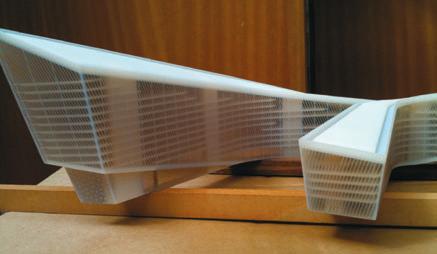

Event report featured Mark Burry (RMIT + Sagrada Familia), Daniel Bosia (AKT), Sara Klomps (Zaha Hadid Architects), Dirk Krolikowski (Rogers Stirk Harbour + Partners), Bob Sheil (The Bartlett). Two of the stand out projects presented here came from Mark Burry and Sara Klomps. Burry, famous for his work on the Sagrada Familia, explained the design of an interior walling systems for an office that, through the shape of its surfaces, would offer a beautiful and acoustically dead meeting room within an open plan office. Using computational methods and CNC manufacturing his team created a sculpted cone based wall which ensured sound stayed inside the space created by the complex sloping walls. With the London 2012 restriction shackles off, firms can now talk about their Olympic designs. Klomps gave a great insight into how Zaha Hadid approached the design and manufacture of the diving boards in the London Aquatic Centre. Using McNeel Rhino, the firm cleverly sculpted three diving boards of varying height using the same three sections. These were machined at real scale in foam, from which fiberglass moulds were made to cast the concrete. This was a great story of digital design and fabrication, showing the

team’s excellent design flair. My only concern was that for known temporary structures, they looked like they were built to survive a direct nuclear hit. In the debate following the presentations, a fairly black and white discussion took place on the place of 2D drawings in the design and construction process. Some participants said that they have dispensed with 2D altogether, other than for contractual needs, while others such as Klomps strongly disagreed. She said 2D had a valid place and had to regularly stop her team from modelling a problem, wasting time, when it could be sketched in 2D much more quickly. The Symposium includes presentations from leading industry practitioners describing computational-based projects or thought leading research. This year SG had lined up: Tristram Carfrae (Arup), Michelle Addington (Yale University), Sarah Jane Pell (Artist & Researcher) and Ben Cerveny (Data Visualization Designer). A major coup for SmartGeometry was getting Tristram Carfrae, structural engineer, Arup to present. Carfrae has helped design some truly amazing and award winning buildings, such as the National Aquatics Centre (Beijing’s Watercube) and is one of the world’s leading experts in light-

weight, long-span structures. He explored a number of designs where generative methods were used to come up with a non-linear solution to deal with site restrictions, leading to a more interesting building that structurally as good, if not better than standard designs.

Conclusion SmartGeometry has a relatively unrelenting schedule over three days and covers such a broad range of topics and ideas that it can leave one a little bewildered, with no time to truly absorb the complexities or far reaching impact of a presentation. It doesn’t help that the event rarely runs to time. Thankfully the Symposium and sgTalkshops should be available to view online in the coming weeks and can be taken with a little more digestion time. At the start, ten years ago, SG workshops were producing little more than CAD spirals with arrays, or unravelling curved glazing schedules. Today’s teams were designing complex vaulted structures, 3D printing them, then assisting an artisan fabricate the form, while using 3D scanning technology to compare the built form against the original design. SmartGeometry and the technology we have at our fingertips has come a long, long way. ■

smartgeometry.org

Bentley turns to the cloud for simulation Event sponsor Bentley previewed a brand new technology that uses Generative Components and cloudbased simulation to explore hundreds of design iterations. Santanu Das, Bentley’s senior vice president for design and modelling, explained how studies have shown that most designs only undergo a few iterations. Time spent modelling and remodelling, setting up simulations, and processing bottlenecks are the big barriers to evaluating more alternatives. Those wanting to do an acoustical analysis, heat analysis or a solar insulation analysis, for example, don’t want to have to remodel every single time, explained Das “[The model] should be smart enough to self describe itself and prepare itself for that type of simulation.”

www.AECmag.com

p16_17_19_AEC_MAYJUNE13_SG.indd 19

Simulation is traditionally used for design verification, but Bentley sees a big opportunity for it to be deployed throughout the entire design process, using early stage conceptual models from the very beginning. “You can get a big ‘red, yellow, green’ as to where am I with my solar exposure, or where am I with my line of sight or my shadows,” he said.

Das was clear that the technology is not just about using the cloud to run more simulations. “You have to make the analytics talk to each other,” he said. “It’s what we call multi-disciplinary optimisations: the output of structural should influence the input of energy. The output of energy should influence the input of acoustics. We can’t work in silos anymore.”

As the model progresses it should be able to be self-aware and provide feedback on how it’s handling the different analytics it’s exposed to, he said.

It’s also about the automatic generation of the different analysis models, which Bentley calls scenario management.

Simulation shouldn’t be a serial process of build > analyse > modify and then analyse again, emphasized Das. “It should be integrated and it should be in real time and with Bentley’s cloud technologies this is all now possible.”

“Using Bentley’s scenario management with our Generative Components we can optimise and automatically generate those models for you – by you giving the constraints and what kind of patterns that you want,” said Das. “All of those models are created and

uploaded onto our cloud and you can see we’ve designed them in real time and we compare them against many different scenarios.” Das gave an example where the system generated 60 different scenarios, but in theory this could lead to 100s if not 1,000s, leading to a much more optimal solution and helping make a building more efficient, both in terms of performance and cost. To handle all the processing, Bentley has partnered with Microsoft and is using its Azure platform. The technology is not just reliant on multi-threaded CPUs though: Bentley showed a slide highlighting GPU compute through CUDA. Bentley’s cloud-based simulation technology will be launched later this year. ■ bentley.com

May / June 2013

19

7/5/13 10:00:53