Presenting Team for BCIA Awards

Arklow WWTP – A global benchmark for water

Arklow WWTP – A global benchmark for water

Delivering a wastewater treatment plant that redefines civil infrastructure through collaborative design and community engagement with a sustainable approach.

• Permanently ends the discharge of raw sewage into the Avoca River and Irish Sea, delivering compliance with the EU Urban Waste Water Treatment Directive and Irish EPA standards and completed 6 months ahead of schedule.

• Overcame decades of opposition and planning delays through a community-led design process, combining best-in-class engagement with architectural leadership selected via public competition.

• Architecture reflects Arklow’s identity, drawing inspiration from the town’s coastal setting and industrial heritage - resulting in a civic landmark that locals are proud of.

• Transformed essential infrastructure into a celebrated public asset - recognised in national media and embraced by the community as a model of how civic infrastructure can serve people, place, and purpose.

• Serves 24,000 PE, expandable to 36,000 PE through modular upgrades.

• Supports Arklow’s growth, enabling the town to triple its population while restoring marine and river ecosystems—a national model for sustainable development.

• Unlocks housing potential in the area, helping address Ireland’s housing crisis

• Integrated major civil works: WWTP, Inlet Works, storm tank, sludge enclosure, odour unit, six secondary tanks, coastal rock revetment, long sea outfall (LSO), underpinning of the 19 Arches Bridge, and new quay wall—delivered with shared efficiencies from the Arklow Flood Relief and Arklow Main Drainage Schemes.

• Ayesa’s leadership across local schemes (Main Drainage, Water Supply, Flood Relief) embedded resilience, flood protection, and sustainability and enabled shared interfaces across public infrastructure

• Architect-led design resulted in a radical rethink of wastewater treatment plants structure and functionality

• Transformed a contaminated brownfield site into a sustainable civic landmark, with innovative design eliminating the need for land remediation.

• Restored safe bathing waters in the River Avoca and Irish Sea

• Boosted biodiversity by rewilding 30% of the site.

• Louvred façades provide natural odour dispersion and new habitats for birds and bats,

• Advanced treatment processes have replaced raw sewage discharges, enabling local wildlife to thrive

• Industry Acclaim: won 3 RIAI awards including the Royal Institute of the Architects of Ireland (RIAI) Downes Medal - the first ever for civic infrastructure.

• National & International Benchmark - 20+ major media features (The Guardian, Irish Times, RIBA Journal, ArchDaily etc., which pronounce this infrastructure as best in class for utility infrastructure).

Precision & Collaboration amongst 20 disciplines and 25 various suppliers as well as Uisce Eireann and local Wicklow County Council Representatives

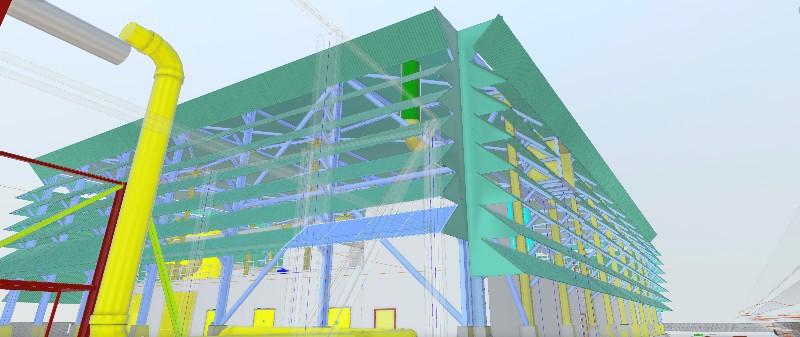

Design Precision

• Comprehensive digital surveys and assessments: flood risk, bathymetric, structural, rainfall, marine, ecological, and topographical mapping — integrated into a shared digital environment.

• Sewer route optimisation considered Arklow’s topography and river constraints; digital modelling led to decision for a tunnel pipeline linking North and South Quays beneath the River Avoca.

• Feasibility studies by Ayesa and Arup compared river vs. marine outfall options. Hydrodynamic and water quality modelling confirmed a marine outfall as the most sustainable and operationally efficient choice.

• Several route options analysed digitally, leading to a cost-efficient solution that reduced the overall outfall length.

• ICM Works coordination platform managed construction interfaces between marine, tunnelling, and civil scopes.

• Tunnel Boring Machine (TBM) modelling optimised shaft positions and reduced utility conflicts.

• Hydrodynamic simulations guided marine outfall design, accounting for tidal shifts, seabed movement, and proximity to existing marine infrastructure.

Digital Collaboration

• Workshops via Microsoft Teams connected architects, engineers, and contractors across Ireland, the UK, and the Netherlands.

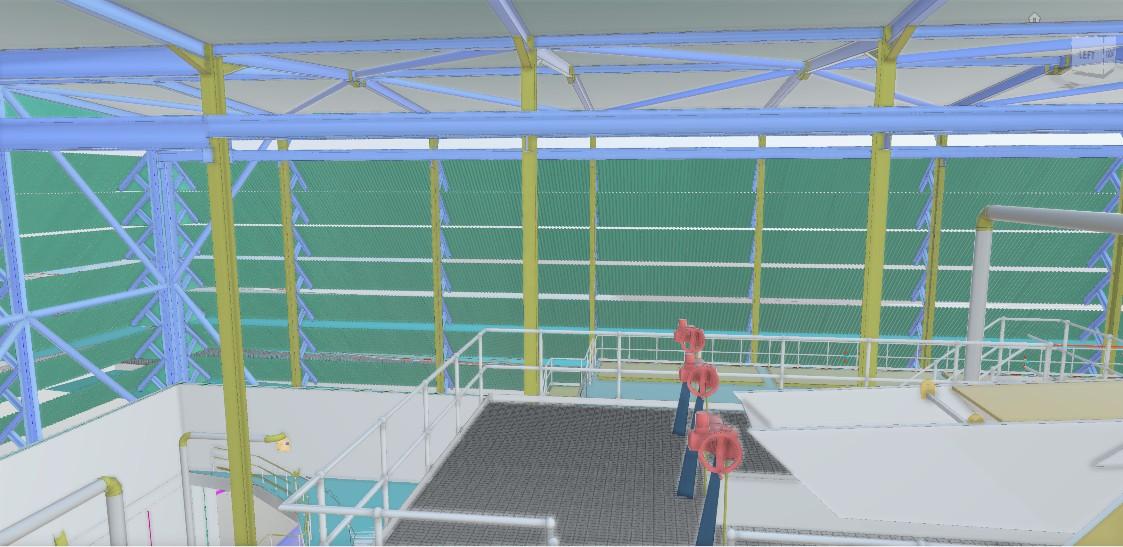

• 3D models and simulations enable adjustments and joint decision-making.

Innovative Design

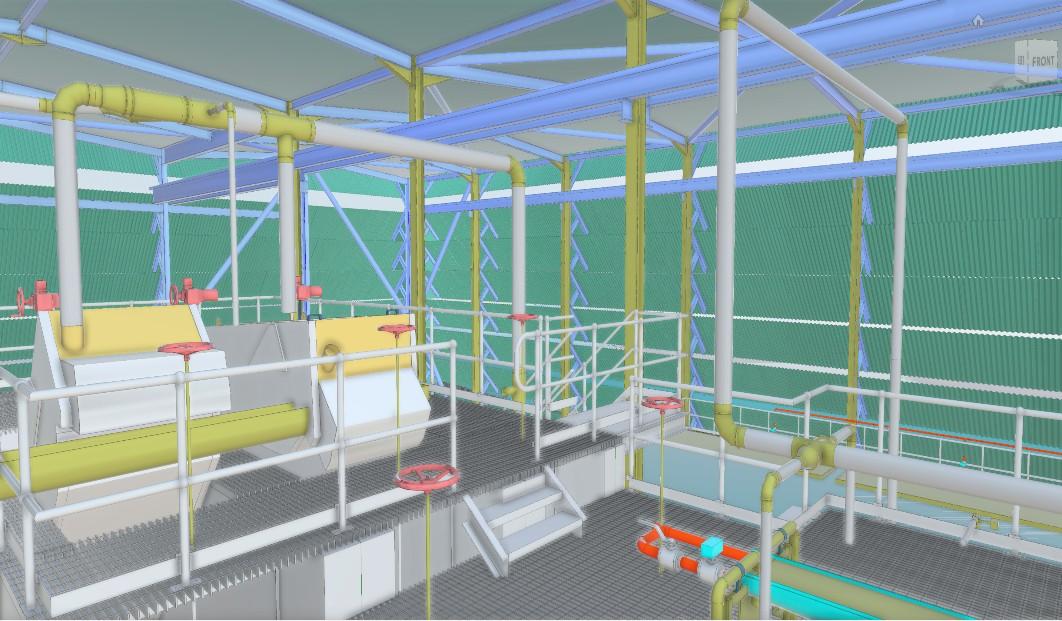

- Engineers, architects, contractors, and community co-created a compact vertical layout, reducing excavation, contaminated soil remediation, and embodied carbon.

- Stacked design replaced sprawling tanks, minimising land disturbance.

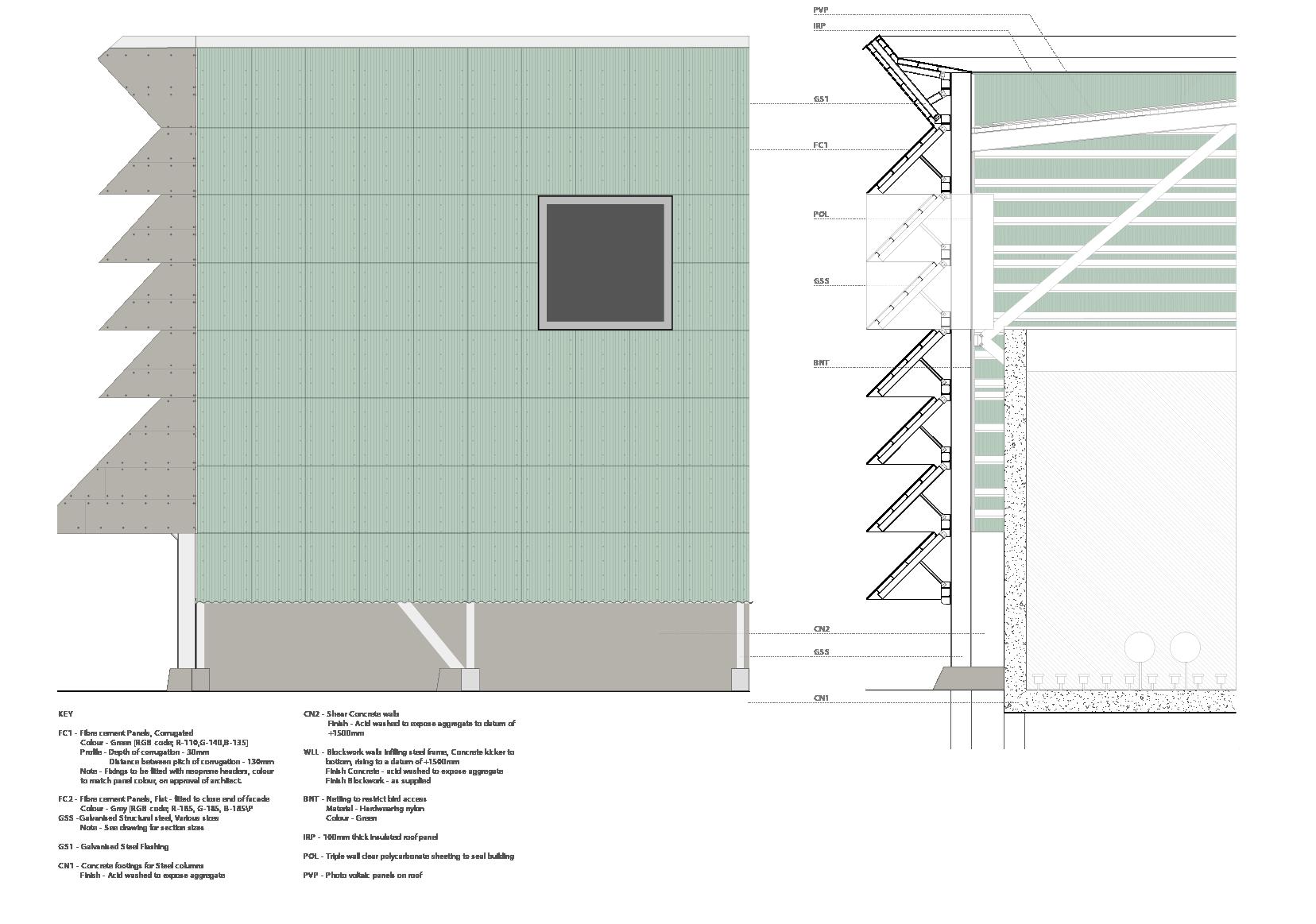

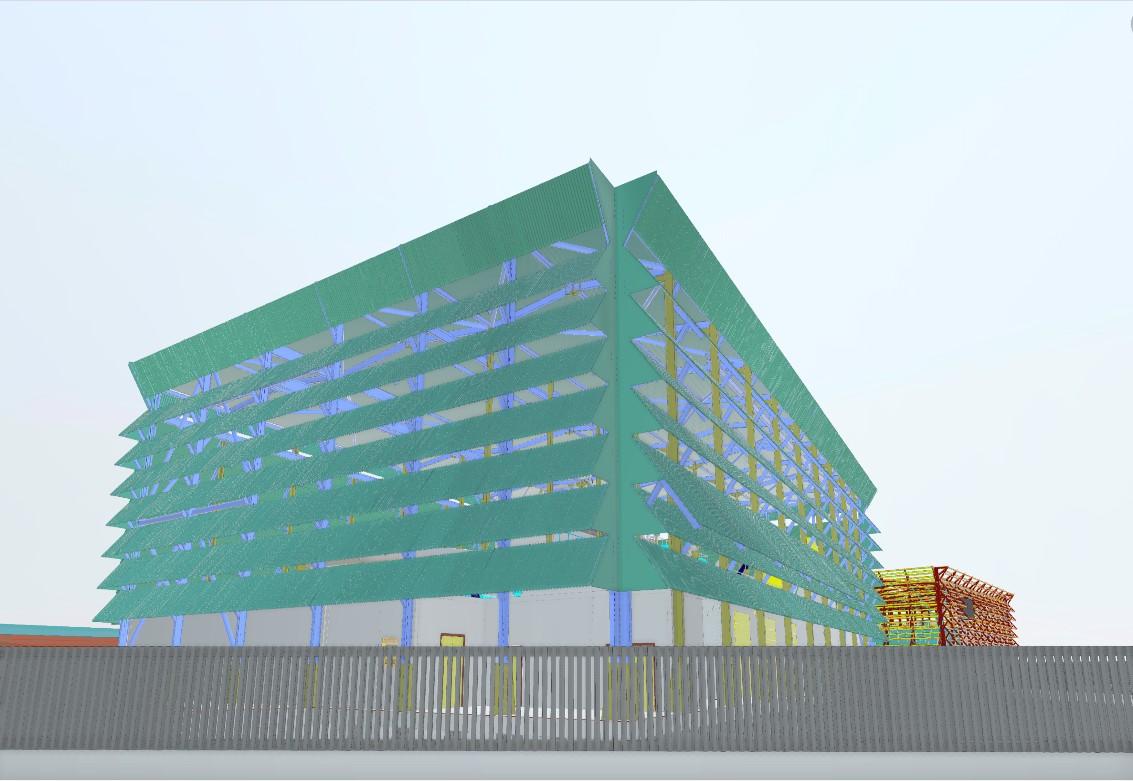

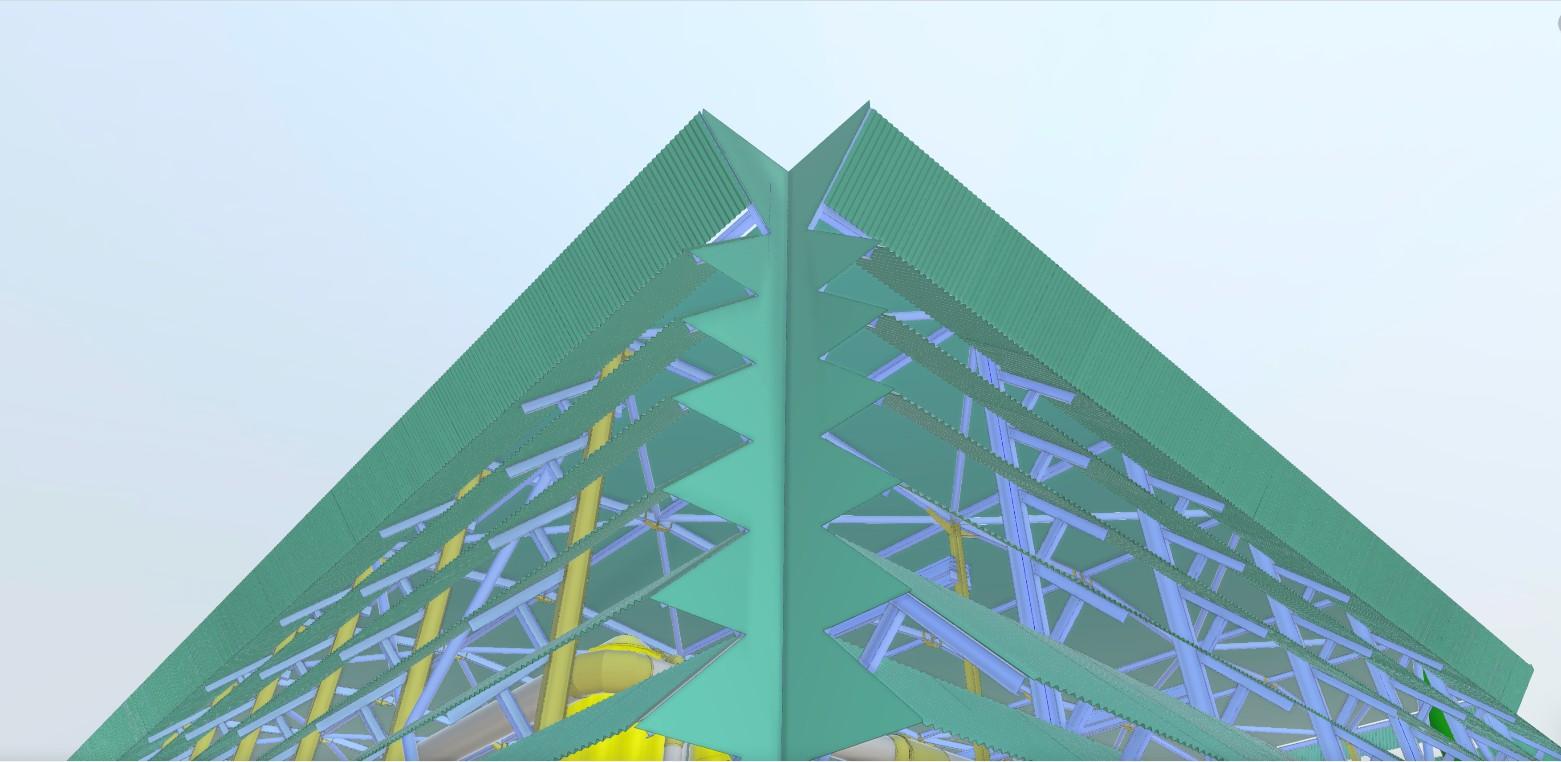

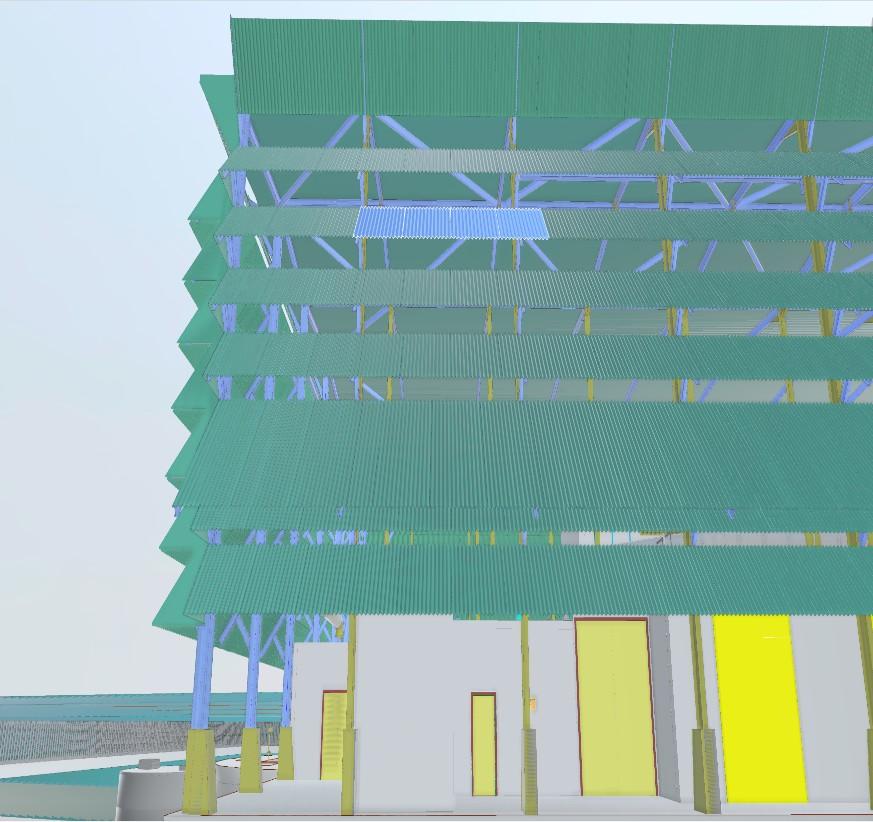

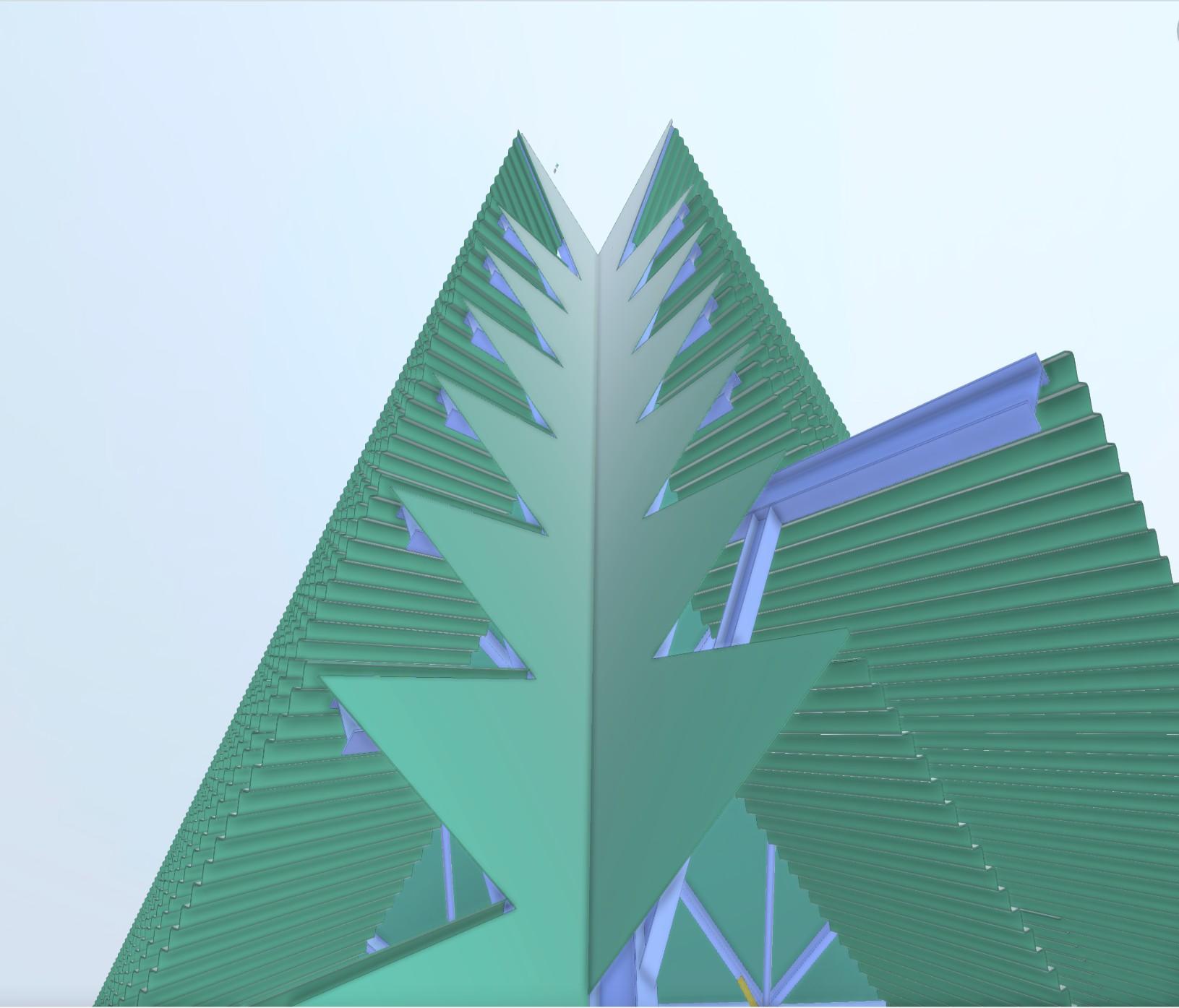

- Enclosed aerated systems with louvred façades enable natural ventilation, odour control, and bat/bird habitats.

Material Optimisation

- Durable, low-maintenance materials — reinforced concrete, steel portal frames, and fibre cement cladding (non-toxic, fully recyclable, long service life) — lower whole-life carbon impact while respecting cultural context.

Energy Performance

- Gravity-assisted single-lift system lowered pumping needs.

- Operational demand =1.4 M kWh/year, with roof PV generating 160,180 kWh/year (up to 40% offset).

Transport & Construction

- 900 m outfall pipe delivered by boat; 1,200 m interceptor installed via trenchless tunnelling; revetment stone transported by boat from nearby quarry, cutting transport emissions, reducing road impacts, and minimising disruption.

Biodiversity & Landscape

- Unique layout rewilds 30% of site to support native ecology and carbon capture.

- Coastal-inspired colour palette ensures visual harmony with Arklow Bay.

Arklow WWTP achieved a 30% carbon saving (7,650 tonnes CO₂e) through efficient design, material optimisation, and energy-efficient processes. This includes a reduction of 2,250 tonnes in embodied carbon, 4,200 tonnes in operational carbon, and a further 1,200 tonnes offset by the rooftop PV system: equivalent to powering 480 homes annually and meeting up to 40% of the plant’s energy demand.

Figures represent estimated embodied and operational carbon over a 30-year lifespan. See appendix for assumptions and methodology.

The architectural form is designed to fully contain the wastewater treatment process within a structure that is energy efficient and reduces carbon footprint while enhancing wildlife and biodiversity

• Durable, low-maintenance materials that are both environmentally responsive and sensitive to the maritime context.

• The primary structure consists of reinforced concrete, forming the base and tank walls, while steel portal frames rise to support the superstructure.

• Main process buildings are clad in fibre cement panels - a non-toxic, fully recyclable material with a long service life and a reduced whole-life carbon impact.

• Sustainability is embedded throughout: a compact and efficient layout limits the footprint, avoids disturbing contaminated ground, and uses gravity-assisted flows to reduce energy demand.

• Rooftop solar PV panels further offset operational energy. Together, these strategies deliver a resilient, lowenergy, and low-maintenance future.

Construction Detail

Designed for a Changing Climate

• Resilience was embedded from the outset, hence the elevated plant layout, reinforced quay walls, and flood-resistant architecture, each responding to risks from sea level rise, storm surges, and coastal erosion.

• Facility design uses low-maintenance materials with long-term durability.

Designed for Energy Efficiency

• The plant adopts a compact, low-energy approach to wastewater infrastructure.

• All treatment processes are placed above ground, avoiding disturbance of legacy pollutants and eliminating the need for soil removal.

• Processes are vertically stacked to reduce land use and optimise flow.

• Unlike conventional plants requiring multiple energy-intensive pumps, this system uses a single pump, with gravity assisting the remainder—significantly lowering energy demand.

• A gantry crane runs along the roof to service the stacked infrastructure, which also hosts a rooftop PV solar farm to offset energy use.

Designed to include Flood Defence Integration

• Shared design and delivery efficiencies with the Arklow Flood Relief Scheme and Arklow Main Drainage.

• Quay walls and underpinning of the 19 Arches Bridge reinforced for long-term resilience and flooding events.

• Rock revetment upgrade around the coastal location of the plant strengthens coastal integrity.

Hydrology & Stormwater Management

• Stormwater storage and overflow facility developed at The Alps site to manage heavy rainfall.

• Alps facility integrated via advanced hydraulic modelling to protect homes and infrastructure.

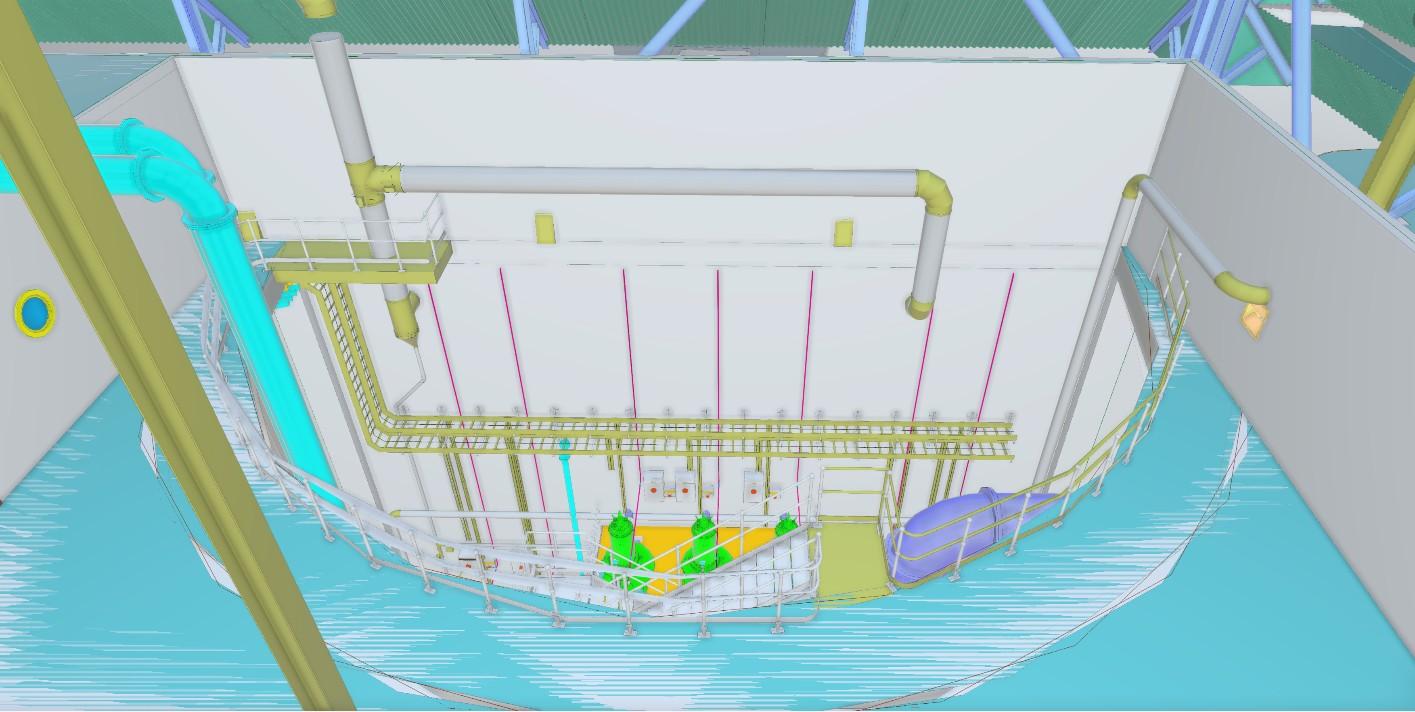

• Landlocked Ferrybank site posed major hydrological and access challenges—overcome through sewer alignment studies and tunnelling under the River Avoca.

Marine Engineering Resilience

• A 900m HDPE marine outfall pipe with six diffusers safely discharges treated water into the Irish Sea.

• Marine outfall design accounts for sediment movement, wave dynamics, and marine biodiversity.

• Installation avoided conflict with existing GE subsea electricity cable and protected sensitive habitats.

Future-Proofed Design for Climate, Coast and Community

• The town had to remain fully operational during construction, requiring precise coordination of access, traffic, and sequencing - especially on the constrained, landlocked Ferrybank site and heritage structures like the 19 Arches Bridge.

• Stakeholders all had to be kept on board including Uisce Éireann, Wicklow County Council, Ayesa, Nicholas O’Dwyer, Clancy Moore Architects, Arup, Ward & Burke, Tobin Engineers, Van Oord, and others.

• The architects acted as mediators between 20+ engineering and environmental disciplines - and the local community - holding multiple meetings with both the project team and residents to keep everyone aligned.

• This collaborative approach delivered a compact, stacked gravity-fed system that reduced land take, energy use, and visual impact, while creating opportunities such as a roof for solar PV panels and gantry crane access.

• Architecture was capped to just 3% of total cost, ensuring it survived “value engineering”. With no drawings in the tender, the design was safeguarded through legally binding text - an innovative move that protected quality through delivery.

• Rather than resisting technical demands, the design team embraced them as creative inputs. Odour control, fluid dynamics, and structural challenges became part of the design conversation - not obstacles. Public consultation helped shape the plant’s location, form, and identity.

• Over 25 specialist subcontractors and suppliers - many sourced locally or regionally - worked across marine, tunnelling, civil, and ecological scopes, supporting the local economy and cutting transport emissions.

• Marine works, including tunnelling through the river and installing the long sea outfall, required real-time coordination between divers, utilities, engineers, and ecologists.

• A shared digital environment enabled seamless communication, while flexible procurement within a DesignBuild-Operate (DBO) model fostered long-term quality and accountability.

• Diversion routes, road upgrades, and coordinated deliveries minimised disruption.

• Designed to keep residents, businesses, and commuters moving.

• Real-time monitoring via a detailed NVMP.

• Quieter equipment, barriers, and restricted hours (7am–7pm weekdays).

• Protected environmental and community wellbeing.

• 24/7 Dedicated Liaison Officer provided regular updates and resolved concerns.

• Centralised online platform/app ensured transparent communication and stakeholder trust.

• Prioritised local recruitment.

• Female engineers from Ayesa-led project management — promoting visibility and representation in civil engineering.

• Outstanding safety record maintained.

• Initiatives included CIF training, wellbeing programmes, and Uisce Éireann’s “Time to Talk” mental health campaign.

• Breakout sessions helped normalise mental health conversations on site.

• The project actively supported Uisce Éireann’s STEM outreach by providing site tours and placements for students and young engineers, with local councillors helping to facilitate visits and embed the plant within the educational life of the community. Designed with learning in mind, the facility includes viewing windows and sightlines to nearby windfarms, offering a real-world educational experience. Digital & Media campaigns include Youtube Shorts on construction milestones by Irish water including Ireland AM on Virgin Media One, highlighting how the plant operates efficiently, sustainably, and without odour.

“This project challenges the notion that utility infrastructure must be hidden, it shows that openness and transparency builds trust.”

1. 2. 3. 4. 5. 6.

Real Multidisciplinary integration between architects, engineers, contractors, suppliers, and the community delivered not just technical success but civic value, design integrity, and operational efficiency. Integrated Planning Yields Shared Resilience; Synergies with the Arklow Flood Relief Scheme and Main Drainage Scheme meant smarter investment and shared climate resilience.

Design Constraints Can Drive Innovation: Tight site, legacy pollution, marine interface, and heritage context forced the team to think differently resulting in a stacked, compact, low-energy design that’s now a potential model for future infrastructure.

Low-Carbon Thinking Must Start at Concept Stage: Embodied and operational carbon were reduced through smarter layout, material efficiency, a single-lift system, and embedded solar into the plant.

Protecting Design Through Legal Mechanisms Works: With no detailed drawings at tender stage, embedding design intent contractually safeguarded architectural quality, something that is replicable in public infrastructure.

Industrial Infrastructure Can Be Civic: Industrial buildings can enhance the townscape, support biodiversity, and even host school visits — when architecture is seen as integral, not optional.

Thoughtful design leads to biodiversity: 30% of the site footprint was freed for rewilding due to the compact layout. Louvred façades provide habitats for bats and birds, integrating ecology into the architecture. Colour and form were designed to harmonise with the coastal setting, not dominate it.

Best practices to create a global benchmark

“We feel it’s a worthy winner, but don’t just take our word for it!”

Gently radical in so many ways, this thoughtful work of architecture in support of engineering is set fair to become an essential reference for wastewater treatment plants everywhere.”

RIBA Journal, May 2025

“This facility has provided the community with an architecturally significant building that is garnering attention at home and abroad. It is protecting the river from raw sewage pollution, transforming it into an amenity for the community while also ensuring new homes can be built and new businesses can be set up allowing the town to prosper.”

James Browne, Minister for Housing, Local Government and Heritage, Ireland

“This project demonstrates our ability, in partnership with industry leaders such as Ward and Burke Construction, to deliver world-class infrastructure on time and within budget. It shows that Uisce Éireann can deliver solutions that support communities and align with the Government’s housing targets. Uisce Éireann shares Government ambitions for new housing and is committed to doing its part through investment in strategic infrastructure developments.”

Uisce Éireann CEO, Niall Gleeson

‘Something to be proud of’: how an Irish town got a sewage makeover – and stopped discharging its waste into the sea. Arklow’s sleek new wastewater treatment plant is a collaborative triumph between engineers, contractors and architects Clancy Moore. And it’s amazingly unsmelly…

The Guardian, April 2025

Clancy Moore Architects’ wastewater treatment plant at Arklow, County Wicklow, transforms a vital piece of infrastructure into a civic landmark – balancing pragmatism with poetic expression on a prominent coastal site. Architecture Today

“The Government recognises the vital role of strategic infrastructure investment in meeting the country’s demand for housing while also protecting and enhancing the environment. That’s why we are committed to working with Uisce Éireann to bring forward essential projects like this plant in Arklow, which is currently capable of supporting a population of 24,000 but holds the potential to expand to 36,000.”

An Taoiseach, Irish Prime Minister Micheál Martin

1.International Project of the Year 2025 – BCIA NCE (British Construction & Infrastructure Awards)

2.Project of the Year 2025 – Irish Construction Industry Awards

3.Downes Medal 2025 – Engineers Ireland, for Outstanding Engineering Achievement

4.ENR Global Best Projects Award of Merit (Wastewater Category) 2025 – Engineering NewsRecord (ENR)

5.President’s Award for Excellence 2025 – Irish Planning Institute, for Best Practice in Planning and Sustainability

6.Infrastructure Winner 2025 - Irish Planning Institute

7.Public Choice Award (2nd Place) 2025 – Royal Institute of the Architects of Ireland (RIAI)

8.Sustainability Award 2025 – Royal Institute of the Architects of Ireland (RIAI)

9.Public Building of the Year 2025 – Royal Institute of the Architects of Ireland (RIAI)

10.Subsea Pipeline Project of the Year 2023 – Pipeline Industry Guild (UK), for the Marine Outfall (awarded by Van Oord)

11.Engineering Excellence Awards 2025 – Civil Engineering Project of the Year

12.Engineering Excellence Awards 2025 – Engineering Project of the Year

Appendix I – Photo Gallery

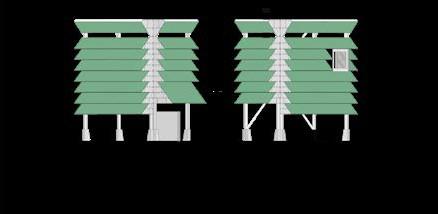

Drawings 3: Arklow Axonometric Detail Section

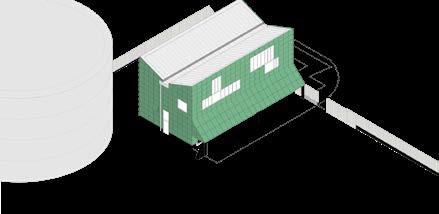

Drawings 6 : Axonometric Administration

Building

stacked design using gravity flow bringing energy savings and no need for land remediation

Complex Multidiscipline civil engineering in a sensitive coastal environment and a live, busy town centre that continued to be operational during construction

• Full site clearance of former industrial lands at Ferrybank to enable construction.

• Construction of New wastewater treatment plant for 24,000 PE (expandable to 36,000 PE through modular upgrades), with process, inlet, sludge and administration buildings.

• Specialist tunnelling under the River Avoca using TBM to lay 1.3 km of interceptor sewer on North & South Quays

• Marine engineering: 900m long sea outfall pipe imported from Norway and laid on seabed using specialist vessels in challenging marine environment.

• Rock revetment upgrade to protect coastal integrity.

• Underpinning of the 19 Arches Bridge and quay wall reinforcement during sewer installation.

• Architecturally sympathetic design integrated into Arklow’s coastal landscape embedded in the town’s history.

• Stormwater storage and overflow management site developed at The Alps.

• Landscaping and environmental mitigation works completed across the project.

Assumptions & Methodology for Embodied & Operational Carbon Comparison

Scope: Th4 comparison includes estimated embodied carbon (from key construction materials) and operational carbon over a 30-year design life. It also accounts for on-site renewable energy generation through rooftop PV.

Arklow WWTP – Project-Based Inputs

Operational energy use: 1,400,000 kWh/year (as provided)

PV energy offset: 160,180 kWh/year

Key material quantities:

• Concrete: 19,280 m³

• Reinforcement steel: 2,300 tonnes

• Structural steel: 760 tonnes

Conventional WWTP Baseline Assumptions

•Embodied carbon:

• 25% more concrete and steel due to flat horizontal layout, greater land take, and excavation.

•Operational carbon:

Carbon Factors Used

• Higher energy use (13,500,000 kWh over 30 years) due to multiple pumping stages and no gravityfed system.

•No renewable energy generation or offset.

Exclusions & Notes

•Estimates are high-level and based on available project data.

•Additional sources of embodied carbon (e.g. cladding, MEP systems, transport, etc.) are not included due to limited data.

•All values rounded to nearest 10 tonnes for clarity.

•Intended for comparative purposes only — not a full Life Cycle Assessment (LCA).