At Tetra Pak they commit to making food safe and available, everywhere; and they protect what is good – protecting food, protecting people, and protecting the planet By doing so Tetra Pak touch millions of people’s lives every day�

And they need people like you to make it happen � Tetra Pak empower you to reach your potential with opportunities to make an impact to be proud of – for food, people and the planet.

Job Summary

Drive all sustainability priorities in Australia as per Sustainability Strategy 2030 with focus on collection and recycling value chain transformation to achieve the recycling rate target Develop plans and drive the execution of key projects including recycling investments and value chain activities� Collaborate with internal & external stakeholders on sustainability issues to achieve the targets and secure business success

What you will do

As Sustainability Manager, you will:

• Executes sustainability programmes to implement Sustainability Strategy 2030 priorities in Australia, main focus on collection and recycling value chain transformation for Liquid Packaging Cartons (LPCs)

• Establish LPCs recycling value chain with external partners like waste management companies/MRFs/ Recyclers, including regulations, DfR, recyclability awareness, collection/sorting infrastructure, recycling capacity/solution and end market of recycled materials�

• Identify the needs of collection/sorting/recycling investment projects and value chain activities, propose operational plan, define required resources and outline long-term ambitions

• Lead the execution of collection/sorting/recycling investment projects and value chain activities to deliver the target in collaboration with relevant stakeholders, e g C&R team, MRFs, Recyclers, etc

• Manage large-sized strategic projects, e � g � coinvestment project with MRFs/Recyclers according to internal process including business case preparation, project management and follow-up�

• Secure compliance with recycling regulations/ targets as applicable in Australia�

• Represents the company in industry associations related to sustainability (e � g � PROs, Alliance, etc ) and propose opportunities for enabling Corporate Affairs, including exchange on legislative developments to secure business success�

• Provide data to secure reliable accounting and reporting of recycling rates as per global methodology, lead data gathering in Australia to maintain internal reporting, e g RVC/capacity mapping�

• Representative of Sustainability Operations team on the ground in handling on-site matters, joining meetings and executing local sustainability activities related to circularity/nature/climate targets�

• Support customer sustainability initiatives to enhance our sustainability credentials

We believe you have

• 5yr+ experience in waste collection/recycling industry and familiar with relevant regulations and trends in Australia, understanding of local packaging policies and an existing network of stakeholders would be a strong plus�

• Can engage and coordinate cross functional teams & external stakeholders, including Managing Director, Corporate Affairs, Market Communications, Government, Recyclers, Associations, etc�

• Strong negotiation, analytical and project management skills to engage partners, drive priorities and meet deadlines�

• A self-starter with passion for collection & recycling and demonstrable experience in strategy planning and turning strategy into actions

• Commercially minded, viewing problems/solutions through a business mind set, ability to bridge technical expertise and business strategy

• Ability to approach problems and situations with a logical and systematic perspective�

• Fluency in English is a must�

We Offer You

• A variety of exciting challenges with ample opportunities for development and training in a truly global landscape�

• A culture that pioneers a spirit of innovation where our industry experts drive visible results

• An equal opportunity employment experience that values diversity and inclusion

• Market competitive compensation and benefits with flexible working arrangements�

PLEASE APPLY TODAY

The AIP would like to take this opportunity to welcome Arindam Haldar MAIP, Graphic Pre-Press Operator, Sealed Air New Zealand and Loo Hooi Wei MAIP, Regional Packaging Lead AOA, Nestlé CPW, to the Institute and share a little bit about who they are and what they do in the industry. Please join with us in welcoming them to the AIP.

1. Why did you join the AIP? What benefits do you believe the AIP offers all their members?

Regional Packaging Lead AOA

Arindam: I joined the AIP to study the Fundamentals of Packaging Technology On-line Course I also want to gain more current knowledge in the packaging industry and AIP members get discounted fees and support Loo Hooi: The AIP offers an overview of packaging industry neither downstream manufacturer or upstream supplier� The AIP connects me to packaging's latest technology, innovation, digitalisation and ECG topic that enhance and open new views for me The AIP also provides information on training, exhibitions and events for the packaging community� This is very useful as I can have access to useful information at my finger tips

2. How long have you been in the industry? What are your areas of expertise?

Arindam: I am working in the printing industry since 2004 My main skill area is graphic pre-press in the large commercial printing, small scale paper based packaging and label printing�

Loo Hooi: I started my packaging career about 19 years ago, beginning from a offset paper packaging company then step into corrugated manufacturing company with intention to learn more about display boxs (or primary cartons) integrated with secondary corrugated case Mainly I deal with new development including board structure design and provide solutions to FMCG customer Moving from there, I joined FMCG (food & beverage) and explored flexible laminate, rigid plastic, aluminum can, aseptic carton, PET bottle and that link to multiple types of packaging technology�

3. What is your current job role and what are your responsibilities?

Arindam: In my current role I am working as Graphic Pre-Press Operator at Sealed Air New Zealand My responsibilities are Pre-Press planning for film and paper bag printing �

Loo Hooi: From my first day in the packaging industry, I have always dealt with new development, driving new products (or types of packaging), cost optimisation, line improvement and support packaging-related trouble shooting At Nestlé, I have been assigned to develop sustainability packaging such as paper straws, paper cluster sleeves (in replacing flexible plastic), rPET (for rigid plastic and tray shrinkfilm) and support the company/ brand on effort plastic neutral as part of puzzle in Net-Zero With this I take a broader role in coordinating Nestlé CPW factories in zone AOA (Asia, Oceania, Africa) to support and drive packaging-related development

The AIP would like to welcome the following new Members...

NAME GRADE STATE/COUNTRY

Carrie Blockley Associate (AAIP) VIC

Arindam Haldar Associate (AAIP) New Zealand

Sarah Hogan Associate (AAIP) VIC

Maria Kabissios Associate (AAIP) VIC

Amanda McIntyre Associate (AAIP) VIC

Jasmine Murray Associate (AAIP) VIC

Amy Radunkovic Associate (AAIP) VIC

Shane Richardson Associate (AAIP) VIC

No-ting Song Associate (AAIP) New Zealand

Celine Tiara Associate (AAIP) New Zealand

Lounny Vongdachit Associate (AAIP) VIC

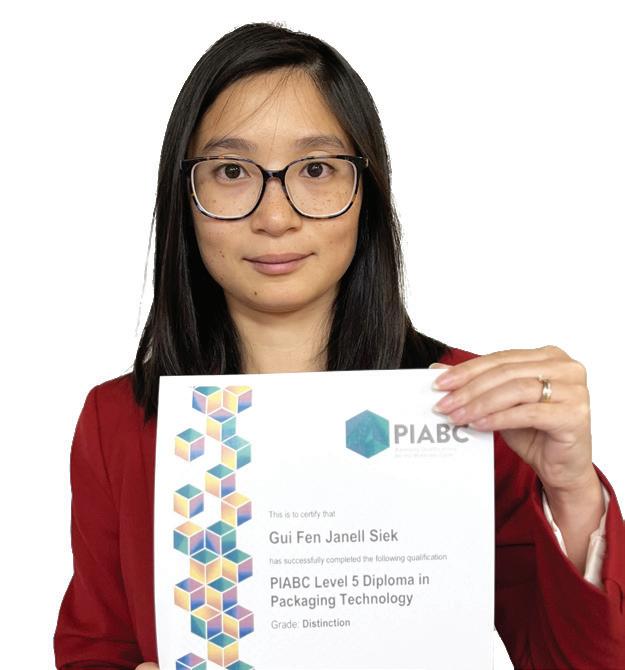

Internationally recognised as the premier qualification in the packaging industry.

The Diploma in Packaging Technology is a Level 5 PIABC, 51-credit foundation degree- level qualification that prepares students to take responsibility for packaging operations at any level through the supply chain and can also lead to higher level study.

What’s in it for me?

Completion of the Diploma in Packaging Technology demonstrates your commitment to your career and to the industry. Students who successfully complete the course and achieve the qualification are equipping themselves for senior positions within the packaging industry.

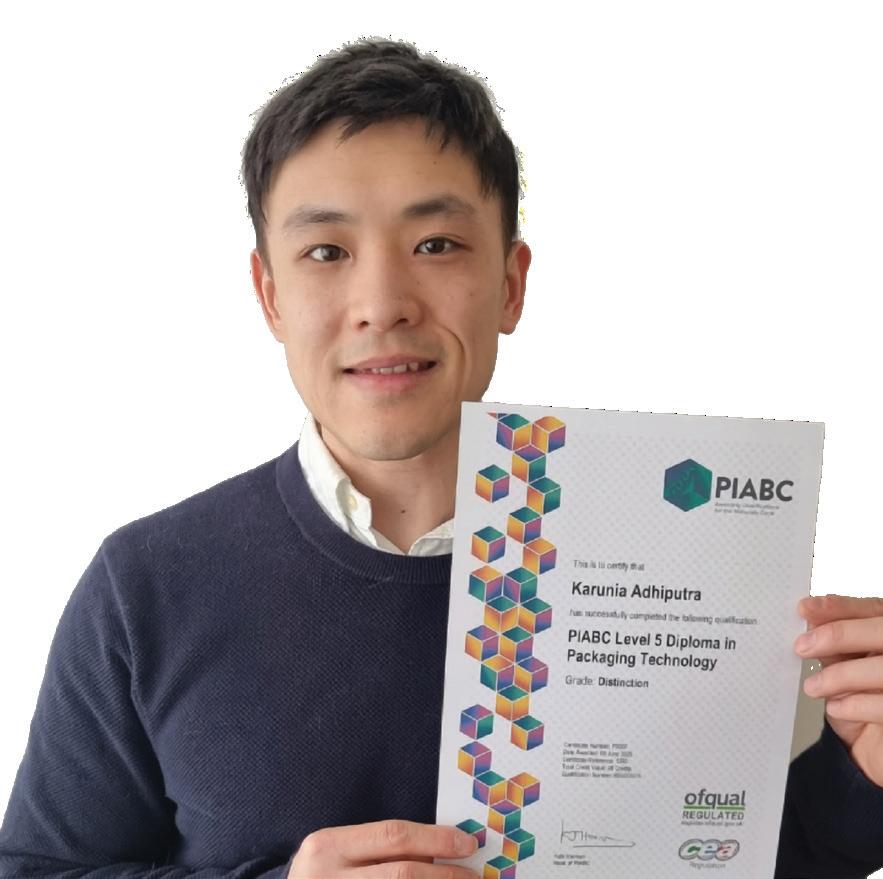

The AIP would like to congratulate our latest Diploma in Packaging Technology Graduate, Karunia Adhiputra (Adhi) Dip. Pkg. Tech. MAIP, Head of Packaging for Nestlé Oceania. Internationally recognised as the premier qualification in the packaging industry the Diploma in Packaging Technology is a Level 5 PIABC, 51-credit foundation degree-level qualification that prepares students to take responsibility for packaging operations at any level through the supply chain and can also lead to higher level study. Adhi kindly shared with the AIP what he learnt during his studies...

1. What is your current role? What are your areas of responsibility?

Adhi: I am the Head of Packaging for Nestlé Oceania� I lead the Corporate Packaging team, supporting functions to develop the packaging sustainability strategy, providing technical support to our factories to minimise packaging related downtime, creating policies and procedures, as well as managing the regulatory compliance documentation of our food contact packaging materials We work crossfunctionally across various business units and brands, and across all Nestlé factories in Australia, New Zealand and Papua New Guinea�

2. What does graduating from the Diploma in Packaging Technology mean to you?

Adhi: Completing the Diploma certainly is a milestone for me and my career When I applied for this Scholarship through the AIP and ABA, I came in with the expectation to build my fundamental packaging knowledge across various material types and machinery, and it has certainly delivered! Having the backing of an industry recognised degree will give me the confidence to challenge myself and learn new things in this industry I thank both the AIP and ABA for such a wonderful opportunity

3. How will you apply this knowledge moving forward?

Adhi: We utilise various packaging material types, across various equipment within our operations� The learnings I have taken throughout my studies in this degree has already given me interesting insights into how packaging materials interact with their respective machinery, even throughout the degree�

Additionally, the thesis has given me the chance to apply my knowledge in experimental design, and transferring this knowledge has been valuable to assist with technical trials preparation

4. Do you have any advice on why other people should complete the Diploma in Packaging Technology?

Adhi: The degree not only teaches you fundamental knowledge on packaging technology, but it also helps you create a very strong network with other industry professionals Conversations and discussions with these amazing individuals will help you expand your critical thinking, leadership and communication skills to elevate you further in your career� Take the chance to connect and share experiences as much as you can�

5. So where to from here for your career?

Adhi: There is still so much to learn within the scope of my current role, so I am simply giving everything a go, while learning from others and sharing knowledge along the way� We are on the pathway of uncharted territory with sustainable packaging materials, so it will definitely keep things interesting for a long time!

6. Will you consider applying to become a Certified Packaging Professional as your next professional development stage?

Adhi: Yes, I’m interested in pursuing the Certified Packaging Professional � I believe in continuous learning and staying prepared for the evolving demands of the industry

At the 2025 Annual General Meeting the Australasian Institute of Packaging (AIP) formally welcomed two new Board Members to the team. Shannon Doherty-Andall MAIP, Sustainability Manager, Australian Beverages Council and Joe Foster FAIP, Close the Loop Group will be joining the board as Associate Directors for Central Region and Northern Region respectively.

AIP President, John Bigley MAIP welcomed both Shannon and Joe to the Board and believes that both will bring a wealth of knowledge and expertise to the roles

“ Shannon and Joe are very familiar to many in the AIP as they have been long-standing contributors and supporters of the Institute for a long time. Joe Foster has been a major influencer in the Australasian packaging industry for many years, being recognised as a Fellow of the AIP, as well as in 2020 receiving a WPO Lifetime Achievement Award. Joe will be a huge asset to the board bringing both his business acumen and passion for education and training. Joe’s pedigree in packaging innovation in flexibles also brings another dimension to the team and I look forward to working alongside him.” Mr Bigley said �

“Shannon is a sustainability professional which helps bring a different lens to the discussions, as well as being such a great supporter and member of the AIP. Shannon’s energy is infectious, and she will bring a different, and very valuable, perspective to the board and I look forward to working alongside her,”

“Both board appointments demonstrate the AIP’s strength in depth and calibre of membership, when we can draw upon such industry expertise. This is a very exciting and dynamic period for packaging and our members, and these appointments mean that the AIP Board is well resourced to help lead the AIP over the coming years.” he said

Shannon added that "The AIP has been an unmatched support throughout her career."

“The education, mentorship and community created by the AIP has helped me become a better member of the packaging ecosystem both in Australia and abroad. With how highly I've always thought of the AIP, I am extremely honoured and excited to have the opportunity to contribute to the future of the organisation, and to help ensure its programs reach every professional who could benefit from them in the region.” she said.

Joe also wanted to express his gratitude to the AIP for welcoming him to the board for the Northern Region�

“I am quite excited to be part of the team as I feel I can assist and contribute further to the packaging industry across Australia and New Zealand. Being in the packaging industry for the past 40 plus years has been so rewarding and an amazing journey starting in Europe, Africa and now Australia. Over these years I have learned and gained a lot of experience and knowledge which I love passing on to the ever changing packaging industry.” he said

Please join with the AIP in welcoming both Shannon Doherty-Andall and Joe Foster to the Board.

If you are looking to better understand careers, salaries, employment & education of packaging professionals in Australasia then complete the 2025 survey today.

Do you have any of the following packaging-related degrees?

• 29% of the respondents have a Diploma in Packaging Technology, 24% have completed the Fundamentals of Packaging Technology, 23% have the Certificate in Packaging and 12% have completed the Master of Food & Packaging Innovation.

• 31% of the total respondents have more than 20 years’ experience in the packaging industry. This is an indication of longevity in the industry and stable careers.

The AIP is pleased to advise that the 2025 Salary & Career Survey is now open for the Australasian Region; Australia, New Zealand and Asia. The annual survey and findings report has been developed in partnership with sister-association the IoPP.

This year’s Salary Survey – the only survey in the Australasian Region dedicated exclusively to benchmarking salaries and employment trends within the packaging industry – will provide a clear look into roles, experience, education, career satisfaction, challenges and salaries of packaging professionals.

The AIP is seeking input from packaging professionals to ensure that we can develop a definitive resource for our industry for the region.

With just a few minutes of your time, your thoughtful responses to the survey’s open-ended questions, will contribute to this important industry staple. The results from the survey will be made in to the 2025 AIP Salary & Career report and will cover roles, education, experience, career satisfaction, concerns and salaries. The report created from this survey does more than report your salary; it touches on your current employment status, educational factors, future career prospects and more.

Those who complete the confidential survey will receive the final 2025 report from the AIP for free.

The deadline to complete this survey is Tuesday 30 September 2025

Thank you in advance for your valuable input and we look forward to the results. Please extend this invitation to all of your colleagues across the region.

To complete the confidential survey please click here https://forms.gle/k8HPJacLeGH3AsAt7

For the fourth consecutive year the Australasian Institute of Packaging (AIP) has released the key findings from the 2024 Career & Salary Survey for the Food, Beverage and wider industries.

According to AIP Executive Director, Nerida Kelton FAIP, the Australasian Career & Salary Survey report was developed to provide a more detailed breakdown of the people who make up the industry including their roles, education, experience, career satisfaction, concerns and salaries� The survey and results cover the industry across Australia, New Zealand and Asia

“The 2024 Career & Salary report has some interesting findings and certainly highlights one of the key challenges that the industry has right now which is upskilling industry professionals in the science and technical side of all materials and pack formats. With more younger people entering the industry and a critical juncture in packaging regulatory changes, it is becoming even more critical that companies develop qualified technical packaging professionals as they start their careers,” Mrs Kelton said�

AIP Education Director, Prof Pierre Pienaar FAIP, CCPL added that ‘The AIP Career & Salary Report 2024 allows business, jobseekers and those hiring to make informed employment decisions based on technical skills and qualifications ’

“If you are growing your team, or simply need to retain the talent you have, then the AIP Career & Salary Report provides the insights to ensure that you have the most qualified team in place to keep your business moving in the right direction,” Prof Pienaar said�

What is your highest level

• 57% of the total respondents have a Post Graduate Degree and 29% have an Undergraduate Degree. This is a continued indication that the industry is highly educated with degree level qualifications.

“The 2024 Career & Salary Survey provides a summary of salary levels for a broad range of roles, but also an overview on how well qualified the people are that work in our industry. The industry is very-well skilled in some degrees, but with the ever-changing landscape for the packaging departments we still need to see more people qualified in the science, engineering and/or technology in packaging.”

“We also need to see more professionals working in the packaging industry, undertaking courses such as the Certificate in Packaging Technology, Diploma in Packaging Technology, undergraduate packaging qualifications and post graduate degrees in packaging disciplines. This will go a long way in improving the overall knowledge, improving the skillsets in the industry, so as to ensure that we have more people in the industry that have the knowledge to make informed packaging decisions, for the overall betterment of the industry. ” he said

Just some of the Key Findings:

• 31% of the total respondents have more than 20 years’ experience in the packaging industry Whilst this is an indication of longevity and stable career pathways within the industry, we have seen a 10% decrease since the previous year�

• 57% of the total respondents have a Graduate Degree and 29% have an Undergraduate Degree This is a continued indication that the industry is highly educated with degree level qualifications�

• 29% of the respondents have a Diploma in Packaging Technology, 24% have completed the Fundamentals of Packaging Technology, 23% have the Certificate in Packaging and 12% have completed the Master of Food & Packaging Innovation

• 31% of the total respondents work in Packaging Technology/Design, followed by 25% in research and 11% in Sustainability & Environment�

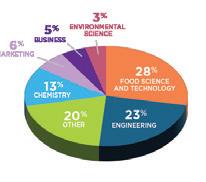

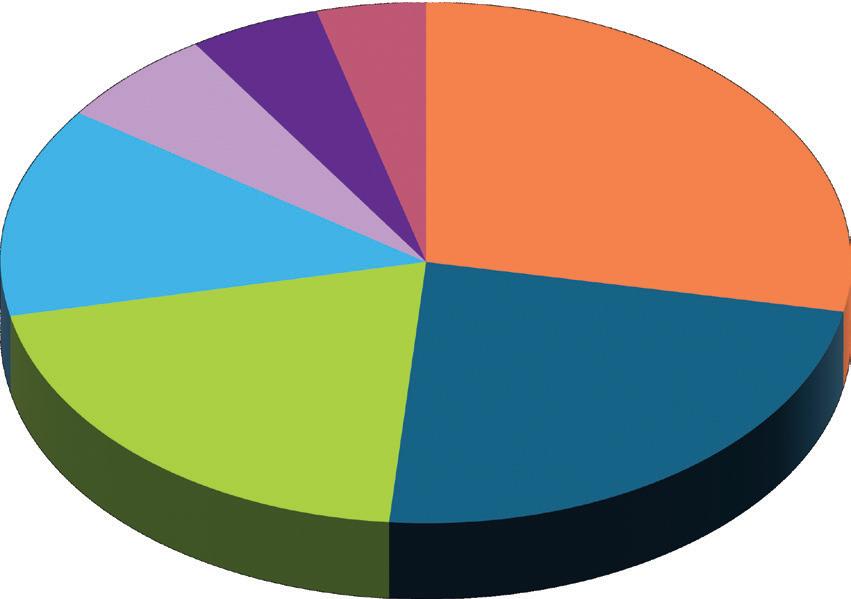

What type of degrees do you have?

58% of the total respondents have a degree in Food Science and Technology and 23% have a degree in Engineering.

• 48% of the total respondents work in the Food industry, followed by 12% in Packaging materials and 12% in the Beverage industry

• 41% of the total respondents feel somewhat very secure with their job, while 34% ‘feel very secure’, which is a significant shift since the previous results

• Respondents indicated that some of the biggest challenges the business is facing includes the cost of raw materials, high labour costs, customer reluctance to understand price increases, recycled content sourcing and pricing, changes to the regulatory framework and meeting the 2025 National Packaging Targets�

AIP Members can access the full 2024 AIP Career & Salary Survey report by emailing info@aipack.com.au with their request for a copy.

An executive summary is available to the wider industry.

Do you have any of the following packagingrelated degrees?

• 29% of the respondents have a Diploma in Packaging Technology, 24% have completed the Fundamentals of Packaging Technology, 23% have the Certificate in Packaging and 12% have completed the Master of Food & Packaging Innovation.

The AIP would like to welcome PEFC as our latest Corporate Partner.

Who are PEFC?

PEFC (Programme for the Endorsement of Forest Certification) is the world’s leading forest certification system and a global alliance promoting sustainable forest management through independent third-party certification� With members in 55 countries, PEFC works to ensure forests are managed responsibly� In Australia, Responsible Wood is PEFC’s national member, championing the forest certification scheme and ensuring Australian forests are managed in line with international sustainability standards, adapted to national contexts�

Together, PEFC and Responsible Wood provide a robust framework for sustainable supply chains for forest-derived products, such as packaging and more PEFC and Responsible Wood offer valuable tools to help Australasian Institute of Packaging (AIP) members source PEFC-certified materials, ensuring that fibre-based packaging is responsibly sourced and aligns with global sustainability goals and consumer expectations� By adopting PEFC-certified materials, AIP members can demonstrate their commitment to environmental responsibility while supporting the global effort to safeguard forests Certification helps businesses meet the growing demand for sustainable products, providing a trusted label that connects consumers to sustainably managed forests�

PEFC are proud to announce they are a corporate partner of the Australasian Institute of Packaging.

is a trusted web-based Life Cycle Assessment (LCA) tool by Lifecycles It is used by packaging professionals to measure and compare the sustainability of packaging options across the supply chain to support science-based decisions Use cases

The AIP would like to welcome Finest as our latest Corporate Partner.

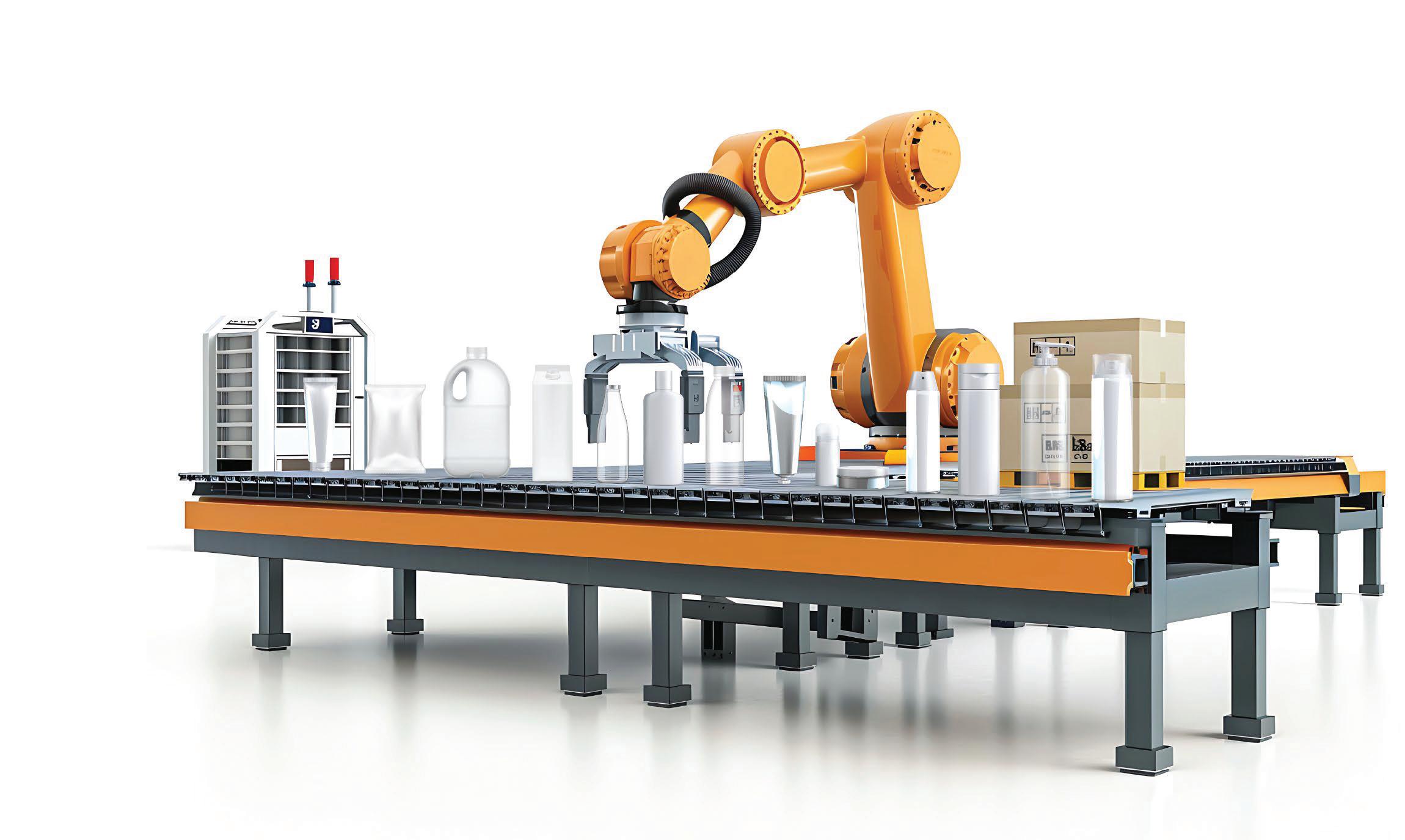

Finest is a globally recognised expert in plastics – family-owned, operated, and committed to ecofriendly manufacturing. As a world-class injection moulder, they specialise in custom packaging solutions for the food and non-food industries. With over 100 highly automated injection moulding lines in operation, their dedication to quality and sustainability has earned them the prestigious Gold EcoVadis Medal.

Finest offer a wide range of sizes, and they are also equipped to develop custom packaging tailored to your needs� Their Easylid containers, tubs, and lids are designed to support your sustainability goals while giving you a competitive edge in the market

Do not hesitate to get in touch to discuss your next project or request Easylid samples� Based in Adelaide, their Commercial Manager for ANZ, Darren Phillips, is available to chat today – feel free to call or email him directly, darren�phillips@finesthk�com�hk, 0403 918 402�

Finest are relatively new to the Australian market and it is evident that AIP play a major role in the sustainable food packaging landscape. Following a discussion with Nerida, it became clear that joining the AIP network was essential. By collaborating, it will help us showcase the patented Easylid design to more sustainable, innovative, forward-thinking brands.

Finest are proud to announce they are a corporate partner of the Australasian Institute of Packaging.

If you have one or these textbooks lying around gathering dust please send them to:

PO BOX 400

Mount Ommaney 4074 Queensland, Australia or drop them off to us at one of our up-coming events.

The AIP is looking to REUSE 3rd, 4th and 5th editions of the FPT textbook and share them with our overseas Members & Colleagues who cannot afford these textbooks.

Please make sure you let us know who you are so that we can take a photograph of the lucky recipient with your book.

The AIP would like to welcome Robatech Australia as our latest Corporate Partner.

Who are Robatech Australia?

Robatech optimises the industrial application process for hot melt and cold glue providing sustainable and innovative adhesive application systems. Since 1975 Robatech has designed and produced high-quality controls, application heads, melting and dosing systems that bring more sustainability, security, and simplicity to gluing processes. The company is headquartered in Switzerland and is known for its fast, straightforward, and personalised service for any gluing system all over the world.

For the Australian market, Robatech Australia actively contributes its in-depth expertise to industry discussions on glue-saving and reliable adhesive application processes — from primary and secondary packaging to tamper-proof folding boxes, resealable shipping packages, bottle labelling, transport boxes, and palletising Furthermore, as well as providing comprehensive service and genuine spare parts for Robatech and non-Robatech systems, their adheisve saving technology can be retrofitted to non-Robatech systems providing siginficant returns without significant investment�

Contact: Robatech Australia 61 2 9748 4559 I infodesk@robatech com au www�robatech�ch

Robatech Australia are proud to announce they are a corporate partner of the Australasian Institute of Packaging. ADHESIVE APPLICATION EXPERT

Personalized advice, fast service, and deep process know-how for the Australian packaging market. Robatech Australia Pty. Ltd. I Unit 9/8 Millennium Court Silverwater NSW 2128 I Australia +61 2 9748 4559 I infodesk@robatech.com.au I www.robatech.ch

Henkel celebrates 50 years of innovation, sustainability and trusted partnerships in Australia

Henkel, a global leader in the adhesive technology and consumer goods markets, marks its 50th anniversary in Australia today� Building on its strong culture of collaboration and innovation, Henkel Australia aims to continue driving purposeful growth with a clear focus on sustainability, high-impact solutions and meaningful partnerships

“As we mark 50 years in Australia, I’d like to sincerely thank our partners, customers, and the incredible teams who’ve helped shape our journey. This milestone reflects our company purpose — Pioneers at Heart for the Good of Generations — underpinned by a strong brand portfolio and our ongoing commitment to collaboration, innovation, and sustainability. Looking ahead, we’ll stay focused on sustainable solutions, creating value for our stakeholders, and supporting the communities we’re proud to be part of,” says Daniel Rudolph, President of Henkel Australia and New Zealand�

Championing sustainability for the good of generations

Established in 1975, Henkel Australia operates both the Adhesive Technologies and Consumer Brands business units with approximately 300 team members across offices and plants in Kilsyth, Seven Hills, Chatswood, and Ingleburn

With sustainability at the heart of Henkel’s global strategy and local operations, Henkel seeks to drive new solutions that develop its business operations responsibly and successfully� In 2024, Henkel defined its net-zero roadmap, substantially extending its targets for emissions reduction along the entire value chain Henkel Australia has been contributing to the global strategy and corresponding initiatives by taking concrete action on several levels: Since January 2022, both Australian manufacturing sites have been operating fully on electricity from renewable energy sources These plants serve a wide range of industries and achieved a 50 percent reduction in carbon emissions in 2022, as compared to the previous year�

Henkel Australia is also a signatory of the Australian Packaging Covenant and actively supports the country’s national packaging targets The company is committed to reducing waste streams and single-use plastics as part of a broader ambition to move towards a circular economy Globally, Henkel has already increased its share of recycled plastic in its packaging to 25 percent, aiming to make 100 percent of its packaging recyclable or reusable by 2030

Another pillar to creating a more sustainable future for all is Henkel’s clear focus on Corporate Citizenship and volunteering initiatives Since 2019, Henkel Australia has had a longstanding partnership with Foodbank, the largest hunger relief charity in the country Over the past six years, the company has supported families across Australia with over two million wash loads of laundry detergent and 50,000 bottles of shampoo and conditioner Furthermore, the company has supported communities during crises like the 2020 bushfires and has continued to make annual winter donations to help vulnerable communities In addition, Henkel contributes to a more sustainable and inclusive society by actively sharing knowledge on responsible consumption across schools, workplaces, and its extensive partner and customer networks Henkel employees consistently demonstrate their commitment by participating in various volunteering initiatives, including environmental efforts like beach cleanups, preparing Christmas hampers for children, and regularly donating products to community groups in need

Pioneering spirit and trusted partnerships at the core of business success

Throughout the last 50 years, Henkel Australia has continued to strengthen its local presence through significant investments in innovation, digitalisation and infrastructure in an effort to better serve the needs of its partners and customers�

In the last decade, Henkel Australia has launched two new centres, with many more projects to grow their innovation capabilities across the Asia Pacific� In 2015, Henkel Australia opened its first Maintenance, Repair and Overhaul (MRO) Training and Application Centre in Melbourne� This was followed by the launch of the Research and Development Innovation Centre for Laundry and Home Care in Sydney a year later

By embracing digital transformation as a foundation for operational excellence, the company has implemented Smart Factory principles and systems At its Kilsyth site, Henkel has significantly invested in warehouse automation and at Seven Hills, the pack-off system has been fully automated to enhance agility, safety, and productivity�

Through strategic partnerships and key acquisitions, Henkel continues to drive purposeful growth, globally and locally, fostering innovative and sustainable solutions with an award-winning portfolio�

The global acquisitions of Critica Infrastructure and Seal for Life Industries in 2023 and 2024 respectively have enabled Henkel to extend its offerings in MRO composite solutions, positioning the company as a comprehensive partner in this field for customers in Australia

In 2015, Henkel strengthened its position as a market leader in the laundry sector by acquiring ColgatePalmolive’s laundry detergent and pre-wash brands in Australia and New Zealand � More recently, in 2023, Henkel expanded its portfolio further with the acquisition of laundry and home care brand Earthwise, broadening its product offerings across key retailers in Australia and reinforcing its commitment to sustainability

“Over the past 50 years, Henkel Australia has been strengthening both its businesses to meet the evolving needs of our customers. With our recent acquisition of the Earthwise brand, Henkel has expanded its awardwinning portfolio within consumer brands, fostering our position as a key player in the regional laundry and home care market,” says Scott Hull, General Manager, Consumer Brands, Henkel Australia and New Zealand

As testament to their strong partnerships, Henkel’s current portfolio has won numerous awards for both its business units Schwarzkopf, an innovative hair cosmetic brand, was recognised as 'Australia’s Most Trusted Brand' in the Haircare category by Reader’s Digest in 2015 and Schwarzkopf Extra Care was named 'Best Hairspray' in 2018 by beautyheaven�com�au’s 'Best in Beauty Awards' � In 2025, laundry brands Cold Power, Dynamo and Sard Wonder were highly commended by Reader's Digest as 'Trusted Brands for Laundry Detergent and Stain Removers' The adhesive product Loctite 55 was honoured with two Red Dot Awards this year, recognising the product’s robust and convenient design as well as the sustainability improvements of its packaging�

- Henkel

Earlier this year, Loctite 55 was also awarded the German Packaging Award 2024 and the WorldStar Global Packaging Award

To further foster innovation and shape the future, Henkel has partnered with universities and industrial partners in technology-oriented research projects This includes the 2023 Formula SEA-A Competition as well as sponsoring and technically equipping several student teams in the upcoming Bridgestone World Solar Challenge Such close collaboration allows Henkel to test the performance of their current sustainable solutions, while strengthening their bonds with future engineers and industrial markets

Empowering strong teams to deliver meaningful solutions

With a corporate culture rooted in collaboration and empowerment, employees in Henkel Australia are encouraged to lead with an entrepreneurial spirit� This allows the company to continuously deliver meaningful solutions that make a lasting impact

"At Henkel Australia, we’ve built a culture where everyone feels a strong sense of belonging and is empowered to thrive. Through our Smart Work approach, commitment to professional development, and a vibrant feedback culture that promotes open dialogue and continuous growth, we enable our people to shape their own career journeys. This environment not only supports individual development—it drives innovation, agility, and lasting success,” says Daniel Rudolph, President of Henkel Australia and New Zealand

Henkel has been named one of the Best Employers in Asia-Pacific 2025 by Financial Times & Statista in their inaugural ranking This recognition highlights Henkel’s ongoing commitment to fostering a workplace culture that prioritises inclusion, innovation, as well as collaboration and empowerment of its people Global initiatives such as Henkel’s gender-neutral parental leave and the company’s Smart Work approach were introduced in 2024 and 2021 respectively and are also available to all colleagues in Australia�

50 Years of Purposeful Growth – A good foundation for a promising future

To mark its 50th anniversary in Australia, Henkel held celebrations across three different locations, where team members from around the country came together to commemorate the company’s journey over the past five decades The leadership team also highlighted Henkel’s longstanding global heritage, while looking ahead to a promising future in the region based on shared values and employees’ vital contributions to business success

As part of the celebrations, Henkel Australia invited employees to select a meaningful cause to support, with the company donating on their behalf� The shortlisted organisations include Polished Man, Cancer Council, White Ribbon Australia, Beyond Blue, and World Wildlife Fund Australia This initiative reflects Henkel’s broader commitment to corporate citizenship and its employees’ wish to make an impact as ‘pioneers at heart for the good of generations’

Henkel Australia remains committed to being a trusted partner and innovation leader in the region With a strong foundation built over five decades and a clear vision for the future, Henkel Australia seeks to continue delivering value to its partners and customers with a sustainable business that benefits the generations to come

Contact Henkel to find out more... Call our toll-free Consumer Information Centre from 7am – 4pm AEST Australia: 1300 856 051 | New Zealand: 0508 528 637 | Email: lhc.consumeraffairs.anz@henkel.com

As a trusted leader of adhesives, Henkel has developed a range of adhesives for packaging and paper solutions that offers fast bonding for enhanced production processing and increased efficiency.

Our packaging adhesives provide excellent adhesion and bonding to a wide variety of surfaces and are used in applications ranging from folding cartons to food and beverage packaging.

Additionally, our portfolio of paper converting solutions enables new creative and sustainable design options for both food and non-food applications.

Global sourcing is a people business People with a worldwide network connecting you to the best global resources for local manufacture

People who know your business, understand your needs and will deliver the best results to you.

People with the supply chain systems experience and expertise to make sure you get what you want, when you want it.

For more than 35 years, National Resources has been connecting people to the best global resources for local manufacturing.

To find out more, contact us today.

National Foods are thrilled to announce their new partnership with LOG Pharma LOG Pharma stands as a premier provider and developer of cuttingedge primary packaging solutions tailored for the pharmaceutical industry� Established in 1971, the company has earned the trust of pharmaceutical giants around the world � Since January 2025, LOG has been a part of Swiss-based Perlen Packaging, which is a member of the international CPH Group

LOG specialises in creating and manufacturing highperformance barrier packaging that safeguards both innovative and generic medications from moisture and oxygen, thereby ensuring an extended shelf life

They provide an extensive array of packaging options designed to ensure that both tablets and liquid formulations are delivered in optimal condition � By leveraging LOG's expertise in innovative pharmagrade polymers and state-of-the-art technologies, the company has introduced an environmentally friendly barrier eco-packaging line to complement its worldclass range of barrier packaging solutions

LOG's diverse selection of innovative active and passive barrier solutions helps to shorten drug formulation development timelines, reduce time-to-market, extend shelf life, and facilitate compliance with drug stability tests� All pharmaceutical products adhere fully to US FDA and European pharmacopoeia standards

Barrier Eco Line by LOG Pharma

LOG Pharma specialises in world-class barrier packaging solutions designed to extend shelf life and safeguard both innovative and generic medications from moisture and oxygen exposure

Their barrier packaging options for liquids and solids come in standard capacities ranging from 15 to 1500 ml, with compatible neck finishes between SP20 and SP53

Recently, LOG introduced the innovative Barrier Eco line, which significantly lowers the production costs of eco-friendly barrier bottles while providing optimal oxygen scavenging solutions

By leveraging LOG's expertise in advanced pharma-grade polymers and state-of-the- art technologies, they enhance their exceptional range of barrier packaging solutions

The product range includes:

• Mono Block ECO: Reducing oxygen permeation

• Oxy Block ECO: Reducing moisture permeation

• Multi Block ECO: Reducing both oxygen and moisture permeation

The product range offers a high-performance barrier and is a cost-effective solution� It extends the shelf life of drugs and is made from lightweight materials� The need for drop-ins is reduced, and it features passive protective attributes A unique pharma grade HDPE resin, developed by DOW, with superior gas properties, allows for the reduction of bottle weight of up to 30%, without compromising on the WVTR (Water Vapour Transmission Rate)�

Check out our Podcast! The coversation connecting industry is proudly available on Spotify and all other audio platforms.

hello@ecoporium.com.au ecoporium.com.au 0421 619 558

Our Labels & Packaging division are specialists in working with brands, printers and convertors on the selection of materials for a diverse range of market sectors. Our products are backed by our specialist teams including dedicated sales and technical support

We are a trusted partner for brands as they journey to explore more conscious materials choices for their products and how this represents them through the lens of their consumers.

Ball & Doggett are the market leader in supplying materials to the Graphics and Communications industry.

We turn big ideas into reality.

• Regularly advertise products in newsletter.

• Logo recognition on AIP emails.

• Logo on AIP website.

• Regularly share product launches and staff updates in newsletter.

• Elevate your brand, products & services in front of the AIP community.

• Dedicated packaging audience across Australasia.

Foodtech Packtech 2025

WHEN: 2-4 September 2025

WHERE: Auckland Showgrounds

WHAT: Foodtech Packtech (FTPT) is New Zealand’s largest food manufacturing, packaging and processing technology trade show Running strong for over 20 years this free to attend event brings industry professionals and decision makers together providing a forum for education, discussion and the sharing of knowledge and expertise, critical in the sustainability and growth of the industry� Held only once every two years FTPT is a must attend event providing visitors with the opportunity to come face-to-face with the experts and discover the freshest ideas, latest technologies and the newest developments entering the F&B manufacturing and packaging technology industries

Featuring the Materials Handling & Logistics Expo, the event will attract 250+ local and international exhibiting companies and some 4,500+ qualified visitors – a must attend event for anyone involved in one of New Zealand’s fastest growing industry sectors�

Looking to exhibit? We are excited to announce you can now book your Foodtech Packtech exhibitor stand through the AIP� Support the industry and AIP by contacting Nerida Kelton +61 (0) 7 3278 4490 / nerida@aipack com au

WHEN: 2 September 2025

WHERE: Auckland Showgrounds

WHAT: The AIP will be once again running the NZ Packaging Forum alongside of Foodtech Packtech on Day one of the show� This forum has been running for over 15 years and will bring together leading experts in all areas of packaging from across the Australasian region� The forum will be a free to attend full day of packaging sessions where attendees can come and listen all day, or just in the sessions they would like

We’re excited to announce you can now book your Foodtech Packtech exhibitor stand through the AIP!

2 – 4 September 2025 | Auckland Showgrounds 3,400+

New Zealand’s premier trade exhibition for the food & beverage manufacturing,

Up-coming AIP supported forums, training, tradeshows & webinars

Tuesday 2 September 2025 | Auckland

Richard Manaton Chief Operating Officer GS1 New Zealand

Nerida Kelton FAIP Vice President - Sustainability & Save Food World Packaging Organisation (WPO)

Shaun Lewis General Manager Waste Systems & Operations Ministry for the Environment

Raewyn Bleakley Chief Executive NZ Food & Grocery Council

Emily Thomas MAIP Snr Packaging Innovation Technologist Fonterra Co-operative Group

Chris Thomas Divisional Manager Packaging BJ Ball NZ Ltd

Sarah Brown Industry Relations Manager Pact Group

Apoorv Mehrotra Field Sales Manager - Paper Bag Oji Fibre Solutions (NZ) Limited

Jess Broun Program & Account Manager Kai Commitment

Daniel Yallop Business Development Manager Re.Group

Alan Adams MAIP Sustainability Director - ANZ Sealed Air

Lyn Mayes Soft Plastics Recycling Scheme Manager The Packaging Forum

Debra Goulding Sustainable Packaging Program Manager Foodstuffs New Zealand

Rob Langford Head Business and Projects Plastoil

Timothy Grant AAIP Founder & Director Lifecycles

Nasim Aflatoon AAIP Sustainability Manager Bunzl Asia Pacific

Blair Jordan Processing Director Oceania TetraPak

Bruce Caldwell Sales Manager ANZ, Corrugated - Sign & Display Kissel + Wolf

Philip Bracey Country Manager, NZ UPM Adhesive Materials

Ben McCulloch AAIP Category Manager – Sustainability Martogg

Sarah Yanez MAIP, CPP Owner Goldies Wholefoods

Sam Loader New Product Development Manager Apex Brands

WHEN: 4 September 2025

WHERE: Auckland Showgrounds, New Zealand�

To be held alongside

WHAT: The AIP will be offering not one, but two globally recognised mini training courses at Foodtech Packtech New Zealand at the Auckland showgrounds. All attendees will receive a Certificate of Attendance and also 6 points per course towards attaining the global Certified Packaging Professional (CPP) designation. Please book your place at either one, or both of the training courses. 1. Understanding the Fundamentals of Flexible Packaging or 2. The Future of Flexible Packaging Design.

WHEN: 4 September 2025: 9 15 am arrival, 9 30 am to 12 00 noon

WHERE: Alongside Foodtech Packtech 2025, Auckland Showgrounds, NZ

WHAT: The Understanding the Fundamentals of Flexible Packaging training course will cover the basic fundamentals of flexible packaging, its benefits, how you chose the specific structures to match the product, its performance, marketing challenges and how the packaging is manufactured

Leading the way in packaging innovation, flexible packaging adds value and marketability to food and non-food products alike From ensuring food safety and extending shelf life, to providing even heating, barrier protection, ease of use, resealability and superb printability, the industry continues to advance at an unprecedented rate�

The life cycle attributes of flexible packaging demonstrate many sustainable advantages� Innovation and technology have enabled flexible packaging manufacturers to use fewer natural resources in the creation of their packaging, and improvements in production processes have reduced water and energy consumption, greenhouse gas emissions and volatile organic compounds

WHEN: 4 September 2025: 12 45 pm arrival, 1 00 pm to 3 30 pm

WHERE: Alongside Foodtech Packtech 2025, Auckland Showgrounds, NZ

WHAT: With global focus still pointed heavily at curbing plastic waste (and plastic packaging waste in particular), the future of flexible packaging is multi-faceted and diverse- just like this mini course

Attendees will be presented with an overview of the industry and what is driving changes in the category both locally and abroad, including considerations surrounding food waste, emissions, legislation, and on-pack labelling requirements

Objectives:

• To understand the important role that flexible packaging plays in the supply chain.

• To learn about the various flexible packaging materials that can be utilised for more sustainable outcomes.

• To understand the key tailwinds driving the flexible packaging industry and the relevant obligations of brand owners and packaging suppliers in the short-medium term.

• To understand the challenges and opportunities that exist with the recycling and processing of soft plastics.

• To discover the vast resources available to brand owners and suppliers to support them through the ever-changing landscape of flexible packaging.

LECTURER:

Joe Foster FAIP AIP Education Team

Product Stewardship & Away from Home Collection

WHEN: 17 September 2025

WHERE: On-line via Zoom

WHAT: The European Union Packaging & Packaging Waste Regulation (PPWR) officially entered into force on 11 February 2025, replacing the Packaging Directive (Directive 94/62/EC).

The Packaging & Packaging Waste Regulation (PPWR) aims to:

• Reduce packaging waste by 15% per person in each Member State by 2040, compared to 2018 levels This will be achieved, for example, by cutting down on unnecessary packaging, especially single-use and overpackaged items;

• Make packaging fully recyclable by 2030, with specific rules and criteria to enhance recyclability of different materials;

• Promote reuse or refill by requiring companies to offer a portion of their products, such as takeaway drinks and meals, in reusable or refillable packaging; and

• Standardise packaging formats and improve labelling of reusable packaging making it easier for consumers to make more sustainable choices

In addition, there will be eco-modulated Extended Producer Responsibility (EPR) fees based on recyclability These rules and targets apply to all packaged products sold in the EU If you export your products to Europe then you need to know about the PPWR

This webinar will provide an update on the PPWR and enable attendees to walk away with a basic toolkit for implementation and next steps Circular Analytics are one of the leading experts in PPWR for packaging designers and technologists so this is a not-to- be-missed webinar�

By attending the Packaging and Packaging Waste Regulation (PPWR) Webinar you will:

• Be introduced to the PPWR regulatory framework and its key provisions

• Learn about the core objectives, timelines, and compliance milestones

• Better understand how to adopt the PPWR – key actions for brands, suppliers, and manufacturers

• Navigate reporting requirements

SPEAKERS:

Lina Wimmer Senior Consultant Circular Analytics

WHEN: 7-10 October 2025

WHERE: Tokyo Big Sight East Exhibition Hall (Koto-ku, Tokyo)�

WHAT: JAPAN PACK is Japan's leading biennial packaging industry exhibition, which has been held 34 times since the first exhibition was held in 1964� The latest solutions, innovations, and trends related to production lines from major Japanese packaging machinery manufacturers and companies from Japan and abroad will be gathered under one roof By matching the various issues faced by stakeholders with solutions to those issues, we create new values, such as improved productivity and promotion of sustainability, as well as develop new business initiatives As one of Japan's leading packaging trade shows, JAPAN PACK continues to be highly anticipated by the packaging and related industries

WHEN: 15 October 2025, 10.00 AEDT / 9.00 am AEST

WHERE: On-line via Zoom

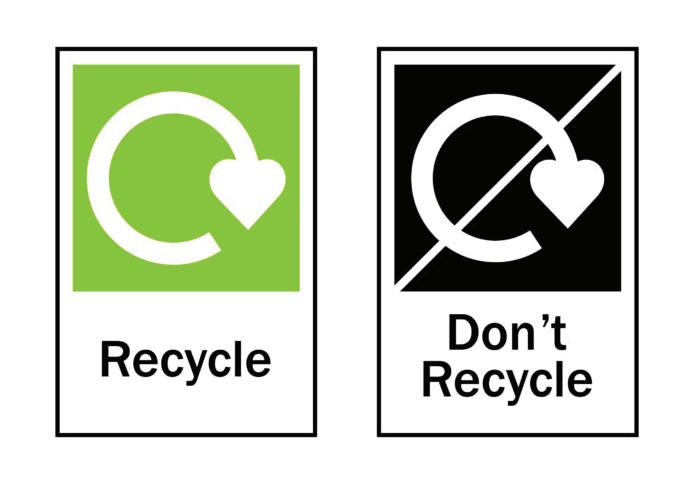

WHAT: Packaging Producer Responsibility obligations and regulations have been in play in the United Kingdom (UK) since 2023, replacing the 2007 Regulations in 2025. Alongside this change is the introduction of further regulatory requirements around Deposit Return Schemes, and harmonised packaging collection for businesses and at kerbside.

Alison Appleby, Packaging Sustainability Specialist for Ecosurety, a UK packaging compliance scheme, joins the AIP to talk about the complex UK packaging regulatory landscape�

Alison will share detail on the following, highlighting similarities and differences with the Australian packaging landscape along the way:

• The UK Packaging Extended Producer Responsibility Regulations, including detail on the Recyclability Assessment Methodology (RAM) and eco-modulation of Waste Management Fees�

• Updates on Simpler Recycling regulations, with detail on upcoming kerbside collection requirements�

• Deposit Return Schemes and how they will operate throughout the UK

• Additional regulations in the region which need to be considered for packaging design

Ecosurety is a leading packaging EPR compliance scheme on a mission to rid the world of unnecessary packaging� Using data-driven insights, market-leading tools and multidisciplinary expertise, they help businesses to comply with packaging EPR and make sustainable packaging decisions A B Corp since 2020, Ecosurety is guided by its purpose of accelerating change towards an environmentally and socially sustainable world

SPEAKER:

Alison Appleby

Packaging Sustainability Specialist

Ecosurety

WHEN: 20 & 22 October 2025, 9 am - 1.00 pm

WHERE: South West - Monday 20th October 2025 | Margaret River

HEART

Perth - Wednesday 22nd October 2025 | The Hub Bentley

WHAT: Come and join the WA DPIRD workshops for Food & Beverage Manufacturers in South West Margaret River & Perth.

Join DPIRD and AIFST for two half day interactive workshops in October, where Nerida Kelton FAIP and Ralph Moyle FAIP, CPP from the Australasian Institute of Packaging (AIP) will discuss all things sustainable packaging for food and beverage businesses

The Unboxing Sustainable Packaging workshop will take participants through regulations, trends and guidelines for packing their product�

Participants will be able to walk away from the workshop with a better understanding of:

• Global, domestic and local WA new packaging and waste regulations, including regulations for single use plastics, extended producers, FOGO, compostable packaging and eco packaging�

• How to design your packaging to be recycle ready, have a lower environmental impact and meet regulations that are coming to Australia

• The importance of data in packaging including packaging specifications and lifecycle assessment

• Packaging design guidelines for Sustainability and Accessibility & Inclusivity�

• Addressing food waste and loss through Save Food Packaging guidelines

After the workshop, participants will be able to register for consultations. The team from the AIP will be offering 15-minute in-person consultations with businesses after the workshop at the venue.

Sessions may be one-on-one or in small groups, depending on the topic You can request a consultation when booking your ticket— you must provide details on the subject matter you would like to discuss A time will be allocated closer to the workshop�

Please note: consultations are limited and not guaranteed.

We encourage you to use this opportunity to connect with the AIP; the peak professional body for packaging training & education in Australasia�

Book your place today so you don’t miss out!

20th October South West Margaret River

22nd October Perth Event

ProPak Indonesia 2025

WHEN: 19-22 November 2025

WHERE: Jakarta, Indonesia�

WHAT: ProPak Indonesia is the leading international processing and packaging trade event in Indonesia for Processing & Packaging technologies Powered by ProPak Asia, ProPak Indonesia is part of the event series taking part in the region showcasing a comprehensive array of innovative products to a thriving and expanding local market in Indonesia� It is the centerpiece where market trends converge, and industry networking evolve to valuable customer insight ProPak Indonesia is the ‘must-attend’ processing and packaging event in Indonesia delivering an industry-focused platform connecting worldwide suppliers to both local and regional buyers in the food & beverage, consumer & personal goods, and pharmaceutical industrial sectors

WHEN: 20 November 2025

WHERE: ProPak Indonesia, JIExpo Kemayoran, Jakarta

WHAT: The AIP will be running the 2nd Indonesian Packaging Forum in partnership with Pamerindo over two days This forum will bring together global and local speakers to discuss a wide range of packaging topics

WHEN: 22 November 2025

WHERE: ProPak Indonesia, JIExpo Kemayoran, Jakarta

Ragita Wirastri Promotion, Marketing & Communication Manager Indonesian Forestry Certification Cooperative (IFFCC)

Pearl Chan Sustainability Director Reloop by Nature’s Lab

Puvaneswaran Jsu Strategic Account Manager Sout APAC X-Rite Pantone

Eki Setijadi Co-Founder & Chief Operating Officer Jangjo

DAY 2: THURSDAY 20th NOVEMBER

DAY 4: SATURDAY 22nd NOVEMBER

FREE TO ATTEND JIEXPO Kemayoran, Jakarta

William Sukiban Sales Manager Indonesia UPM Raflatac Indonesia

Yanjie Zheng Manager – Circular Economy, Packaging & Consumer Goods Adhesive Technologies Henkel Management Centre (HMC)

Ralph Moyle FAIP, CPP Education Coordinator Australasian Institute of Packaging (AIP)

Huangyi Chen Sustainability Manager, APAC South SIG Group

LTC Joseph Ross Jocson President Asian Packaging Federation (APF)

Terrynz Tan Sustainability Director – ASEAN Tetra Pak

Hiroyuki Otsuka Technical Manager Toppan Plasindo Lestari

Ovy Sabrina Co-Founder & Chief Operating Officer Rebricks Indonesia

Devaki Rajendran APAC Sustainability Manager MCC Label

Rocky Pairunan NPAP Manager/Ocean & Plastic Waste Manager World Resources Institute (WRI) Indonesia

Jayant R. Kadu Manager (Marketing) Functional Materials Division Mitsui Chemicals

Surendra Soni Executive Director - Marketing, Asia SealedAir Corporation

19-22 Nov 2025

Opening hours: 19-21 Nov (Wed-Fri) 10AM-06PM I 22 Nov (Sat) 10AM-05PM JIEXPO Kemayoran Jakarta, Indonesia

WHEN: 25-27 November 2025

WHERE: Shanghai New International Expo Centre (SNIEC), China

WHAT: swop is the essential event for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors No other trade fair in China represents the entire supply chain And at no other trade fair in China does the packaging industry provide all industry sectors with tailored solutions and innovative designs based on such a variety of materials

WHEN: 9-11 December 2025

WHERE: Egypt International Exhibition Centre, Cairo, Egypt

WHAT: The International Exhibition for Processing & Packaging in the Middle East and Africa

• Addresses the requirements of the food, beverages, confectionery, bakery, pharmaceuticals, cosmetics, non-food, and industrial goods sectors in the Middle East and Africa region�

• Brings together local and international industry stakeholders from across the entire value chain

• Capitalises on mega opportunities in one of the major economic hubs in North Africa; also serving as the gateway to regional markets�

WHEN: 4-6 February 2026

WHERE: World Trade Centre Metro Manila, Pasay City�

WHAT: ProPak Philippines is the leading international processing and packaging trade event for the Philippines It is the perfect platform for market trends, investments and industry networking through product exchange and a variety of conferences, seminars and technical workshops offering sustainable solutions for the country’s enterprises The event provides various industries with access to the latest development in packaging and processing machines and technology from leading companies across the globe The exhibition delivers a brilliant industry-focused event connecting international suppliers to local and regional buyers in food, drink and pharmaceutical manufacturing industries� With supportive governance, the Philippines has forecasted strong and dynamic growth across its industries with the backdrop of rising incomes, expanding & changing consumer demands, and increasing export potential

WHEN: 31 March - 2 April 2026

WHERE: Saigon Exhibition & Convention Centre (SECC) Ho Chi Minh City, Vietnam

WHAT: ProPak Vietnam is poised to showcase the latest advancements in the Processing, Packaging, and Packaging Technology sectors, solidifying its status as the 18th International Exhibition and Conference dedicated to these industries in Vietnam� Organised by Informa Markets - Vietnam, this tradeshow will take place at the Saigon Exhibition and Convention Center, a prominent venue located in Ho Chi Minh City The exhibition is not just a display of technology but an engaging platform for industry professionals to explore cutting-edge solutions tailored to enhance operational efficiency and product quality in the manufacturing and processing sectors

AIP to Partner - Vietnam Packaging Forum, Training Courses & Stand

What’s New in Food Technology Manufacturing magazine and the Food Processing website provide busy food manufacturing, packaging and design professionals with an easy-to-use, readily available source of information that is crucial to gaining valuable industry insight.

ProPak Asia 2024 Post Show Fact Sheet

Show Title: ProPak Asia – The 31st International Processing and Packaging Exhibition for Asia

Date & Time: 12-15 June 2024

Venue: BITEC, Bangkok, Thailand

Exhibit Area: 55,000 Sq.m.

Participants: 2,000 Exhibitor Brands from 42 Countries

International Pavilions: 14 International Pavilions from 12 Countries and Regions

Australia, Bavaria, China, France, Italy, Japan, Malaysia, North America, Singapore, South Korea, Switzerland, and Taiwan ROC

Trade Attendees: 68,218 Attendees from 83 Countries and Regions

JUNE 2026

ProPak Asia 2026

Top 10 International Visitor Countries:

WHEN: 10 - 13 June 2026

WHERE: Bangkok, Thailand

Afghanistan, Africa, Australia, Austria, Bangladesh, Belgium, Bhutan, Brazil, Brunei, Cambodia, Canada, Chile, China, Costa Rica, Czech Republic, Denmark, Egypt, Fiji, Finland, France, Georgia, Germany, Ghana, Holland, Hong Kong S.A.R., Hungary, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Japan, Jordan, Kenya, Kuwait, Kyrgyzstan, Laos, Lebanon, Lithuania, Luxembourg, Macau S.A.R., Malaysia, Maldives, Mauritius, Mexico, Mongolia, Morocco, Myanmar, Nepal, Netherlands, New Zealand, Nigeria, Oman, Pakistan, Palestine, Papua New Guinea, Peru, Philippines, Poland, Portugal, Romania, Russia, Saudi Arabia, Singapore, Slovakia, South Africa, South Korea, Spain, Sri Lanka, Sweden, Switzerland, Taiwan ROC, Tanzania, Thailand, Tonga, Turkiye, UK, United Arab Emirates, The USA, Vietnam, Yemen

AIP to Partner - Global Packaging Forum, Training Courses, Workshops, PIDA showcase & Stand

Philippines, Malaysia, China, Japan, Cambodia, Indonesia, Vietnam, Singapore, Myanmar, India

WHAT: ProPak Asia is Asia's Number One international trade event for Processing & Packaging Technology� ProPak Asia truly is the 'Must-Attend' industry event in Asia for Asia, as quality and variety of products increase and expand, and productivity of operations and manufacturing standards are driven higher by consumer demands and new automation and technological advances, which will be presented at the show

VISIT OUR WEBSITE WWW.PROPAKASIA.COM

TO REGISTER YOUR INTEREST, PLEASE EMAIL US AT INFO@AIPACK.COM.AU

EXPERIENCE A WEEK OF UNPARALLELED OPPORTUNITIES

nnual Global Packaging Forum: Gain insights from industry leaders.

Exclusive Training Courses: Enhance your skills and knowledge.

Interactive Workshops: Collaborate and innovate.

Showcase Display: Witness cutting-edge packaging solutions.

AUSTRALASIAN INSTITUTE OF PACKAGING (AIP) IS THRILLED TO INVITE AUSTRALIAN AND NEW ZEALAND PROCESSING AND PACKAGING BUSINESSES TO JOIN OUR DEDICATED GROUP DELEGATION AT PROPAK ASIA 2026 DURING 10 – 13 JUNE IN BANGKOK!

JOIN THE AUSTRALASIAN INSTITUTE OF PACKAGING (AIP) GROUP DELEGATION AND GAIN

Access to leading suppliers across Food & Beverage, Pharmaceutical, Cosmetics, and related industries. Exclusive networking with key industry decision-makers. Benefit from complimentary airport pick-up and drop-off services, as well as a shuttle bus service between the hotel and the venue during your stay. Delegates may be eligible for complimentary accommodation for a seamless experience. Enquire today!

“It was great to be part of the first Australasian Delegation, hosted by the Australasian Institute of Packaging, at ProPak Asia 2025. ProPak Asia is thriving, with strong industry engagement and many returning exhibitors. AIP’s training sessions and workshops drew strong interest, and the AIP PIDA showcase was a standout.”

“Thank you so much AIP for organising the first-ever Australian Delegation and for the invitation for us to attend. Propak Asia was such a great show, fantastic exhibitors, very well run, the AIP stand featuring all the PIDA winners was amazing, and the organisation of the delegation, dinners, and getting in and out of the show was seamless. Can’t wait to do it all again. Many thanks.”

“Another year at ProPak Asia but this time around I was there as AIP Australasian delegate. Thank you to the AIP for the continuous support for those AIP Members outside of Australia. Your continuous effort in organising events and upskilling packaging professionals around Asia is commendable. I was also very lucky to gain knowledge from Ralph Moyle and Prof Pierre Pienaar during the four days. Their experience and efforts to share knowledge to people of all different levels is quite remarkable.”

foodpro 2026

WHEN: 26 - 29 July 2026

WHERE: Melbourne Convention and Exhibition Centre

WHAT: Australia's Leading Trade Event for Food Processing, Packaging and Innovation

The manufacturing sector is vitally important for our economic future, with food and beverage processing being Australia’s largest manufacturing industry.

For over 50 years, foodpro has gathered the industry to celebrate the contribution of Australian food producers, distributors and manufacturers foodpro connects professionals across the food and beverage value chain seeking cutting-edge solutions in processing, packaging, beverage equipment, digital technologies, logistics, and sustainability to drive efficiency, compliance, and growth�

Foodpro returns in 2026 to the MCEC as Australia’s leading event for the food processing and manufacturing industry

The AIP will be once-again partnering with foodpro with an exhibition stand, some packaging sessions and training courses� Stay tuned for more information�

WHEN: 16 - 18 November 2026

WHERE: Shanghai New International Expo Centre (SNIEC), China

WHAT: swop is the essential event for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors No other trade fair in China represents the entire supply chain And at no other trade fair in China does the packaging industry provide all industry sectors with tailored solutions and innovative designs based on such a variety of materials

Written by Nerida Kelton FAIP

It is not very often that I have the honour of speaking as the VP Sustainability & Save Food for the WPO World Packaging Organisation, in my own country, so yesterday was a wonderful opportunity to present a global view at the annual Australian Food and Grocery Council Sustainability Summit.

The AFGC Sustainability Summit was also a perfect avenue to showcase to the 100 attendees, all of the amazing work that the WPO undertakes to develop free position papers, case studies, reports, waste stream mapping tools and of course, the Global Packaging Design for Recycling Guide � Many attendees were unaware of these free resources that are available on the WPO website

�

I provided a global lens on what sustainability looks like for many of the WPO Member countries and showcased the 2025 Sustainability WorldStar Awards winners I also discussed some of the barriers, challenges and gaps that many countries are facing right now to establish, robust Sustainable strategies, programs and regulations

Whilst it important to think globally and with a consistent harmonised approach, each country still needs to act locally and take the appropriate pieces of the Sustainability puzzle to suit Country-specific requirements

�

The message was loud and clear yesterday from all of the speakers and attendees��� the entire industry must collaborate and work together to harmonise design standards, create recycle-ready packaging, prioritise domestic recycled content, design out waste at the start, and ensure that there are appropriate systems to collect, sort, recover and recycle valuable resources� The sentiment in the room was that the food and grocery industry supports the principle of Extended Producer Responsibility for Australia, but it needs to deliver real outcomes to strengthen existing infrastructure and facilities, create new capabilities where needed for materials that sit outside of MRFs and ensure that we have strong and viable end markets for all materials

�

There was support from many of the multinational Brands in the room for the work that Soft Plastic Stewardship Australia is undertaking to create a single harmonised soft plastics kerbside collection program for Australia

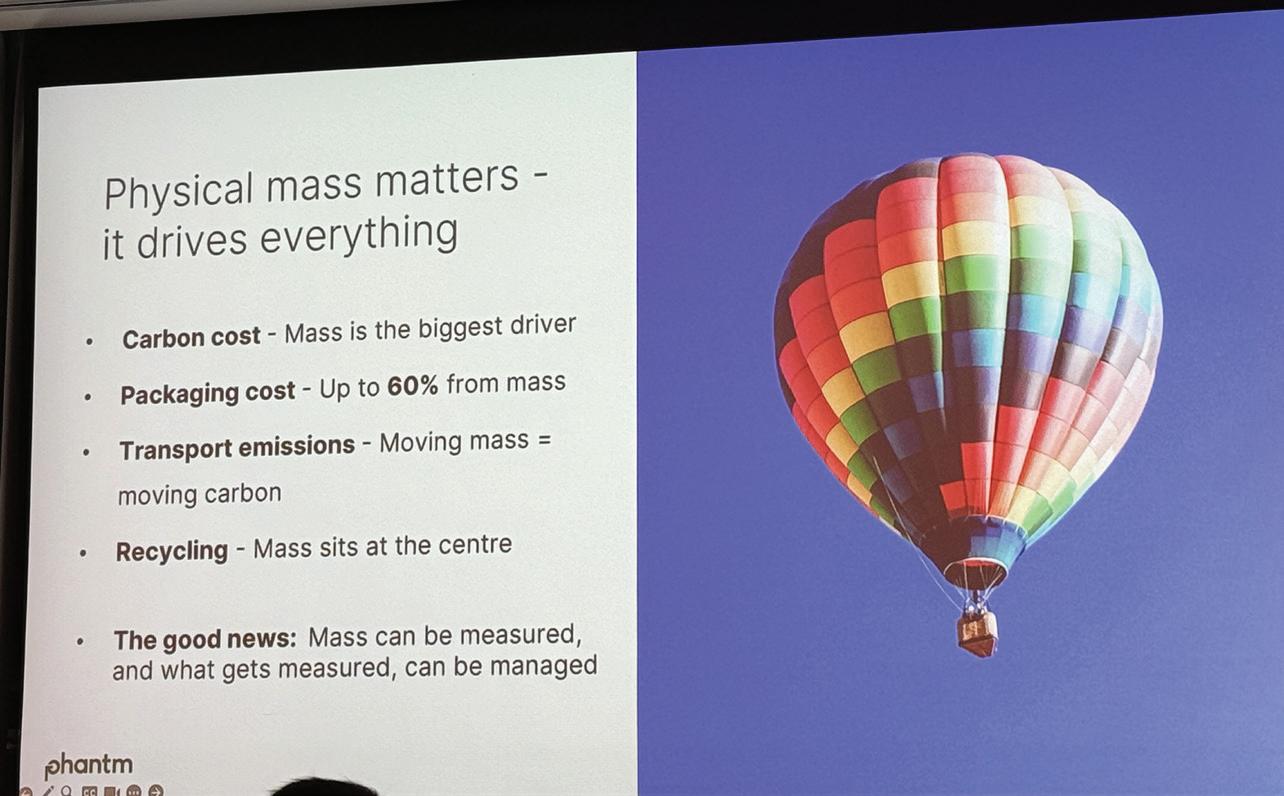

AIP Education Director, Ralph Moyle FAIP, CPP, was also invited to speak about the importance of data and why sitting on your hands waiting for Extended Producer Responsibility (EPR) regulations to come is going to cost your business time and money Ralph encouraged all of the attendees to start now, if they haven’t already, and to focus on the 2025 National Packaging Targets and the Sustainable Packaging Design Guidelines He also reminded everyone that they needed to get ready for the regulations by establishing data management systems for packaging specifications, packaging recyclability, evidencebased lifecycle assessment tools

As Bill Heague, General Manager, Mars Food Australia, said in his keynote address, the industry needs to take the lead in Australia and not wait for the regulations to come Bill encouraged the brands to be proactive and demonstrate real action through sustainability initiatives that make a difference and to engage in shaping the policies and regulations that are coming �

Bill also reminded everyone that that “Most people overestimate what they can do in one year and underestimate what they can do in ten years."

Food Entrée & Manufacturing is a comprehensive digital publication offering contents on the food and manufacturing industries. Published in English five times annually, the magazine covers a wide range of topics, including food automation, food processing and machinery, packaging and labeling, food ingredients and nutrition, nutraceuticals, snacks, confectioneries, food technology and innovation, beverage, milk and dairy, as well as news and trends in the food industry.

Our ultimate goal is to provide our readers and manufacturing businesses worldwide with the latest insights and information. With over 47,000 readers from the Asia Pacific region and beyond, our magazine is read by professionals, including managers, marketing executives, R&D professionals, business development managers, and marketing communication specialists.

The 2025 WorldStar Packaging Award Trophies have arrived in Australia and New Zealand and the winners are finally able to 'celebrate' their global recognition with their teams! DON Small goods held a WorldStar Award ceremony with the team in person and AIP Executive Director, Nerida Kelton joining them on-line to formally congratulate the team that won three WorldStar Packaging Awards. The AIP would like to once again congratulate all of the winners and we hope to see lots of entries into the 2026 Australasian Packaging Innovation & Design (PIDA) Awards later this year. Keep an eye out for when the entries will be open.

DON Smallgoods Deli Cuts recognised with WorldStar Packaging Award + 2 Special Awards

Biopack receive trophies for The Art series and Indigenous art series BioCups and Home Compostable Container range

Did you know that only winners of the PIDA awards in Australia and New Zealand are eligible to enter the prestigious WorldStar Packaging Awards each year?

The full list of 2025 WorldStar Packaging Awards are available to view on https://worldstar.org/winners/worldstar/2025/ ANZ PIDA winners receive 2025 WorldStar Trophies

The trophies have arrived for the Australian winners of the WorldStar Student Awards that came from RMIT and UNSW.

Fresh Herbs, Fresher Packaging receives overall Bronze for Save Food

In an Australian-first a team of Industrial Design students from the Royal Melbourne Institute of Technology (RMIT), Cameron Campbell, Nadia De Fazio and Cynthia Mullaly, entered a Save Food Packaging design into the WorldStar Student awards that went on to take out a Bronze Overall and a Silver in the Food Packaging category

The AIP interviewed the Students via video so please take some time to watch the interview.

The trophies have arrived for the Australian winners of the WorldStar Student Awards that came from RMIT and UNSW.

Bio-Soul Reusable Shoe Box receives Silver award for the Household category

The Bio-Soul Reusable shoe box was created by a single student Christopher Leong, who is undertaking a Bachelor of Design at the Industrial Design school at the University of New South Wales (UNSW)

Christopher designed the shoe box after working with the AIP Education Team on how to embed the 10 Sustainable Packaging Design guidelines into new product development

Congratulations to, Cameron Campbell, Nadia De Fazio, Cynthia Mullaly and Christopher Leong for being such amazing students and you should all be very proud of winning both Australasian Packaging Innovation & Design (PIDA) Student awards and WorldStar Student Awards.

The AIP has joined forces with leading sustainability software company Empauer, to offer a comprehensive and cost effective LCA Decision Package for Small to Medium Enterprises (SME’s). AIP and Empauer have entered into an exclusive MOU, providing Life Cycle Assessments (LCAs) to SME’s to ensure that they are making informed and science-based decisions when selecting packaging materials. The driving force behind this collaboration is recognition of the challenges faced by SMEs. The AIP, through its SME training programs, identified a pressing need for affordable and customised LCA solutions that simplify the often-complex process of undertaking sustainability assessments for packaging design.

The report part of the package can then be utilised for internal decisions including selection of packaging materials, components and the shift towards more sustainable alternatives within the business

This innovative LCA Decision Package will enable businesses to make informed and sustainable decisions when it comes to the packaging design they utilise and choices in selecting the most appropriate packaging material format It will provide AIP Members and the wider industry, with access to the latest tools and expertise, enabling them to reduce their environmental footprint and make responsible choices in line with global sustainability goals

The main benefit to SMEs in using the AIP / Empauer LCA Decision Package means you don’t have to understand all the complexities of LCAs, as you will be provided with the comparison information and assistance to understand from your selected LCA parameters the environmental impact for each packaging material choice�

The LCA Decision Package for SME’s provides four easy steps to complete your own Streamlined Lifecycle Assessment:

Step 1: Choose your packaging

Step 2: Choose your environmental indicators

Step 3: Data Collection

Step 4: Use the results for internal decisions including selection of packaging materials, components and the shift towards more sustainable alternatives within the business

The AIP & Empauer LCA Decision Package for SMEs provides the information for sustainable packaging design decisions

• Complete the online ‘Expression of Interest’ form www empauer com/lca-program/ and the brief questionnaire and then submit to Empauer

• Upon submission, you will receive a confirmation email acknowledging receipt of your interest

• The LCA will require you to provide some basic data about the packaging options being assessed You will be provided access to a ‘Data Collection Sheet’ and a video with instructions by a followup email to help you provide the data

• The LCA report will be provided within 2- 3 weeks of the submission of the Data Collection

Please register your interest using the QR code or go to www empauer com/lca-program/

Should you have any enquiries please email info@empauer.com

The Australasian Institute of Packaging (AIP) are pleased to announce that the Institute has formally become an Executive Member of the Asian Packaging Federation (APF).

According to Nerida Kelton FAIP, Executive Director of the AIP, "the decision to elevate the AIP’s support of the Asian Packaging Federation (APF) is an important step to not only collaborate with other packaging centres and associations in the federation, but to also provide even more training and educational programs within the Asian region."

“Becoming an Executive Member of the APF helps the AIP to solidify our already strong position in the Asian region as a pinnacle peak professional body for packaging education and training. The AIP has worked in the region for a long time now, particularly in Vietnam, Indonesia, Thailand and the Philippines, so it is the logical next step to support the APF at the highest level of membership. We have also commenced training in Cambodia, are working on a new project for Mongolia and look towards Malaysia as the next country we would like to support,”

“The AIP education team are always here to help all APF Members to provide qualified technical packaging training in all topics, materials and industries that need primary, secondary and tertiary packaging. The AIP is proud to be an Executive Member of APF and we look forward to contributing even more education and training assistance to the Asian region.” she said�

The Asian Packaging Federation (APF) Newsletter Issue No. 2 (April - June 2025) is now available to read.