We are a leading provider of custom solutions for the handling of bulk materials for processing businesses across various industries. Dynamic Air has over five decades of expertise in designing and manufacturing pneumatic conveying systems and equipment for handling dry bulk solids.

At Dynamic Air, we set the standard for excellence in bulk solids handling. With a relentless focus on quality, reliability, and customer satisfaction, we deliver reliable, high-quality pneumatic conveying systems, equipment, and custom solutions that exceed expectations. BULKBUSTERTM

We never take a cookie-cutter approach just to cut costs up front; we know that the right solution will save you money in the many years to come. Our tailored solutions involve thoughtful planning, meticulous engineering and precise manufacturing that optimize efficiency and productivity.

Sales Director: James Scrivens

Production: Sarah Daviner

Accounts Manager: Avery Hudson

Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

ADVERTISING & EDITORIAL

Please contact us at: Tel: 01933 316931

Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday.co.uk Web: www.bulksolidstoday.co.uk Twitter: www.twitter.com/ BulkSolidsToday

CIRCULATION

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119

Akona Process Solutions will exhibit at PACK EXPO Las Vegas 2025, taking place September 29 - October 1 at the Las Vegas Convention Center. Located at booth N-7402 in the North Hall, Akona will unveil its all new US stand, bringing together its full portfolio of processing and material handling equipment brands under one identity for the first time.

As a regular Pack Expo exhibitor, Akona is reinforcing its presence by showcasing Cablevey, Kason, Marion and Spiroflow, alongside Automation by Akona. Together these brands demonstrate Akona’s ability to provide complete, end-to-end system solutions across mixing, blending, sifting, screening, conveying and bulk material handling.

The stand will showcase a

functioning Cablevey conveyor unit, a horizontal fluidized mixer and a large display screen featuring a new full system animation.

The exhibition follows soon after Akona’s new website launch, which offers a detailed view of the company’s expanded portfolio.

The site showcases Akona’s shift from four leading brands into a unified solutions partner, making it easier for customers to explore technologies, system capabilities and application expertise all in one place.

Clear navigation, mobilefriendly design and detailed product information, including 3D models and solution overviews, provide visitors with an accessible way to understand how Akona can support their process needs. For Pack Expo visitors, the website acts as an extension of the stand,

offering deeper insights into the displayed equipment and the system-wide capabilities Akona offers.

Ryan Long, North American sales director at Akona Process Solutions, said: “Pack Expo provides a platform to show how Akona supports customers with integrated solutions. By uniting our brands under a single name, we can demonstrate the value of working with one partner for process challenges. Our new website and revamped stand both reflect that commitment, bringing together expertise, capability and customer focus.”

Akona’s team of process specialists will be available throughout the event to offer insights and tailored recommendations for visitors’ production needs.

Parker Hannifin, the global leader in motion and control technologies, today announced the launch of its innovative VA130 mobile valve, completing the Parker VA Series valve portfolio, a cutting-edge solution designed to revolutionize mobile hydraulics. Drawing on decades of expertise in load-sensing directional control valves, the VA130 delivers industry-leading performance, exceptional controllability, and enhanced energy efficiency. Precision-engineered using high-grade materials, this valve offers unmatched flexibility and customization, enabling seamless integration into both simple and complex hydraulic systems across a broad range of applications.

The VA130 valve stands out for its modular design and versatility, allowing it to be tailored to meet virtually any hydraulic function requirement. As part of the VA Series, the VA130 is combinable with the VA450 and VA300 making it the ideal valve for compact valve solutions in machinery where there are varying needs in terms of flow. Combining the modularity and an extensive variety of valve functionalities and combination options, Parker provides customers with optimized solutions for their specific machine needs. The valve’s design incorporates function-adapted spools, pressure compensators, and load signal pressure limiters, all developed through Parker’s deep expertise in load-sensing technology. This innovative approach significantly reduces energy losses while boosting productivity, marking a new standard in energy-efficient hydraulic control.

In addition to its superior performance, the VA130 offers multiple actuation methods — hydraulic or electrohydraulic —

with optional manual lever control available in any combination within the same valve. This flexibility is complemented by the ability to combine the VA130 with tailor-made function manifolds, crafted from Parker’s comprehensive product range, to fully customize auxiliary function control. This integration reduces the number of system components, simplifies hydraulic system design, and enhances overall reliability and ease of maintenance.

The VA130 valve also incorporates advanced features designed to meet the rigorous demands of harsh operating environments. These include precompensated, load-independent flow control with function-adapted main spools for precise machine operation, LS pressure limitation, active tank gallery refilling, and emissions reduction technologies. Performance monitoring is facilitated through dedicated measuring points and Parker’s spool position sensors, available in both analogue and digital formats. Parker’s unique online

configurator further streamlines development by providing instant access to automatically generated code reports, schematics, spare part lists, and 3D/2D models.

Targeted at key industries such as forestry, construction, material handling, and mining, the VA130 is ideally suited for a wide array of applications including forwarders, forestry harvesters, forest cranes, harvesting heads, mining machines, drill rigs, loaders, dump trucks, excavators, forklift trucks, material handling cranes, and reach stackers. With the VA130, Parker Hannifin continues to lead the way in delivering innovative hydraulic solutions that enhance machine performance, reduce environmental impact, and meet the evolving needs of modern industrial equipment.

For more information about Parker Hannifin’s VA130 valve, please visit: https://ph.parker. com/gb/en/product/mobiledirectional-contol-valve-vaseries/va130-mobile-valve

• Investment includes immediate £32m spend to grow steel and metals storage at the Port of Liverpool

• Plans include new automated terminals in Liverpool and London Medway, with the development of a new automated rail facility in the Midlands

Peel Ports Group is to invest £100m into the steels and metals sector in a move to enhance capacity and boost the efficiency of logistics.

The UK’s second largest port operator is progressing with £32m to add a further 140,000 sq ft of storage at its Port of Liverpool steel and metals terminals.

Overall across the Ports of Liverpool and London Medway, warehousing will be increased by 50 percent from the current 1

million sq ft to create an additional 500,000 sq ft of capacity.

Further plans include creating a second automated terminal in Liverpool dedicated to steel coils, as well as a new automated terminal for the Port of London Medway in Sheerness.

These will be developed to include rail connectivity by a new inland rail terminal in the Midlands.

This fresh investment by the port group follows a record year for steel imports at the Liverpool facility and will help further grow the volumes of steel it transports across the UK.

David Huck, Chief Operating Officer at Peel Ports Group, said: “This is a game-changing investment for us.

“Demand for steel and metals handling across our port group, and the UK in general, has risen sharply over the past five years

and this will allow us to expand our support to the construction and manufacturing supply chain right across the country.

“This investment ensures we have the scale, speed, and specialist expertise to support our customers today and long into the future, helping to also address some of the storage and transportation issues the steel sector currently faces.

“With expanded capacity and a growing, dedicated steel handling team, we can now move more product, more efficiently than ever before. Our location in Liverpool is in the heart of Britain and gives us a clear advantage - perfectly placed to serve stockholders and fabricators nationwide, supported by excellent road and rail links.

“Warehousing will remain a key focus for the business, with further expansion already in the pipeline as we continue to futureproof our service for the UK’s critical industries.”

“The addition of a new rail terminal in the Midlands will allows us to efficiently connect the two strategically located deep-water ports of Liverpool and London Medway, boosting the efficiency of logistics for our customers and partners.”

The business is already working with customers to bring steel cargoes closer to major centres of demand across its seven statutory harbour authority ports and 24

terminals.

This is the second time in under two years it has extended its Port of Liverpool steel and metals terminal and will involve the creation of two newly dedicated warehouses at its Seaforth Dock to handle these products.

The port group has added a new team of specialist Stevedores at the Port of Liverpool and is actively recruiting for extra positions and training internal staff to enhance handling capability to meet the rise in demand.

The port now boasts more than 610,000sqft of storage for the commodity, and this expansion means it will be able to store an additional 35,000 tonnes of steel and metals.

This fresh investment by the port group follows a record year for steel imports at the city facility.

The port group has the capability to store and handle many different types of metal products, including rebar, plates, coil and aluminium, and handles significant volumes.

In April, the company reported

a record-breaking year for steel imports at the Port of Liverpool, with volumes increasing by more than 35% year-on-year.

702,000 tonnes of bulk steel were processed at the port in 2024, coming from across the world including from South Korea, Vietnam, Taiwan, Turkey, and Europe.

The port operator also recently underlined its commitment to supporting UK steel and metals supply chains by becoming the first and only UK port operator to join the Aluminium Federation (ALFED).

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

• Less friction

Low torque

Low maintenance • Lower actuator costs • Longer valve life • More reliable

Eriez® will debut new and enhanced inspection and magnetic separation solutions at PACK EXPO 2025. From Sept. 29-Oct. 1 at the Las Vegas Convention Center in both SL11000 in the Lower South Hall, attendees can take part in live equipment demonstrations and connect directly with Eriez product specialists to discuss their processing challenges and explore application-specific solutions.

Eriez will feature its latest PrecisionGuard X8 Metal Detector, as well as one of its new SenseGuard X-ray Inspection Systems, along with Vibratory Feeders and Magnetic Separators. Throughout the show, company subject matter experts will be available to answer questions, share industry best practices, and recommend equipment configurations for various production environments.

The X8 Metal Detector provides exceptional sensitivity to detect ferrous, nonferrous, and stainless-steel contaminants, even in demanding applications. It offers an intuitive interface with the largest touchscreen in the industry, and advanced auto-learn capabilities to streamline setup and operation. Eriez X-ray Inspection Systems provide high-resolution imaging and adaptable software

to identify a broad range of foreign objects and product irregularities, helping processors enhance product safety and protect brand reputation.

At the Eriez booth, attendees can see firsthand how metal detectors, magnetic separators, and vibratory feeders can work in conjunction to maximize performance. Together, Eriez technologies improve product purity, optimize productivity, and help customers meet rigorous requirements. Beyond the specific equipment featured at PACK EXPO, Eriez offers a comprehensive portfolio of solutions for the packaging industry.

“By understanding the unique demands of each application, we can recommend the best combination of equipment and support to help customers achieve consistent, reliable results,” explained Craig Lorei, Eriez Global Market Manager-Light Industry. “PACK EXPO allows us to engage in meaningful conversations with processors and packagers about their most pressing challenges—whether it’s satisfying stricter food safety regulations, reducing false rejects, or improving line efficiency.”

To learn more, visit https://www. packexpolasvegas.com/.

We’ve got smart measurement technology.

The journey to a smarter future begins now. VEGA’s intelligent level and pressure instrument solutions simplify everyday operations – with reliable sensor data analysis, secure industrial communication, you can streamline your logistics and inventory management. This is how efficiency becomes standard: secure, connected, and future-ready. Everything is possible. With VEGA

Rotary valves are essential components for discharging and conveying bulk solids, isolating pressure differentials, and serving as flame and explosion barriers in hazardous areas. With over fifty years of experience, the UK-based Gericke RotaVal is a leading company in this field. As part of the Gericke group of companies, they combine the expertise of a dedicated rotary valve manufacturer with global experience from numerous successful powder processing and bulk handling installations.

Rotary valves are commonly found in pneumatic conveying systems and can act as safety devices to isolate different process steps, such as airlocks, flame barriers, and explosion propagation valves. They are also used for metering applications, such as loading pneumatic conveying pipelines or filling of FIBCs. Designing and manufacturing rotary valves beyond the commonly used sizes requires specific knowledge and large machining centers. Large rotary valves are utilized for high throughputs or handling oversized and lumpy particles, particularly in the petrochemical and chemical industries.

Using Rotary Valves in Petrochemical Industries

Rotary airlock valves play a critical role in petrochemical industries by providing reliable control over the transfer of bulk solids such as catalysts, resins, polymers, or additives within processing plants. In these environments, maintaining process integrity is essential due to the presence of hazardous materials

and strict safety regulations. The robust construction of such airlocks ensures, that they can withstand abrasive or corrosive substances often encountered in petrochemical applications.

In addition to their basic function as metering devices for powders and granules, these valves help maintain pressure differentials between various process zones— such as reactors, storage silos, pneumatic conveying lines, or dust collection systems—thereby preventing unwanted gas leakage that could pose safety risks or lead to product contamination. Their precise operation allows for accurate dosing and consistent feed rates into reactors or mixers.

Furthermore, rotary airlock valves used in petrochemical plants are often designed with features such as explosion-proof motors, high-temperature seals, wear-resistant coatings on their internal surfaces, and easy-clean access for maintenance. These enhancements ensure long-term reliability under demanding conditions typical of petrochemical production facilities. By integrating advanced rotary valve technology into their processes, petrochemical companies can achieve improved operational efficiency while meeting stringent environmental and safety standards. With in-house development and production, Gericke RotaVal has extensive experience manufacturing valves up to sizes of 600 by 1200 mm, often with special coatings.

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

• Self-aligning

• Self-grounding

• High pressure rated

• Full vacuum rated

• Stainless or mild steel

• Usable on thin or thick wall pipe or tube

• Low cost

• Reusable

• Absorbs vibration

• Externally leakproof

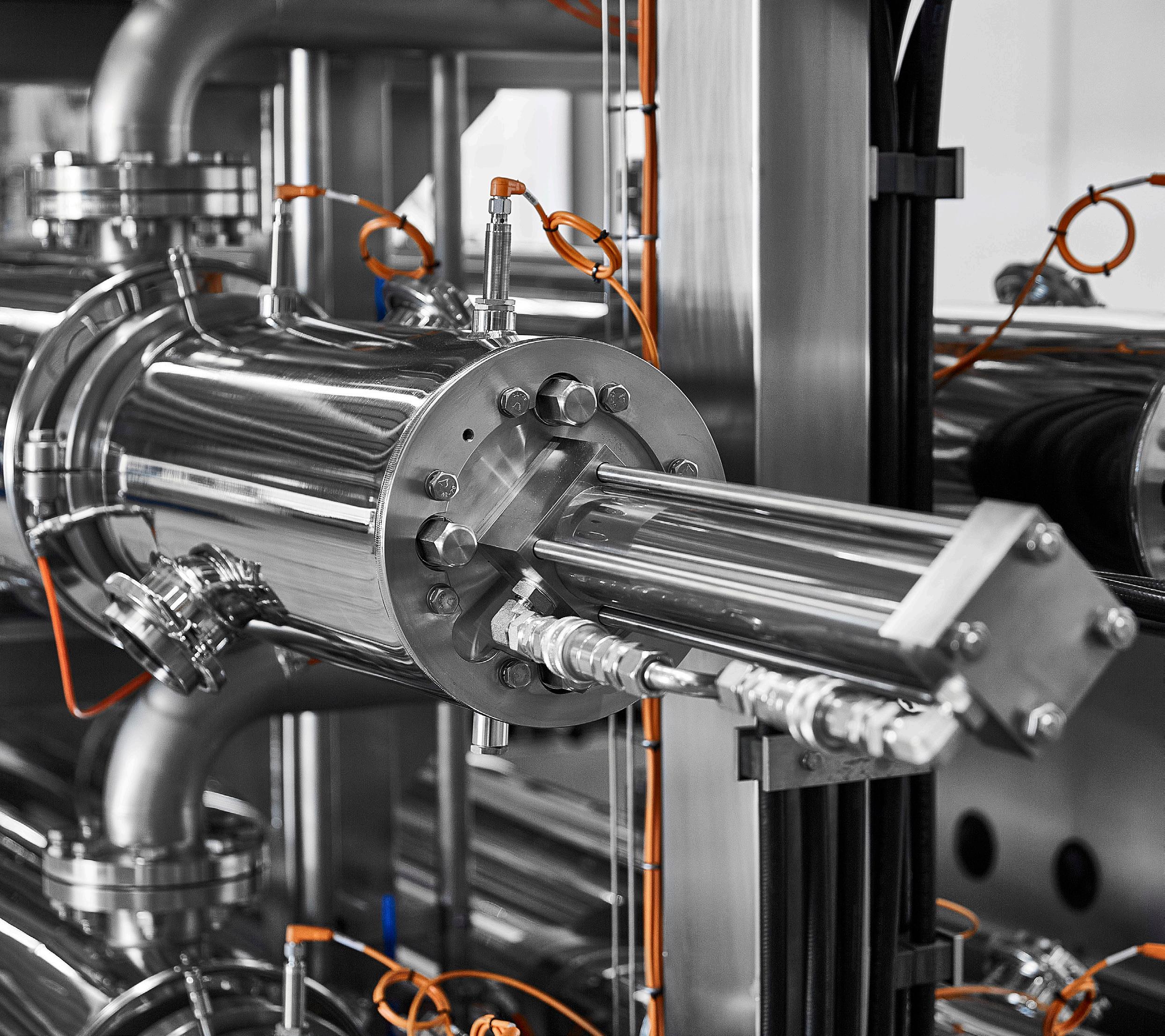

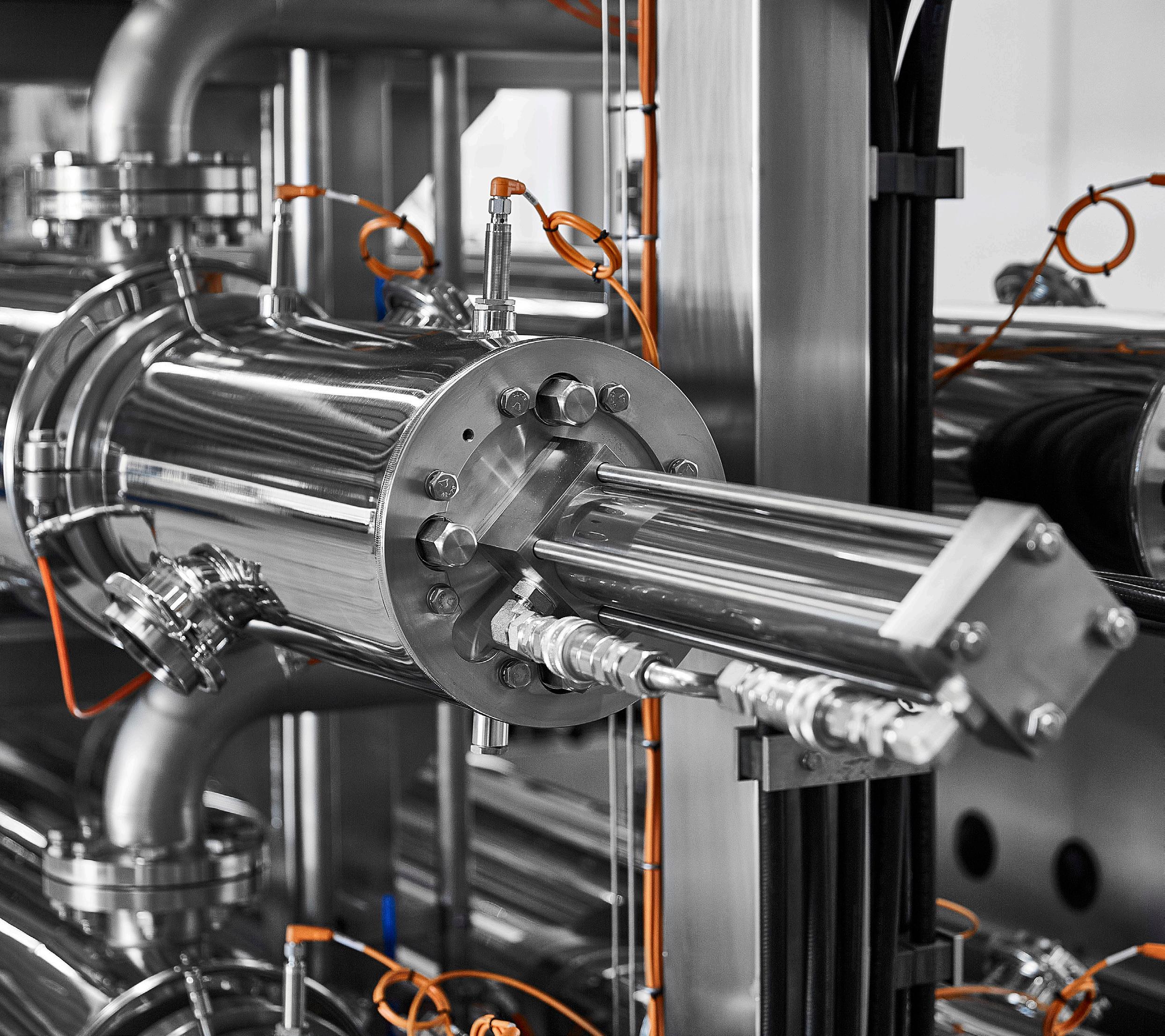

By Antonio Guillermo Jara Ponce, Systems Sales Manager, HRS Heat Exchangers

Heat exchangers are key components in many processes in the food industry, from heating and cooling to pasteurisation, sterilisation and evaporation. They come in many forms, from the simplest plate heat exchangers to corrugated tube-in-tube and scraped surface designs. With so many different food and drink products in production across the globe, choosing the right heat exchanger for the right product and the right process is vital, not only to ensure effective processing and optimum product quality, but also to maximise operational and energy efficiency.

This is particularly true when dealing with viscous foodstuffs (such as honey, mayonnaise, syrups, purees and nut butters). They require more energy to pump and move and often have a higher potential to foul pipework and heat exchangers, reducing heat transfer and operational efficiency. However, as their texture and viscosity are also important quality characteristics, it is important that processing equipment, including heat exchangers, does not change or disrupt them during production.

What is meant by viscosity?

When considering different sorts of viscous food and drink materials, it is useful to clarify what we mean by viscosity. It is normally defined as a measure of a substance’s resistance to motion under an applied force, based on the amount of force required to remove one layer in relation to another (shear stress) and the change in speed of the layers relative to each other (the shear rate). It is measured in units called centipoise (cP) with one cP being equal to 1 mPa sec1 (millipascal per second). For example, depending on temperature, milk may have a typical viscosity between one and 20 cP, while molasses may be 5,000 – 10,000, ketchup (which thins when sheared) 10,000 – 18,000 cP, and peanut butter as much as 250,000 cP.

However, the viscosity of different products can change as they are subjected to different levels of sheer stress and temperature. Because of this, most fluids are classified as being either Newtonian, or nonNewtonian. Newtonian fluids have the same viscosity irrespective of changes in temperature or shear stress – the most common example of this is water. NonNewtonian fluids (which can then be sub-divided into

five different categories) have viscosities which fluctuate depending on the shear rate applied.

In practice, this means that when dealing with nonNewtonian products (such as cheese, cream, batter or custard, and certain fat-free products), elements of the processing operation –including pumping, heating, cooling and passing through pipework – all have the potential to affect a product’s viscosity and end quality if not handled correctly.

Corrugated tube heat exchangers: design & selection

Choosing the correct type of heat exchanger, together with careful system design, helps avoid such problems. Corrugated tube heat exchangers, such as those designed and produced by HRS, ensure that delicate products such as cream can be processed efficiently without damage. This is because the corrugated tube design helps minimise fouling, increasing thermal efficiency during operation, and extending operational periods between cleanings. In addition, corrugated tube heat exchangers have a lower pumping requirement than smooth tubular heat exchangers due to their compact nature, which results in a lower pressure drop. This helps to increase operational life while reducing maintenance costs compared with other types of heat exchanger.

Scraped surface heat exchangers for the toughest challenges

For the most viscous products, the use of corrugated tubes will not be sufficient to prevent fouling or maintain movement through the exchanger. In these cases, scraped surface heat exchangers (SSHEs) are ideal, particularly for evaporation. At HRS we produce two types of SSHE: the rotating HRS R Series, which includes a unique spiral scraper bar system and baffle placement; and the HRS Unicus Series, which uses a reciprocating movement to mix the fluid whilst cleaning the heat exchange surface.

Products with low or medium viscosities, such as milk, thin sauces, soups and creams, fruit and vegetable juices and purees, can usually be efficiently processed in multi-tube corrugated heat exchangers, like the HRS MI Series. These feature multiple tubes that carry the product within a large vessel which contains the service fluid. Where products contain pieces or particulates, such as fruit and vegetable dices, then a double-tube heat exchanger, like the HRS DTA Series, is recommended. In a double-tube heat exchanger, one large tube carries the product, so there is less chance of blockage and fouling by the particles contained in the food product.

For products such as thick sauces, honey and syrups, an annular-space heat exchanger like the HRS AS Series is preferable. These consist of three or four concentric tubes, with the product flowing through the annular space between the tubes and the service fluid flowing through the inner and outer tubes to ensure even heating and cooling. This arrangement increases both heat transfer and energy efficiency and minimises potential fouling.

For extremely viscous products and demanding applications, such as nut butters, a heavy-duty version of the R Series, the HRS RHD Series has been developed. This comprises all the features and benefits of the standard R Series but with increased motor size and scraping rods, together with extra mounting supports for the scrapers and motor.

The separate hydraulic action of the Unicus Series means that the speed of the scrapers (which are available in a number of different designs) is highly controllable and can be optimised for the product being processed. Materials which are susceptible to shear stress or pressure damage can therefore be handled gently to prevent such damage while still providing high levels of heat transfer.

Between our range of corrugated tube heat exchangers, and the three models of SSHE, HRS has a heat transfer solution for any viscous food product, including condensed milk, tomato paste, purees, juice concentrates, honey, butter, margarine, nut butters, chocolate, sauces, minced meats, and many more.

For more information, please contact your local representative or our food systems specialists today.

•Beverage sloshing at high filling capacities causes loss and soiling

•KHS analyzes bottle and machine parameters using simulation

•Around 850 CFD calculations for optimization performed to date

If, at high filling capacities, beverages slosh out of the bottle, levels of efficiency and hygiene suffer. KHS prevents this by drawing up extensive calculations.

If beverage filling is to be safe with little loss, physics comes into play: given the rotation speed and change in direction, especially at the transition from the transfer star to the closure system, high levels of centrifugal force act on the content of the containers. This can cause liquid to slosh out of the bottle. This may only comprise a few drops of spillage at a time – but with up to 90,000 fills an hour, the amount of product lost soon mounts up. Another aspect is hygiene. It’s not hard to imagine that on the one hand, sloshed sugary beverages soil container necks and closures, with mold even being formed in some cases. On the other, the machine is also contaminated. This in turn increases cleaning requirements and takes up valuable production time.

Two groups of parameters

In order to counter this, Dominik Weirich has been drawing up CFD calculations since 2013. “Ever higher filling outputs mean that the technology’s reaching its physical limits, so that we also have to take liquid sloshing into account when designing the machine,” says the KHS development engineer at the factory in

Bad Kreuznach, Germany. Data collected from the simulations he carries out form the basis here. “First, we take a look at the geometric parameters of the beverage containers themselves: here, we investigate the impact the bottle shape, fill height and neck diameter have. This is done in close consultation with our Bottles & Shapes experts, especially in conjunction with new line projects,

when changes are made to the geometry or the bottle weight is reduced, for example. Second, we have the physical parameters of the machines. These depend on the capacity, machine pitch and diameter of the stars. Adjustments can be made here relatively easily. Adapting the containers, however, is usually an iterative and more extensive process.”

Increasing number of simulations

As a rule, it can be said that the larger the product surface and the closer the beverage is to the bottle mouth, the more likely the liquid is to slosh. This interaction of the various factors requires calculations to be made that are then included in both the design engineering and the offers for the machinery. Weirich has already performed about 850 of these simulations – with this number continuing to rise.

For more information go to: https://www.khs.com/en/company/media

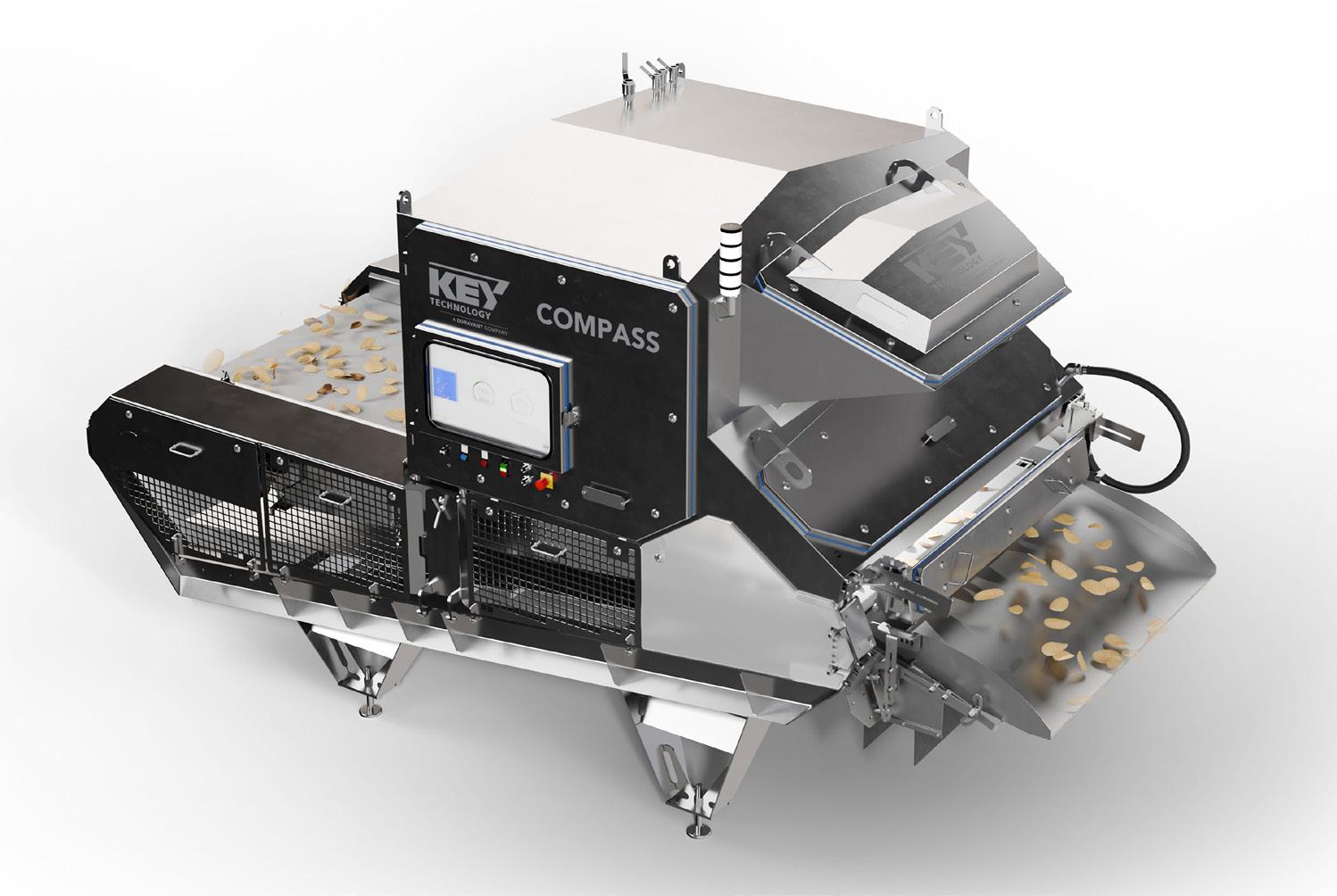

Key Technology (Key), a member of Duravant’s Food Sorting and Handling Group, introduces its COMPASS® optical sorter for chips at Pack Expo Las Vegas booth W-1040. Designed specifically for potato chips, tortilla chips and similar snack foods, this belt-fed sorting system identifies and removes product defects and foreign material (FM) to protect food safety and product quality. Delivering sustained performance over long production cycles with minimal human intervention, COMPASS simplifies operation, cleaning and maintenance while providing a quick return on investment.

“Key has been at the forefront of potato chip sorting and handling technology for decades, and COMPASS represents the next evolution in our commitment to this industry,” said Jack Lee, Duravant Group President - Food Sorting and Handling. “We’ve leveraged our extensive applications expertise to develop innovations that address the real operational challenges of chip processors, including automatic belt tracking, intuitive controls and clean-in-place features for extended run times between sanitation cycles.”

COMPASS improves routine operation with recipe-driven programming and a user interface designed to mimic smartphone app navigation. Operators can easily create and adjust sort recipes, including adding new products to sort, new grades or different varieties of an existing product. A new operator without any technical skills can learn how to operate the system in production in as little as 30 minutes. Intelligent belt control automatically maintains proper tracking, including compensating for belts that have either stretched or shrunk, to reduce downtime and manual adjustments.

Powered by Key’s advanced NEXT sort engine, COMPASS detects and rejects product defects such as, dark spots, green discoloration and white knot bruises, along with FM like fryer debris. Equipped with customizable camera options and up to 8 channels of multispectral sensor data, the sorter can detect the color, size, shape and structural properties of every object to identify more, smaller defects than systems with conventional 3-channel cameras.

Designed for maximum sanitation, COMPASS features open architecture, sloped surfaces and minimal moving parts. Sensors and light windows are positioned away from product splatter, and stain-resistant belt technology helps sustain accurate inspection throughout long production runs. Specialized collection systems, including counterrotating brushes or scrapers, direct oil and chip debris into easily removable bins for safe, efficient disposal. The belt can be quickly removed for thorough cleaning, while the open design allows easy access for workers and reduces cleaning and maintenance requirements. Washdowns can be completed in as little as 15 minutes.

Every COMPASS is equipped with Key Discovery™, a powerful data analytics and reporting software that turns the sorter into an IIoT-connected device and information center. By delivering detailed product quality and sorting process data, Key Discovery gives processors valuable insights into line operations, quality trends and opportunities to optimize upstream processes like fryer settings.

COMPASS is available in multiple configurations to meet individual application and capacity requirements, including the ability to integrate Key’s high-performance infeed and discharge conveyors for complete system solutions. Beyond traditional chip applications, this belt-fed COMPASS can handle other snack products including extruded snacks, pellets and specialty items like sesame sticks.

Key supports its customers worldwide through an extensive sales network and its global service team. For more information on Key’s optical sorters, visit www.key.net/en/our-products/sorting/.

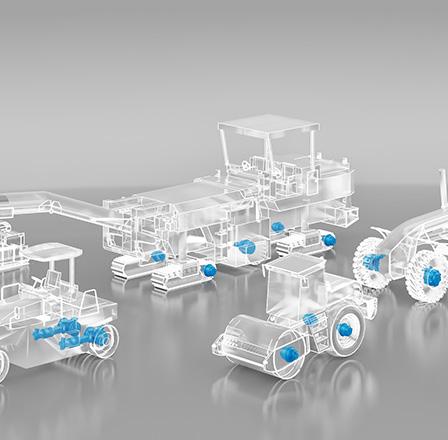

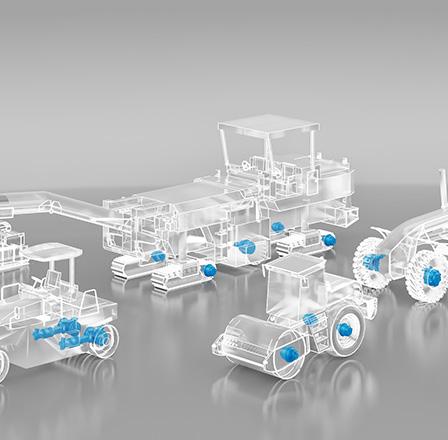

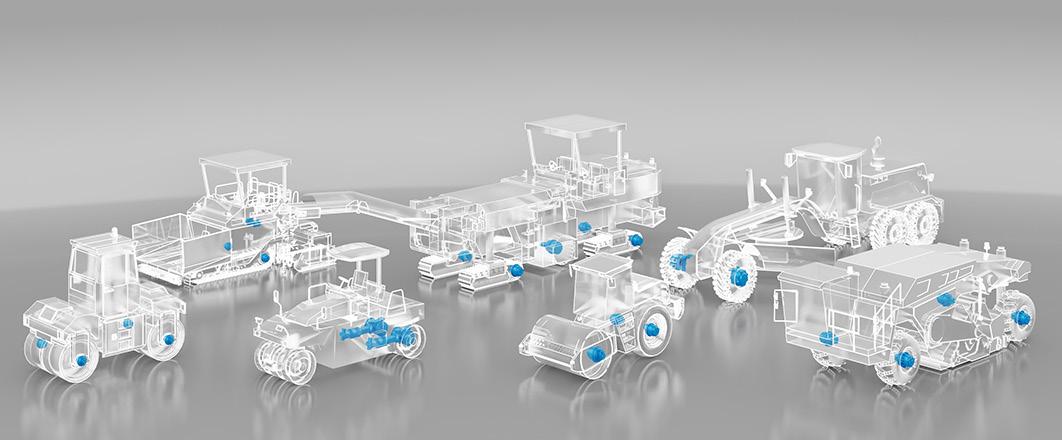

Global leader in final drives and state-of-theart technologies, Bonfiglioli is able to provide high-performance, customized complete systems for construction and mining machinery, ranging from electronics to mechanics.

Sustainability through Bonfiglioli’s next gen electrification

Bonfiglioli supports customers on their path toward electrification, regardless of their field of application. This path involves the final drives, not just the main power source. This approach, compared to the one where the engine is replaced by a single electric motor, offers significant advantages in terms of energy efficiency, reduced emissions and a considerable reduction of maintenance costs, resulting in a much faster return on the initial investment.

In earth moving, the electrification process targets excavators (mini and midi) for which a special kit has been developed, combining three different components: an electric swing drive of the 700TE Series, ultra-compact and high-performing, equipped with an electromagnetic brake and speed and temperature sensors; an electric track drive of the 700CE Series, easy to install and maintain due to the reduction of mechanical parts; and an electric motor for pump drive of the BPM Series, featuring permanent magnets with SAE connections and ideal for the electrification of mobile machines. The system is completed by inverters responsible for motor control. By

adopting Bonfiglioli’s Next Gen Electrification Approach, the Battery Capacity can be reduced by 50% thanks to the improvement in energy efficiency and reduction of maintenance costs.

Focus on Bonfiglioli’s flagship solution for compact track loaders: machines ranging from 1.5 to 6 tons, for which it supplies the planetary track drive paired with high-power density electric motors, specifically designed for electric systems. The 5-6 ton compact track loader version also integrates the IoT functionality through the sensorization of the gearmotor, allowing the user to view all the main operational data of the machine and use it correctly. Bonfiglioli’s electrified solution represents a cutting-edge product already available as standard on machines from leading manufacturers.

For road construction, reliable, highperformance gear solutions have been developed, which keep the fleet of pavers and tandem rollers running smoothly. For both, a totally electrified solution is proposed, i.e. all drives – track and loader for the paver, drum rotation for the tandem roller – and motors – in the latter, the one responsible for the vibration and steering functions – are electric. The same transformation has also involved cranes and aerial platforms. For the former, Bonfiglioli develops winch drives – 800 Series – marked by high modularity and flexibility, thanks to the possibility to add further standard stages, motor

flanges and bevel gears of the 300 Series. For aerial platforms, scissor lifts and boom lifts, Bonfiglioli provides the travel drives of the 600WE series, boasting compact dimensions, low noise and high efficiency. An advanced powertrain solution which uses a two- or threestage gearbox offering reduction ratios of up to 1:145 to satisfy the widest possible range of needs.

A dedicated solution for twin shaft mixers used in the road and building construction has been conceived. An evolution of Bonfiglioli’s, modular planetary drive of the 300 Series – a highly versatile gear, due to several options for mounting, gear layout, output shaft – it is a specific bevel gear set which allows to have both e-motor bell housing and synchro drive shaft. Easy to fit and almost maintenance-free, it optimizes the machine structure, by avoiding the presence of pulley and increases the efficiency with a positive impact on the Total Cost of Ownership. The set guarantees the easiest layout configuration for asphalt and concrete applications by virtue of its simplified assembly and maintenance procedures.

For electrified mining equipment, the protagonist is the gear unit of the 3/H Series, a product boasting resistance, robustness, thermal capacity, high performance and torque density, thanks to the combination of the planetary and the helical bevel Heavy Duty gear units. In this case, the drive is integrated into an apron feeder, but also applicable to several applications, such as bucket wheels for stackers/reclaimers and horizontal roller crushers, as well as belt filters. For apron feeders, Bonfiglioli offers the entire system in an ultra compact design, consisting of gearbox and motor that can be mounted directly on the machine shaft or installed with a base plate. All

units can be supplied with IoT instruments for predictive maintenance function, able to measure real time working conditions, in order to support end users within their mantenance programs. The 3/H Series is designed to endure extreme environmental conditions, withstand temperatures ranging from -50 to +50 °C, high shock loads and extremely dusty environment.

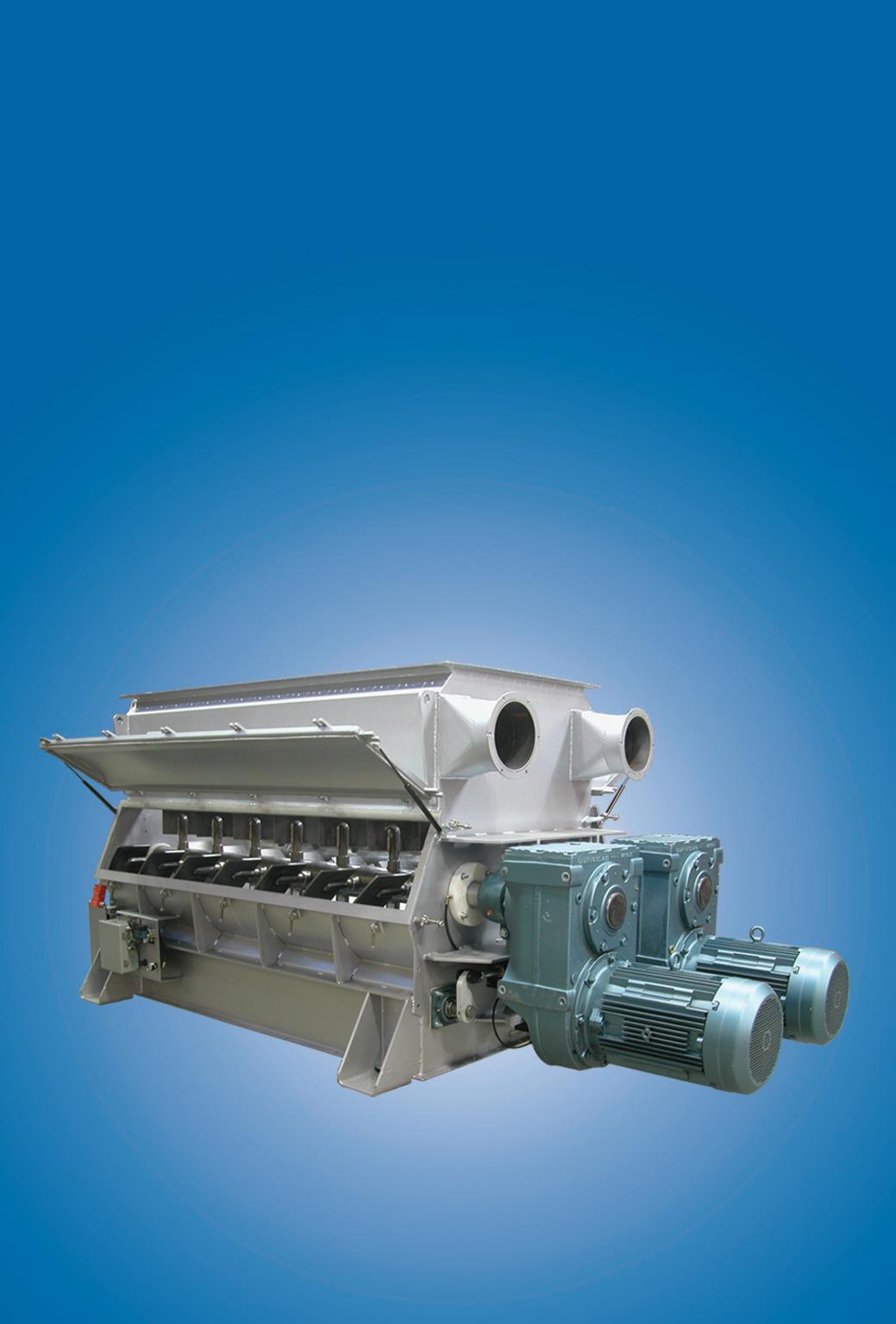

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

To celebrate the start of production for its new R2Series 1-2 tonne mini excavators, Bobcat is releasing a special, limited-edition run of its top models. Only 50 of these exclusive Premiere Launch Edition machines will be produced for the Europe, Middle East and Africa (EMEA) markets, making them a rare and highly collectible piece of equipment. The latest generation R2-Series comprises the new E16, E17z, E19 and E20z models, first seen at the Bauma show in April 2025.

The exclusive limited-edition version will be available for the top-of-the-range models of the 1-2 tonne range: the E19 and the E20z. Only 25 units of each will be produced. The first deliveries of both the regular and Premiere Launch Edition machines will begin in September. The special features offered by the Premiere Launch Edition include:

• Exclusive charcoal grey colour

• Premium red and black cloth or leather seat

cover designed by MAD for demanding users of luxury, sports and classic cars

• Individually numbered plate in the cab

• Aluminium pedals

• 4 high-value aftermarket kits as standard:

o Direct Return to Tank

o Top Guard Cab

o Travel Motor Hose Guard

o Bucket Cylinder Cover

Miroslav Konas, Product Line Manager for Doosan Bobcat EMEA, said: “We are launching the Premiere Launch Edition to promote the new range and to emphasise our market presence at the time of the start of production for the new machines.

“The Premiere Launch Edition is a strong conversation starter and sales tool and gives dealers an opportunity to offer customers a truly unique, high-spec machine that is both visually distinctive and technically enhanced. The non-standard colour and editional branding help increase awareness

and generate buzz and it serves to show that the new generation mini excavators are not just an update - they are a bold step forward.”

NEW SMARTFLOW HYDRAULIC SYSTEM FOR MAXIMUM PRODUCTIVITY

The E16, E17z, E19 and E20z new generation R2-Series 1-2 tonne mini excavators replace the previous M-Series E17, E17z, E19 and E20z machines, respectively. The new models offer a fresh look, signifying new levels of performance and features and are designed to meet all the variations found across the EMEA market.

Among the many new features that are creating excitement around the new R2-Series 1-2 tonne mini excavators is the high-performance SmartFlow load-sensing hydraulics system coupled to a closed centre/flow-sharing valve block powered by an upgraded engine, providing a sophisticated engineering set up that is unique in smaller machines like these.

This combination essentially provides the power on demand seen in larger excavators, ensuring continuously available power that improves precision and efficiency. The new mini excavators always offer the required flow, utilising the minimum energy needed, ensuring the minimum of power is expended, allowing the operator to always work hard with the excavator, but at the same time save fuel. This results in a lowering of fuel consumption of up to 18% coupled with a noise reduction of 4 dBA (compared to the previous generation machines).

Like in larger machines, the new hydraulic system allows the operator to smoothly carry out multiple functions simultaneously in the new 1-2 t mini excavators. So even when working with equipment that requires a lot of hydraulic power, such as a flail mower on a quick coupler running at full speed, the operator can drive, slew and lift smoothly at the same time.

Herbold Meckesheim, a brand of Coperion, will showcase its latest advancements in plastics recycling technology at K 2025, taking place from October 8 to 15 in Dusseldorf, Germany. Building on its long-standing expertise in modular system solutions for size reduction, washing, separation, drying, and agglomeration of plastics waste, Herbold Meckesheim offers tailored, highly automated plants for numerous industrial recycling applications. The company will present a range of integrated systems and solutions designed for mechanical processing, including the new high-capacity Mechanical Dryer T150-300 and the latest SMS granulator model. Visitors can explore these innovations firsthand at Hall 9, Booth 9B34. In addition, a Hydrocyclone Separation Stage will be showcased in the Coperion and Herbold Meckesheim Recycling Pavilion in the Open Area FG/CE07, where the companies will demonstrate their comprehensive interlocking recycling solutions. This participation highlights Herbold Meckesheim’s and Coperion’s ongoing commitment to delivering cutting-edge machinery and process solutions that drive the shift toward a more circular plastics economy.

Herbold’s latest innovation, the Mechanical Dryer T 150-300, debuts in a new size at K 2025 in Booth 9B34 in Hall 9. This high-capacity model sets new standards in large-scale drying applications, reaching

throughputs of up to 2.5 tons of film per hour or >10t/h of PET or rigid flakes. The dryer features a fully redesigned construction, including a rotating sieve basket with integrated water spray nozzles for fullcoverage cleaning and a centrifugal drying chamber for rapid moisture removal.

Designed for maintenance simplicity, it is equipped with hydraulically hinged housing for quick access and advanced monitoring systems supporting predictive maintenance. This innovative dryer is perfectly suited for demanding industrial workflows, particularly for film processing, ensuring consistent surface cleanliness and superior drying efficiency.

GRANULATOR:

The next size of Herbold’s SMS Granulators, renowned for its durability and precision, will also be showcased at Hall 9. The SMS 80-200 Granulator is built for demanding applications. It integrates energy-efficient double cross-cutting action and pre-adjustable rotor and bed knives to produce a high-quality regrind with minimal fines and consistent particle size distribution. Its design emphasizes ease of maintenance, featuring a hinged housing and quick knife change system, ultimately reducing downtime and operational costs.

As the largest model in the series, the SMS 80-200 Granulator’s robust construction and forced feeding system—via three horizontally mounted screws— enables a high throughput of PET and rigid plastics, making it ideal for large-scale recycling operations.

The SMS series is optimized for a wide range of materials and ideal for the size reduction of standard applications in the recycling industry, as well as special processing needs—for example, heavy lumps, tough fibers, thin films, or substantial amounts of material.

AT THE RECYCLING PAVILION: HYDROCYCLONE STAGEINTEGRATING PRECISION SEPARATION

At Coperion and Herbold’s Recycling Pavilion in the Open Area (FG/CE07) a Herbold Hydrocyclone Separation Stage, a key component designed to deliver precise material separation through centrifugal forces, can be seen together with a Coperion ZSK FilCo filtration compounder. Herbold’s hydrocyclone stage enhances the purification of plastics during recycling, extending equipment lifespan and improving product quality.

The Hydrocyclone system, featuring a robust density separation, accommodates various application needs, providing additional washing and efficient impurity removal. The system includes capabilities for separating residual contaminants such

as sand, glass, or metals using heavy medium cyclone technology and high-turbulence washing. The system includes also a friction washer which is capable to remove paper and other fiber contaminants.

SYSTEM SOLUTION FOR PET RECYCLING: SEAMLESS INTEGRATION

Together, the Hydrocyclone Stage and the ZSK FilCo filtration compounder are exemplary exhibits that demonstrate how integrated Herbold and Coperion process modules produce highquality recyclates. The ZSK FilCo recycling extruder system allows filtration and compounding in a single production step, and works in tandem with the Hydrocyclone Stage to deliver a complete, streamlined system for post-consumer recyclate (PCR) or any highly contaminated polymer reprocessing. This combination ensures the highest levels of purity and efficiency, meeting the stringent end product quality standards.

Additionally, visitors can find Coperion’s comprehensive compounding solutions in Hall 14, Booth 14B19.

UK automation specialist Endoline Robotics has completed the installation of a fully integrated robotic palletising system for Bird Brothers, one of the most well-established, family-run UK egg producers.

The new system marks the latest milestone in a long-standing automation partnership between the two companies – and plays a central role in Bird Brothers’ strategy to deliver greater efficiency, sustainability, and growth capacity.

Supplying up to 5 million eggs every week to retailers, wholesalers, and food service businesses across the UK, Bird Brothers recently invested over £1 million in automation to streamline operations and overcome end-of-line bottlenecks at its Bedfordshire headquarters.

At the core of this investment is a pair of robotic palletising cells from Endoline Robotics, designed to intelligently handle high-speed SKU sorting and palletising with precision and minimal manual intervention.

This latest installation builds on a fully integrated end-of-line solution developed in multiple phases over several years through a trusted partnership with Endoline. The process begins with Endoline Automation’s space-efficient 251 Slimline Case Erectors, designed specifically to integrate with MOBA MR12 robotic loading systems – a marketleading egg packing solution. These erectors form cases with speed and consistency, feeding directly into the line for packing.

Once filled with egg cartons, cases are sealed using Endoline’s high-speed 734 Fully Automatic Random Case Sealer. This system efficiently seals up to 22 randomly sized cases per minute, supporting the high-volume demands of Bird Brothers’ distribution network.

After sealing, cases are scanned to verify contents and ensure they’re sent to the correct palletising line. Previously, misrouted products could lead to full pallet rejection – a costly waste point.

Endoline’s solution resolves this with intelligent product scanning and routing, drastically reducing waste and increasing order accuracy.

ROBOTIC EFFICIENCY – BUILT FOR GROWTH

The newly installed robotic palletising system, commissioned in February 2025, is capable of handling up to 40 cases per minute. Operating across eight SKU lines the system is built for both performance and scalability.

The two robotic palletisers, automate the palletising of the four highest-volume SKUs, while the remaining four lower-volume SKUs are currently handled manually – with infrastructure already in place to automate these in future phases.

To maintain seamless operations, Endoline installed 50 metres of conveyor systems, including a carousel-style accumulation conveyor designed to handle brief pauses in palletising. When the palletiser is momentarily halted, the carousel gently loops cases in continuous motion. As soon as the system detects a new pallet is ready, it automatically feeds the cases back into the line - ensuring consistent, uninterrupted productivity.

OVERCOMING LABOUR AND WASTE CHALLENGES

Before automation, all eight packing lines were manually palletised. This not only demanded significant labour but introduced inefficiencies, especially if egg cases were incorrectly sorted by weight or SKU. With Endoline’s intelligent routing and scanning, these risks have been virtually eliminated.

“This system brings together intelligent scanning, high-speed sealing, and precision palletising into one seamless line – enabling Bird Brothers to dramatically improve throughput, accuracy, and resilience,” comments Andrew Yates, Managing Director of Endoline Robotics. “It’s a future-proof solution that supports both immediate operational needs and long-term growth.”

Bird Brothers’ investment aligns with its wider Vision 2028 strategy – a multi-million-pound plan to phase out colony cage egg production by the end of 2028 and transition to more sustainable and welfare-conscious practices.

With rising consumer demand, growing SKU complexity, and labour pressures across the supply chain, this project demonstrates how Endoline Robotics can deliver intelligent, scalable automation to meet the evolving needs of modern food production.

“Partnering with Endoline Robotics has enabled us to take a major step forward in our automation journey,” comments Matthew Bird, from Bird Bros. “This new robotic palletising system not only removes bottlenecks from our end-of-line process but also gives us the scalability we need to meet growing customer demand. By investing in smart, integrated automation, we’re strengthening our efficiency today while laying the foundation for long-term, sustainable growth.”

HAVER & BOECKER, the global leader in processing, storage, handling, mixing, filling, packing, palletizing and loading of bulk materials, launches the AMICUS® DEPAL Edition and AMICUS® PAL Edition. The robotic depalletizer and palletizer complement and completely automate packing lines from empty to full bags, enhancing productivity and safety for customers.

“Robots improve the efficiency of processes, provide more work capacity and create a stable, reliable and safe packing cycle. The AMICUS — which is the Latin word for ‘friend’ — complements existing packing lines,” said Mr. Bernhard Pagenkemper, Chief Sales Officer at HAVER & BOECKER Machinery Division. “The advanced technology increases efficiency by precisely handling the bags, drums and other materials, leading to less downtime due to manual processes and required monitoring by employees.”

The AMICUS DEPAL utilizes image recognition which allows the DEPAL to detect bag bundles quickly and effectively, then securely grip them using the unique End of Arm Tool (EOAT) developed by HAVER & BOECKER before transferring them from the pallet to the automatic bag placer, seamlessly integrating with an existing packing line. When paired with a packing machine and bag applicator, the DEPAL offers an output of up to 6,000 bags per hour. The end-of-arm tool is both effective and versatile with the ability to grip unstrapped empty bag bundles of 15-20 bags and accommodate different bag sizes without the need for a tool change.

The AMICUS DEPAL offers a compact design allowing for easy integration to any packing line, even those with limited space. Setup requires little downtime and therefore can be completed quickly. In addition to providing increased precision, the DEPAL is easy to operate and simple to maintain, resulting in enhanced efficiency and increased uptime.

Continuing HAVER & BOECKER’s focus on end-to-end automation, the AMICUS PAL robotic palletizer completes the packing/filling process by taking the filled bags, pails, canisters and drums and stacks them on a pallet. The smart HMI allows for intuitive adaptation to customer containers and pallet sizing, saving time and boosting efficiency. Its capacity, flexibility for palletizing various products and space saving form make it a popular choice for a wide range of operations. The end of arm tool is adapted to your container type and production needs. HAVER & BOECKER offers optional slip sheet, film and pallet magazines for the PAL.

The PAL seamlessly integrates with HAVER & BOECKER’s full line of bulk packing equipment to provide customers with a tailored solution and full system integration. Custom-built tools are available for specific customer applications. Like the DEPAL, the PAL can work with two packing machines at the same time. The PAL can also be configured to work seamlessly with a variety of packing machines, making it an automation solution for any plant.

The AMICUS robots provide 24/7 functionality, ensuring maximum uptime. To learn more about the AMICUS robot family and how to completely automate a packing line, visit https://www. haverboecker.com/en/product-solutions/ machines/amicus/

The Blendcon® air blender by Dynamic Air is a fast, efficient blender for mixing batches from 5 cubic feet to over 4000 cubic feet of dry bulk materials. The blender is unique in that it lacks moving parts required to displace the material in the mixing process. Instead of shafts, paddles, or agitators, compressed air is pulsed into the material in an upward circular pattern to lift, turn, and tumble dry materials. This makes the Blendcon air blender especially effective for abrasive blends such as glass batch, tile grout, and concrete mixes. Since the process area is a cone-bottomed vessel, the Blendcon air blender empties nearly 100%, making cleanup easy. Plus, the Blendcon air blender’s blending method is so effective, the ratio of horsepower to blended material is very low, resulting in high energy efficiency.

https://www.dynamicair.com/ product/blendcon-air-blender/

Dynamic Air Ltd.

Milton Keynes, United Kingdom

+44-1908-622344

e-mail: sales@dynamicair.co.uk www.dynamicair.com

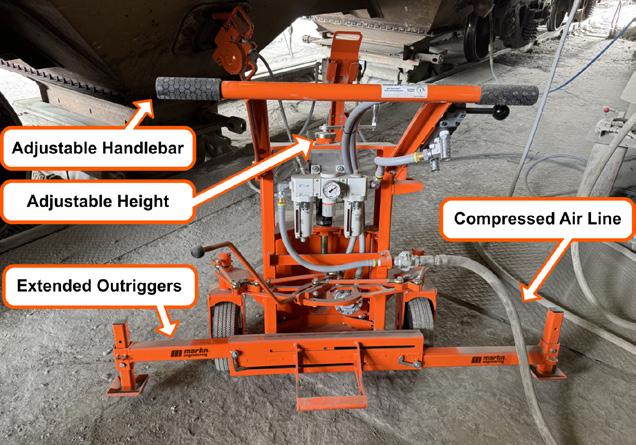

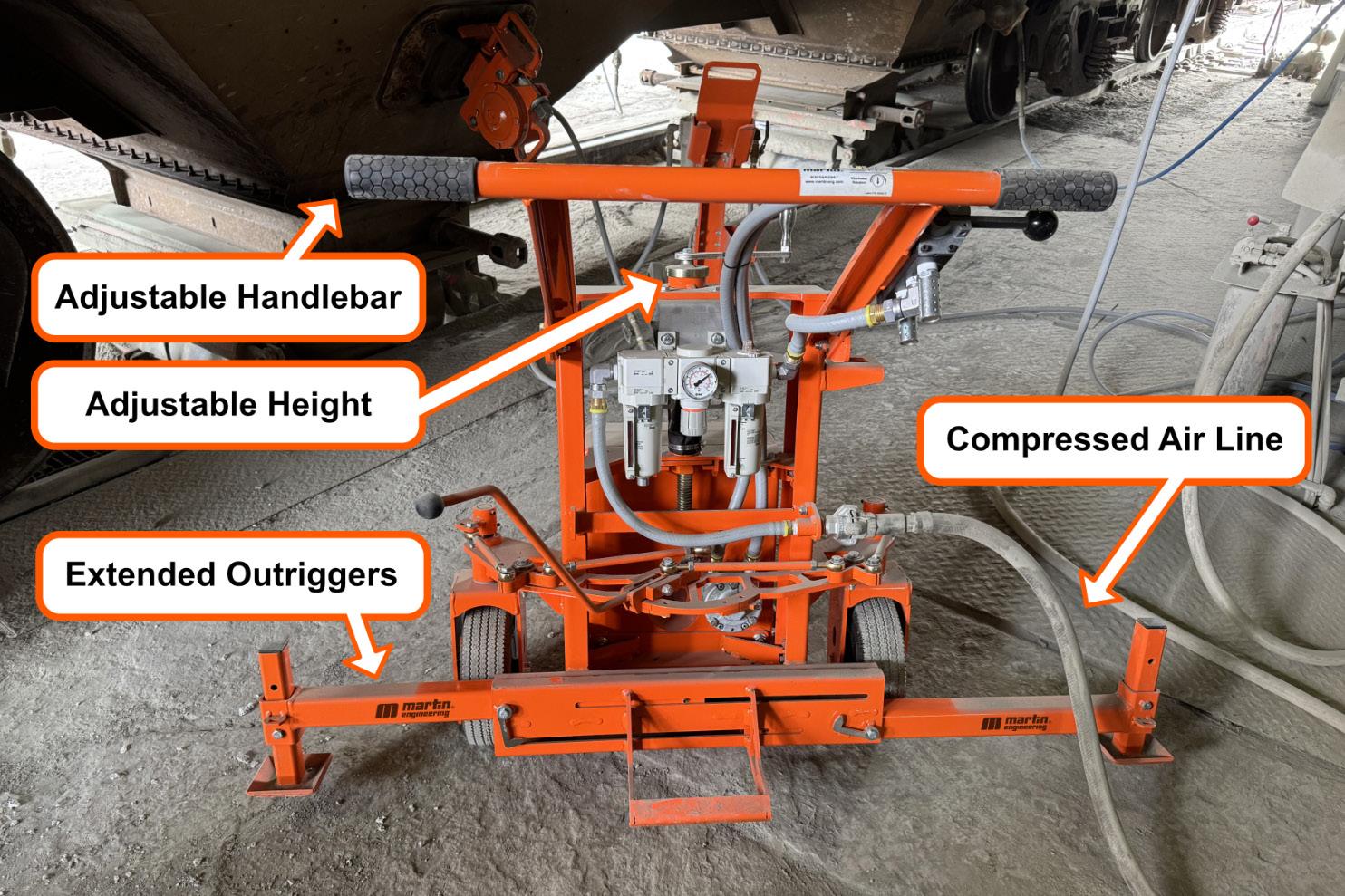

The global leader in bulk material flow accessories is introducing a redesigned railcar opener that improves ease of use and reduces potential hazards for workers. The two-wheeled Martin® Gen 4 Railcar Opener from Martin Engineering delivers strong, controlled non-impacting power to open and close even the most difficult railcar gates. It features simple maneuverability and lateral turning wheels for moving capstans, outrigger support, and height adjustment. Additionally, the innovative “stepped” drive tip improves the gate opener’s contact with the capstan. This new design boosts efficiency, leading to less demurrage from stalling and a safer workplace, which results in a lower cost of operation.

Martin® Gen 4 Railcar Opener

“We’re excited about the 4th generation of this model because it’s been painstakingly designed over years using real-world feedback from customers,” said Marty Yepsen, Business Development Manager for Railcar Unloading Products at Martin Engineering. “We approached this with reliability and safety in mind, using heavy-duty materials for a long equipment life. The result is a non-impacting opener that can compete with impacting-type openers. In fact, given the

controlled force of the Gen 4, it may be preferred.”

Railcar openers are semi-automated systems controlled by a worker to enhance the speed, efficiency, and safety of unloading materials. A cargo train generally offloads into a storage facility or conveyor by dropping cargo through an underside opening sealed with a gate. A capstan connected to a shaft and pinion gear is used to open the gate.

A worker inserts the bit into the capstan on a stopped hopper car to release the gate.

A poorly maintained gate will require a great deal of force to open. Since most facilities do not know the condition of the gates upon arrival, it is wise to have an opener that has some range. The Gen 4 will generate the power necessary to open and close gates safely and without damage.

The rugged steel-framed Martin® Gen 4 Railcar Opener requires an air supply of 75 cfm at 100 psi (2124 L/min at 6.9 bar). It delivers 3750 ft/lbs (5080 N-m) of non-impacting torque to open tough gates without causing damage. The new “stepped” profile of the replaceable drive tip provides more surface contact with the railcar’s capstan, reducing rollback of the opener under load. This minimizes wear and tear on both the drive tip and capstans.

Engineered for versatility across many applications, the Gen 4 allows easy adjustment

of the driveshaft height to match various rail car capstan heights and to account for variations in unloading platforms. Fitting through 36-inch-wide door frames, the unit’s outriggers expand up to 67 inches (1719 mm) for greater stability during high torque operations.

Attach the ½ inch hose, adjust the handlebar, position the unit, adjust the height, set, insert the bit, and engage the power.

Designed with ergonomic operation in mind, the handlebars are adjustable to accommodate different operator heights. The 10x4 inch (254 x 102 mm) “Never Flat” tires make the 305 lbs (139 kg) unit easy to maneuver and position by a single worker. One lever rotates the pivoting wheels 90 degrees, allowing the unit to roll with a traveling capstan for increased unloading efficiency.

Although the industrial environment can be loud, the Martin® Gen 4 Railcar Opener is relatively quiet at only 88 dBa, a safety feature that decreases the need for ear protection and lowers noise pollution.

“The nearly effortless single operator design transforms a hazardous and grueling job into a comparatively routine and risk-free task,” Yepsen concluded. “Field tests have shown that the Gen 4 not only improves efficiency, which lowers demurrage, but it also increases safety and reduces labor costs. All this drives down operating costs and boosts ROI.”