize and enhance the strength of soft soil structures. The function of this type of geosynthetic is to lock the aggregates above the geogrid so that the aggregate layer becomes stiffer and easier to compact.

Geogrid is widely used in road construction to prevent cracking and shrinkage on roads/soil. Additionally, this material can also be used to reinforce soft or loose soil, increase the load-bearing capacity of foundations, and provide stabilization to prevent local settlement (differential settlement). Test

Polypropylene (PP)

at 2% Strain

at 5% Strain

Geobags are non-woven geosynthetics made from polyester (PET) or polypropylene (PP) that are sewn and filled with sand/soil to form a cushion that serves to protect against abrasion, stabilize slope edges and dams, and even reinforce riverbanks or reservoir walls. These geobags have excellent resistance to abrasion and chemicals, allowing them to withstand various soil and marine conditions, as well as UV rays, making them environmentally friendly.

(Material PP)

(Material PET)

Type

Thread Size

Sewing Thread