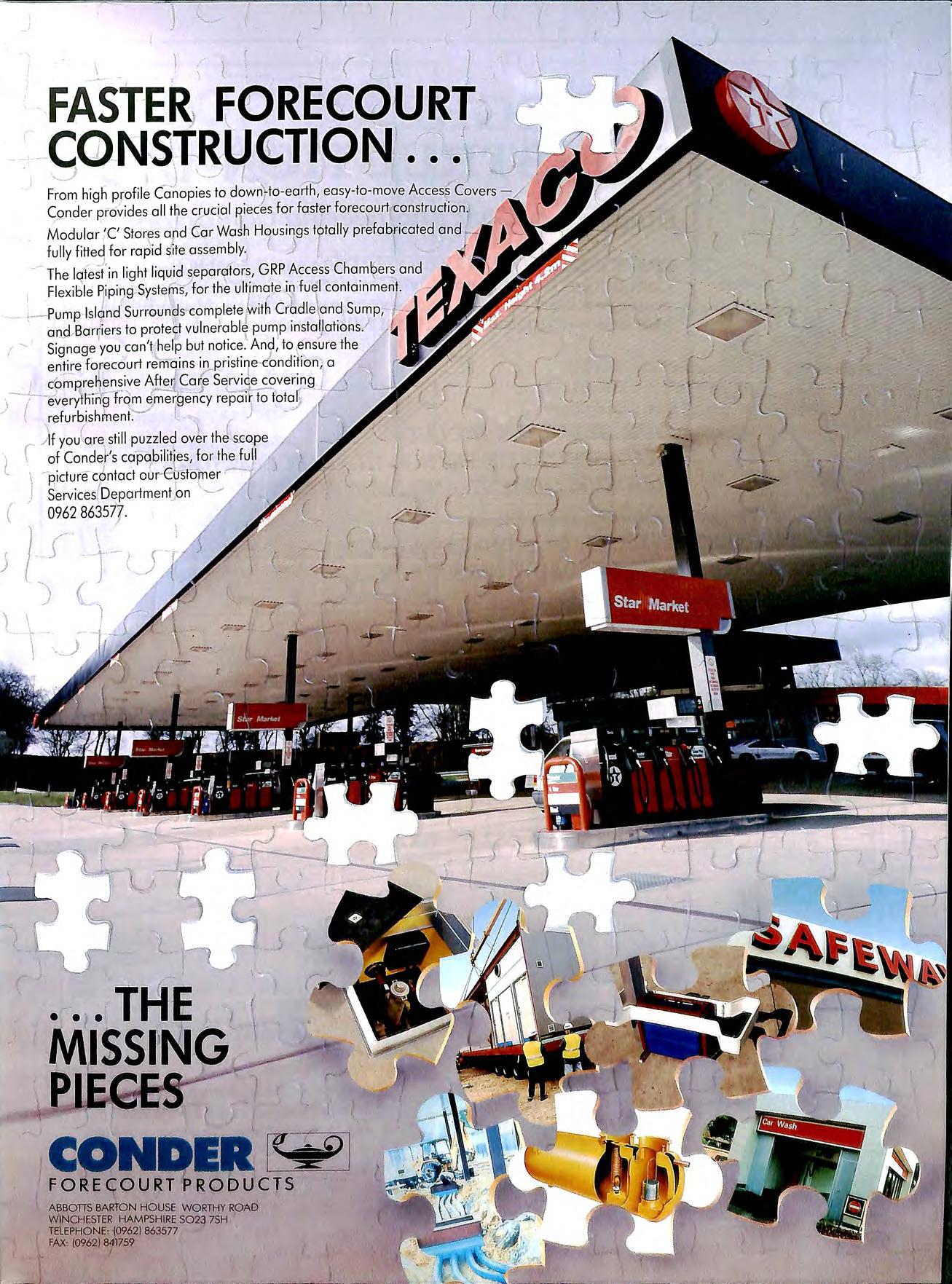

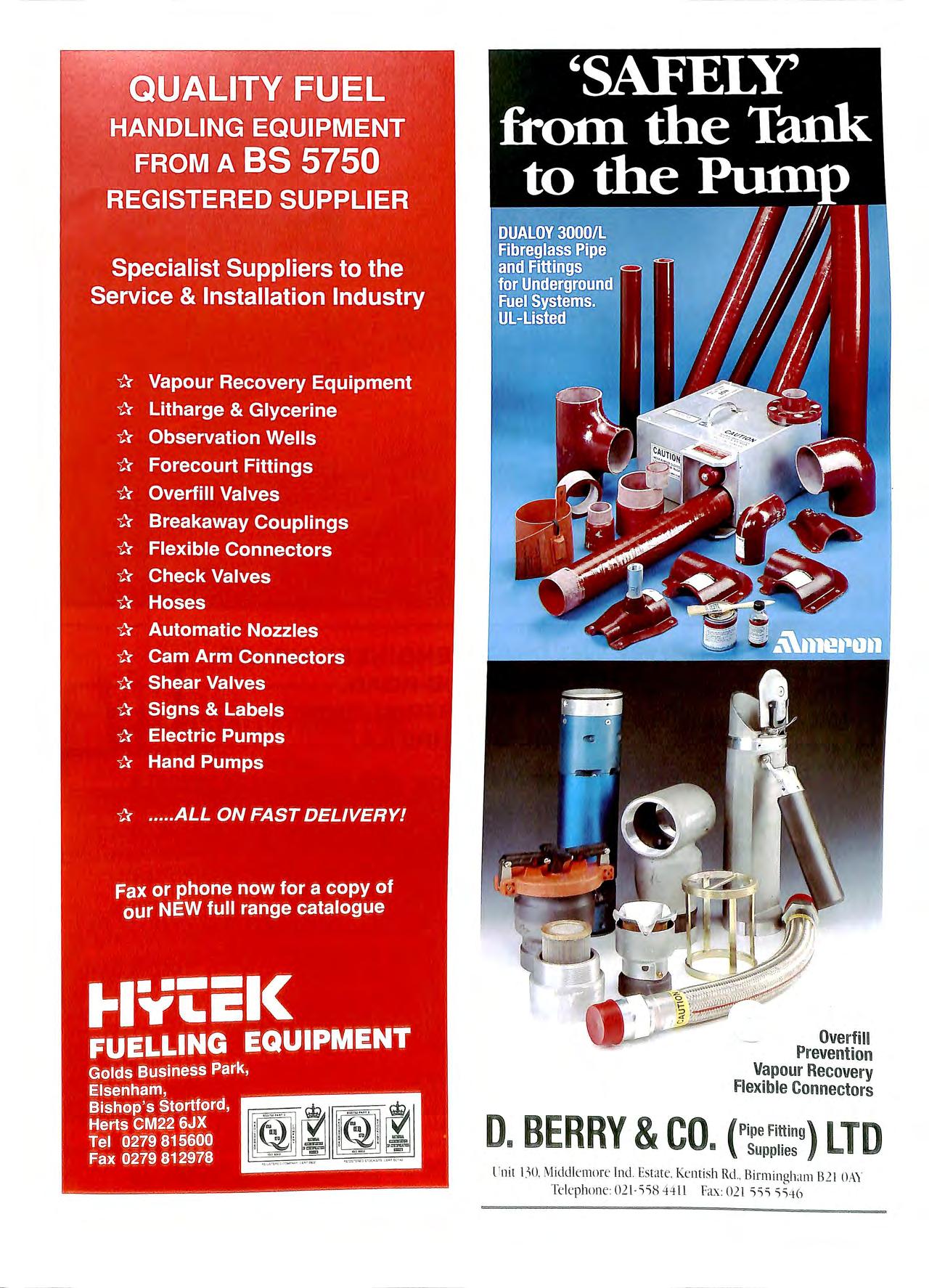

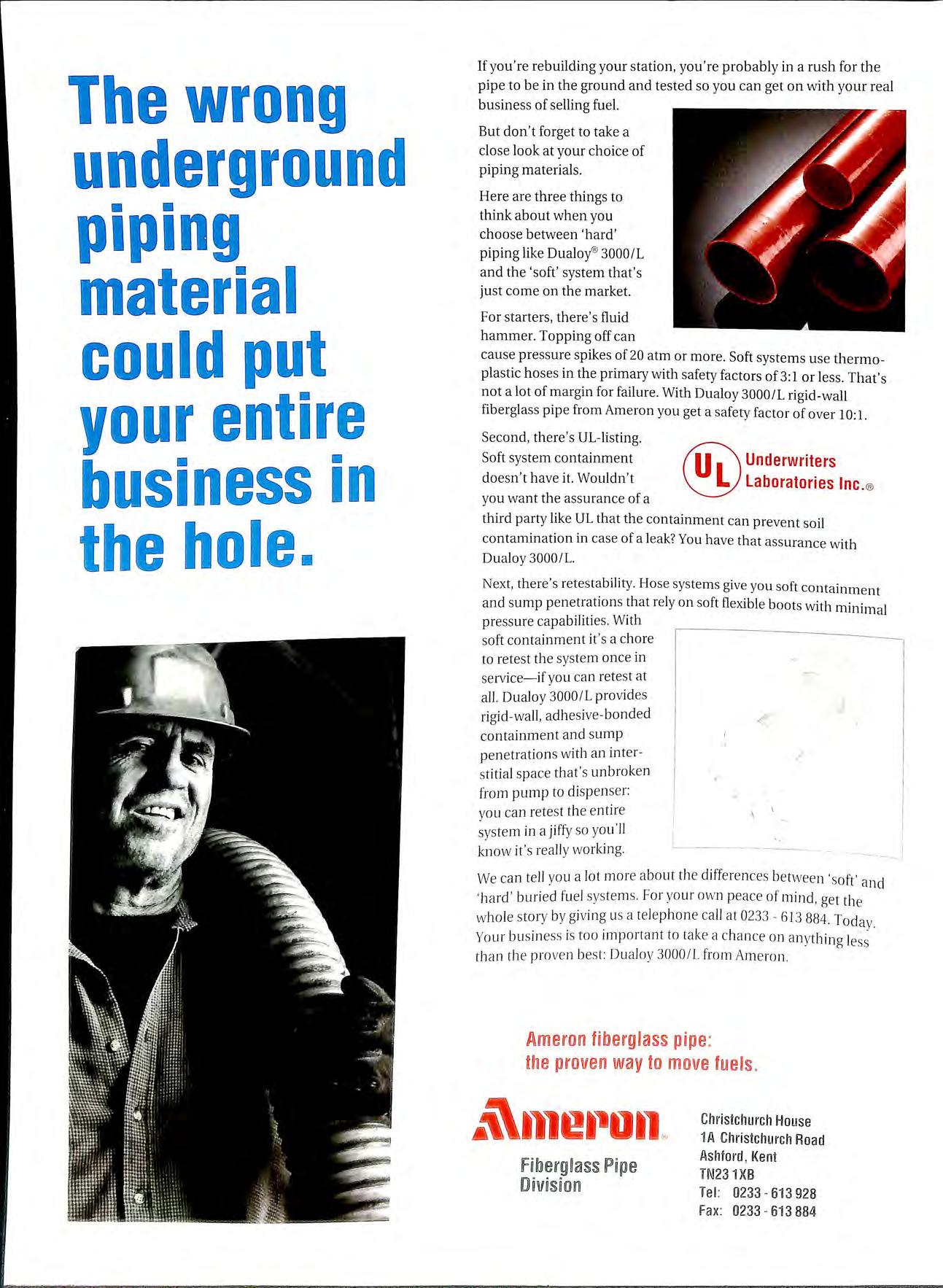

The wrong underground piping material could put your entire business in the hole.

If you're rebuilding your station, you're probably in a rush for the pipe to be in the ground and tested so you can get on with your real business of selling fuel.

But don't forget to take a close look at your choice of piping materials.

Here are three things to think about when you choose between 'hard' piping like Dualoy®3000/L and the 'soft' system that's just come on the market.

For starters, there's fluid hammer. Topping off can cause pressure spikes of 20 atm or more. Soft systems use thermoplastic hoses in the primary with safety factors of 3: 1 or less That's not a lot of margin for failure. With Dualoy 3000/L rigid-wall fiberglass pipe from Am e ron you get a safety factor of over 1o:1.

Second , there's UL-listing. Soft system containment doesn't have it. Wouldn't you w ant the assur a nce of a

ril:'\ Underwriters Inc .@

third p a rty like UL that the containment can prevent soil contamination in case of a leak? You have th a t assurance with Dualo y 3000 / L.

/ we can te ll you a lot mor e a bo ut th e diffe re n ces be twee n 's oft' and ' h a rd' buri ed fu el sys te m s For yo ur ow n pe a ce of mind , ge t th e whol e s to ry by giving us a tel e phon e call a t 0233 61 3 88 4. To da y Yo ur bu s in ess 1s too importa nt to ta ke a ch a n ce on an yt hin g les s th a n t he pro ve n best : Du a loy 3000 /L fr o m Am e ron.

Next, ther e's re tes ta bili ty Hos e sys tems give you soft containm e nt and sump pene tration s th a t rely on soft flexibl e boots with minimal press ur e capabilities. With soft containment it's a chore to re test th e sys te m once in se rvice-if you can re te s t a t a ll. Dualo y 3000 / L pro vid es rigid -wall , adhe sive- bonded containm e nt a nd sump p e n e tration s w ith an inte rs titial s p ace th a t' s unbrok e n from pump to di sp e n se r : yo u can re te s t th e e ntire sys te m in a jiffy so you '11 kno w it' s reall y workin g Amernn fibergiass pipe : Urn prnven way to move h.rnis . Christchurch House 1A Chri stchurch Road Ashford , Kent Ti\123 1)(B Tel : 0233 613 928 Fa)(: 0233 613 884

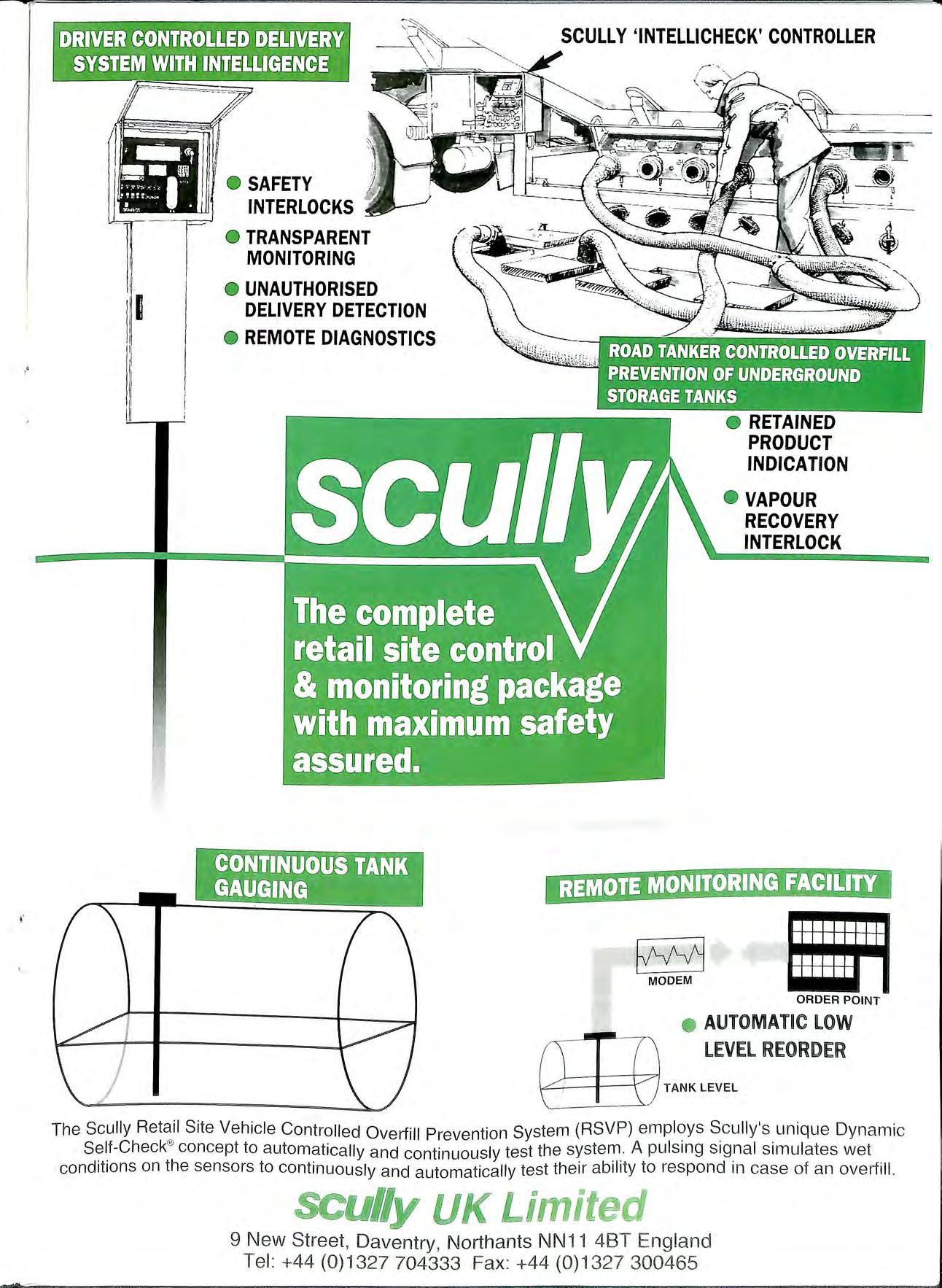

,• SAFETY J INTERLOCKS Q.; 0 TRANSPARENT MONITORING UNAUTHORISED DELIVERY DETECTION O REMOTE DIAGNOSTICS SCULLY 'INTELLICHECK' CONTROLLER MODEM RETAINED PRODUCT INDICATION VAPOUR RECOVERY INTERLOCK ORDER POINT e AUTO MATIC LOW LEV EL REORDER TAN K LEVEL The Scully Retail Site Vehicle Controlled Overfill Prevention System (R SVP) employs Scully' s uniqu e Dyn a mi c Self-Check®concept to automatically and continuously test the system. A pulsin g si g na l simulates we t condi tions on the senso rs to continuously and automatically test thei r ability to respo nd in ca se of an ov erfill. ta .I ited K 9 New Stre et , Daventry , Northants NN 11 4 BT En g land T el : +44 (0 ) 1327 704333 Fax : +44 (0) i 327 300465

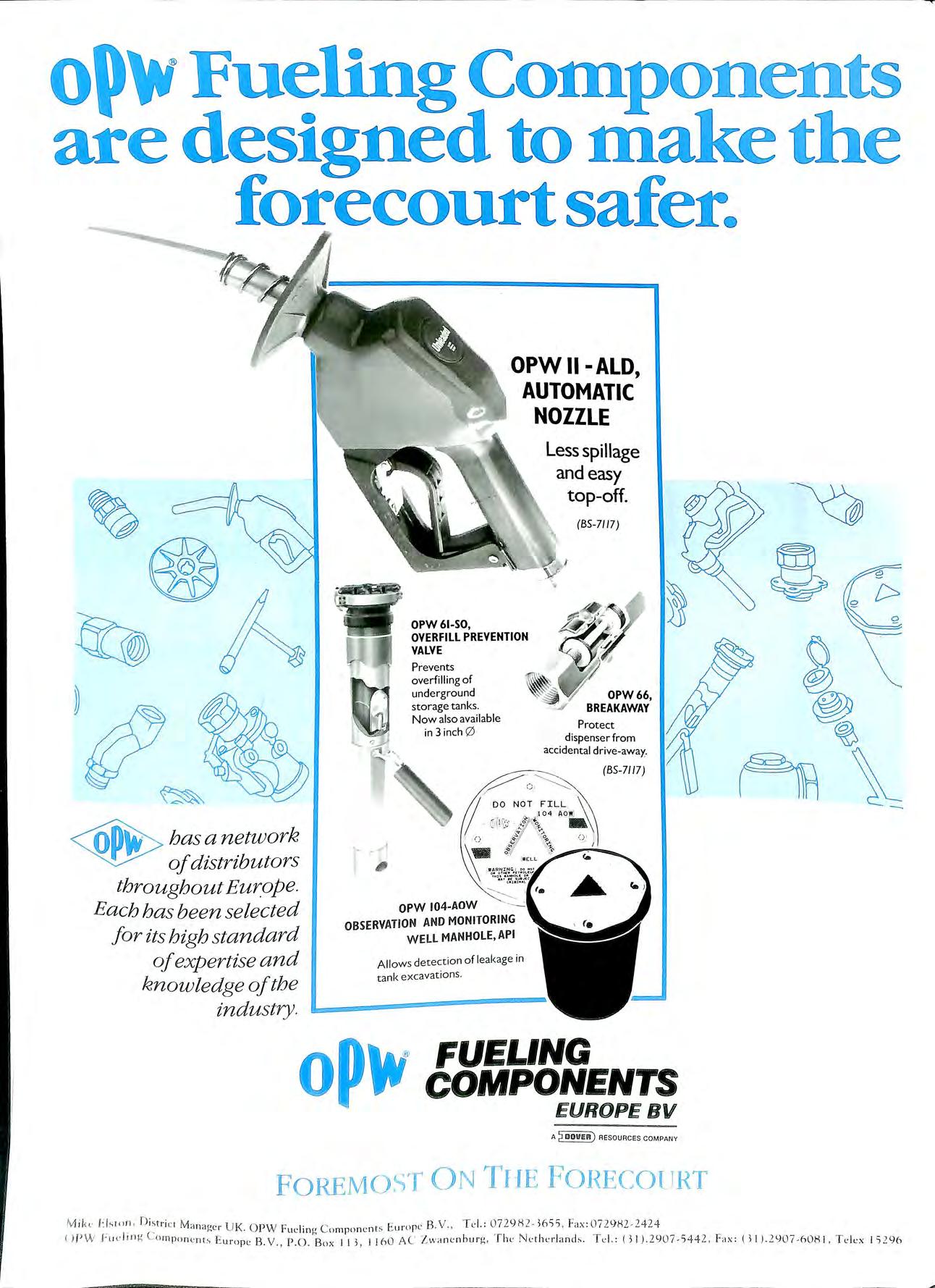

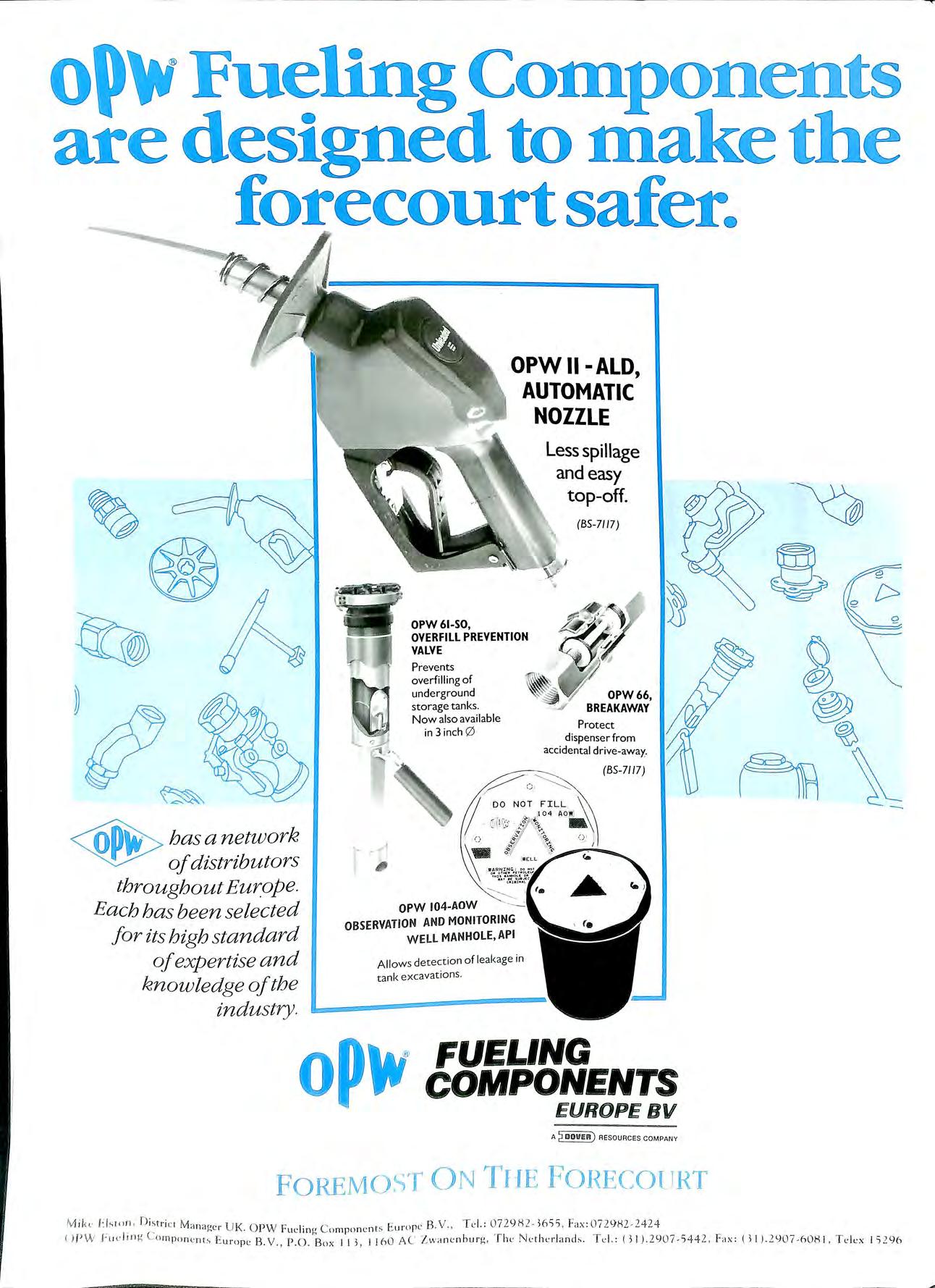

OPWll-ALD, AUTOMATIC NOZZLE

OPW61-SO, OVERFILL PREVENTION VALVE

Prevents ove rfilling of underground st orage t anks. N ow also available in 3 inch 0

has a network distributors throughout Europe. Each has been selected for its high standard ofexpertise and knowledge ofthe industry

Allows detection of leakage in tank excavations.

Less spillage and easy top-off. ..

( BS-7117)

OPW66, BREAKAWAY Protect dispense r from accidental drive-awax(85- 71/ 7)

pw

iv

are

c

to

FUEi.iNG C OMPONENTS EUROPEBV A 2D01fEP1 ) RESOURCES COMPANY FOREMO ST O N TI IE FORECQl IRT M ik '" 1'1' 1 11 Ma nar:c r U K O P W Fuc lin g Co mp o nen t' Euro pl' B V ., T c l. : 0 7 29 K2 365 5, Fa x : 072 9 1'2 · 24 24 ( JP W h H' ling C o mpon e n t' E ur o pe B. V., p .O. Bnx I I 3, I 160 A C Zw a n c nbur g, T he Ne th e rland >. T c l. : ( 3 I ).2 9 07 · 544 2 , Fa x : ( l 1) 2 9 07 608 1, T elcx I 5 2 911

JAMES LUKE AND ASSOCIATES Safety & Training Consultants to the Petroleum Retail Industry SALUKI HOUSE Postbox 41 BILLINGSHURST WEST SUSSEX RH14 ovo Tel: 01403 871471 Fax: 01403 871425 J obn OOlligfull & ([o. 1Ltb. Comprehensive service for liquid fuel & LPG installations Consultancy, design, installation, maintenance, decommissioning & gas-free certificates Pressure Systems Regulations Surveys FIRST HANGINGS BIABYROAD ENDERBY LEICESTER LE9 SAQ Tel 0533 862287 Fax 0533 751232 MEMBER APEA, LPGA, CORGI REGISTERED TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET LONDON E2 6QQ Tel: 071-739 9538 Fax: 071-729 6108 MEMBER A.P.E.A. D DC BUILDERS LTD FOR SERVICE QUALITY & RELIABILITY WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D D C BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL ILFORD ESSEX IGS OPA Teh 081°550 5216 081 =550 6095

and groundwater

with petroleum products at your retail site

you

?

treatments for contaminated soil and groundwater can remove the hazard

interruption to business. Site investigations, fully-costed remedial proposals, specialist treatments and

of petroleum contamination. For a free confidential consultation and/or site visit please call Peter Vernon

our

IBI 11 Biotal Limited, 5 Chiltern Close, Cardiff, CF4 5DL, UK. Tel: 01222 766716 Fax: 01222 766945 RIETIERG DOUBLE WALLED SAFETY CONTAINERS Rietberg Containers for Hazardous Liquids r---------------, Suitable ta feed or collect, store and trans· port inflammable and other water polluting liquids • Double walled steel construction • Inside and outside hot dip gaivanised • leakage indicator • Explosion blast proof• Volumes from 80 I up 10 ?SOO I • Permission for transportation on roods (ADRI and rail (RID) • Various designs to meet your demands • Options complete stainless Hazardous liquids Container steel consrruction, acid proof inside cooling • Models available Fuel Container the mobile perrol station Chemical c . d liquids 5 onta1ner · for fresh Chemicals, Hazar ous Container h d , .vaste ad and other .voter polluting l1qui s Please contact U' ' or further information SEPPELEf!!i_IJ.U_!_PE RiffBf Rf ,WERKE GMBH & CO 'i' Jf >TP >5 D KG 01 BMINt 33397 RIETBERG !El (0 52 44) 9 83-0 FAX (0 '.>2 441983 2 TRAINING IN-COMPANY

Fle.xible

to meet your requireme11rs at competitive rates • Electrical

Petrol

Stations

• Electricity at Work Regulations 1989 • Inspection and Testing of Electrical Installations l'resenter: TERRY

DA. FIEIE. MIOA Original author of the highly successful IEE 15th Edition 2-day short course Phone: 0737 553328

e

to

requirements

e

based

e

AND TEST CERTIFICATES based on model in BS 5266: Part 1: 1988 FIRE ALARM SYSTEMS: e INSTALLATION & COMMISSIONING CERTIFICATES based on model in BS 5839: Part l: 1988 e CERTIFICATES OF TESTING based on model in BS 5839: Part 1: 1988 £9.87 [ £8.40] +VAT per pad e PRACTICAL GUIDE TO ELECTRICAL INSTALLATION TESTING £16.95 Prices include p&p Order with cheque payable to· UNEEDA PUBLICATIONS, 5 HIGHWOLD, CHIPSTEAD, SURREY CRS JLG Complete the coupon and we'll introduce you to the most advanced, effective techniques for combating subsurface contamination. With a unique range of processes including German and American technologies. Miller Environmental specialise in the investigation and removal of pollutants such as petroleum products. solvents and chemical contamination. our methods are fast cost effective. safe and designed not to 1-nt ' errupt your business. Miller Environmental Miller House Whitwood Enterprise Park Whitwood Lane Whitwood, Castleford W Yorks WF10 SPX Telephone: (0977) 555427 Fax:(0977)555684 MILLER MILLER GROUP-CIVIL ENGINEERING-CONSTRUCTION DEVELOPMENTS-ENVIRONMENTAL-HOMES-MINING -·--------Name ______________ _ Company ____________ _ Address fel 8 '<.l

Soil

contaminated

Are

concerned about your site

Biotal's

without undue

sound advice on all aspects

on

helpline.

SHORT COURSES

a"a11geme11ts

requirements for

Filling

(New HSE code HS(G) 41) • 16th EDITION IEE WIRING REGULATIONS

HEDGELAND

PETROL FILLING STATIONS:

CERTIFICATES OF ELECTRICAL INSPECTION & TESTING

HS(G) 41 & LACOTS

EMERGENCY LIGHTING:

COMPLETION CERTIFICATES

on model in BS 5266: Part 1: 1988

PERIODIC INSPECTION

A. J. Bayliss (Stourport) Ltd Petroleum Engineers Petrol, Fuel Oil and Electrical Installations Urtitlcs.teSo FM 275 12 11/12 HODFAR ROAD, SANDY LANE INDUSTRIAL ESTATE ' STOURPORT-ON-SEVERN DY13 9QB TELEPHONE: 0299 824541-2-3 FAX: 0299 827638 SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS AND SERVICING FULLY ACCREDITED TO BS 5750: PART 2: 1987 §0 We do no t compro mi se o n quality where ..-\ env i ronmen t a l iss ues a re concerned. Interna l p ipework and ov erf low prevention valv es can be supp li ed, fitted and teste d at our w orks t o ensure the integrity of th e system. 1 -.e: . ' COOKSON AND ZINN .. ..: .: :_., ··.· Station Road Works Hadleigh, Suffo lk, IP7 5PN tel: 04 73 823061 fax: 04 73 824 i 64 j

Emco Wheaton Gold Valve? That will do nicely. The Emco Wheaton A1100 OPS is fast becoming the market leader Overfill Prevention Valve VERSATILE. Can be installed in any position within a full 360 degree rotation, without any risk of fouling suction pipes etc simply the best valve all round! DURABLE. Floats are internal and protected by a metal shroud which prevents damage during installation or inspection. FAIL-SAFE. In the event of the valve not resetting , it will close during the next fill, preventing a dangerous and costly overfill other valves can fail in the open position VAPOUR TI GHJ. Emco Wheaton have not had to introduce a bottom seal recently, because the A1100 valve has always been fitted with one. DIPSTICK FRIENDLY• Dipstick can be used whether tank is full or empty. FAST SERVICE. The A1100 is assembled and tested in the UK. Therefore we are able to respond quickly to demands from our two UK stockists For further information on the Emco Wheaton range of products for Service Sta tions, plea se contac t; Ged Norris at our Did cot sal es office : ® WHEATON ', / -J""""'" / ' NASH N I t e rs h ip w ith th e as i & Pa rtne rs have bee n wo rk m g 111 pa 1 11 R I s p la nni n g a nd e ta il Pe tro le um indus t ry for a lm ost t iir ty yea i ' d I · I t fo r wa rd pump eve o pm g re taj l ins ta ll atio ns fr o m a s tra1g 1 cha nge to Euro pe's la rges t fi llin g s ta ti o n. E d. d s ur vey in g, very s te p of the way, fr o m feas ibi li ty stu 1es an . ke ca re o f eve t y p rojec t m a na ge m ent an d co mm iss 1o rnn g , we ta d t 1 · d v id u a l d ea le i, e a i · Whe the r a m a jo r o il co m pa n y o r a n 111 1 t q u a lity a nd o ur cli en ts a re ass ure d of the Nas h co mm itm e nt 0 ad he re nce to BS57SO, bac ked by up -to-t he -minute tec hn o logy, in n ova fion a nd expert ise. F II fon Nash & rorn a g ree nfie ld s ite to a fu ll y opera ti ona l 1. nsta a 1 Parh1 ers de live r c rea ti ve ye t hi g h ly p ra ct ica l so lu t io ns. • ARCHlT ECTS + SU IWEYORS PLA NNERS MA N AGERS CONSULTANTS Emco Wheaton UK Limited 12 Station Ro ad, Did cot, Oxon, OXl 1 7LN Telephon e: 0235 510888 Fa x: 0235 510524

GCS NationallnspectionCouralfot 8actric:al lnstallction Contracting • •lll: EIG APPROVED CONTRACTOR G c s a rage onsultancy ervices Ltd Cert. No. FM 23290 UNIT 10 MERTHYR TYDFIL INDUSTRIAL PARK PENTREBACH MERTHYR TYDFIL MID GLAMORGAN CF48 4DR TELEPHONE (0443) 692008 FAX (0443) 692159 FUEL PUMPS AND TANKS FUEL MONITORING AND METERING EQUIPMENT PROJECT MANAGERS/ENGINEERS We are delighted to inform you that the British Standards Institution has approved our Quality Management System and awarded us BS5750 Part 2 Creditation. ·-·-·-·-·-· We shall continue to assess and inspect our Quality System to ensure that we meet the rigorous demands of our industry 1973 21 YEARS OF SERVICE TO THE PETROLEUM INDUSTRY 1994 j

ED WARDS (Tank Removal) Ltd THE COMPLETE FUEL TANK SPECIALISTS PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED SER VICES IN CLUDE: • Gas Free Certification • Tank Removal - Disposal • Cotd Cutting • Hot Cutting • Butk Fue/ Uplifting • Slurry Fitr • G 1ng • 8 arage Demolition • 8 attte Plate Cutting • Fi asement Tank Removal oam lnerting Ace ALL WORK IN STRICT WITH CURRENT SE AND PETROLEUM REGULATI ONS We spec iali se in the remo val by co ld cutt ing of so li d fill ed tanks and dispo sal of these tanks from site. EDWARD§ (Tm11k RemovaO LTD 11 3 0 CHURCH § TREET9 CROYDON 9 §URREY9 CRO !RF mn 686 9775 mn 680 1890

fuel delivery. Total secondary containment for suction or preS$Ure system$, or Monotlex for direct suction systems. Easy to insteill amd maintain, compatible with all fuels and additives currently on the market. UL listed

PETROl-LINc: For ofrfset-fill, vent and vapom recovery. Robust and easy to use, ,this leak-f.ree petrol and additive resistant system is based on Durapipe's patented electrofusion jointiAg method.

NEW from and

SUPPLIED' BY THE OFFICIAL DISTRIBUTORS - for further information on either, or both, of these products call FORECO URT EQU IPMENT SPEC IA LI STS PURFLEET COMMERCIALS LIMITED 520 London Road West l'hurrock Essex RM 16 1BE Te l: (0708) 863931 Fax: (0708) 868226

It you were losing .4,000 chocolate bars a year

•••

This is what 0.1 % fuel loss represents to a typical forecourt operator. Most sites are losing many more times this amount each year!

PetroVend 's SiteSentinel forecourt monitoring system guards against wetstock loss, leaks , theft, short deliveries to mention just a few!

It tells yo u through accurate printouts an d easy to understand graphical analys is , not only how much fuel yo u are los ing on a day by day basis but indicates where in the sys t em th e loss is.

It is a modular sys t em that ca n be t ai lored to yo ur prese nt needs and expanded later.

SiteSentinel is already proving a winner in Ameri·c b a eca use it is easy to under stand and use, and pays for itself in real · savings .

SiteSentinel

... you'd past a guard! In one package SiteSentinel offers you: T Automatic Inventory T Auto gCalibration Petra I/end ... AutogReconciliation PetrnVrem KI Ud ,, Appn:rved Tarnk TesUri!g Every Day 76 Leeds Roa d, Newton Bar , T leak Detection Wake fie ld, Wf1 20F TEL : (0 9 2 4 ) 291919 'Y Trend A01aiy sis Package FA X : (092 4 ) 37 6 511

POWERED BY EXPERIENCE ELECTRICAL SERV CES & PROJECTS LTD SPECIALIST ELECTRICAL ENGINEERS &CONTRACTORS TO THE PETROLEUM INDUSTRY • Close-circuit TV • Fire Alarms & Emergency Lighting • Planned Maintenance e Inspection & Testing • Forecourt Earthing Systems l 'Y'J MEMBER \tY' OF A.P.E .A 1 /x Elecf17·m/ Co11tmctors' Assa-il'1tio11 IUoG ISTioRED MEMBER ECTRICA S RVICE & RO Nalional Inspection Council for Efectrica\ Installation Contracting • •1c&1c APPRCMDCONTRACfOR HEAD OFFICE : PROJECT HOUSE · THE DRIVE · WORTHING · WEST SUSSEX · BN11 SLL TEL: 0903 700321

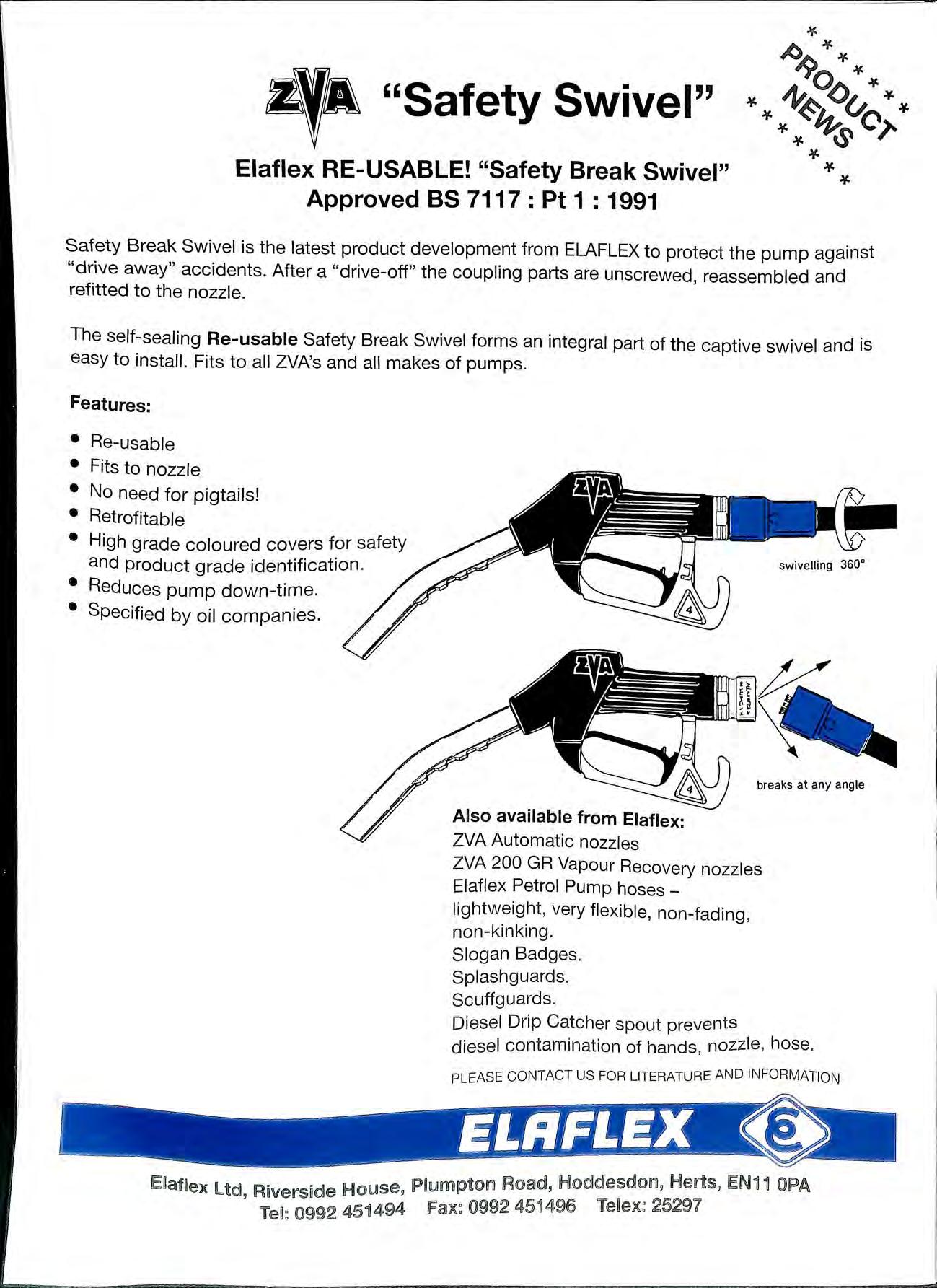

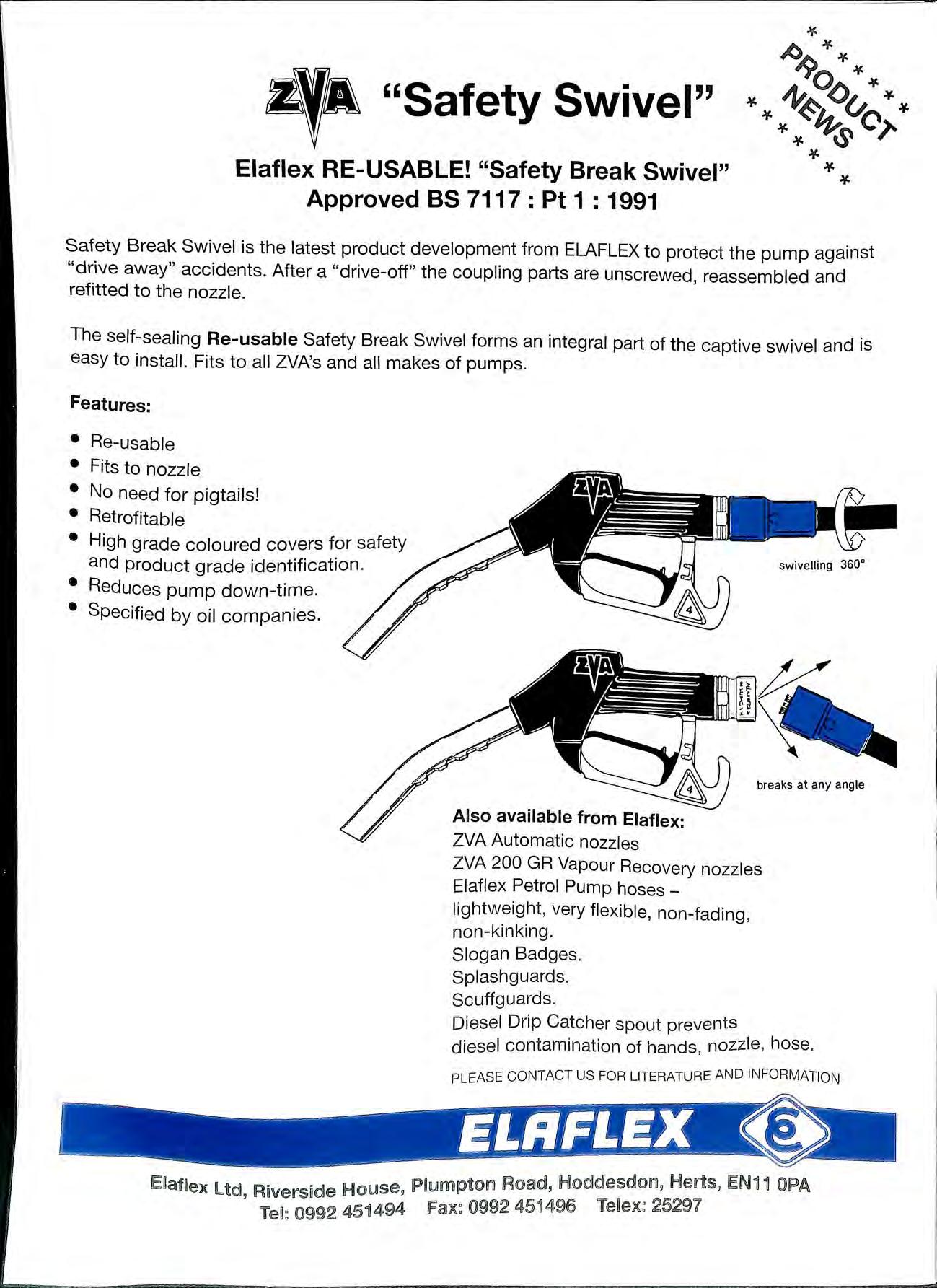

dfA "Safety Swivel" Elaflex RE-USABLE! "Safety Break Swivel" Approved BS 7117: Pt 1 : 1991 Safety Break Swivel is the latest product development from ELAFLEX to protect the pump against "drive away" accidents. After a "drive-off" the coupling parts are unscrewed, reassembled and refitted to the nozzle. The self-sealing Re-usable Safety Break Swivel forms an integral part of the captive swivel and is easy to install. Fits to all ZVA's and all makes of pumps. Features: • Re-usable • Fits to nozzle • No need for pigtails! • Retrofitable • High grade coloured covers for safety and product grade identification. • Reduces pump down-time. • Specified by oil companies. breaks at any angle Also available from Elaflex: ZVA Automatic nozzles ZVA 200 GR Vapour Recovery nozzles Elaflex Petrol Pump hoses lightweight, very flexible, non-fading, non-kinking. Slogan Badges . Splashguards Scuffguards Diesel Drip Catcher spout prevents diesel contamination of hands , nozzle , hose PLEASE CONTACT US FOR LITERATURE AND INFORMATION I - -- ---- --- -- - ---------=,,,.. -- -. i .,,, _·:. _- -=- ::___ :. -·__ ___ _

Talking Point

In the UK all parts of the Industry are waiting to see if the much heralded De-regulation initiative produced by government comes to anything. We heard last year at our AGM the aspirations of the Industry and the HSE on this initiative and how things will have to change. Almost 12 months since that initiative the talk has been of organising committees, holding meetings and producing a series of guidance documents to replace HS(G)4 I, but the process is proving far slower than many expected. The talk of legislation changes within 2 years is now being realistically chancred into a 5 year programme. The first documents were0 supposed to be produced in the first quarter of 1995 but many of the have yet met. To ensure that the cruidance is wntten to the time scales, not only should be a willingness to but there should also be a commitment of staff and time by Industry.

VOLUME33 Number 1 FEBRUARY 1995 £8.00 (Free to Members) Contents TALKING POINT NOTES&NEWS PROSECUTIONS The Bulletin Published by the Association for Petroleum and Explosives Administration A company Limited by Guarantee registered in England No. 2261660 ISSN 0263 4597 2 7 Opinions expressed in this Journal are not necessarily the views of the Association

ABOVE GROUND TANKS BELOW GROUND TRACER TIGHT TESTING 9 12

NEW OVERFILL PREVENTION VALVE TRAINING COMMITTEE LETTERS TO EDITOR NEW MEMBERS 13 14 15 16 IRISH BRANCH EASTERN BRANCH MIDLAND BRANCH E. Riney Mrs B. Jacketts L. Lloyd Texaco Ltd Cookson & Zinn Ltd Veeder Root ADVERTISING SEC. HUMBERSIDE BRANCH NORTHERN BRANCH R. G. Green P. C. Lusmore M. Silman Honorary Secretary: Mr. D. Bucknall Honorary Editor: Mr .J. A. J. Thompson. NORTH WESTERN BRANCH H. Reid Pump Services (Manchester) Ltd SOUTHERN BRANCH J. Luke Membership Secretary: Mr. B. J. Thompson

TANK TESTING

A review by one of the petroleum licensing authorities recently found out that of over 800 installations tested during a 12 month period (routine testing due to age), using precision testing systems 12% had failed and of these failures 28% were from the tank and fittings, and the remaining 72% were from associated lines.

This has confirmed the wide held experience in most parts of the country that the lines cause the biggest problems, and these figures certainly has proved the worth of a precision testing programme.

One disturbing fact from the review revealed that one of the proprietary precision tank testing systems which had been certified as complying with the US EPA had yet to fail a single tank. It had also since discovered that some of the tanks tested using this system had afterwards proved to be leaking.

EUROPEAN PETROLEUM

ENGINEERING

CONFERENCE AND EXHIBITION BERLIN 6 & 7 APRIL 95

The Association is moving into Europe this year by working with Expoconsult at the Major petroleum engineering show in Berlin on 6 & 7th Apnl. !he APEA is arranging and chairing the conference and an Interesting line up of speakers on the European petrol station have been oroanised for Thursday afternoon and Friday morning. 0

The APEA have also arranoed special rates with the German Tourist Service for s;heduled flights three nights accommodation at £284 per person. This. enable · · d h"b ton to not visitors to the conference and three ay ex 1 1 1 . only visit the conference but have time to see the s_ights of Berlin. These rates can be booked by contactm_g German Tourist Service on O1992 456111 and mentwmng the APEA.

PIPE JOINT PROBLEMS

The London Fire Brigade has recently experienced problems with leaking pipe joints on polyethylene pipework.

The thermowelded joints which have been successfully used in the industry in recent years were on offset fill pipes installed over railway lines.

In two separate installations the joints failed after the installation was in use for some time and product escaped from the joint. The installations due to their position were secondarily contained and had leak detection installed which alarmed as the product escaped. There is concern that other joints not monitored by leak detection may also be leaking.

In both cases the joints were found after excavation and a subsequent investigation revealed the following:

I. The welding had not taken around the joint. This indicated insufficient or no preparation of the pipe work to remove oxides from the pipe to ensure fusion to take place. This is normally prepared using abrasive paper or a scraper.

2. The fusion indicators on the pipe joint had not "popped out".

3. In these cases the normal pressure test of 0.5 bar had not been enough to find these leaks during testing before backfilling and use.

a result of these findings the London Fire Brigade has reqmred the following:

I. All joints which do not have fusion indicators showing to be rejected.

2. P.E. pipe to be tested to I bar which should indicate such failures.

D ·1

·b· · an be obtained eta1 s of the conference or exh1 1t1on c . f from either the Hon Secretary or Marianne Heemsktrk o Expoconsult 01031 3465 73777.

YEAR BOOK 1995

Me b II received their m ers of the Association will have_ a . . a '. 9?5 Year book which it is hoped they w1ll hnd useful as. 1eleren. b b k has once a 0 am b ce ook as well as a diary. The oo · "' een p . d bei·s and was . 10 uced free of charge to mem · 1esearch d b Should any e Y a small group ot voluntee1 s. member h· . . h t pomt to any 0 ave any suogestions or w1s 0 d · Ym1ss1ons please use the page in the year hook to sen m our comm d b 1· re the next year. ents which will be considere · e 0

B AIPREMA CONFERENCE EXHIBITION INGHAM

The dates for the Conference and Exhibition for J 995 ii I J w and 26 September 1995. Please note these dates 111 "' 1111 diary.

3. Manufacturers to encourage contractors training and courses to ensure joints are prepared, mstalled and tested in the proper manner.

As with most site work the product installed is only as good or bad as the contractor who installs it.

THE WAY FORWARD

D. M. Petroleum Services have been assessed and registered by National Quality Assurance Ltd, to B.S.EN ISO 9002: 1994.

As one of many small installation companies we felt that creclitation is an acknowledgement of our commitment to quality in all aspects of our activities, says company Proprietor David Major..

ISO 9002 that demand is met. and we will continue to maintain this standard.

notes & news

ANNOUNCES SETTLEMENT OF LONG CONTESTED PATENT INTERFERENCE

On September 29, TCI announced that it had received an unfavourable decision from the Patent and Trademark Office regarding its U.S. Patent No. 4,971,477 coverino o• among other things, the retractability feature of its Enviroflex™ piping system. This decision, of the interference procedure, could have been appealed to the Federal Courts delaying a final decision for several years.

However, TCI is pleased to announce the settlement of this action with the opposing party. The settlement provides for the granting of an exclusive, world-wide license to TCI for the practice of any and all inventions covered by the opposing party's patents, patent applications, and continuations, in exchange for TCI abandoning its rights to appeal of the aforementioned decision. The opposing party will retain rights similar to those granted to TCI. The opposing party is also required to terminate its existing license with Ameron and Ameron's sublicensee, Environ. Consequently, only two companies, TCI and the opposing party, will be active in the double wall flexible retractable piping systems market. This agreement will also release any past or future end users of the Enviroflex System of potential infringement liability.

For the granting of this exclusive license, TCI will pay opposing party $5.45 million, approximately $1.5 m1lhon of what will be in Total Containment common In addition, a royalty of 3% on future sales of Env1roflex Systems will be paid. This royalty is similar to the 3% royalty that TCI currently pays to the co-owner of the "477" patent. These royalties will be discontinued, as the patent is expected to be abandoned. TCI will also advance $1.5 million to the opposing party as a prepaid royalty.

This $5.45 million will be capitalized as a license under long-term assets of the company and amortized over 17 from the date of issue of the related patent. Simultaneously, the Enviroflex Patent carried on the books of. Con:ipany at. a value of $1.2 million (after tax of $1.0 million) will be wntten off in the fourth quarter.

!CI's .believes that the settlement of the act10n and the acqms1tion of this L' . . . . , 1cense 1s an important step 111 preservmg TCI s market sh· and profitability in th .ire, g10ss profit m,ugms e commg years.

Total Containment, Inc d . . underground systems a d · esigns, engmeers and sells · n products fo · tl containment of petroleum d 1 1e conveyance and an alcohol b· d h' 1 fuels from underground storaoe .ise motor ve 1c e d · ·· · 0 tanks to above oround fuel 1spense1s. ""

EMPHASIS ON QUALITY AND CUSTOMER SERVICES PAYS OFF AT S.T.M.

It has been a good year for S.T.M. Ma111 te 11 1 • S . . . ' 'nee erv1ces with the awards earlier 111 the year of the F' ,. · . . d 111.i sign an covering 280 Jocat10ns. s sign and Maintenance Contract covenng 240 locat10ns and Conoco's lmaae Maintenance Contract covering a further 200 locations. ""

And during November they were awarded the coveted Company of the Year Award for Yorkshire and Humberside presented by the Commerce Business Magazine.

Sean Kearney Sales Manager for S.T.M. recently interviewed on the BBC Radio Yorkshire business programme puts their success down to the companies commitment to quality and customer service. He says "We see the Company of the Year Award as a benchmark of the of our adopted policies and business practices m relat10n to other companies".

PETROLEUM EQUIPMENT INSTALLERS & MAINTENANCE FEDERATION

The Petroleum Equipment Installers and Maintenance Federation was founded to establish and promote oood working practices and common standards within ° our industry, by working with the legislative bodies, providino support and guidance from a firm and practical Current membership exceeds 25 independent installation/contracting companies. The present committee is set up as follows:-

Chairman Mr John Jepson, Dunkerleys 0614569090

Secretary Mr Joe O'Reilly, Pump Services 061 873 7428

Treasurer Mr Jeff Young, Delpetro 0244 520731

Committee Mr Colin Thomas, Ronco! 0492 623787

Committee Mr Melvin Chunn, Camerons 0226 742441

Considerable progress has made by our _committee over the last twelve months, makmg representat10ns the Health and Safety executive, the A.P.E.A: and the In.st1tute of Petroleum; and just recently by havm? in Liverpool with Dr. Andre"". Cottam, the ch1et P?hcymaker H S E He shares the view that our Federat10n should at · · · f h f h · now obtain representation one o t e ort commg Technical Policymaking Comnuttees.

Our Federation has received feedback from local authorities and Officers, who see the collective expertise and expenence: based on good sound k 0 practices in construct10n. installation and wor m,,, ' · servicing. as very welcome.

Commercially the future is beginning to look more ·ao111 o for our industry. and the P.E.l.M.F. will encou1 "' ,,,, . t. ie to 1110ve forwards to develop and co-orclmate the con 1m installer's '"voice". so that we may be heard.

Membership continues to grow and we need more. so if you feel you as an installer or contractor. ha\'e something to contribute. or want to knmv more. plcasl' nllltact our Secrt'tary Mr Joe O'Reilly. c/o Pump Senicl's at Manchester on 061 87 .1 7428.

TOTAL CONTAINMENT, INC.

NORTH WESTERN BRANCH MEETING

On July 27th 1994, thirty-two members attended the North West Branch meeting at The Firs, Bowdon, Cheshire.

Harry Reid made a presentation on the structure and organisation of the new guidance system to be put into operation following the HSE recommendations. The presentation covered the structure, objectives and composition of the four new bodies that will be responsible for the production and implementation of new guidance to the Petroleum Industry.

members of the meeting represented the full range of mterests w1"th1"n · d · our m ustry ie· Petroleum L1censmg A th . · ' u manufacturers, installers, consultants and oil Not surprisingly, a very lively debate took place on this new structure and its implications to the industry. It would be to say that there were very diverse opinions on the ments of this new set of organisations but the area concerned all members was the 'question of implementation of the guidance. The change in direction from pr · · · escnptive gmdance to a system of risk assessment many members. There were those who wished to strict guidance measures to ensure national umfonnity in standards, whilst others wished a more risk assessment or similar based guidance system whic?. could allow local site variations to suit local conditions.

The one clear point to come out of the discussion was the. Licensing Authorities intend to pass the pons1b1hty to the contractor and licensee which would fundamentally change the approach and relationship b between these parties. As the discussions continued it ecame · b · ' . qmte o v1ous that the Petroleum Licensing Authonty representatives were more enthusiastic for this new structure than the rest of the industry.

HReid Secretary _ APEA North Western Branch

EASTERN BRANCH AGM

T The APEA Eastern Branch plan to hold their AGM on 7th March 1995 in Needham Market, Suffolk. C ter the business meeting/election of officers, Dr Andrew 0 ttam w·11 · · 'HSE' · P t I G . 1 give a presentat10n on s e ro eum uidance the new arrangements'. Also, following their at the Eastern Branch Meeting of the I 3th 1994 on HS(G)4 l, Mike Lugg and .Barry Lo:we P date members on the progress of thetr respective committees.

There we h u bi re several requests from members w o were na e to att d c J . Th en the September meetmg. 1or am1e t <t)hmpson to repeat his slide presentation on bygone days 0 e petrol · 7 th M eum industry. This he has agreed to do on the arch. · ·

If you wish lo attend or would like more information, please contact Barbara Jacketts. Secretary/Treasurer APEA h1stern Branch. c/o Cookson and Zinn Limited. tel: 01473 X.:? HJ6 I A!temlance fee £6 (incl tea/coffee/buffet lunch).

MORE CASUALTIES OF FIREWORK ACCIDENTS

An Ashby man became the first person in Humberside to die in a fireworks tragedy since 1974 when he was fatally injured at his home last year.

The death of the 23-year-old chemistry graduate was among nineteen incidents in Humberside recor?ed on or in the run up to November 5, according to a council report.

In the report to Humberside's public committee, Eddie Furniss, the county's chief trading standards officer, says this is the highest figure since 1990.

"After three years of seeing a gradual reduction number of incidents requiring hospital treatment, it is disappointing to report a significant increase in 1994," he said.

In 1993, only nine people required treatment as a result of bonfire night accidents.

Disregarded

Mr Furniss said of the 1994 total, there were six street incidents the highest figure for five years.

"This indicates the Jaw forbidding the discharge of fireworks in a street or public place is still bemg disregarded," he said.

"There is a heavy penalty for such an offence, but it is clearly extremely difficult to enforce in practice."

Mr Furniss said the majority of incidents were of a nature and did not require the person to be detained in hospital.

"Sadly, however, the lead-up to November 5 saw a fatality in the county, the first since the department started keeping such records in 1974.

"A 23-year-old chemistry graduate was fatally when handling fireworks in the bedroom of his home," he said.

After suffering severe burns, he died in the burns unit of Pinderfields Hospital, Wakefield.

Mr Furniss said the incident was under investigation by the health and safety executive pending an inquest.

In the run-up to bonfire night, 73 joint visits were made by police and trading standards officers to shops 111 bid to get the message across that it is illegal to sell fireworks to under-16 's.

RAYFORD ACQUIRES ELF SITES

The Bayford Group of Bramham, near Wetherby. West Yorkshire has acquired 22 filling stations from Elf Oil (UKl Ltd.

All sites are situated in Yorkshire and will be operated under the Group's petrol retailing division. THRUST PETROLEUM.

The Group Chairman, David Turner commented "The acquisition increases the number of company owned sites. strengthening Thrust 's position as the county"s largest independent operator of filling stations. It is also another step in the Group's planned programme of expansion through continued growth and acquisition."

4

"NO DIG" TESTING SYSTEM PINPOINTS PIPELINE LEAKS

Precision testing system scores hole ill Olle at Total Oil service station in London

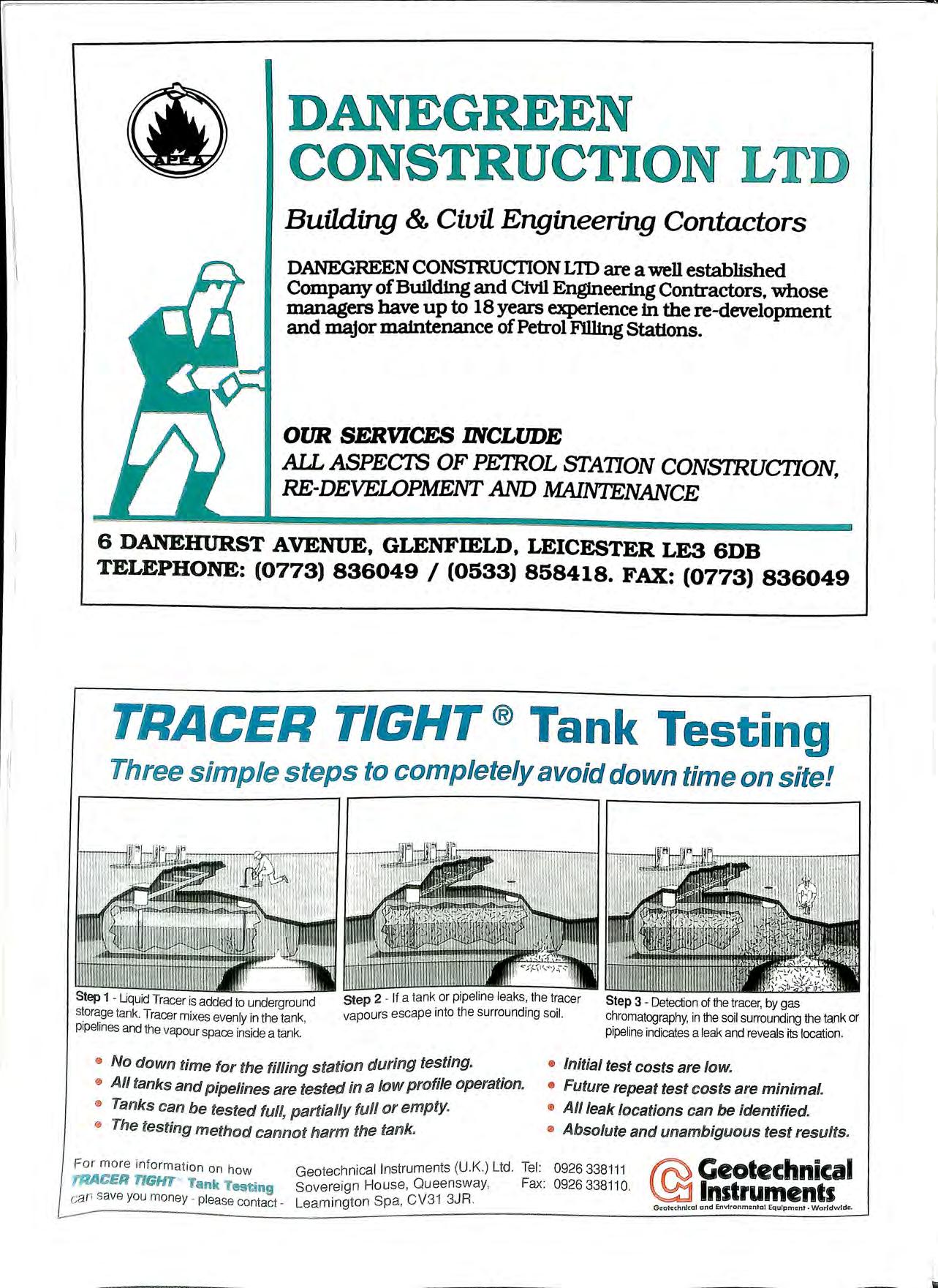

Since its UK launch in February this year, the "Tracer Tight" precision tank and pipeline testing system has notched up a series of successes in pinpointing leaks m pipelines, notably in petrol forecourt delivery systems.

The system, which has already earned acceptance from licensing authorities in virtually every county in the UK, is a significant improvement over conventional methods since it completely eliminates the need for unnecessary and costly exploratory excavation. It also allows tanks and pipelines to remain in service during the test apart, of course, from the line being tested. Pipelines carrying fuels, lubricants, heating oils, solvents, volatile or non-volatile chemicals and hazardous wastes can all be tested regardless of size or situation.

Tracer Tight in action

That the system works, and works well, can be clearly seen in the case of a contract recently undertaken for Total Oil Great Britain Ltd.

In June 1994, following a routine pressure test, Total was advised that a leak was occurring in a 30 metre long vapour vent line at their service station in Homchurch, Essex. Total naturally wanted to precisely determine the location of the leak in order to minimise the amount of excavation and disruption on the site and of course to reduce the cost of the repair.

Geotechnical Instruments (GI) of Leamington Spa, the sole UK licensees of the "Tracer Tight" leak detector system, was called in by Total and asked to locate the leak. The pipeline was capped at each end and a tiny amount of vapour -a highly volatile yet inert compound was mJected mto the line which was then pressurised to I bar.

GI then installed a series of 40mm diameter monitoring pomts to 0.5 depth every 3 metres along the length of the defective hne. When this was completed, some 2 hours later, the crew started to extract soil vapour samples from the points.

These samples were then subjected to on-site gas chromatography analys 1 · b T s Y racer Research Corporat10n, the mventors of the leak det f h . TI f. t round of sam 1 ec ion tee mque. 1e irs b . d P. es produced a positive result with tracer emg oun m two adjacent . . , . GI immediately install d . . momtonng pomts. d e an add1t1onal series of probes in this area an more vapour samples we. t k 1e a en and analysed.

From the resulting tracer conce t . t deduce the probabl . . n rations, it was possible 0 e position of the leak to a redicted accuracy of ± 0.3 metres and the coilci·et " p e 1orecourt was marked. accordmgly. Pmpointing of the leak had taken a total of JUSt 3 hours.

Proof that the operation had been succe. f I . h ss u was supplied later t e same . day when the forecourt was excavated. The leak was found to be a small hole in the pipe - within 0.3 metres of GI's mark on the forecourt!

The concrete-surrounded pipe was immediately repaired and put back into service. The complete leak location and repair had taken less than one day and the station continued to operate throughout thus ensuring that costs were kept to a minimum.

All work was supervised by and carried out to the satisfaction of the LFDCA petroleum officer.

Further details of the Tracer Tight system, including the loan of a free VHS video outlinina the method and its benefits, can be obtained on to Geotechnical Instruments on 0 I 926 338 I I I.

DCD

"Quest Engineering & Design Ltd have been awarded a £115,000.00 contract by Fina, the International Oil Company, to supply and install Driver Controlled Delivery and Tank Gauging Systems.

The equipment wiU be located at three Butler Fuel depots, at Foss Cross, Higham Ferrers and Wooler and the premises of A.F. Fuels, a Fina distributor at Penrith.

QED have been asked to handle the whole project, including design, build, installation and commissioning for all aspects of electrical, mechanical and civil works.

The project is being co-ordinated by QED's Gary Johnson."

NOZZLE TALKER GOES ON THE RECORD

This year will see the appearance of a new form of direct advertising on the forecourt. The NOZZLE TALKER™ is a flexible vinyl boot that. fits over the nozzle and puts an advertising mhto UthSeAhandd ?f consumer. It was developed m t e an is emg marketed in the U.K. by Trans Global Concepts

The company worked closely with the regu_latory authorities in 1994 to gain approval for the mtroduct10n of NOZZLE TALKERrM. It is the only f01m of 1 dveitising in the U .K. At the begmmng of 1995 nozz e a . d . . 1 several fuel companies are comm1tte to site tna s.

omplement and emphasize ex1stmg colour-coding for grades of fuel NOZ2:LE TALKERTM is available in a vaiiety of colours. To_ satisfy U.K. standards a f. t dant has been added which has been tested by ire-rear · . W · ton Fire Research Council and approved by a arrmg . . h .·. number of petroleum hcensmg aut 011t1es.

NOZZLE TALKERTM is easily .. boot fits I Over the handle without any mod1hcat1on of the snug y 1 · t·· · h k · · · · approved pump. s.m?oth, g. ma es 1t easy to clean and the material 1s 11nperv10us to g11me and weather.

The advertising message is silk-screened onto a styrene insert which is protected by a clear slip-on cover. This is a low cost process. which makes the use of NOZZLE TALKERn1 extremely flexible as the messages can be replaced frequently.

5

When you consider the billions of customer transactions on our forecourts every year and you multiply that number by two, which is the number of minutes that each customer is exposed to NOZZLE TALKER™ you begin to appreciate the power of nozzle advertising What is more the message is actually in the customers hand and cannot be ignored.

The fuel companies will use this new advertising medium in a wide variety of ways It will help stimulate impulse purchases in the convenience stores . Promote onsite services such as car wash. Encourage participation in company promotions. The space can even be sold to other retailers such as the confectionery companies who have already expressed their enthusiasm.

At _a time when margins on fuel sales are being squeezed ever tighter NOZZLE TALKER™ will be a valuable tool in the drive to intensify and diversify the profit potential of the fuel site.

If you want any further information about NOZZLE TALKER™ contact Duncan Duff, the U K representative of trans Global Concepts on 0181 968 5517 .

SITESENTINEL DOESN'T COST THE EARTH

PetroVend's fully integrated leak detection and tank aauaina system literally doesn't cost the earth.

b b b

SiteSentinel can save individual sites thousands of pounds in lost fuel, tank testing and repairs.

And the sophisticated system protects the environment against fuel leakage , keeping site managers ahead of tightening fuel management guidelines.

Flexible and easy to use, the SiteSentinel integrated monitoring system has full EPA, CENELEC and BASEEFA approval.

If required , it can test tanks every night to detect leaks immediately, rather than leaving them undiscovered for months awaiting the next annual tank test.

And its modular composition means customers only to purchase the elements suitable for them , offenng instant savings in exchange for minimal capital investment. A DCD option is also available.

Philip Prow, sales manager for Petro Vend (Europe), said: "Proper site management is critical, our system not only provides automatic calibration and reconciliation but indicates why they have occurred . The bottom line is added profitability and peace of mind.

"Testing tanks for leaks can cost individual sites between £1,200 and £2,000 depending on how many tanks they have that's before site disruption is considered.

" So it makes sense for site managers to think and insure themselves against such high costs by installmg a SiteSentinel sy stem.

"It"s al ready proving a winner in Americ a , where it has been thoroughly tried and tested and, with ever increas mg regulations such as HS(G)41 and commercial needs for tight inventory control , site managers really shouldn ' t be without it."

The system collects information through a serie s of tank probe s and leak detection sen sors i.e pump sen sors, vapour sniffer, interstitial sen sors (for double-skinned tank s) making it flexible enough to meet the requirement s of virtually any fore court.

SiteS e ntinel is al so an effective way of te sting pipes and lines a reg ular fi ve year requirement under curre nt guidelines

PetroVe nd ha s more th an 25 years e xpe ri e nce in fu e l mo nito rin g equipme nt and is a wo rld lead e r in a utomat e d fu e llin g sys te ms. Th e co mp a ny is ba sed at Wa kefi e ld in West Yo rk shire a nd Chi cago in th e USA

6

Prosecutions

A bulk oil storage company was fined £17000 by Magistrates in Grays, Essex, after they heard how a "?isastrous" permit to work system led to 7000 litres of highly flammable spirit spilling from an open pipeline.

The accident happened on 11 April 1994, when a road tanker anived at Duffryn Terminals' Purfleet site, which is registered under the Control of Industrial Major Accident Hazards Regulations, to pick up a load of high grade natural spirit (HGNS). As the pump used to fill the tanker was started up, HGNS began to flood out of the nearby drumming shed. It was later discovered that a valve used to seal the end of a pipe feeding HGNS to the shed had been removed by a company maintenance team.

The court heard that Duffryn was dismantling some of its facilities at the time of the accident. As part of this process, contractors were employed to ensure that certain pipes were empty spraying them yellow before the company's fitters recovered valuable headgear and valves.

The prosecuting factory inspector Adrian Billingsley told the court that the permits to work issued to the employees were vague. He said that they did relate to the removal of pipework in the drumming shed, but did not specify the HGNS system. He added that the company's permits to work often covered periods of a month, where 8 hours was the norm.

Duffryn Terminals entered a plea of guilty for failing to ensure the safety of employees under section 2( 1) of the Health and Safety at Work etc Act 1974.

Fining the company, presiding magistrate Mr Berwick Wood said that there could easily have been a dangerous occurrence. He added that the permits to work were a "disaster" and should never have been completed.

Since the occurrence, which was notified to the European Commission, a new, HSE-approved permit to work system has been introduced by Duffryn Terminals.

EXPLOSIVES PROSECUTION

l 9th July 1994 at Colchester Magistrates' Court Roh1d Patel trading as R & M News of 2 Osbourne Street, Colchester was convicted under Sections 22 and 39 of the above Act.

Mr Patel was sole proprietor of a s_hop premise was registered for the storage of fJJ"eworks. Early 111 November 1993 the trader was advised not to store fireworks in the window. On a second visit the same advice given and the fireworks were removed from the On the third visit (after the 5th November) the fneworks · · d d" I · were again stored in the wm ow 1sp ay

was fined £200 and ordered to pay £100 p1 osecution costs.

EXPLOSIVES - APPEAL AGAINST AN IMPROVEMENT NOTICE

On 8th August 1994. an Industrial Tribunal at Ashford.

Kent heard. what is believed to be the first appeal (in agamst an Impro_vement Notice, requiring premises for the storage of explosives to be equipped with a remote alarm.

_In accordance with Health and Safety Executive gmdehnes the owner of a Mode A premise (steel store on rural l_and) in north Kent, used for the storacre of hicrh explosives fuses and d h ':' 0 • etonators ad been advised that it would be neces · to mstall a connected alarm to cover his store on two previous visits.

However the owner t ·1 d eith d" ' ar e to take any positive steps to the explosives or have the necessary was served on him bsubseqOuffiently an Improvement Notice S Y an icer of Kent County T d" cr tandards Department on l 3th Ma 1994 ra mo y,

owner appealed on the basis that the cost of an would be unreasonable for a small store w ere the nsk of attack (in his view) was minimal the Tribunal upheld the Improvement and d1sm1ssed the appeal.

It is that similar objections have been raised 111 the C_oun_try where the Health and Safety _gmdehnes have been applied to registered premises, but it 1s thought that this was the first argued appeal to be decided.

MOBILE EXPLOSIVES

"A man who illegally sold fireworks from his mobile grocers van landed up in Hull Magistrates Court on 2 November. Following complaints from residents on a Hull housing estate in late September about a series of incidents of loud explosions being hear? late in the evenings Humberside Trading Standards Officers traced the firework seller in early October.

Inspections of known registered sellers in the area showed that none had received their 1994 fireworks stocks and all intended to keep faith with the voluntary 3 weeks sale period.

When the van was entered, parked in a regular sales position, examples of each type of firework available were seen pinned to the edges of open shelving.

The bulk of the fireworks (of the banger, air bombs and whistling rocket variety) were kept in a lidded bin in the van.

3 summonses were proceeded with, under the Explosives Act 1875, for:-

a) keeping at an unauthorised place (the vehicle)

b) exposing for sale whilst not in a substantial receptacle and c) hawking upon a street in Hull.

Fines of £500 were imposed plus£ I 00 costs".

7

PETROLEUM LIMITED

On 28 April last, an off duty ADO Nick Tong of Hainault Fire Station happened upon a serious car fire adjacent to the petrol pump forecourt of this filling station. He attended the fire with extinguishers he borrowed from another filling station close by and called the Brigade. Having notes that the petrol pump attendant was continuing to dispense petrol during the fire, he reported this matter to Senior Petroleum Inspector and in the result, this licensee company was brought before Havering Justices on 30 November 1994, for a hearing schedules to last 3 hours.

The inspection investigated and reported the defendant company for 5 offences of breach of the conditions of their petroleum spirit licence, one offence being failure to notify the Authority in writing of a fire fil the premises. The defendant pleaded not guilty to that offence but before the hearing pleaded guilty to the other 4 offences which related to failure to keep registered and to train staff etc.

. The defence solicitor called 3 witnesses including one mdependent witness who gave evidence that the car on fire was not on the licensed premises. They claimed it was 33' !rom the boundary. This point became more mterestmg because the plan on the licence did not demarcate the boundary in question although the small inset "location" plan marked "SITE" did exclude the area where the car was.

The advocate argued inter alia both that the location of the car was on the licensed premises because the definition of "licensed premises" in the licence included the " h _catc ment area" and even if it was not, that "at" the licensed premises must be interpreted purposively and contextually, producing a court case and dictionaries as authority for his proposition that "at" can also mean "near, close or by".

The defence argued inter alia that if the licence condition meant "near" it should have stated so particularly when the condition was creating a criminal offence with high penalties.

In all 5 witnesses were called, the case ending after 5.30pm with the result that the defendant was found guilty of the offence disputed and ordered to pay fines totalling £900.00 with what the magistrate called a "contribution" to the Authority"s legal costs of£ I ,OOO.

that the unlicensed occupier was not keeping petroleum delivery records, had dipsticks in the wrong tanks etc, such that there might easily have been a spillage.

Counsel for Burmah pursued several lines of defence. In particular, he claimed that Burmah had not "transferred occupation of the site", (as the licence condition stated for this offence). He said they had surrendered the lease of the site back to the landlord who then, apparently re-let it as a petroleum filling station. In the alternative he said the landlord rejected Burmah's offer to "decommission" the site, hence he claimed the defence that his clients had exercised all due diligence to avoid the commission of the offences.

The defence further claimed that if they were to be found guilty of transferring occupation without notifying us they could not be responsible for contraventions of the Regulations as ipso facto, they were not at the site at the time of the contraventions. This last defence raised an important point for the Authority i.e. whether during the currency of a licence, the licensee could move out without notifying us and then plead not guilty to offences relating to the running of the site because the contraventions are not their acts or deeds.

The case turned on the interpretation of the Regulations and its parent Act, the Health and Safety at Work etc Act 1974. The advocate for the Authority argued inter alia that to hold that licensees were not liable in such circumstances render the Authority's control of such sites 1mposs1ble. He mentioned that whoever was on site at any during the currency of the licence, the licensee was gmlty of any contravention.

The court agreed. Burmah was fined £1,950 and ordered to pay the Authority legal cost in the sum of£ 1,000.

The also earlier prosecuted the person who was _runnmg the site. He pleaded guilty to unlicensed keepm_g but having been found impecunious after a probation report, he was given a conditional discharge (ie if he offends again, he could be dealt with for the earlier and the later offence) and ordered to pay £500.00 cost to the Authority.

LFCDA v BURMAH PETROLEUM FUELS LTD

CoIn this case, which was heard at Wells Street Magistrates p urt on 23 September and 14 October 1994, Burmah etroleum pleaded not guilty to the Authority's prosecution 1?r 5 offences involving breach of their petroleum spirit S1cebnce and the Road Traffic (Carriage of Dangerous u stances · C · ) R . m Road tankers and Road ontamers egulat1ons 1992.

The prosec t. · · · h. · u 1011 arose out of a routme v1s11 to t 1s petroleu fir r m 1 mg station by Petroleum Inspector when he that Burmah had apparently transferred iu up<1lion of the site without notice to the Authority and

SECTION 9A FIRE PRECAUTIONS ACT 1971

The above case was heard at Aldridge Magistrates Court on_ 2lst September 1994. Where Mr P. Bannister pleaded gmlty to storing 2, l 00 litres of petroleum based thinners and adhesives without a licence and failure to provide a re.asonable means of escape in case of fire from Unit 16 Vigo Place. Aldridge. West Midlands.

The magistrates awarded a fine of £I OOO and £500 respectively. together with combined costs of £239.68 in favour of West Midlands Fire Service.

LONDON PROSECUTION LFCDA v CYMA

UNDER PETROLEUM (CONSOLIDATION) ACT 1928 Storage of Petroleum based mixtures without a licence and

PROSECUTION

Failure to provide a reasonable means

escape

of

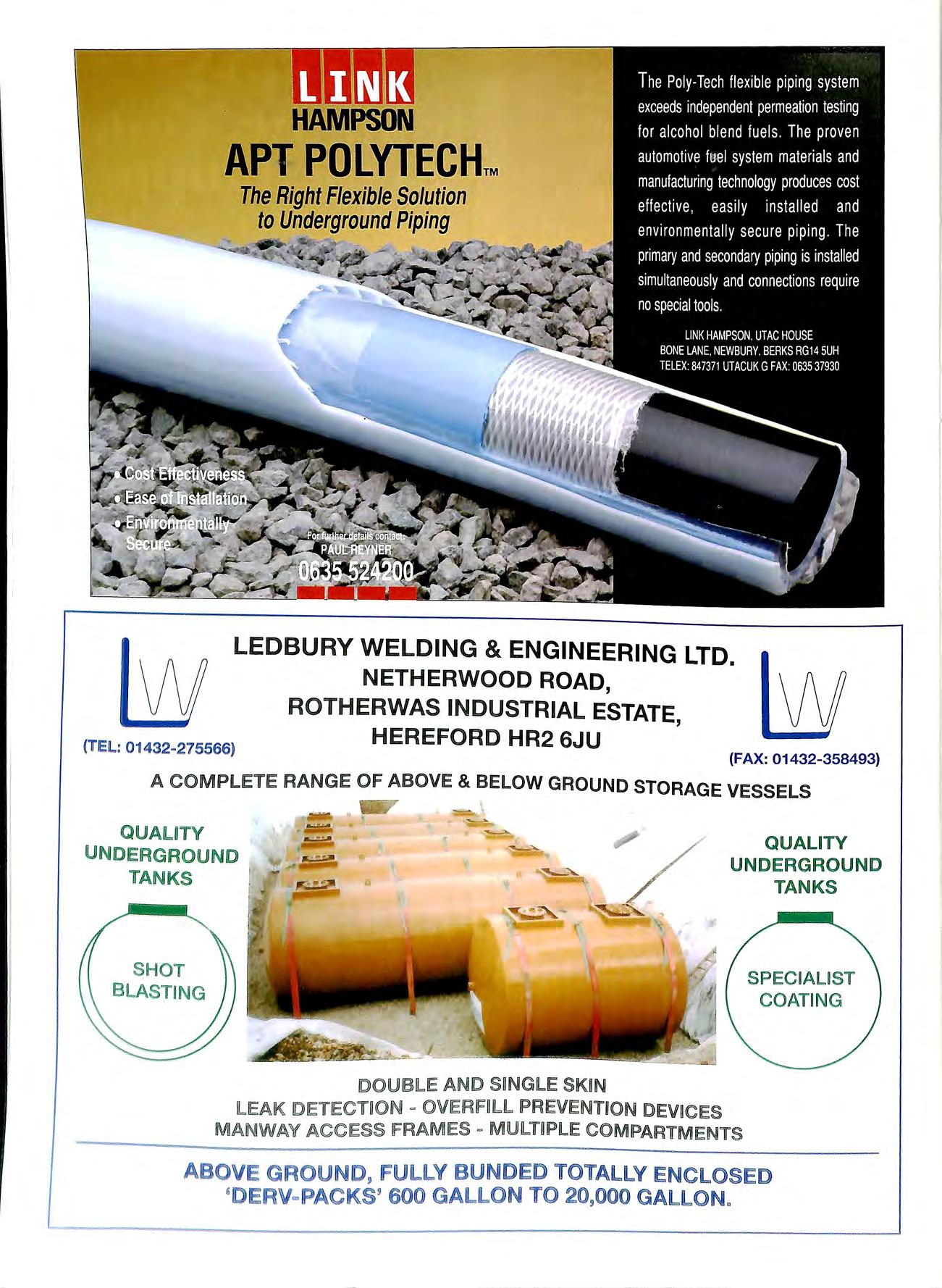

TANKS BELOW

BEST OF BOTH WORLDS

By Howard Upton

Until the late 1980s, petrol storage tanks in U.S. service stations were routinely buried beneath the forecourt.

Following adoption in 1988 of strin aent federal b environmental regulations for underground tanks , however, a growing number of petroleum marketers have opted to move their tanks above grade level. Among other this permits tank owners to make visual of their storage vessels. If an aboveground tank is leaking, that fact can be quickly and easily confirmed. No elaborate tank-tightness testing is needed; no costly leakdetection equipment is required One can simply take a look at the surface of the tank to assess its condition

But aboveground petrol storage tanks also present clear disadvantages. One of the most serious relates to fire safety. A ruptured aboveground tank one that has been struck by a vehicle, for example can release thousands of gallons of fla.mmable liquid onto the surface of an urban neighbourhood. If the liquid happens to be ignited by a stray spark, the results can be catastrophic.

Aboveground tanks also pre sent the disadvantaae of occupyi c ng expensive surface space space that could be put to more profitable us e .

S imil arl y I d c , un c e1ground petro l storaae rnvolve s clear 1sadva nt ·:iaes Cl · "' co · i1 e · a mong th e m 1s the fac t that a leak 1n a n und e raro u d k o n ta n may go und e tected , for month s o r eve n for yea rs Of · b f c te n, e o re a leak 1s di scove red and co rrec ted re l I ' easec p1 oclu c t co ntarn mates the s urro und ma so il a nd gro und wate r C oJTect ive act io n is both

and protracted

A New Approach

Against this background , a company headquartered in Chandler, Arizona has developed a tank storage system that combines the advantages of both aboveground and underground storage

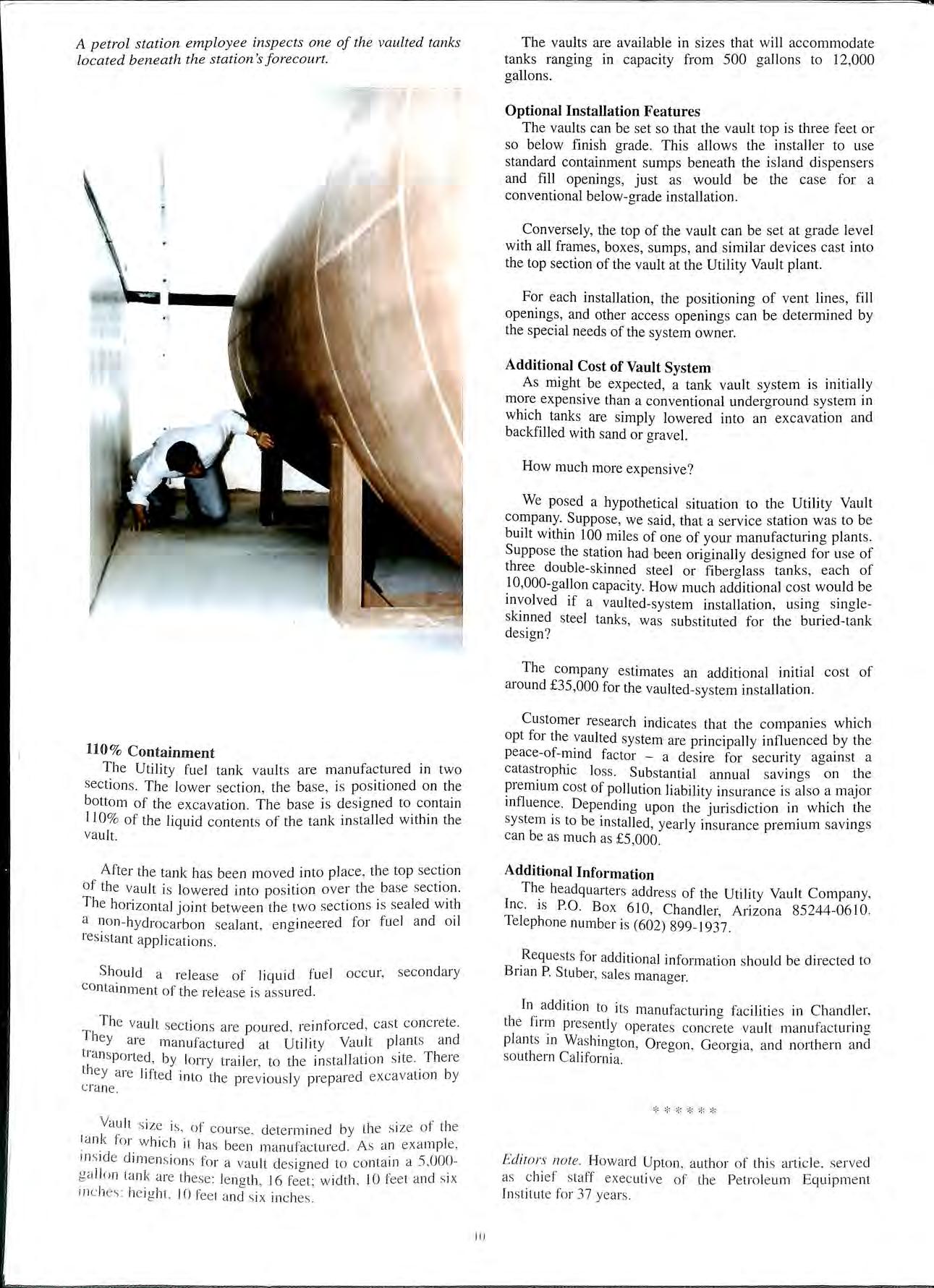

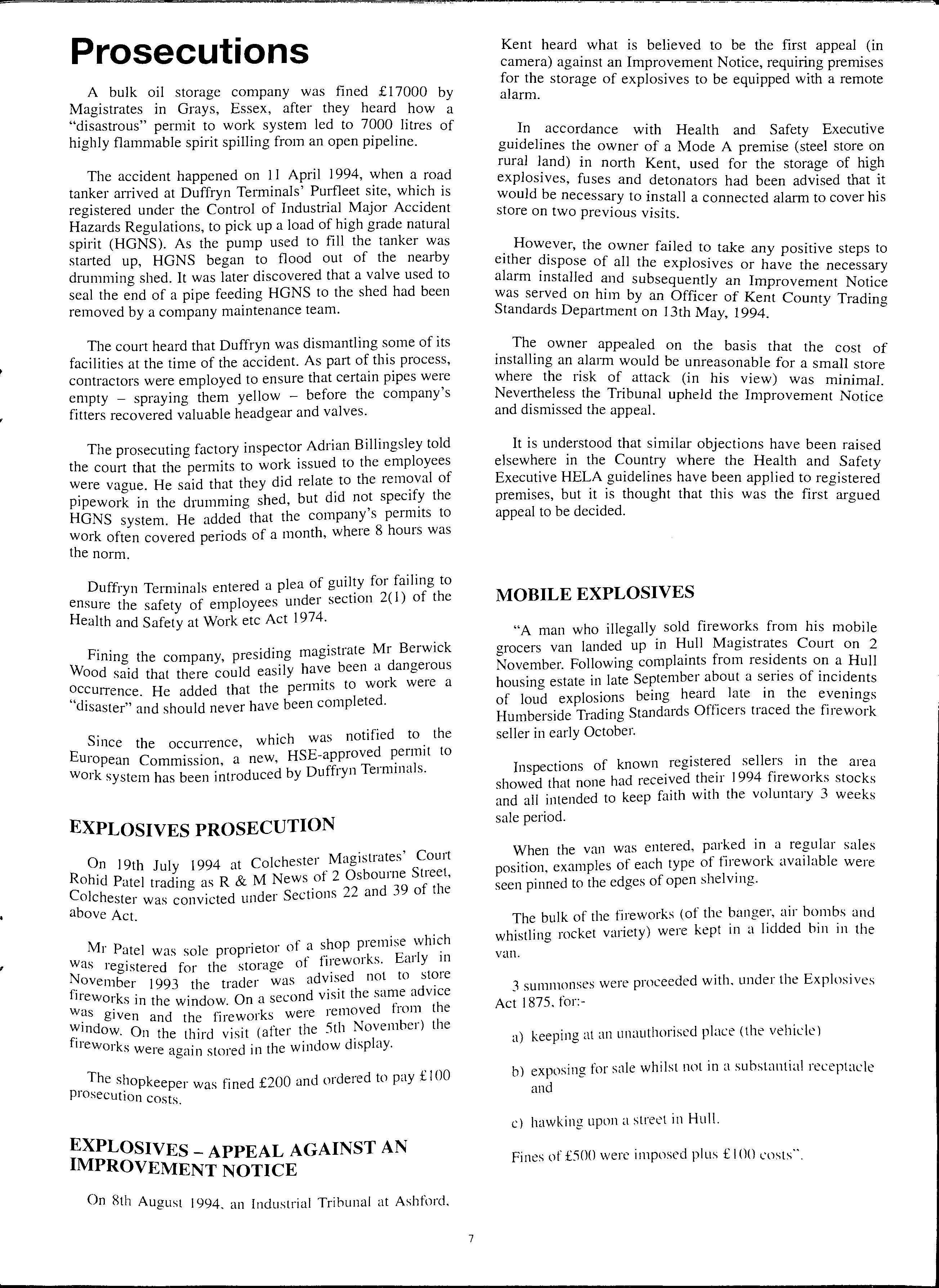

The company, Utility Vault Company, Inc. , m a nufactures reinforced concrete vaults that are being installed in belowforecourt excavations at U.S. automotive fuelling sites, principally in the western states. A steel , aboveground tank is installed within each vault. Following installation of the vaults , with the tanks inside , the forecourt above the tanks is paved over.

The resultant service station appears to be no different from those stations in which the und erground tank s h a ve been buried in backfilled excavations beneath the forecourt.

There is , however, a major difference : a station operator in a Utility Vault station ca n open a m anhol e above eac h vault and desc end a ladder into the room-like va ult below. There, he can move fr eely about , malcing a visual in spection of the smface of the tank. If the t ank is no t leakin g, he ca n absolutel y ass ure him se lf of that fact, w itho ut rese rvat ion.

The station operator a lso know s th at if a tank s p ill do es occur. th e escap 111 g li q md w 1II not c rea te a ne i ghbourhoocl fir e da nge r. as is the case w he n a co n ve ntion a l abovegro und tank rup tures.

ABO VEGROUND

GROUND:

Ult.111 , MA.1 to 411\lO!IJ.

The top section of a tank vault is lowered into position.

9

11 0% Co n tainme n t

Th e Utility fu e l tank vault s a re manufactured in two secti o ns The lo wer section , the base, is po s itioned on the bottom of the ex c avation Th e base is designed to contain 110% of th e liquid c o ntent s o f the tank in s ta lled within the vault.

Afte r the ta nk has been m o ve d into place, th e top section of the va ult is low ered into pos ition o ver the base section. Th e hori zo nt a l j o int be t wee n the t w o sec ti o ns is seal ed w ith a no n hydro carb o n se a la nt , en g in e ered for fuel and oil res is tant appli ca ti o ns.

Sh o uld a re lease o f liquid f ue l occ ur, sec ond a ry co nta inm e nt of the re le a se is ass ure d.

T he va ul t sectio ns are po ure d , re in fo rce d , cas t co nc re te T hey are m anu fac tu re d at Ut ili ty Va ult pl a nts a nd tran s po rted, by lo rr y tra il e r to th e in sta ll at io n s ite T here they are li fted in to t he pre pa red excavatio n by c rane.

Vau lt s ize is, of cou rse , dete rm ined by t he s ize of t he lank for whi c h il has been man ufact ured. As a n exa m pl e, m side dime ns io ns fo r a va ul t d es ig ned to co nta in a 5.000ga Jl o n tank are these: le ngth , 16 feet; wi d th. I 0 feet a nd six in c hes ; he ig ht. I 0 feet and s ix in c hes.

The vaults are available in sizes that will accommodate tanks ranging in capacity from 500 gallons to 12,000 gallons.

Optional Installation Features

The vaults can be set so that the vault top is three feet or so below finish grade. This allows the installer to use standard containment sumps beneath the island dispensers and fill openings , just as would be the case for a conventional below-grade installation.

Conversely, the top of the vault can be set at grade level with all frames , boxes, sumps , and similar devices cast into the top section of the vault at the Utility Vault plant.

For each installation, the positioning of vent lines, fill openings, and other access openings can be determined by the special needs of the system owner.

Additional Cost of Vault System

As might be expected, a tank vault system is initially more expensive than a conventional underground system in which tanks are simply lowered into an excavation and backfilled with sand or gravel.

How much more expensive?

We posed a hypothetical situation to the Utility Vault company. Suppose, we said, that a service station was to be built within 100 miles of one of your manufacturing plants. Suppose the station had been originally designed for use of three double-skinned steel or fibera]ass tanks, each of 10,000-gallon capacity How much additional cost would be involved if a vaulted-system installation, using singleskinned steel tanks , was substituted for the buried-tank design?

The company estimates an additional initial cost of around £35,000 for the vaulted-system inst allation.

Cu stomer research indicates that the companies which opt for the vaulted system are principally influenced by the peace-of-mind factor -a desire for security against a catastrophic lo ss . Substanti al annual savings on the premium cost of pollution li ability in s urance is al so a major mfluence. Depending upon the juri sdiction in which the system is to be in stalled, yearly insurance premium saving s can be as much as £5 ,000 .

Additional Information

Th e headquarters addre ss of th e Utility Vault Company, Inc . is P.O. Box 610, Chandler Arizona 85244-06 I 0. Telephone number is (602) 899 I 9J7.

Requ es ts for additional information s hould be directed to Bri an P. Stuber, sale s man ager.

In additi o n to its manufac turin g faciliti es in Ch a ndl e r, th e firm prese ntl y o perates co nc re te vault ma nufac turin g plants in Was hin gton , Orego n, Georgia , and northern and so uth ern Cali fo rnia.

Editors note. Howard Up to n, autho r of thi s art ic le. se rve d as c hi ef s taff exec u tive o f the Petro le um Equi p me nt fn s ti t ute fo r 37 yea rs .

A petrol station employee inspects one of the vaulted tanks located beneath the station's forecourt.

A petrol station employee inspects one of the vaulted tanks located beneath the station's forecourt.

10

******

.... _,_._ ___ J.:

Ve n! p i p es and 1•ent il ators se r\'in g a vault ed tonk i n staf f a t i o n a l a U.S. se n 1i cl:' s toti o 11. 11 -

A petrol sta tion, w ith vaulted tanks installed ben eath th e fore court, is ready for th e insta llation of canopies.

"TRACER TIGHT" TANK TESTING

by Robert C. Weeks of Geotechnical Instruments (UK) Ltd

Acceptance

Although "Tracer Tight" was only introduced by ourselves into the U.K. in January, 1994, the technique has now gained acceptance from virtually every licensing authority in the country. The system tests all pipework and tanks on a site and is completely different to any other precision tank testing system currently in use.

"Tracer Tight" has been used extensively in the U.S.A. for more than 7 years and in excess of 250,000 tanks have been tested to date. The method has also been predominantly adopted by the United States Air Force for testing aviation fuel tanks and pipelines.

How "Tracer Tight" works

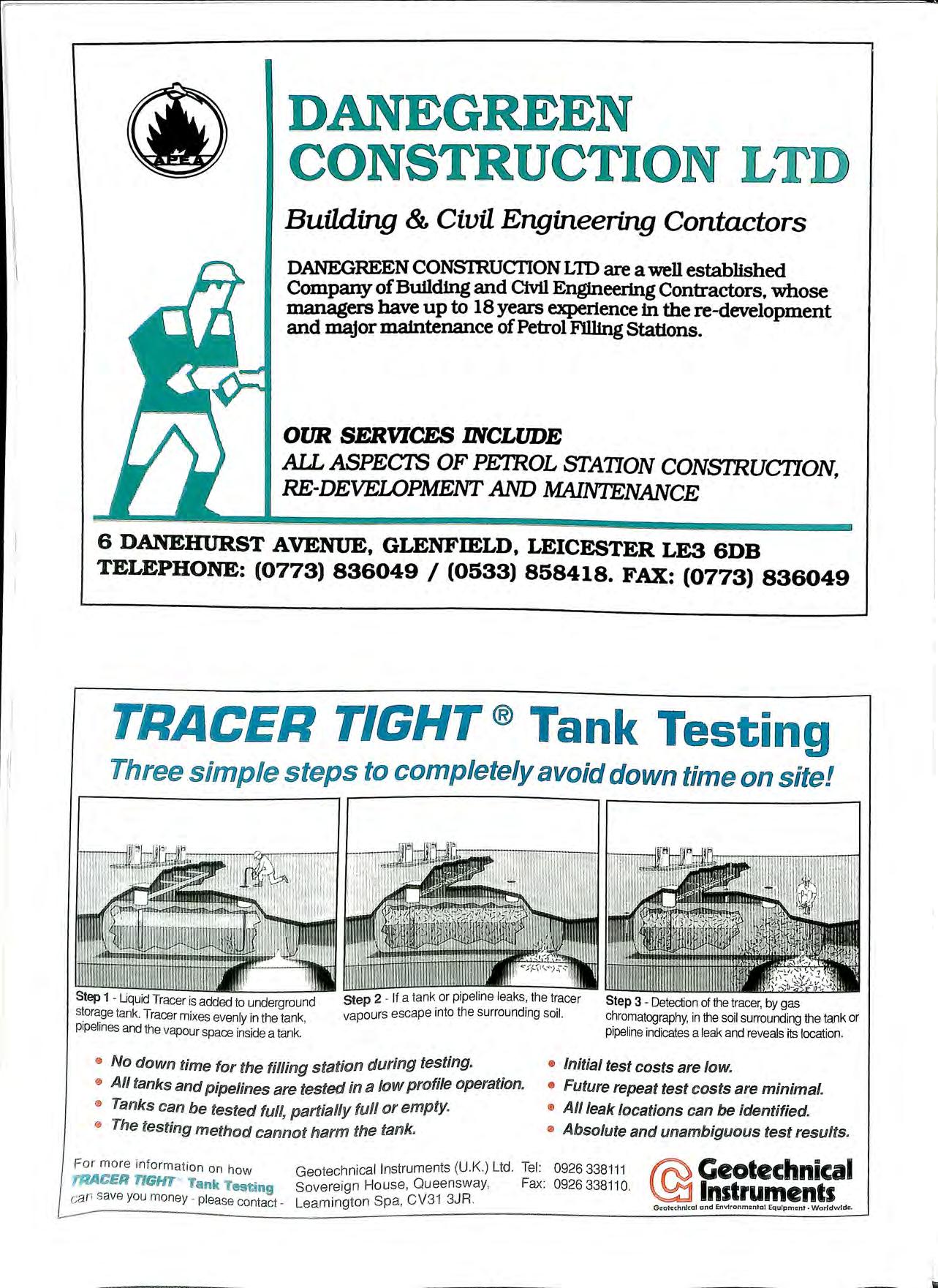

The technique is simple in principle. It involves adding a tracer chemical to the product inside a tank and then looking for the chemical outside the tank. If the tracer can be found, it follows that a leak is present.

In practice, there are three stages to the complete operation inoculation of the product, installation of small diameter monitoring boreholes (probes) and collection/analysis of soil vapour samples extracted from these probes.

Inoculation

Up to 8 different tracers can be used (in or?er to distinguish between tanks) and each is a highly _volatile, yet inert chemical. They are added to m measured quantities so that the final concentrat10n 1s a few parts per million. As well as being absorbed into the product, the tracers also occupy the ullage space and vent lines in the form of vapour.

Thus the technique will check for leaks in the and ullage space of tanks and also in all associated pipework on a site.

Installation of probes

Before any drilling is started on a site, a full underground service survey is carried out. This the use of electromagnetic location equipment and is designed to all underground services and metallic on site. A permanent record of the position of the services m fo°!l of a CAD drawing or a disk is given t? the service station operator and many clients regard this as a very useful by-product of the test.

The probe layout is designed to give complete of the site and using a combination of hydraulically powered rotary and percussive hand-held drills, probes are normally installed to a depth of approximately 3 metres arou d h · E h n t e tanks and 0.5 metres elsewhere on the site. ac pro.be terminates at ground level in a 40mm diameter cap is flush with the forecourt and may be driven over by vehicles.

The service station continues to operate normally throughout this operation _there are no Jost sales.

Sample collection and analysis

If a leak is present, tracer will escape from the tank or pipeline, either with the leaking product, or in the form of vapour. In both cases, tracer vapours will then migrate by molecular diffusion and will reach the probes which surround the leak. Samples of soil vapour are obtained using a vacuum pump and are stored in small, specially designed containers. These containers are then shipped to Tracer Research Corporation's laboratory m Buckinghamshire for analysis by gas chromatography.

The samples are examined for the presence of tracers and also total volatile hydrocarbons. A report is then prepared which clearly states if the tanks and lines have passed or failed.

Whilst the presence of hydrocarbons does not influence the result of the tank (which is based solely on the absence or presence of tracer), the data is extremely useful in determining the degree of contamination on a site. In fact, by adding some simple soil sampling, the tank testing exercise can be easily extended to become a basic environmental survey for a fraction of the normal cost.

Users

. Although "Tracer Tight" is relatively new in this country, has met with considerable interest throughout the mdustry: It has already been used by several major oil c?mpames and many independent dealers. It offers advantages over other forms of precision tank testmg.

Benefits

• The service station continues to operate normally throughout the tank testing process thus no product sales or shop sales are lost

• Tanks do not need to be filled to a particular level thus avoiding inconvenience and cost

• The initial cost is no more than other forms of precision tank test but repeat testing in future years shows savings of up to 50%

• A soil vapour hydrocarbon survey is included in the cost of the test thus the extent of any existing site pollution can be assessed at no extra charge

• Similarly, an underground service survey is included thus allowing records to be updated

• The test checks all parts of the underground product storage and delivery system, including pipelines

• Unlike other forms of test, "Tracer Tight" does not put any abnormal stress on a tank.

12

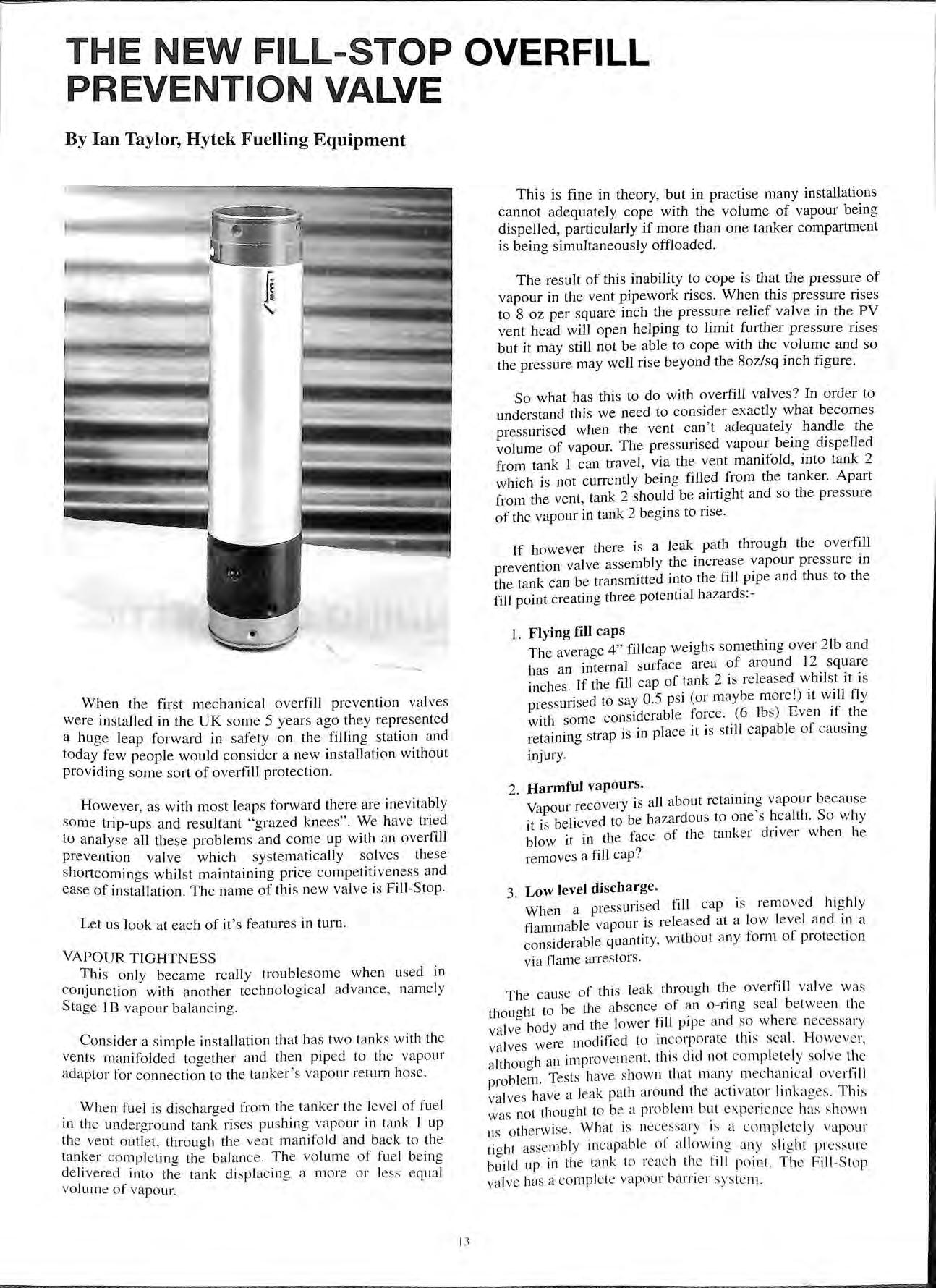

THE NEW FILL-STOP OVERFILL PREVENTION VALVE

By Ian Taylor, Hytek Fuelling Equipment

This is fine in theory, but in practise many installations cannot adequately cope with the volume of vapour being dispelled, particularly if more than one tanker compartment is being simultaneously offloaded.

The result of this inability to cope is that the pressure of vapour in the vent pipework rises. When this pressure rises to 8 oz per square inch the pressure relief valve in the PY vent head will open helping to limit further pressure rises but it may still not be able to cope with the volume and so the pressure may well rise beyond the 8oz/sq inch figure.

So what has this to do with overfill valves? In order to understand this we need to consider exactly what becomes pressurised when the vent can't adequately handle the volume of vapour. The pressurised vapour being dispelled from tank I can travel, via the vent manifold, into tank 2 which is not currently being filled from the tanker. Apart from the vent, tank 2 should be airtight and so the pressure of the vapour in tank 2 begins to rise.

If however there is a leak path through the overfill prevention valve assembly the vapour pressure in the tank can be transmitted into the fill pipe and thus to the fill point creating three potential hazards:-

1. Flying fill caps

---

When the first mechanical overfill prevention valves were installed in the UK some S years ago they represented a huge leap forward in safety on the filling station and today few people would consider a new installation without providing some sort of overfill protection.

However, as with most leaps forward there are inevitably some trip-ups and resultant "grazed knees". We have tried to analyse all these problems and come up with an overfill prevention valve which systematically solves these shortcomings whilst maintaining price competitiveness and ease of installation. The name of this new valve is Fill-Stop

Let us look at each of it's features in turn.

VAPOUR TIGHTNESS

This only became really troublesome when used in conjunction with another technological advance, namely Stage I B vapour balancing.

Consider a simple installation that has two tanks with the vents manifolded together and then piped to the vapour adaptor for connection to the tanker's vapour return hose.

When fuel is discharged from the tanker the level of fuel in the underground tank rises pushing vapour in tank l up the vent outlet , through the vent manifold and back to the tanker completing the balance. The volume of fuel being delivered into the tank di splacing a more or less equal volume of vapour.

The average 4" fillcap weighs something over 21b and has an internal surface area ?f around 12. inches. If the fill cap of tank 2 1s released "".hils_t 1t 1s pressurised to say 0.5 psi (or maybe more!) 1t wdl fly "tl some considerable force. (6 lbs) Even 1f the WI 1 bi f . retaining strap is in place it is still capa e o · causmg injury.

2. Harmful vapours. V I i·ecovery is all about retaining vapour because apou , ·t · believed to be hazardous to one s health. So why I IS k cl . h blow it in the face of the tan er nver w en he removes a fill cap?

3. Low level discharge. When a pressurised fill cap is removed highly flammable vapour is released at a low level and m a considerable quantity, without any form of protection via flame arrestors.

The cause of this leak tlu·ough the overfill valve was thought to be the absence. of an o-nng seal between the I e body and the lower fill pipe and so where necessary va v valves were modified to 111corporate this seal. Howev e r, althouah an improveme nt, this did not compl e te ly solv e th e Tests have shown that many. mechanical overfill valves have a leak path around the activator linkages Thi s was not thought to be a probl e m but expe ri e nce has shown us otherwise What is nec ess ar y is a compl e tel y vapour tight assembly incapabl e of allowin g an y sli g ht press ure build up in the tank to re ac h th e fill point The Fill Stop valv e ha s a compl e te va pour barri e r sys te m.

13

SHUTOFF SHOCK

When the level of fuel in an underground tank rises to the shutoff point the float of a mechanical overfill prevention valve rises to start the activation of the valve. However the real work of closing the valve is done by the force of the flow of fuel from the tanker. Some valves attempt to stop this flow instantly using a single closure mechanism. This sudden closure generates an enormous force on the valve and it's fixings. Repeated shutoff of the overfill valve can and has led to the failure of the fixings allowing the overfill assembly to fall to the bottom of the tank.

Some valves have a spring loaded pressure relief mechanism to help relieve this pressure once it has built up but it is much more effective if you can prevent the massive pressure peak before it occurs by progressively closing off the flow path.

The Fill-Stop valve does this by closing the flow path in 2 stages. The first reduces the flow by 90% and the second completes closure.

AUTOMATIC RESET

If the Fill-Stop valve is activated by an attempted tank overfill the floats, flappers and linkages are all automatically reset to their ready position as soon as the

level in the tank drops. There is no need to remove and manually reset the valve.

EASE OF INSPECTION

The top tube of each Fill-Stop valve is fitted with a lift bar to help when withdrawing the overfill valve assembly for routine inspection. A basic study of human nature tells us that if an overfill valve is not easy to withdraw then it doesn't get inspected!

ENCLOSED FLOATS

The activation floats of the Fill-Stop are completely enclosed within the body of the valve. This means that the assembly can be installed without regard to it's rotational position and there is never any danger that it's operation could be hindered by adjacent pipework or obstacles inside the tank.

Many overfill prevention valves look alike. The Fill-Stop valve can be identified by it's distinctive black ends and gold centre section.

Hytek (GB) Ltd

THE WORK OF THE TRAINING COMMITTEE

By Mike Sewell, Chairman of the Training Committee

By Mike Sewell, Chairman of the Training Committee

The APEA has for some time been concerned at the level of, or possibly the lack of training in some of the aspects of construction and operation of petrol filling stations. Under the Health and Safety at Work etc. Act 1974 the onus for training employees is on the employer, but there has been a deai1h of courses in this field to which employers could send their employees.

The APEA sees a need for such courses and has attempted to rectify the situation in some small way. Some two years ago Council decided that the APEA should become involved in running training courses and consequently set up a Training Committee as. P.art of administrative reorganisation of the Association. Th.is Committee currently comprises five members .of namely. Clive Stephenson. Philip Monger. Mike Silmon, Rory Hennessey and myself as Chairman.

The APEA uses hotels or other venues which .have conference facilities. Whilst most of these courses will he held somewhere in the centre of England. some of the more popular ones will be held in different parts of the so as to cut down the cost and time of travelling tor the trainees.

The first courses stemmed from the publication of HS!f1J4J.

Thi: first of these has dealt with electrical installations at p1·1rol filling stations and there have heen three so far. the

first two, both held in the Retford, Nottinghamshire area, were of two days' duration but the third held in Kenilworth, Warwickshire in November 1994 only of one duration. A further one day course' is due to be held m May 1995, probably in Newton Aycliffe, Co Durham, and another may be held towards the end of 1995.

The other type has dealt with wet stock control and there also been three of these. They have been held in Kemlworth, Retford and Gloucester, the last being as recently as 29 November 1994. A further course is due to be held in April 1995, in the Bradford West Yorkshire area, with the likelihood of a further towards the end of 1995.

By far the most need is recognised in the fields of safety. These courses .will be mainly for petroleum officers/oil company orgamsers and will be of 2/3 days' duration. The pet!·oleum course will cover the question of ent01:cement mcluding the Road Tanker Regulations. Details of these courses are not yet available but they will be held in the second half of 1995.

If any member has any comments to make on training courses. especially on topics for such courses and the question of the issue of attendance certificates. the writer would he pleased to hear from you. Please write or telephone to M G Sewell. 30 Greenhurst Lane. Oxted. Surrey. RH8 OLB. Tel 01883 714683.

l.t

Letters to the Editor

Dear Sir,

I read with great interest, the article in the August "Bulletin", headed, "Mechanical Float Valves versus the Scully RSVP", by Kevin Dawson.

Historically, the "Bulletin" has been a vehicle for those APEA members representing Equipment Manufacturers, to introduce new products and technology. Indeed the Editor was kind enough to publish my article on Mechanical Overfill Prevention Valves, in the May, 1990 issue.

Since then, there have been many submissions from manufacturers, all of interest, some barely disguised as advertising but NONE to my knowledge resorting to "competitor bashing".

It could be argued that drawing comparisons with competitive equipment is valid. By doing so however, one must be careful to present accurate data, supported by EVIDENCE, while at the same time protecting one's rear from counter argument against one's own product.

I am sure Mr Dawson is well aware that NO overfill prevention device is totally fool-proof, or perfect in perpetuity, including the one he describes. Mechanical valve manufacturers would not make these claims. One could ask what guarantee exists in the event when a site equipped with RSVP, is visited by a road-tanker not so equipped, or vice-versa.

The case for mechanical valves is strong and simple. More than five years experience, world wide, provide strong evidence that many thousand valves have given reliable and safe protection. The very low incidence of reported failure, have invariably been diagnosed as incorrect or incompetent installation procedure. Come on Kevin, I know times are tough, but Jet's stick to selling our products on their merits, and lay off the competition.

Mike Elston OPW Fuelling Components Europe BY

Dear Editor,

Many people do not believe in coincidences. However, how else can we explain that the Bulletin, Vol 32, No. 3, arrived with a readers survey. This survey included the engaging question "Do you believe that Bulletin features are too commercial ?" and in the same issue was an article by Kevin Dawson of Scully. This thinly disguised commercial for Scully products is hardly likely to enhance the Bulletin's reputation as a serious technical journal._ I wonder whether Kevin actually paid advertising rates for the two and a quarter page article?

I would like to comment briefly on some of the inaccuracies contained in the article. As leading manufacturers of mechanical overfill prevention devices. we would have to point out that any service station which is fitted with one of these devices would prevent a road tanker from causing an overfill during delivery. This is because the device operates independently from the road tanker and is not reliant on any additional equipment being fitted to the

road tanker. To avoid possible claims of commercialism myself, I would stress that this applies to any mechanical overfill prevention device, whether it was made by OPW, EB W, Lafon or even Emco Wheaton!

Unfortunately, the same cannot be said of devices which do rely on additional equipment being fitted to the road tanker, "dependent devices" such as Scully, Q.E.D. or any one of numerous European manufacturers. If a road tanker, which has not been fitted with this additional equipment, delivers to a service station with no mechanical overfill prevention device, because it is set up for a dependent device, there is a real possibility that an overfill will occur. Also because there is no universal interchangeability the various dependent devices available, equipment on the road tanker not be compatible with that at the service station. In this mstance attempts may be made to bypass the system, b)'. use of "dummy sockets" for example. This may also result m an overfill.

Th hrase "Mechanical Float Valves" is used repeatedly · K e.P,s arti'cle to refer to Mechanical Overfill Prevention 1n evm ,, rfill . D · The various "dependent ove 1 prevention ev1ces. · f I devices all rely on the mechanical closmg o a va ve h d tanker The control valve, which shuts off the on t e roa · . . fl · overfill prevention device, 1s surely part of the ow man 1 A Kevin points out, mechamca eqmpment is system. s 1 · Id " t sti'ck or fail." In all of these examp es, It wou prone o · d · Id h t the "dependent" overfill prevention ev1ces cou seem t a . b "f ·1 fi "? fail to be safe. If this what Kevm means y ai sa e .