SUSTAINABLE INNOVATION

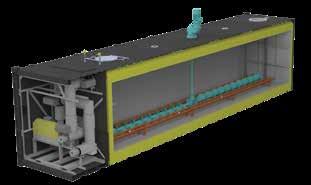

NEW IntelliPac ™ Moisture System

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

BUILT TO CONNECT

TO SEE VIDEO

NAVIGATE TO CLEANER AIR WITH THE

The reverse air baghouse engineered to lead your plant to peak performance.

The Dust Pilot reverse air baghouse is built for high-capacity operations with precision airflow control and fewer moving parts, minimizing maintenance. Its robust, customizable design ensures cleaner air, enhanced plant performance, and compliance with environmental standards. Available in multiple sizes, the Dust Pilot delivers reliable and effective dust control tailored to your plant's needs.

2026 GENCOR TRAINING SCHOOL

2026 DATES

• Week 1: January 12 - 15

• Week 2: January 19 - 22

• Week 3: January 26 - 29

• Week 4: February 2 - 5

DETAILS

Details can be found at www. gencor.com/training or call us at 407-290-6000 ext. 342.

REGISTRATION

CLASS SIZE IS LIMITED!

To secure your seat, please register before December 15, 2025

Improving overall plant production and efficiency are all common concerns for plant owners and operators. Having a well-trained technical crew is vital to maintaining plant performance and efficiency

Gencor and its training staff represent the biggest concentration of knowledge and expertise in all the sciences and technologies involved in the production of asphalt plants. Customers who attend these seminars benefit by having the support and focused attention of the best specialists in the asphalt industry

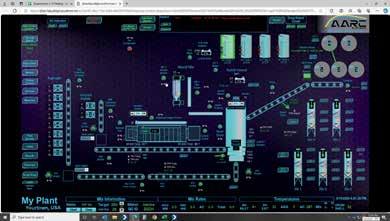

Using Gencor’s state-of-the-art control simulators and actual equipment, our experts take you step-by-step through a comprehensive & intensive concentrated hands-on training program providing the latest techniques on optimizing production efficiency.

We’ve built our business and reputation through our unparalleled focus on equipment design, durability, and attention to detail. We apply these foundations to our complete range of asphalt plants and asphalt plant equipment. Let us customize to your request - big or small.

Should Asphalt Pay for the Competition’s Growth?

IIn this issue of AsphaltPro Magazine, we present topics and projects that are of interest to the asphalt industry. From hotmix asphalt (HMA) to warm-mix asphalt (WMA) to preservation of pavements to use of green materials in asphalt pavement designs, we explore ways you can improve your bottom line as an asphalt supplier, producer, contractor or related business.

It irks me, as the editor of this magazine, to see legislation presented as beneficial to the asphalt industry when a brief investigation reveals it to be a boon to competing materials for improving their products while potentially lobbing more regulations at asphalt binders and mix designs. I’m talking about Senate Bill S. 1067 and what I see as undermining the road-building funding conversation.

Don’t get me wrong. I fully believe the concrete industry should continue its foray into becoming environmentally friendly. Cutting down emissions from the material used in about 30-50% of all vertical construction (wood framing remains dominant in residential building, according to National Association of Home Builders) can only be good for the planet. It is my opinion that seeking out funding for research is wise on their part, but I hesitate to encourage it coming at our industry’s expense.

The asphalt industry has been paying its way since the Macadam days with research fundraising, industry donations, the kindness of original equipment manufacturer (OEM) funding, and, yes, government grants, and the like. I don’t think we should be expected to accept additional regulations while the concrete industry steps up in 2025 to get funding from taxpayers for emissions reduction. I don’t think departments of transportation (DOTs) should be bribed to use one type of material over another, but should, instead, choose the material that’s going to work best for the conditions, traffic and taxpayers of the area in question.

I’ve oversimplified what I see happening with the Concrete and Asphalt Innovation Act (CAIA), which is a clean-energy bill disguised as a research and development program. It was introduced in March when most of us were prepping for World of Asphalt travel. As of press time, the bill had been referred to the Committee on Energy and Natural Resources, according to congress.gov. In four and a half months, nothing had happened with this bill. So is this a nothingburger we can ignore?

Or is it indicative of the entitlement mentality in society? The asphalt industry is organized and thoughtful in being good stew-

ards of the air, land and water, so others wish to learn from us. That’s wonderful and we should be willing to share knowledge in a collaborative spirit. But should we be excited to devote taxpayer dollars and divert the funding conversation into turning our competition green?

Personally, I would like to shelve the environmental regulations of the funding conversation. Instead, let the concrete industry query its membership for donations to research and development of the tools and technologies necessary to cut emissions. “Concrete” has already worked with the Federal Highways Administration’s Every Day Counts program (see the EPIC2 research as one example), sought out partnerships with university research departments, prepared demo projects with DOTs, and so on.

This is the way “asphalt” did it, too. And I would say we’ve been highly successful.

Since 2001, the Asphalt Pavement Alliance has recognized more than 170 pavements that are over 35 years old with a Perpetual Pavement Award (PPA). The award program was so popular, it had to be augmented with categories. We now recognize these structures as perpetual pavement by performance, by design and by conversion. Asphalt pavements are proven long-lasting and our industry-initiated research and development has been improving their performance for decades.

Let me ask you: Do we need an act of Congress to share monies with the competition to encourage more research on our part? Do we need our funding to depend on a law demanding multi-departmental oversight that’s supported by the likes of CarbonCure, Center for Climate and Energy Solutions (C2ES), Clean Air Task Force, World Resources Institute and others? Because those entities are among the supporters of the CAIA listed at ClearpathAction.org.

It is my opinion that I would rather spend my energy convincing my representatives to fund a roads and bridges bill that helps us build economy-supporting infrastructure and maintain everything that’s in place, rather than hindering progress of the same. I would rather my tax dollars go to fixing highways and byways and connector streets than to research for greening up the competition.

602 W. Morrison, Box 6a Fayette, MO 65248 (660) 728-5007 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

EDITOR

Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR

Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year. Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

Stay Safe, Sandy Lender

2 0 2 6

PAVER OPERATION AND MAINTENANCE TRAINING BLAW-KNOX UNIVERSITY

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

The Blaw-Knox University, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and handson application courses.

Blaw-Knox provides improved technical and problem-solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

DETAILS

• January 12 - January 15

• January 19 - January 22

• January 26 - January 29

• February 2 - February 5 2026 DATES

REGISTRATION

All details can be found at www.blawknox.com/training or contact at (407) 290-6000 ext. 342 or training@blawknox.com

Enhance Work Zone Safety Response

BY KEN HALEY

Smart device communication has reshaped industries across the globe, and road safety is no exception. The rapid detection and timely response to roadside collisions can mean the difference between a quick repair and a tragic secondary crash. Roadside safety devices like crash cushions, guardrails and signs are essential tools for minimizing harm, but their effectiveness depends on knowing when they have been compromised and acting quickly.

This is precisely where advanced impact detection and alert systems are transforming the landscape of roadside safety. In particular, these technologies are revolutionizing safety in highway work zones, where workers are exposed to live traffic and the risk of secondary crashes is highest.

Work zones are dynamic, high-risk environments that demand rapid, informed responses to keep both workers and motorists safe. Immediate notifications to maintenance crews not only save lives but also ensure that damaged safety equipment is replaced or repaired before it puts other motorists or workers at risk. In a time when many transportation departments are juggling limited resources and high traffic volumes, having quick access to the right information in work zones is a game-changer for keeping crews safe and infrastructure in working order. Consistent data flow supports faster decision-making, predictive maintenance, and ultimately, safer roads for both drivers and workers.

CONNECTED WORK ZONES = REAL-TIME SAFETY MANAGEMENT

Modern roadside safety systems address critical safety concerns that frequently arise in temporary and permanent roadway environments. Traditional methods of monitoring roadside safety devices have relied on manual checks and rudimentary alerting systems, posing risks due to delayed responses and inaccuracies in information.

In work zones, where conditions change rapidly and equipment is frequently repositioned, these risks are magnified. Today’s advanced alerting systems provide real-time notifications in case of impacts, allowing road crews and emergency medical services (EMS) to respond swiftly. Rapid response significantly reduces the risks of secondary accidents, where vehicles collide with already impacted devices, thereby protecting additional motorists and roadside workers.

Additionally, these systems can provide information around crash location, helping response teams prepare with the accident site’s specific needs in mind. From traffic control measures, repair parts, and personnel needs, this information enables response teams to be more proactive, rather than reactive once they arrive at the scene. The result is not only a measurable increase in efficiency, but also a meaningful reduction in risk and lives saved.

OVERCOMING CHALLENGES IN ROADSIDE ASSET TRACKING

A major challenge for transportation agencies, particularly departments of transportation (DOTs), is accurately tracking and maintaining the numerous safety devices deployed across roadways. Temporary

Roadside safety devices like crash cushions, guardrails, and signs are essential tools for minimizing harm.

work zones present an even greater logistical complexity due to their dynamic nature, frequent repositioning of safety devices and the number of assets involved.

Advanced tracking tools directly address these challenges by providing precise GPS locations, product identification and impact history data for each safety asset. Federal regulations require DOTs to maintain detailed Roadway Asset Databases, focusing on critical safety features like crash cushions and guardrail end treatments. These databases are essential not only for day-to-day maintenance but also for staying compliant when national safety standards change. When crash testing criteria are updated, agencies must know exactly where outdated devices are located, to prioritize replacements. Real-time data makes that process both faster and more accurate. Additionally, with better tracking capabilities, asset management becomes seamless, fostering compliance with federal

BIGGER PLANTS GREATER SUPPORT

SAFETY SPOTLIGHT

the

standards and greatly improving the efficacy of asset maintenance and replacement cycles.

Perhaps the most powerful feature of modern roadside safety systems is their ability to detect impacts instantly. This capability drastically reduces emergency response times, ensuring that damaged safety equipment is repaired swiftly, which helps maintain consistent and optimal protection for motorists. In work zones, this also means less time that workers are exposed to hazardous conditions while waiting for repairs or replacement of safety devices.

A striking example of the life-saving potential of immediate alert systems comes from a recent case involving the California Department of Transportation (Caltrans). Upon receiving an impact alert, Caltrans crews were able to reach a severe crash scene within minutes, rescuing a family trapped inside a burning vehicle. This rapid intervention underscores the critical value of real-time crash notification systems in roadside safety management.

ASSET MANAGEMENT AND RESOURCE ALLOCATION

The availability of real-time data empowers departments to make informed decisions regarding maintenance and infrastructure upgrades. For work zone crews, this means being able to proactively manage maintenance schedules, anticipate necessary traffic control measures during repairs and reduce their exposure to hazardous working conditions. These proactive insights significantly enhance operational efficiency and safety for maintenance teams.

By having immediate access to comprehensive asset data, transportation agencies can effectively prioritize repairs, replacements and infrastructure upgrades. This data-driven approach facilitates better resource allocation, reduces inspection times and lowers the overall cost of roadway maintenance.

Investing in smart road safety technology presents clear long-term economic advantages. These systems reduce the frequency of manual inspections, streamline repair processes and decrease downtime for safety equipment. By optimizing asset utilization and reducing maintenance costs, transportation departments can reallocate financial resources to other critical infrastructure improvements.

Additionally, data collected from these systems enables more precise safety analyses, supporting evidence-based decisions for road in-

frastructure upgrades. When regulatory changes require hardware updates, transportation agencies can easily identify and prioritize outdated equipment, ensuring continuous compliance with evolving safety standards.

Another long-term benefit lies in the ability to minimize redundant site inspections. If systems can confirm a crash cushion has not been impacted, for instance, a crew can skip that location, conserving labor and vehicle hours. This efficiency compounds over time, generating substantial budgetary and environmental benefits.

ROAD SAFETY REVOLUTION

The real-world impact of real-time alert systems on road safety is already here. From letting crews know exactly where a crash happened and what they will need to fix it, to helping agencies stay ahead of changing safety standards, these systems are turning static safety gear into intelligent tools. It is less about flashy tech and more about better decision-making, faster responses and safer outcomes.

Companies like TrafFix Devices are leading the way. TrafFix Devices demonstrates the benefits of data connectivity in road safety with its Sentinel Impact Tracker. Engineered for use on various roadside safety devices, such as crash cushions, signs and guardrails, the Sentinel is designed to deliver immediate notifications upon impact. It provides critical data including asset GPS location, product specifications, images of road conditions and detailed repair histories.

The Sentinel can be mounted on both temporary and permanent installations, offering flexibility for departments managing diverse types of infrastructure. Its adaptability ensures that safety insights are not limited to fixed locations but can also extend to mobile or seasonal work zones where risks are often higher.

Designed to withstand rigorous environmental conditions and adhere to international highway safety standards, the Sentinel Impact Tracker exemplifies the transformative potential of real-time, actionable data in the road safety space. By enhancing response times, reducing secondary crashes and optimizing asset management, the Sentinel positions TrafFix Devices at the forefront of innovation, ensuring safer roads and protecting lives across the globe.

The evolution of roadside safety is being defined by the ability to detect, analyze and respond to incidents in real time. As transportation networks grow more complex and the demands on agencies intensify, immediate impact detection and connected asset management are no longer optional; they are essential to protecting lives and infrastructure.

In the context of work zones, these tools are critical for reducing worker exposure to hazards, improving crew response times and ensuring that every worker returns home safely. Tools like the Sentinel Impact Tracker from TrafFix Devices transform static safety equipment into dynamic, data-driven assets, empowering agencies to act faster, allocate resources more efficiently and maintain compliance with ever-changing standards. As live-time data tracking continues to evolve, its influence is both practical and profound, giving transportation agencies better visibility, letting field crews work smarter and safer, and ensuring no crash goes unnoticed. In a world where every second counts, the future of road safety belongs to those who leverage real-time intelligence for better efficiency and safer outcomes for all.

Ken Haley is the director of business development for TrafFix Devices

With

help of the TrafFix Devices’ Sentinel Impact Tracker, Caltrans crews were able to reach a severe crash scene within minutes, rescuing a family trapped inside a burning vehicle.

Hard-won know-how for the next generation

Beyond the Spec Book: Bill Stanley’s Standards for Blue-Collar Quality Control

In this no-nonsense guide, the owner of American Pavement Specialists lays out the habits and standards his crew follows to deliver blue-collar quality you can see, not just measure.

BY BILL STANLEY

When people talk about asphalt quality, they usually mean numbers. They’re talking density, profile, smoothness. And that stuff matters. We hit those numbers every day. But there’s another kind of quality that’s just as important. I call it blue-collar quality. It’s what the crew sees. It’s what the customer remembers. It’s the broom lines, the edges, the finish. It’s whether you showed up ready, laid it down right and left the job looking like it should.

At American Pavement, we don’t just hit the numbers. We make sure the whole job reflects the pride we put into it. If you want to build that kind of quality, here’s where it starts.

1. QUALITY STARTS AT CLOCK-IN

Quality control doesn’t start with a test or a spec sheet. It starts the minute your boots hit the ground.

At American Pavement, most of the crew clocks in at 6:15. But I’ve got guys who roll in at 5:45 to start loading trucks, checking tools and making sure we’re not chasing down missing gear when we should be paving. Every shovel, broom, rake and tape measure has a place—and it better be there.

If you show up to the job and realize you forgot something simple, like a transit or the chalk box, you’ve now delayed your start, pulled someone off task to go get it, or worse, you’re stuck without it. And when you don’t have the right tool for the job, quality takes the hit. If you want to lay down a quality mat, it starts with showing up ready with tools in hand, mind on the mission. That’s how you set the tone for the day. That’s how you build quality from the ground up.

2. RUN YOUR RACE, YOUR WAY

At American Pavement, we have a certain way we do things and everybody on the crew knows it. Whether it’s how we prep equipment in the morning or how we leave a site at the end of the day, there’s a standard. And when everyone’s pulling in the same direction, quality becomes the norm, not the exception.

That doesn’t mean our way is the only way. I was helping another contractor recently, jumped in a machine, and started working how I usually do. He politely stopped me and said, “We have a certain way we do things around here.” And I respected that. His crew

knew their system, they followed it, and they got the job done right. That’s what matters.

You don’t need to copy what the next guy’s doing. You need to know your own process and make sure your team sticks to it. That’s how you keep quality consistent. That’s how you build trust, job after job.

3. DON’T COWBOY THE EQUIPMENT

At American Pavement, we expect full production out of every machine we own. But we also expect our operators to respect that machine. That’s what I mean when I say, “Don’t cowboy the equipment.”

That means no driving too fast, no rough handling, and no running a machine harder than it’s built to be run. When you push a machine past the point of smart operation, you’re not helping the team. You’re risking the job, the schedule and the equipment we rely on to achieve quality.

And it’s not just the big iron. It’s the shovels, rakes, brooms—every tool on that truck matters. If you run over a broom and now we can’t sweep the job, that’s not a small mistake. That’s a direct hit to our finish.

The American Pavement crew lays down a fresh mat during a night job, where preparation, teamwork and attention to detail drive the kind of quality that goes beyond the spec book.

IN THE WORLD.

Custom counterflow drum with Rotary Recycle Mixer ®. Multiple RAP and A.C. injection points.

Conversion from old parallel flow drum to 600 ton per hour counterflow running 50% recycle. technology.

Every Hotmix asphalt plant has different operating conditions, therefore, each replacement drum and dryer is custom designed and precision manufactured to meet your specific production demands.

Up to 17 ’ in diameter x 110 ’ long

Replaced failed triple drum with RAP EATER TM - Available in portable or stationary. Customized to retain existing frame, burner and trunnion spacing.

Upgrade every brand built in the last 100 years

Feed and flighting for every material

Asphalt knowledge and experience

Proven quality with over 6,000 rotary dryers built

Replacement and new dryers are Lowest Cost Per Revolution

Dependable per formance for decades

4. THE FOREMAN WALK-THROUGH

Before the first ton hits the ground, our foreman walks the site. We treat that walk-through like it’s part of the work. It’s our chance to make sure nothing’s going to get missed, broken or misunderstood before the machines fire up. That includes checking access, spotting utility covers, planning truck routes and making sure nobody’s tracking asphalt into the porta-john and back across the jobsite.

We’ll also confirm with the customer that we’re on the same page about what quality means for this specific job. For example, some customers want the smoothest finish possible. Others want a little texture for traction. Either way, we get clear on expectations before we lay a single foot of mat.

The walk-through also gives us a chance to flag any other customer concerns—don’t drive on the lawn, don’t block the driveway, don’t scare the dog. Ignore those small details, and you’ve already damaged the customer’s perception of our commitment to quality on the big things.

5. PERCEPTION IS QUALITY

Asphalt is a visual trade. We’re not pouring footings or running conduit underground. We’re the last ones in, and our work is what everyone sees. You can hit every number on the spec sheet— grade, compaction, temperature—but if the site looks sloppy, the customer’s going to think the work is sloppy.

To the untrained eye, a well-swept site with straight joints and crisp transitions looks like a quality job. And to most customers, that is the definition of a quality job. That’s why we pay attention to the finish. Clean lines, swept edges, no stray piles of mix, no tire tracks where they don’t belong. Those details matter, even if they don’t show up on a test result.

I’ve had cars drive over a fresh mat and wreck a lane before we could even get the roller on it. That’s why we plan traffic like we plan everything else—because once that paver starts moving, we don’t want to stop.

6. USE THE RIGHT EQUIPMENT FOR THE JOB

You don’t just grab whatever machine’s available and hope it works. If you want a quality result, you’ve got to match the equipment to the job.

At American Pavement, we run three different pavers, three different mills, and several sizes of rollers and trimmers. We do this because a tight cul-de-sac doesn’t want the same paver you’d run on a big commercial lot. And if you try to muscle a 28-foot paver into a 150-foot section of winding roadway, you’re going to fight that job all day—and your finish is going to show it.

Having the right equipment doesn’t guarantee quality, but it makes quality possible. The wrong setup, no matter how skilled your crew is, will work against you.

STREET SMARTS

7. KNOW YOUR CRAFT

Not every job comes with a stack of specs to meet. In fact, about half the asphalt we lay doesn’t require any density testing at all. That might mean we don’t bring out the density gauge or use PaveScan tech on that particular job. But that doesn’t mean we’re not paying attention.

Asphalt was laid for hundreds of years before we had all this technology. What did folks do before they had all this technology at their fingertips? They relied on their experience! And that’s exactly what we do when the tech’s not on the job. We rely on experience, just like the folks who came before us.

8. REVISIT YOUR WORK

We’re lucky that we’re a local contractor. That means I pass a lot of our jobs just going about my day—weeks later, months later, sometimes years. And I pay attention. I want to see how it held up. I want to know what worked, what didn’t, and what we can do better next time.

That’s how we get better. Sometimes we change our pattern. Sometimes we adjust which direction we pave. Sometimes we flag a mix that didn’t perform the way we hoped. But we don’t learn any of that unless we go back and look.

Quality isn’t just about the job you finished yesterday. It’s also about the job you’re going to do better tomorrow.

9. KNOW WHEN TO SAY NO

At American Pavement, we know what kind of work we’re set up to do well and we try to stay in that lane. When we chase projects that don’t match our equipment, our schedule or our crew’s strengths, quality suffers. Not because the team isn’t trying hard, but because the job throws them curveballs they shouldn’t have to deal with.

You can have a great crew and still end up with a bad result if the project isn’t a fit. That’s why sometimes the smartest thing you can do is say no.

10. QUALITY IS A MOVING TARGET

What passed for a quality job 10 or 20 years ago might not pass today. Standards change. Expectations change. You’ve got to be willing to change with them.

You’ve got to be open to the idea that there might be a better way than how you learned it. That doesn’t mean the old way was wrong. It means we know more now. And if you’re not willing to adapt, you’re going to get left behind.

Quality isn’t a fixed point. It’s something you have to keep chasing.

THE BOTTOM LINE

The spec book tells you what quality looks like on paper. Blue-collar experience tells you what it looks like in the field. You need both. One proves the work. The other gives it pride.

And pride doesn’t come from checking a box. It comes from how you prep, how you pave and how you leave the site when it’s done. That’s what quality means to me.

HIGH-PERFORMANCE, COMPACT MILLING MACHINE

WITH EFFICIENT ASSISTANCE SYSTEMS

W 150 F (i): The most powerful cold milling machine in the compact class is ideal for use on major construction sites with restricted space. The innovative MILL ASSIST machine control system ensures sustainable and efficient machine operations with high productivity. The state-of-the-art LEVEL PRO ACTIVE leveling system, the intuitive operating concept, and digital assistance systems enable efficient one-person machine operation and precise milling results. The machine’s low weight and mid-mount milling drum assembly ensure that its weight is ideally distributed. Its 9-liter John Deere engine impresses with high torque and low noise emissions under all load conditions.

Start Paving Off Right: Part 2

BY BENJAMIN EVERETT

In the training department in July, we discussed investigating the screed and paver and looked into maximizing the grade and start-off point for your best paving success. This month, we’ll dive into placing the mix.

First, I'm not going through the full suite of every proper start-off step when there is plenty of excellent established material that covers this at TheAsphaltPro.com, within the Asphalt Paving 101 online training course, and in Caterpillar’s “Paving by the Numbers” method. Instead, I’m sharing tips and techniques I’ve learned over the years that may be new and helpful to you.

#1

START WITH TEMPERATURE.

The screed must be at proper temperature to place any hot mix. This means each section of the screed—mains and extenders. The heating elements must all be working properly to allow the screed to float properly and to behave in a controllable manner. A cold screed will always dive immediately after coming off the take-off reference. It will be next to impossible to achieve the target thickness and finished profile if the screed is not up to temperature or has some heating elements not working.

I’ve been on several pavers in the last few years that were in very poor condition, and it’s next to impossible to hold target grade and finished

height when the screed doesn’t heat properly. You can put the tow points way up and end up with the screed planing like a surfboard and still not be able to get target depth until the screed has heated up properly. It can take at least 150 feet or more before the screed starts to plane properly and start floating on the mat as it should. You need to watch it like a hawk, because once it starts heating up, the depth will increase quickly as it comes up to target temperature. Before you know it, you’ll be chasing your tail and having to reduce depth fast.

QUICK TIP: Remember to install auger and mainframe extensions (aka tunnel guards) to within 18 inches of the endgate inside. If you don’t, you will have an inconsistent material feed, an erratic mat texture and a difficult time managing the screed. Basically, remember, “Control the feed; you control the screed.”

#2

GET THE SETTINGS RIGHT.

Check your screed extender match height and slope, main screed crown and extender angle of attack relative to the main. (NOTE: This last adjustment you should have dialed in during step 1 on the flat, workshop floor before it came to the job site.)

Proper Line of Pull: This picture shows the proper line of pull between the tow point and screed pivot point.

Set your screed width and try to always balance the screed by having each extender out the same amount on both sides. I’ve found that some screeds are quite sensitive to being used with one side out more than the other; try to keep it symmetrical if you can. If you must have one side out more than the other for job site conditions, I always prefer to have the lower side out more than the high side. It’s a lot easier for the material to flow downhill to the lower side of the mat than it is to try and push it uphill.

#3

MEASURE AND CALCULATE.

Physically measure the true depth of the start joint. Oftentimes it might be a milled edge from a previously placed mat. Sometimes, the depth may be quite a bit thinner or thicker than it should be, and this requires you to carefully tailor the starting boards to the right thickness to ensure the roll down is right and to avoid having to stop after 15 feet to fix the joint, which we discussed in part one in July. Most repetitive work like asphalt paving is 99% preparation and 1% execution. In other words, the effort you choose to invest each time by following a well thought out, repetitive step-by-step set-up process directly translates into success or failure. This is why airplane pilots must follow a checklist every single time they take off. The act of following a known, established and proven process almost always results in a safe, successful takeoff. If you want to enjoy consistent, repeatable and predictable results every time you take off from the joint, then follow a good process. (If you’re still not sure what that process should be, refer to the AsphaltPro Magazine’s online course, Asphalt Paving 101.)

#4 SQUARE UP.

Once you have the correctly calculated starting boards under each side of the main screed and in the center of the main, be sure to back the paver up square to the joint. You want the machine lined up properly for a straight longitudinal joint to be placed.

QUICK TIP: You also want to place starting boards under the extenders if those are out more than about 20 inches.

Don’t accept or allow the paver to be crooked. Back it up so the foremost part of the screed frame is about 4 inches behind the edge of the take-off joint. Next, I recommend setting the tow points at the approximate correct height for the mat depth you are placing, taking into account the need to keep the line of pull as close to being parallel to grade as you can.

Not every paver will be able to be set to pull in an exactly horizontal plane. I’ve found some screeds are not well balanced. They may be heavy on the front or the rear, or the height of the screed pivot point isn’t on a similar plane to where the pull point is. Oftentimes you have to experiment to find a happy medium that gives a good mat. (See the picture of the Proper Line of Pull for notes.)

Lower the screed onto the take-off boards (or starting reference) and be sure the screed switch is in “float.”

To place a quality longitudinal joint, we must pave a straight, sharp line or replicate a nice, smooth curve or radius. The key to doing this is twofold: 1. Ensure you paint a nice, sharp clear paint line to give the paver operator a good reference. 2. Set out an accurate reference for the paver operator to follow said paint line. The best way is to use an adjustable steering guide or pointer or guide bar that they use to trace accurately the line they need to follow. Make sure these things are in good shape and not bent or broken or difficult to adjust. Recently, manufacturers have released aftermarket devices that mount on the paver and point a colored beam of light along the painted line, centerline or other reference point.

Next, be sure to slowly (at low engine speed) creep the tractor forward about 2 inches to take up the slack at the tow points and to introduce a load on the screed. This is a critical step that, if not done properly, invariably leads to a poor takeoff with a dip or bump.

If you did everything right so far, the leading edge of the screed should now be about 1 inch behind the edge of the start joint.

Next, null out your depth screws (if you have them on your screed) so you are sure both sides of the screed are relaxed or nulled. Then, one side at a time, introduce about 1/8- to ¼-inch slight “nose up” angle of attack with the depth cranks. Remember that earlier you should have already set your extender vertical height relative to the main screed. This will act as a means to help set that approximately 3/16-inch angle of attack, because once you null the screed out, it tends to rest on the extender section. Similar to a plane flying through the air or a boat on water, the screed nose must also be slightly “up” to provide lift.

Now, lower the endgates so the skid plate is lightly contacting the grade on the leading edge. But make sure to have enough “space” with the spring so there isn’t too much down pressure, as that can interfere with the ability of the screed to float properly on the mat.

If the other side is matching a previously placed pass, set that side plate at a suitable height to avoid it digging into the mat. (See the “Float the Endgate” sidebar.)

#5

HALF-FILL THE AUGER CHAMBER.

Next, I fill one side of the auger chamber at a time with the engine at low idle and the augers and conveyors at slow speed. Try to fill the area in front of the extender to the level that you would normally have it when paving; about halfway up the auger shaft is a good rule of thumb. It helps to have someone carefully shovel mix out by hand to avoid the temptation to power it out with the augers and overload it.

QUICK TIP

: Don’t overfill this area (it’s easy to do this) as this will affect the screed when you pull off the joint. Also remember safety! Ensure laborers working near the augers are kept safe and their limbs and clothing are well away from moving parts. Shut the augers off once “full.”

Once both sides are full, choose your target paving speed and ensure the trucks being pushed by the paver (or the MTV operator) are informed you are about to start so they are ready and can anticipate how much brake pressure to set and so on to avoid spills. If everyone is on point and working as a cohesive team, many big mistakes can be avoided, and we can have a good day.

Some operators prefer to start in automatic, while others like to stay in manual until they validate that the mat depth is on target. If you know your screed well and how it behaves in all circumstances, and you have performed the set-up steps correctly, start in auto. Typically, I prefer to start manually and switch to automatic after one to two paver lengths; once I’m satisfied I’m on the target mat depth.

To assist me both at startoff and for matching joints or adjacent structures like a concrete channel lip, I use a bobbin and chain. I like to have a visual, tangible reference for fast and accurate feedback as to whether I’m at target depth. Also, although I always advocate for and prefer to use dual grade averaging, there can be some occasions on almost any job where that just isn’t feasible.

On car parks and many siteworks or commercial jobs, it’s typically less about achieving a “billiard table” smooth ride and more about matching adjacent equipment or structures such as concrete channels or light stands and other things of this nature. Frequently, these things we need to match can be at a different elevation or level to the paving thickness we have to meet. Therefore, discretion and a solution are needed. This requires quite a lot of forward thinking and planning to ensure water will still run off the right way and not create a bird bath. If you have the bobbin and chain calibrated to your target loose mat depth, when you need to deviate to carefully match to something on the fly, it’s great to have a trusty reference you know is already right that you can use to quickly get back on grade.

When we have the auger chamber dialed in right, the screed set up per industry best practice and everyone’s ready to go, it’s time to pave.

When we remove the tarp from the start-off joint, we reveal a clean edge. We take loose material left on the tarp to the next lane over and place it where the paver will begin, compacting it in a thin layer while preparing the starting boards for the next lane’s pull.

#6

PULL OFF THE START-OFF JOINT.

I pull off the joint at the same speed I’m intending to pave, and I focus solely on hitting target depth, having a consistent, steady 2040 RPM auger speed and a smooth mat without irregular texture. I make sure to trim the extender heights if required to take out any transition lines.

We all know the goal is a consistent mat texture free from segregation and defects. I have a couple of skilled laborers who work as a team and lift up the start-off tarpaulin, fold it in half lengthwise, then carefully place the mix from the tarp on the grade at the next lane over and screed it out fairly thin by hand, then compact it by walking on it. There is usually no need to touch the transverse takeoff joint this way.

If you did things right—if you made sure the screed starting reference was carefully calibrated for the thickness at the joint, set up the screed properly, and took the slack out of the side arms to preload the screed so it behaves in a predictable, controllable way—then the breakdown roller can get onto that joint immediately after the starting tarpaulin and laborers are out of the way. He can start getting

FLOAT THE ENDGATE

This picture shows the endgate lightly floating on the existing surface or grade. Consultant John Ball also describes it as “gliding” on the grade, which is a good analogy. Basically, the side plate or endgates need to lightly (but positively) contact the grade. This is to confine the unsupported edge, and it helps to build a nice, strong, square edge. We need that to build quality joints. If you pave with the endgate raised up, what happens is the longitudinal joint becomes weak, segregated and it rolls over under the compactors. When you confine the edge by putting the endgates down, you build in some density and uniformity because there’s a wall there that defines the edge of the mat. When you match a hot joint, you also want the endgate down, lightly gliding on the previously placed hot mat you are precisely matching.

3 Key points:

• Don’t force the endgates down “hard” on either an existing grade when placing the leading edge (the first pass or the open longitudinal joint) or when doing a hot joint match on a previous pass. Be sure it’s floating nicely.

• Leave some room in the endgate springs so it has a couple of inches of float or travel to move up or down as the grade changes or you have a variable depth. If you have too much down-pressure on the endgate springs, it can interfere with the screed’s job of floating on the mat. That’s why it needs to gently glide.

density. That roller needs to nail that joint in a timely fashion and then keep up with the paver following the pass pattern.

I'm not going to do a narrative on how to compact the transverse properly; others have covered this very well many times over. If you’re still not sure about it, look at the AsphaltPro Magazine online course, Asphalt Paving 101, for some helpful tips from industry veteran John Ball III or Caterpillar’s Todd Mansell with “Joint compaction and roller operations” and “Transverse joints—avoiding the bump!”

These two installments of Start Paving Off Right offer tips and techniques I’ve learned and used over decades in the field. These are some of my “go to” tips to keep the screed from nosediving when coming off the starting reference, thus they are tips for avoiding re-work and achieving success. Let me know which elements you found helpful or which you’re going to try out on your next project. Let’s continue to learn not only from the training courses offered around our industry and in these pages, but from one another as well. I look forward to connecting with you on TheAsphaltPro’s social platforms to share ideas.

Benjamin Everett is the owner of About Asphalt Ltd., and has worked in the asphalt industry for nearly four decades. For more information, contact him at bjeverett@aboutasphalt.co.

• On a hot joint match, you will soon figure out how much the sweet spot is for your down-pressure. If it’s down too hard it will dig into your uncompacted hot mat and scar it; if it’s not down enough you will get excess material bleeding out, creating a lot of unnecessary hand work to fix that excess up, not to mention likely a nasty line of bones.

LEARN MORE

Delta Brings Larry H. Lemon Award to Missouri

BY SANDY LENDER

Apex Paving Company, a division of Delta Companies Inc., located in Cape Girardeau, Missouri, took the farm-tomarket road concept to heart in the fall of 2024. They performed an exemplary overlay project for the Missouri Department of Transportation (MoDOT) on Route UU amid the fields of Mississippi County while communicating with the farmers in the area to meet everyone’s needs. Here’s how they accomplished this for an award-winning finish.

The project ran from Route 62 to Route D in Mississippi County, through the city of Charleston. Not only did the crew place a 1-inch lift of plant mix surface leveling mix, but they also handled detail work along the way.

Construction Manager Cecilia Cain explained, “This job had a mill/fill section in the city limits of Charleston where a job installing ADA sidewalk had recently been completed. No quick thinking per se, but extra care in not getting mix or tack stains on the new concrete was important.”

The Apex Paving Company crew placed 5,069 tons of plant mix surface leveling course with 34% RAP to increase the smoothness of Route UU, improve safety, enhance the driving experience for the end users and garner a Larry H. Lemon Award. Photos courtesy of Delta Companies Inc.

SERVICE THAT RUNS HOTTER THAN YOUR DRUM

IN THIS BUSINESS, HEAT IS EVERYTHING.

That’s why we bring more than just tools, we bring the fire.

From retrofits and relocations to maintenance, parts, and plant upgrades, Motion Engineering keeps your plant running hot and smooth. With over 30 years in the asphalt industry, we’ve seen it all and solved it all.

Let’s talk about how to make your next project faster, cleaner, and more efficient.

PAVEMENT

Starting Sept. 3, 2024, the Delta team produced mix with 34% recycled asphalt pavement (RAP) at its Aesco-Madsen plant located about 18 miles from the Route UU project. Plant Operator Daniel Baker averaged 235 tons per hour at 330°F.

Trucks delivered the mix directly to the Cat AP655F hopper—no material transfer vehicle was used. Chris Lombeida, the paver operator, managed the material expertly to the front-mounted screed and placed it for the rolling train. The breakdown roller, a Bomag BW190, was operated by Jason Duckworth.

The team managed the project with a combination of good communication and the latest technology.

“This road was paved in the fall in the heart of row crop country,” Cain explained. “We managed to arrive ahead of time and communicated with the farmers in the area that we would be paving, resulting in a safer and better-quality finished product. This also resulted in farmers being able to communicate with us that they would

like for driveways to be paved further back, resulting in a long-term benefit for the owner of the road with less gravel tracked onto the roadway and improving long-term safety.”

The Delta team also tracked and managed all that movement internally, using Fleetwatcher for electronic ticketing and truck fleet monitoring.

By Sept. 5, 2024, the team had placed 5,069 tons of plant mix surface leveling course to increase the smoothness of the route, improve safety, enhance the driving experience for the end users and garner one of the 10 Larry H. Lemon Awards for the year.

“The standard deviation of the test results along with the appearance of the finished product is how we knew this product was worthy of submitting,” Cain shared. “The ride and aesthetics of this road are enormously improved from what was there before. It takes a team that truly cares about the project to have such a good-looking finished product.”

TOP LEFT: Paver Operator Chris Lombeida paves the mainline for the award-winning Route UU project. BOTTOM LEFT: Screed Operator Kennith Pitts helped bring together an award-winning overlay on Route UU. RIGHT: The finished pavement of Route UU in Mississippi County, Missouri, offers a safer and smoother experience for the end user.

Oklahoma Launches Next WofA Branch

BY SANDY LENDER

Oklahoma can now boast of its commitment to mentoring and encouraging women in the asphalt industry as the state has launched its branch of the Women of Asphalt organization. The new group held its kickoff meeting May 23 during a video chat with the national organization, where they also revealed their Oklahoma WOA logo.

Trish Morris, project manager for Silver Star Construction, Moore, Oklahoma, leads the charge in bringing the branch to life and shared the group had its first official meeting at the Oklahoma Asphalt Pavement Association (OAPA) headquarters office with lunch after the inaugural meeting. At the meeting, Morris asked for volunteers to serve on the initial board; after the meeting the board was finalized, and those members are as follows:

• Morris, chairwoman

• Kati Ratliff of Rudy Construction, vice chair

• Krysta Green of First Water Contracting, secretary

• Chante Kizer of OAPA, treasurer (temporary)

That summary might sound basic on the surface, but the process of bringing a new organization online took months of preparation and has already started reaching out to the next generation of construction workers.

Morris has worked as a project manager and estimator at Silver Star Construction for three years and has been in the asphalt industry for 15 years. Her immediate supervisor at Silver Star is a board member of OAPA advocated for Morris to attend the WofA inaugural executive seminar at Astec Industries in Chattanooga in November 2024. Morris wanted to bring this encouragement and motivation to Oklahoma and saw interest already growing in the state.

“There were close to 30 members in Oklahoma already interested in a Women

of Asphalt branch,” Morris said. “I took that back to Larry [Patrick], who took the information to the board.”

Larry Patrick is the executive director of the OAPA and was pleased to see Morris and Aaron Parker of Silver Star poll the membership to find the level of interest had grown. Patrick shared that the three of them met before the OAPA annual conference to come up with a plan. They would set up a sign-up sheet during the conference for members to show their interest and receive a WofA

hat when doing so. “Silver Star had the hats made, and I can't thank them enough for all of their help,” Patrick shared. “In the meantime, I sat down with the OAPA executive committee telling them of the interest and they liked the idea but wanted to see the number of signups.” Patrick stated that the executive committee may have been taken by surprise by the amount of interest among the membership.

The WofA national organization tracks what state its members are from and shares

After a Zoom meeting with the Women of Asphalt organization, the newly formed Oklahoma branch had its first meeting with lunch to name officers and get down to business.

The newly formed Oklahoma Women of Asphalt branch teamed up with Construct My Future for construction camp during the week of June 2 and worked with 96 "campers” on Paving Day.

those signups with the branches, and that’s where Morris’s roster began. Adding conference signups to the spreadsheet she received from the national organization showed the interest level was high.

From there, Patrick presented the concept to the OAPA board, which he said was very supportive. Morris next reached out to the “signups” to tell them about the kickoff meeting and Patrick reached out to the membership at large to inform them about the branch and how to join.

“Trish has done a fantastic job at reaching out and getting the chapter started,” Patrick shared. “OAPA will be there to help, and I think once we get it announced, we should see financial help coming in. That is one thing I can say, our members are always there to help support OAPA and I don’t see any change for Women of Asphalt Oklahoma. Our meetings will be here at the OAPA office where we have a conference room that holds about 40 people. But we have access to the Oklahoma Home Builders Association right next door to our office that has a conference room that can hold 80 and I hope in the near future we can fill that room.”

With the branch officially formed, the first event took place with Construct My Future, Oklahoma City. “We did construction camp last week with the middle schoolers,” Morris shared. “We had 96 campers on Paving Day. WOA made asphalt candy with them. We had four ladies, myself included, at the event.”

“Overall, the ladies seem excited,” Morris continued. “We are planning to meet in July or August (or both) to plan our next event, and I am working with Larry to fundraise at the OAPA golf tournament in September.”

Next steps include setting up all the social media platforms for the group where board member introductions and information about events will be posted, and volunteering at additional Construct My Future events like construction rodeos to encourage and educate youth on a career in the asphalt industry.

“I am very excited to see the Oklahoma chapter being put together,” Patrick shared. “The time is right and the interest is there.... This is something I have had in the back of my mind and Trish moved the needle to the front of my mind, along with many others. I can’t thank her enough for her hard work to get this off the ground.”

Trish Morris stands with one of the students at the awards lunch for construction camp to take “a pink picture.”

CONTRACTOR’S GUIDE FOR HANDLING PMA

Authors’ Note: This article is based on the Association of Modified Asphalt Producers training workshop. The original presentation was developed by Ron Corun and edited by Bob Kluttz. No AI was used in writing this article.

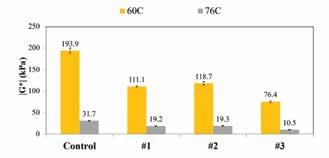

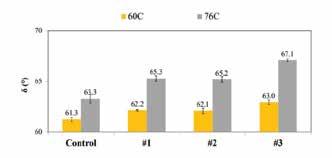

CCurrently up to 20% of all paving asphalt is polymer modified. The most common polymer-modified asphalt (PMA) binders are in the range of PG64-28 to PG76-28. Key for all modified asphalts is to be safe and follow the manufacturers’ recommendations.

HANDLING AND STORAGE

PMAs are not all created the same way. Mixing modified asphalts from different suppliers can cause the mixture to fail to meet the performance grade (PG) requirements. Some guidelines help reduce contamination at the terminal. Make sure that the tanker trunk is empty before loading, then make sure to load from the correct loading arm. It is important to minimize the heel in both trucks and tanks. As little as 6 inches of residue in a tank can cause up to 10% contamination by a different grade.

At the asphalt mixing plant, use dedicated tanks, if at all possible. If a dedicated tank is not available, empty the tank as much as possible from the previous material and then add two or three loads to fill the tank before testing. Diluting PMA may cause the PG grade to fail.

Vertical tanks are optimum as they provide more efficient agitation. Most PMAs today do not require agitation to prevent separation, the exception being ground tire rubber (GTR). Horizontal tanks work fine for most PMAs but it’s important to circulate to achieve uniform temperatures above and below the heating coils.

For proper circulation it is important that the product should be pumped out of one end of the tank with the return to the other end of the tank. If the circulation is all at one end of the tank the other half of the tank will be a dead zone. It is also important to ensure that the return line goes into the tank below the liquid level. Otherwise, you are spraying liquid asphalt through the remaining air in

BY RON CORUN AND BOB KLUTTZ

the tank and essentially running RTFO on your virgin binder.

As mentioned above, beware of mixing modified asphalts from different suppliers as not all PMAs are created with the same components by the same process and may not be fully compatible. Direct fire heating is not desired. Direct fire heat tubes will have hot spots, which cause two problems. Hotspots will damage the polymer network and lead to loss of PG grade and/or undesired viscosity rise. Hot spots can also lead to coking, which effectively insulates the line requiring ever increasing heat to maintain temperature.

Highly modified asphalt (HP or HiMod) is increasing in use around the United States. Handling and storing HiMod is not much different than handling and storing conventional PMA. The same general guidelines apply, but shelf life of a HiMod may be substantially shorter than a standard PMA. Check with your supplier to get his recommendations.

An ideal tank storage temperature is 320330∞F. A key point for HiMod as well as all PMA is do not overheat it. Overheating can cause the HiMod to further shorten the shelf life. The hotter the temperature, the more rapidly aging can take place in the binder, so it is important to keep the temperature as low as comfortably possible for easy pumping.

Long-term storage of PMA is feasible, but cooling is required. For 60 days or longer, the heat must be turned down or completely off. When bringing back up to temperature, do it slowly. The tank contents must heat up uniformly through conduction and convection until the material is pumpable. Use increments of 20°F over three to four days to get the material back up to circulation temperature.

MIX PRODUCTION

Pay attention to optimum mixing and compaction temperatures for PMA. The classic rule of rotational viscosities at 135 and 165∞C does not apply to PMA. The low shear rotational viscosity of conventional asphalt is similar to the viscosity at high

shear—mixing and compaction. PMAs, however, are shear thinning. The apparent viscosity in a drum is much lower than that from a rotational viscometer. Consequently, rotational viscosity will yield a much higher temperature than is actually recommended. Again, your provider should recommend ideal temperatures for their product.

Ensure that all plant equipment is in good condition and suitable for PMA. PMAs tend to be higher in viscosity so they will draw higher amperage at the pump. The pump should be calibrated and the strainer likely will require larger than standard holes—you want a minimum of 1/8-inch holes.

At startup, circulate unmodified asphalt first. Once everything is hot, switch to PMA and circulate again before starting production. Switch back to unmodified asphalt after the shutdown of the shift to leave unmodified asphalt in the pump and the strainer. The slat conveyor must be properly sized and in good condition. PMA will increase the amperage draw on the conveyor. It’s good practice to start out at reduced tonnage with unmodified mix to get everything up to temperature.

Again, not much is different with HiMod. The ideal mixing temperature is dependent on the mix as always, but 325 to 340°F is generally good. Check with your supplier on recommended warm-mix additives and again start up a little hotter and slower to heat up the whole system, slat conveyor, silos and trucks, to make sure every point in your process is allowed to get up to good operating temperature. On overnight modified asphalt storage there is varying guidance. If you are new at this, or if you have older storage systems, it is probably unwise to store overnight. If you’re well experienced with modified asphalts, if your silos in particular are in excellent condition, well insulated and well maintained, it may be quite feasible to store overnight.

CONSTRUCTION AND MORE THOUGHTS ON HIMOD

When transporting to the paver, make sure as always that the truck bed is smooth and

clean. Use of release agents is recommended, but do not use hydrocarbons. Tarping is a very good thing and probably required in your state. These same practices apply for general PMA and for HiMod. Placing hot-mix asphalt (HMA) generally requires no modifications to equipment. Handwork likely will be more difficult, depending on the mix. The ambient temperature guideline recommended by the Association of Modified Asphalt Producers is 50°F and rising.

Compaction equipment, again, is normal. Keep the mix temperature high enough for good compaction, but no higher. Every 10°F increase doubles the amount of fumes and the higher temperature can damage the PMA polymer structure. Keep the roller up right behind the screed. If available, direct temperature and density measurement is great. Compacting PMAs may actually be easier than unmodified asphalts as it’s been noted that PMA may help reduce or eliminate a tender zone.

There is not much different when placing HiMod. Aim for the temperature behind the screed to be about 300°F. Hotter is not better as it can lead to shoving. Keep the breakdown roller close to the paver. The only significant caveat, and this is an important one, is cooling. HiMod mixes are not any stiffer at operating temperatures than conventional PMA mixes. The cooling rate is about the same. However, the HiMod mix will stiffen up faster than a conventional PMA so your working time on the mix is shorter. This applies to cleanup as well.

Best practices from some states that regularly use HiMod have shown laydown of HiMod binders does not pose a significant problem as reported so far but keep in mind general good construction practices. Prevent end of load segregation. HiMod binders may magnify poor construction practices. Balance your production rate, plant to truck to paver to rollers. Keep the mix moving. Delays will add to cooling of the material, which will give you an increase in viscosity and difficult handling.

Be ready when the trucks arrive on the project as temperature is critical for the mix. Keep compactors tight with the paver. Adjust the rolling pattern as needed to maintain target density. Plant storage may be somewhat different as previously noted. HiMod binders do have a limited shelf life, so scheduling and frequent communication with the binder supplier and the agency is important. Do not store indefinitely. Follow supplier specific handling guidelines, storage temperature, storage time and circulation. Recommended best practices may vary with suppliers, so as with all modified asphalt follow your supplier’s advice.

SOME FINAL COMMENTS:

• Do not overheat. High temperature accelerates viscosity rise. Monitor viscosity daily.

• Warm-mix additives are good.

• Unused high polymer binder can readily be diluted to a PG76-22 or -28.

• Repeat—do not overheat.

A good quality control plan is as important or more so with PMA than it is with conventional unmodified asphalt. Especially if

the plant uses both unmodified and PMA, all of your materials, all your tanks, pumps, valves, sampling points, all need to be well labeled. Establish standard procedures and hardware settings for asphalt flow into the storage and into the HMA plant. In summary, PMA improves the performance of asphalt pavements. Understand the product that you’re using and treat it with respect. Follow supplier’s recommendations and use best practices.

Kenco Engineering, Inc

SUPPORT THE ROAD WITH LIGHTWEIGHT AGGREGATE

BY VERNON MORTENSEN

TThe American Society of Civil Engineers (ASCE), in the 2025 Infrastructure Report Card, explained that deteriorated and congested roads still cost the average driver over $1,400 per year in vehicle operating costs and lost time. Poor road conditions also cost counties. Asphalt maintenance experts estimate that every $2 spent on pavement preservation can save $4 to $18 on future costs.

As departments of transportation and municipalities plan maintenance, repair and road improvement projects, it is important to consider paving materials that not only support safer roads, which include preventing damage to constituent vehicles, but also ones that provide longterm resistance to polishing, expected wear and other types of damage.

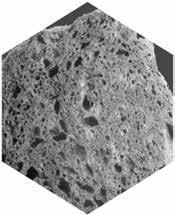

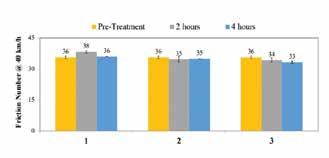

As demonstrated in projects in North Carolina and Utah, expanded shale, clay and slate lightweight aggregates (ESCS) in asphalt chip seal can be a cost-effective and long-lasting solution to many challenges in asphalt pavement improvement. This material provides a high-friction surface that resists polishing over time to extend the service life of most asphalts by approximately 20 to 40% compared to conventional aggregates, depending on traffic and environmental conditions. It can also reduce damage to constituent vehicles caused by dislodged stones.

HIGH-FRICTION SURFACES THAT RESIST POLISHING CREATE COSTEFFECTIVE SOLUTIONS

ESCS is produced by heating raw material until it softens and air bubbles form. The bubbles remain as unconnected voids when the aggregate cools. These voids create a surface texture with a higher skid number than common natural aggregates (like limestone, dolomites and gravel), approximately 65 for chip seal (compared to limestone’s 50)

and 44 for hot mix (22 for limestone). Further, because the air pockets are found throughout ESCS, the material inherently resists polishing to maintain adequate skid resistance over the pavement’s service life.

In “Pavement Friction for Road Safety,” a primer from the Federal Highway Administration (FHWA), it is noted that high-friction surfaces result in “significant crash reductions in both wet and dry crashes.” Using materials with a high and stable skid resistance, like ESCS, can be a viable option for increased safety along rural and municipal roadways.

For example, the North Carolina Department of Transportation (NCDOT) sought to reduce accidents along Highway 71 near Lumber Bridge. This stretch experienced heavy truck traffic and consistent wet road conditions. To determine if ESCS would be an effective and cost-efficient high friction surface treatment (HFST), NCDOT tested a single layer of ESCS applied at approximately 12 pounds per square yard over CRS-2 emulsion at approximately 0.30 gallons per square yard for 200 yards. The rate of accidents did not increase, demonstrating that ESCS offers an economical HFST alternative to calcined bauxite.

Similar tests to the efficacy of ESCS have been conducted by the Texas Department of Transportation (TXDOT). The results demonstrate this material provides both initial and long-term skid resistance.

IMPROVE MECHANICAL AND CHEMICAL BONDING WITH ESCS

The network of voids provides other benefits in addition to long-term skid resistance. It allows the asphalt sealant to penetrate deep into the aggregate mix.

Crews place aggregate over an asphaltic emulsion. Photo courtesy of the Expanded Shale, Clay and Slate Institute (ESCS)

Committed to Your Success, Every Step of the Way. Let’s build something great together.

Scan Here To Learn More!

Because this material is produced, its size is highly regulated, and the amount of dust is reduced. On the one hand, the predictable size helps reduce machine clogging. On the other hand, it allows a more even coat. Being nearly dust-free, ESCS improves contact with asphalt emulsion for better retention; it also supports less dust kicked up during projects. Finally, the almost cubical shape of ESCS aggregate enables it to lock into the stone matrix to further improve its long-term performance.

In addition to the physical properties of ESCS that support a better mechanical bond, ESCS has a slight ionic affinity to many asphaltic emulsions. ESCS typically has a net negative surface charge. When used with a cationic emulsion, such as CSS1 or CRS-2, the ionic charges of these materials allow them to bond on the molecular level. This supplements the mechanical bond between ESCS and emulsion for greater retention rates over the course of a road’s service life. The improved bond strength also reduces the instances of flying rocks dislodged by passing vehicles.

REDUCED AGGREGATE DENSITY MINIMIZES DAMAGE TO CONSTITUENT CARS

Aggregates can lose adhesion to asphalt emulsions for a number of reasons: over coverage, being too wet or too dusty, as a result of long-term UV damage or simply being at the end of its service life. Without enough adhesion, tires can dislodge stones and send them flying. When this happens with conventional aggregates, their weight and speed of travel can exert enough force to damage windshields and car bodies.

Because they create a strong bond with asphalt emulsion, ESCS is less prone to being dislodged. If stones are dislodged, they are far less dangerous, due to the low density of the material. Thus, windshield damage claims are practically eliminated, reducing liability and helping to stretch road construction budgets.

The Utah Department of Transportation (UDOT) used ESCS on multiple stretches of interstate, totaling approximately 20 miles in length and using over 10,000 cubic yards of lightweight type C/type II chips. Representatives from UDOT reported zero claims or complaints of broken windshields or vehicle damage, which is unheard of when chip sealing a section of interstate. There were also no areas where chips peeled off the road after a year’s time and a season of snow plowing.

Similar results have been reported from the Louisiana Department of Transportation and Development (DOTD), the Kansas Department of Transportation (KDOT) and in other pavement improvement projects across the country.

LESS WEIGHT CAN TRANSLATE INTO DOING MORE

By reducing the cost of vehicular damage and sidelining expensive HFST material, ESCS can help DOTs do more with less. This alone positions ESCS as a cost-effective option for raising the grade on roads in America.

But it is also important to note that the increased bond strength improves the retention rate of the aggregate to reduce overall costs. In a 2018 report, Carbon County, Utah, found that using ESCS increased the retention rate from 30% to 99%, resulting in a significant reduction of application costs.

Further, since ESCS has a lower density than conventional aggregates, DOTs can expect more yards of coverage per truckload, which can cut fuel and labor costs associated with hauling materials to project sites nearly in half. In addition, because ESCS provides increased durability and skid resistance, it can be specified in smaller aggregate sizes than conventional stone. The Carbon County report indicates that smaller aggregate supports more efficient coverage and shot rates. As the report indicates, the surface area covered with fine chip is often approximately double that of frequently used larger chip sizes. Further, less emulsion is needed to achieve the desired embedment of the aggregate when the particles are smaller.

Both the improved retention rate and a greater per ton coverage rate resulted in over $300,000 in savings annually in Carbon County.

ACING ASCE’S REPORT CARD WITH ESCS

ESCS in asphalt chip seal can be a viable option for improving rural, interstate and municipal roads. With a lower density and the ability to be specified in smaller aggregate sizes, ESCS requires fewer truckloads, less fuel and less emulsion than conventional aggregates. When the total cost of a project is considered, ESCS also represents an economical solution to repairing and replacing pavement across the country. This, in turn, allows DOTs to cover more mileage with their annual budgets.

Between the 2021 Infrastructure Report Card and the 2025 one, road infrastructure did see a slight improvement, moving from a D to a D+. Due to its ability to create longer lasting and more cost-effective asphalt, ESCS can contribute to an even greater improvement between now and the 2029 report card.

Vernon Mortensen is an Aggregate Salesperson at Holcim Lightweight Aggregates–Utelite. He is active in the Expanded Shale, Clay and Slate Institute (ESCSI) Asphalt Committee and has served as the committee chairperson.

LEFT: An asphalt chip seal made with ESCS preserves rural roads. Photo courtesy of Stalite and ESCS. MIDDLE: With higher retention rates and better bonding, ESCS represents a cost-effective road repair solution. Photo courtesy of ESCS. RIGHT: ESCS’s unconnected voids maintain skid resistance over a pavement’s service life. Photo courtesy of Stalite and ESCS

From Backlog to Breakthrough: All Roads' High-Efficiency Approach to Cut Repair

With no prior maintenance division, All Roads took on 1,800 utility-cut repairs in Vancouver—and used an all-in-one machine never before seen in Canada to do it.

By Sarah Redohl

n 2025, All Roads Construction took on one of the most ambitious municipal patching programs in British Columbia: a $5.4 million pilot contract from the City of Vancouver to restore asphalt, curbs and sidewalks at 1,800 utility-cut locations across the city. Though structured as a one-year initiative, the project offers an option to extend annually for up to five years based on performance.

With a backlog that stretched more than a decade and urban working conditions that left little room for staging equipment, the project demanded more than tradition-

al patching methods. It required speed, efficiency and innovation. “This project is really just for one year with an option for four more years,” said Denis Labelle, vice president of operations at All Roads. “So we really wanted to impress the City of Vancouver because we want to make sure those four years come our way.”

The pressure to perform was matched by the scale of opportunity. “The project is set at $5.4 million a year, but the city has $30 million worth of patches to catch up on,” Labelle said. “So it really comes down to what we can accomplish in a year. If we

keep going the way we’ve been, we might get through $7 million worth of patches this year. The more efficient we can be, the more revenue we can generate.”

Although All Roads wasn’t the lowest bidder for the job, they were ultimately selected based on their ability to deliver. “The city trusted that we were capable of marshaling the resources needed for such a massive undertaking,” Labelle said. To deliver on the city’s expectations, All Roads knew they’d need more than manpower—they’d need a new approach.

The JCB Pothole Pro, shown here with its side-mounted planer attachment, was selected for its compact footprint and ability to operate in dense urban environments.

With no prior history in maintenance work, the project gave All Roads a chance to break into the space in a big way. Unbound by conventional patching methods, they had the freedom to rethink the process from the ground up. And they’ve done just that— rewriting the playbook on municipal maintenance and becoming the first contractor in Canada to deploy the JCB Pothole Pro.

Taking On the Backlog

The backlog All Roads was brought in to tackle was staggering. The repairs themselves weren’t complex—but the sheer volume and age of the outstanding work underscored how far behind the city had fallen. “Right now, there are still work orders from 2008, 2010 that haven’t been done,” Labelle noted.

In Vancouver, when developers connect new buildings to water, sewer or gas lines, they typically leave behind temporary patches in sidewalks, curbs and roadways. The City holds back funds to complete the repairs but often ends up doing the work itself. Over time, the backlog grew into the thousands, far beyond what in-house municipal crews could handle.

The conditions in Vancouver—tight alleyways, street parking scarcity and dense

residential traffic—added layers of complexity that went beyond scheduling. The All Roads team realized the traditional equipment model—milling machine, skid steer and excavator—wouldn’t be feasible on a citywide scale.

With so many small sites across a dense urban area, conventional equipment setups weren’t going to cut it. “Once we got

the project, in typical fashion, we started looking at what’s the quickest way to do it,” Labelle said.

That led him to an unexpected discovery. “I kind of stumbled upon the JCB Pothole Pro. I didn’t even know this machine existed.” As he researched further, he realized the machine hadn’t yet been deployed in Canada— and could offer a significant tactical edge.

A two-person crew completes surface preparation on a residential street. All Roads trained its operators on the new equipment prior to the start of the season.

The machine’s integrated broom attachment prepares the surface for patching, helping crews move directly from milling to cleanup without separate equipment.

The JCB Pothole Pro combines a 24-inch side-shifting planer, 4-foot sweeper, 16-inch cropping tool and 180° tilt rotator on a wheeled excavator platform. It also featured a 25-mph travel speed, eliminating the need for lowboy transport between urban patch locations.

All Roads arranged a demo at their asphalt plant, and the results were immediate. “I actually had to tell my guys to quit praising the machine in front of the salesman because you’re making it harder for me to get a deal,” Labelle said.

Labelle said the machine’s versatility makes it invaluable: “Besides patching, there are other things you can use the machine for. It could mill around your manholes on a larger milling job, it can cut your edges straight, it can dig trenches, it can do all kinds of things. It’s really a Swiss army knife of a machine.”

Replacing Three Machines with One