Prints charming 3D printing is causing a stir in industrial design and engineering circles, but how can it help AEC professionals who don’t want to take the technology in-house? AEC Magazine looks at how bureau services can model projects down to the finest detail by Stephen Holmes

W

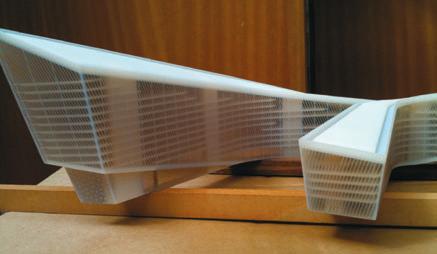

hen trying to win bids, impress clients or explain planning procedures, the traditional scale model has always been a clear, reliable method. Nothing works quite like a 3D model that a potential client can walk around and inspect, yet the cost and time they take to produce often make them impractical for an industry where developments move at high speed. Traditional model makers still exist, but many have taken on new 3D printing technology to produce amazing models and dioramas in a fraction of the time. In this case a 3D printer builds up a model in paper-thin micron layers on top of one another, taking its data straight from the CAD model. The level of detail and structural strength offered by highend machines means that fine details and angles can be outputted as the designer intended. So how can you get the best from this technology by using a bureau service? 3D printing is far from a clean and straightforward process; you cannot simply press a button and ‘voila’ a fully finished model appears. Bureaux not only have the machines needed to print the parts, but also the skilled staff to adjust data, clean up, finish and assemble parts, and crucially, guide customers through the process with advice and experience. The parts can usually be shipped anywhere in the world, and because repeat custom is key, reliability is paramount to what bureaux provide.

What is the model for? Before choosing a bureau you need to define exactly what your model will be used for. All bureaux offer different material processes, but many also have other specialities, such as increased production speed or skilled 12

May / June 2013

p10_11_12_13_AEC_MAYJUNE13_3dprinting.indd 12

craftsmen with years of experience building models to the highest quality. A model for public viewing might need to show how people will interact with the building, requiring additional figures, trees, transport and sense of realism. Models to win a pitch, or impress a client might focus on fine details within the structure and need the right materials to have this pin-sharp. A 3D print does not have to be simply a stationary object for aesthetic viewing. The reduction in costs in 3D printing means models can be printed fast and cheap for use during the design phase. Models with colour printed straight from the 3D printer can show computational

which affects assembly, cost and time. A simple, small model might be easily printed in one go, but to get the best from a more complex model might require a combination of builds, materials and techniques. A good bureau service will be able to provide these, advise on any areas that might benefit and add value.

Data decision

Sending data to a bureau can be the trickiest thing to get right. Different bureaux accept different files, with the outcomes and potential problems varying. “To run a 3D printer we require data in STL format,” says Gary Miller at IPF ltd. “Yet when the client converts their data to STL there’s Fine detail architectural model produced by IPF nearly always teething problems.” Common problems including scaling, wall thickness and optimising buildings for print by ‘hollowing out’ plague such data transfers. Mr Miller explains that the way for clients to solve this simply themselves is through thirdparty software. “The larger, more experienced architects now have a seat or two of Magics, a file fixfluid dynamics (CFD) data for wind flow ing software, which helps them prepare the and air pressures on the building; highlight data for printing. “We have to insist on STL CAD data as a specific architectural feature within a build, or different networks in a plan such changing file formats on behalf of a client as HVAC (heating, ventilation and air con- can lead to complications in their critical ditioning) and electrical lines. data.” Strength and durability can vary greatly Other bureaux sometimes have the facilibetween different 3D print materials and ties to take on other file types, yet this can processes, so there’s a choice to be made add extra time on to a project. between a model that will be placed in a Thorp has been a model maker for over glass casing, or one that will be passed 125 years and can offer more assistance at around between architects studying every this stage, converting models from 2D data possible angle. into 3D data, even working from visuals or The size of a model obviously carries its photographs. restrictions. Machines have ever increasing “We accept all file formats for SLA modbuild envelopes, yet still have restrictions els including Revit or SketchUp files, but on what can be produced in one print, we usually have to complete some work on www.AECmag.com

7/5/13 09:20:10