23 minute read

Tower cranes on the up?

Tower cranes on the up?

After several years in the doldrums, the tower crane market appears to be gaining some new momentum, possibly due to the increasing number of prominent high rise projects getting underway in many countries, along with new higher capacity models that provide a more efficient lifting solution. Whatever the reason, the sector is finally buzzing again, at least in relation to new product introductions and innovations in all sectors, from small self-erectors to the mid and large capacity luffers, flat-tops and saddle jibs.

By their very nature, tower cranes are very visible, seen working high above a town or city, dominating the skyline. It was said many years ago that the economic prosperity of a country can be measured by the number of tower cranes in use in its major cities. In London for example, during a recession there may only be a handful visible, but during a boom period there are often more than 50.

Unfortunately, being so visible means that any problem or incident involving a tower crane is immediately seen by local residents and passersby and splashed all over social media. For some reason, last year had more than its fair share of incidents such as dropped jibs, tower collapses and dropped loads etc - which on a global basis occur far too often.

More recently there have been some more unusual events involving tower cranes. Three cranes in Munich, Germany and one in Sydney, Australia all suffered foundation base problems resulting in the cranes leaning to unsafe angles. In Munich’s old town, torrential rain caused three tower cranes to lose stability within a few days of each other, with the local residents informing authorities. One toppled over while it was being secured, another collapsed before efforts to secure it got underway, while the third was successfully dismantled without incident. It would appear that the heavy rain had washed away some of the ground around and beneath their concrete foundations or bases. With jib lengths of up to 30 metres the potential fall zones were extensive causing hundreds of people to be evacuated from their homes while disrupting local traffic. Fortunately, no injuries were reported.

Three unstable tower cranes in one city within the space of a few days is highly unusual of course and questions are being asked as part of the ongoing investigations, such as how much attention was paid to the design of the foundations and whether anything more could have been done to prevent such incidents? While the details of each incident may vary, one thing is certain - the unprecedented and exceptionally heavy rain over the past year has played an important factor in all three and given the changing weather patterns, this may trigger changes to some tower crane installations.

But it is not just heavy rain that has caused a loss of stability. In Sydney, high winds were blamed when a flat top tower crane started leaning at an unsafe angle after two of its foundation anchor bolts failed. The incident is thought to be purely due to bolt failures which are being blamed on high winds of 100kph/60mph, however the wind speed should not have caused a bolt failure if properly sized and installed in the foundation. Perhaps foundation designers need to reassess possible changes in ground conditions due to excessive rainfall and high winds?

Self-erectors?

One tower crane anomaly is the lack of selferecting tower cranes in certain countries such as the UK and the USA to mention just two, given their widespread use in countries such as France, Italy and the German speaking markets. We have written about this many times before, often citing the proliferation of telehandlers in the UK, and possibly the use of mobile cranes in the US, however France is a major telehandler market, in addition to using self-erecting tower cranes, however builders there seem to prefer small tower cranes on multi-home construction sites and small infrastructure projects. But could the Anglo American indifference be changing? In the UK, manufacturers, distributors, a few rental companies and the HSE have been trying to convince UK contractors and builders to adopt what they see is a better lifting solution for many small sites. The HSE would like to see less ‘traffic movements’ on projects, reducing the number of traffic related incidents. While a few builders have seen the light, most stick stubbornly to their ‘traditional’ material handing solution - i.e. telehandlers. Perhaps the trend of less space on many sites will persuade some?

Earlier this month, a builder in Devon, KM Developments took delivery of its first tower crane - a 1.5 tonne MiDi LS15.17A-RD trailer mounted self-erector. MiDi cranes are manufactured by Euro Crane of Zaragoza and have been marketed under the MiDi brand since 2008. The company was established in 1965 by the Sarasa brothers, producing their first crane, a 500kg model almost 60 years ago.

The crane was purchased through The Trailer Crane Company, a division of Ladybird which also offers Potain self-erectors and mobile self-propelled models from Montarent. For many years, Ladybird Crane Hire was one of a few UK rental companies with a sizeable fleet of selferectors and it has cut back on this part of the business in recent years, but it is still one of a handful of UK companies with around 30 or more cranes in its fleet. The leading players in the UK are Mantis Cranes and Falcon Tower Cranes Services.

The key benefit of the MiDi crane is the ability for an end user to transport the crane themselves behind a pick-up truck or 4x4, a major cost saving compared to other small cranes that need low loaders or specialist transport to get to site. However a key factor is the ability and confidence of the builder to install and erect the crane with inhouse staff, a responsibility many companies shy away from. If a telehandler incident happens it’s a whole different ball game to a tower crane going over because it was poorly installed.

The MiDi LS15.17A-RD is the latest addition to the company’s self-erecting range and can lift its 1,500kg maximum capacity at a six metre radius, while the jib tip capacity is 510kg at 17 metres with a hook height of 15 metres. The jib can also luff from horizontal to 30 degrees for a maximum tip height of 23.7 metres and a radius of 15.3 metres. Several counterweight options are available between 800kg to 2,800kg. The normal outrigger footprint is four metres square but can also be set at a narrower 3.0 by 4.6 metre configuration if required.

The crane has an overall width on the road of 2.2 metres, is 10 metres long over the tow bar and 3.2 metres high and total weight of 3,500kg. KM Developments ordered the crane with LED floodlights, radio remote controls with screen, nylon outrigger mats and a few accessories such as lightweight aluminium brick forks, a block grab and skip, all manufactured by Kranmeister.

Another company eyeing the UK and Ireland self-erecting crane market is Kranlyft UK which was appointed Terex Self-Erecting Tower Crane dealer in late 2023. It now offers the complete nine model lineup from 21 to 40 metres including the new CSE range and FC 6.24 top slewing self-erector. The new CSE Series adds advanced electronic controls and safety features such as the Terex Power Plus and Easy Setup which ensures rapid, hassle-free deployment on site.

The first CSE32 to arrive in the UK has been delivered to the Harren Group. The crane has a 32 metre jib with a maximum lift capacity of 4.4 tonnes and tip capacity of just over one tonne, which increases to 1.15 tonnes with Terex Power Plus (TPP) function. The crane has a variable hook height from 21.5 to 27 metres and a swing radius of 2.25 metres.

New crane brands

Over the past year or so, two new tower crane brands have been launched - Giraffe Cranes in the Netherlands and the more international Stafford Tower Cranes, a rebrand of Portuguese manufacturer Soima, following its acquisition by the Stafford crane family in 2021.

Dutch sales and rental company Bulten Bouwmaterieel based in Zelhelm east of Arnhem launched its first crane under the Giraffe brand just over a year ago. The company installs self-erecting crane superstructures on its own wheeled or tracked chassis. It has been working in the tower crane market for more than 40 years and typically offers Potain and Cataneo self-erectors. Earlier this year it exported its first unit - the 1.5 tonne Giraffe 350.15-M trailer crane - to Bultech, which it has appointed its distributor for Belgium. It has a jib tip capacity of 350kg at 15 metres radius, and a hook height of 14 metres with the jib horizontal, or 450kg at a radius of 13 metres and hook height of 20.3 metres with the jib luffed to its maximum height. The overall length on the road is 9.7 metres with an overall width of 2.3 metres and total weight of 3.5 tonnes. The outrigger footprint is 4.4 metres square.

Stafford Tower Cranes

Since acquiring Soima in 2021, Arizona based Stafford Crane has been investing heavily in new products and production upgrades, reaching the point in June last year where it felt comfortable changing the name from Soima to Stafford. Soima was established in 1977 and since 1980 has been exclusively producing tower cranes including hammerheads, flat tops and self-erectors and has carved out a respectable market share in southern Europe, with sales throughout Portugal, Spain, France and a number of Mediterranean countries.

At Bauma Stafford unveiled its new 20 tonne STL.257 luffing jib tower crane with 60 metre jib and 40 metre free standing tower for an under hook height of almost 58 metres. Maximum jib tip capacity is 3.3 tonnes at its 60 metre maximum radius and this can be increased to four tonnes in specific configurations. The crane has a rear slew radius of 7.5 metres, while hoist options include 70kW or 110kW drive motors, with the larger unit offering line speeds of up to 250 metres a minute. A larger STL.757 model is also available with a maximum capacity of 42 tonnes and 5.8 tonne tip capacity.

The company also introduced a new operator’s cab, along with an inboard mounted operator/ emergency access lift system. The new cab is said to offer significantly improved visibility, comfort - including standard air conditioning - as well as new safety features and its own ‘Smart System’ with its inhouse telematics system monitor which records and uploads any misuse or overloading, the location and a range of technical data and is now available for all crane models. The first crane equipped with the new cab and updated electronics, an STF7022, was shipped to a customer in the Bahamas. All Stafford cranes are manufactured at the company's facility in Canas De Senhorim, inland between Porto and Lisbon, with research and development support from its Milan Design Hub.

Wilbert now Zoomlion Germany

Not a new company but another name change. German crane manufacturer Wilbert Tower Cranes changed its name to Zoomlion Deutschland last month - six and a half years after it was acquired by the Chinese manufacturer.

The move comes almost three months after the group ‘broke ground’ on the €50 million, 60,000 square metre Phase II expansion of its German production facility at Wilbert headquarters in Waldlaubersheim, south west of Mainz. Going forward the plant will manufacture tower cranes, along with mobile cranes and concrete pumps.

New luffers and flat-tops

Terex Tower Cranes has introduced a new 32 tonne luffing jib tower crane which includes new technology to improve speed and control along with quicker, easier and safer assembly. The CTL 702-32 features a 70 metre jib with a jib tip capacity of six tonnes. Other features include free standing heights of up to 90 metres when using a wider lower tower and transition section, and a more powerful luffing motor for greater speed, control and reliability.

Terex says it has prioritised safety with enclosures and handrail protection to prevent falling objects, while providing greater protection for technicians and operators during maintenance, operation and assembly/ disassembly. The slack rope system feature prevents conditions that could compromise crane stability and load security. Improvements to the erection and dismantling process include standardised pins and bolts requiring fewer tools, and smart assisted assembly solutions. The design also reduces the number of cables and connectors making maintenance simpler and more efficient. Additionally, the crane's main assembly is completed on the ground, for faster, easier and safer setup. A new T-Line system is said to place loads more precisely during jib luffing, ensuring a consistent load height is maintained.

1,100tm Saez

Spanish tower crane manufacturer Sáez Cranes has launched its 1,100 tonne metre TLS 1100 50T which can lift almost 11 tonnes at its maximum radius of 86 metres. Maximum capacity is 50 tonnes and maximum free standing hook height is 92 metres. Its distributor in Germany and German speaking markets is BKL Baukran Logistik - BKL - which has ordered five of the new 1,100 tonne metre cranes along with a number of other high capacity Saez models for delivery this year. The company has more than 40 cranes from 500 to 1,100 tonne metres in its fleet of more than 500 tower cranes.

New Liebherr luffers

The latest generation of Liebherr HC-L luffing jib cranes was introduced at Bauma. The 440 HC-L is available in two capacity versions: the 12/24 tonne 440 HC-L and the 18/36 tonne 440 HC-L, while the 620 HC-L - aimed at large scale construction projects - also has a maxmium 18/36 tonne capacity. Both models claim to offer fast load handling in single fall operation, improving construction times for building heights of 100 metres and more and rapid re-reeving for two fall operation for heavier loads.

Both the 440 HC-L and 620 HC-L feature ‘LoadPlus’ which offers higher capacities for specific load charts. The 440 HC-L offers a 52 percent increase in jib tip capacity up to 1.65 tonnes, while the 620 HC-L increases by up to 76 percent to 3.25 tonnes. Liebherr says the crane series is the first to make use of lightweight aramid fibre pendant ropes which reduce the weight on the jib compared to steel rope, increasing lifting capacity.

Pre-assembled assemblies reduce the time needed for setting up on site - for example the hoist and luffing ropes come mounted on their drums and the counter-ballast consists of a single ballast block. A central switchgear cabinet, mechanical quick connections and a small number of transport units also help speed up assembly time.

UK based rental company Bennetts Cranes ordered three 36 tonne 620 HC-L’s at Bauma - the first units to be delivered worldwide. The crane features a maximum hook height of 74.3 metres and a maximum radius of 65 metres, at which point it can handle 7,550kg. The cranes offer a minimum out of service radius of 4.1 metres and are equipped with the manufacturer's EMS-4 control system and radio remote controls.

Wolffkran

Wolffkran - always at the forefront of technology - launched four new cranes and several other new products at Bauma. The cranes included the Wolff 550 B luffer, the 900 tonne/metre class Wolff 8095 Compact, the 8038 Clear and the 7021 Clear which was unveiled last year. Also new is the Wolff Crane Control and Wolff Cam, Wolff Assist and its High Speed Positioning System - HiSPS.

The company says the new 550 B luffer is aimed at the rapidly growing demand for high capacity cranes around the world. Mohamed Abouelezz, head of business & product development said: “Our customers are increasingly requesting cranes in the 500 to 600 tonne metre range for infrastructure projects, industrial plants and data centres and despite a weak economic outlook, there is still a lot of new construction projects happening in these sectors.”

The 550 B slots between the Wolff 355 B and the Wolff 630 B. Initially launched with a 110kW hoist, it has a maximum capacity of 30 tonnes in two fall operation or 15 tonnes in single fall mode and a jib tip capacity of five tonnes on its 65 metre jib.

“By the end of the year, the 550 B will be available with a more powerful winch, capable of up to 36 tonnes in two fall operation, there will also be a US version with a 132kW hoist,” said Abouelezz.

Fast lifting, fast climbing

The 550B has a standard 2.3 metre tower connection, allowing freestanding heights of nearly 52 metres, while 82.2 metres is possible with the 2.9 metre tower. The crane is also compatible with Wolffkran’s KSH 23 internal climbing frame, enabling the crane to climb nearly 27 metres in a single phase, significantly more than the 15.5 metres achieved by the standard climbing system, saving time and reducing costs. Features for high-rise construction include a single line speed of 200 metres a minute and a new Flex Cab, which can be mounted on the right or left side of the crane. The 550 B is now available to order and is expected to be launched in Europe, the US and the Middle East later this year.

Compact double trolley

Wolffkran’s new 8095 Compact is its first trolley jib crane in the 900 tonne metre class. It is available in two versions, the two fall 25 tonne 8095.25 and the four fall 40 tonne 8095.40 which also features a double trolley with automatic coupling for additional flexibility. Both have jib lengths from 30 up to 80 metres in five metre increments, with maximum 80 metre jib tip capacities of 10.5 and 8.6 tonnes respectively. Wolff says that the main advantage of its new double trolley is that no one needs to climb on the jib to manually separate the trolleys. In two fall operation with a single trolley, the 8095.40 achieves a capacity of 9.4 tonnes or 10.3 tonnes with ‘Wolff Boost’. The new crane is ideally installed on Wolff’s 2.9 x 2.9 metre TV 29 tower, but when combined with the larger TV 33 tower it has freestanding tower heights of up to 100 metres.

The 110kW winch achieves line speeds of up to 160 metres a minute. For lower power demands, the hoist is decreased by up to 50 percent helping reduce the size of the generator required. A hoist rope support on the jib is said to reduce ‘rope sag’ from seven metres to just 1.5 metres, minimising the risk of catching another cranes’ hoist rope while slewing. Wolff says that the new crane can be assembled with a standard 350 tonne All Terrain crane, while the tie-ins for the jib can be adjusted directly from the tower top section without the need for a mobile crane.

The 8095 Compact also features improved bolt storage at critical locations where bolt installation is particularly demanding. For example, in the counter jib section, where bolts weighing up to 70kg can now be installed without excessive effort. Assembly, maintenance and tear down have been improved by a wide access route to the cab, a maintenance platform for the slew gear, and galvanised walkways. Other safety equipment includes electronic overload protection, anti-collision interface, fine positioning modes, automatic performance optimisation for hoisting and trolley travel, as well as ‘Wolff Link’ remote maintenance system with a real time display of the crane.

Bigger flat top

Wolffkran has also launched its largest flat top to date - the 560 tonne metre 8038 Clear. The crane has a maximum capacity of 20 tonnes at a 33.4 metre radius. The 80 metre jib has a jib tip capacity of 3.8 tonnes, while an extension takes it to 85 metres reducing the capacity to 2.1 tonnes at an 86 metre radius. The crane has a standard 2.3 metre tower connection but can also be mounted on a two metre tower to fit into elevator shafts. It has also been designed for easy transport and installation - the heaviest single component weighs 15 tonnes and according to the company the entire crane can be transported on six trucks.

To ease installation, it is equipped with a patented smart jib design where the top chord can be assembled with a simple plug connection without the need for a hammer, also providing a smoother transition between sections. At the same time, it features ‘bolt depots’ at all points where the crane components need to be installed overhead, such as the jib top. The bolts always remain in the correct position and only need to be slid into the designated holes with a single motion, making it physically easier on the installation crew.

Additional support for assembly and maintenance is provided by extra platforms for divided jib assembly, foldable guardrails on the counter jib, and optional auxiliary cranes for tasks involving the hoist and slewing gear.

As a pure two fall crane, the 8038 Clear can be ordered with either a 75kW or 110kW winch with speeds of up to 132 or 190 metres a minute respectively. The speeds can be reduced by up to 50 percent when not required, reducing power consumption. The new crane can be equipped with a second brake on the winch and Wolff’s High-Speed Positioning System (HiSPS), as well as being pre-equipped for an under hook camera system.

Back to the drawing board

The 200 tonne metre Wolff 7021 FX Clear, shown as a prototype at Bauma 2022 has been redesigned following customer/operator feedback, resulting in the new 224 tonne metre Wolff 7021 Clear.

Designed as a two fall crane the Wolff 7021.8 Clear has a maximum capacity of 8.5 tonnes or 10.5 tonnes on the 7021.10. A four fall version with a 12.5 tonne capacity will be released later this year. The jib can be extended from 25 to 70 metres in 2.5 metre increments, jib tip capacity at 70 metres is 2.1 tonnes or 2.3 tonnes with Wolff Boost. The crane is equipped with two slew gears and, depending on the version, is available with a 45kW or 67kW winch with line speeds of up to 94 metres a minute.

New control and camera systems

Wolffkran has also launched the updated Crane Control System (CCS) and Cam hook camera. With a new 10 inch display, CCS provides a direct interface with Wolff’s Link fleet allowing users to access diagnostic profiles for the entire crane fleet. The system continuously records operational and error data, generating documentation and maintenance reports. Operators can also access essential data sheets and manuals. The new PLC system integrates the optional Wolff High-Speed Positioning System (HiSPS) and includes a data interface for anticollision systems. Both systems can be managed directly via the display which also supports a live feed from Wolff Cam extending the operator’s view.

The Cam hook camera integrates into the CCS and can be installed within the HiSPS sensor box and connects using the same adapter. For Wolff cranes without HiSPS or the latest Wolff CCS, the camera can still be installed separately and operated with its own display. With two rechargeable batteries, the system can operate up to 20 hours.

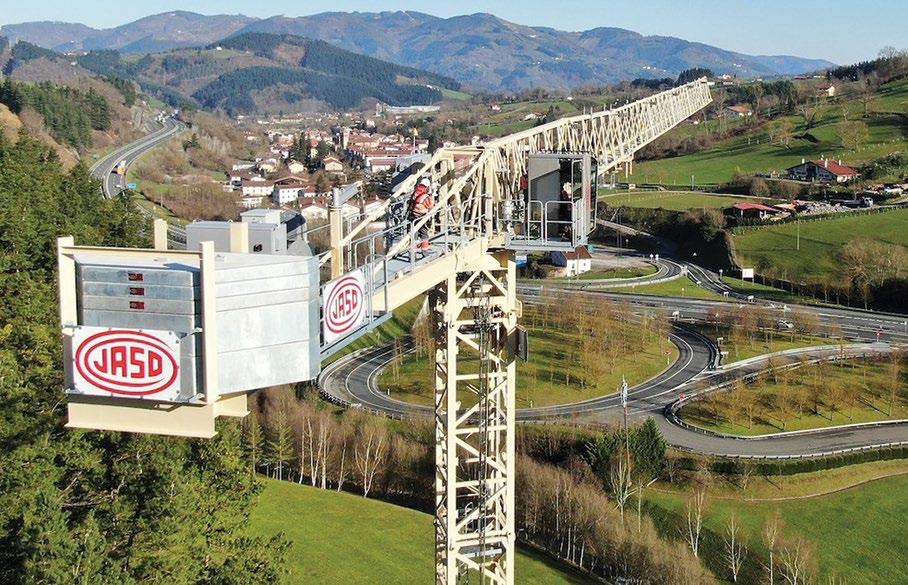

Jaso 50th anniversary

As well as celebrating 50 years in the construction sector at Bauma, Spanish manufacturer Jaso Tower Cranes also unveiled the J165.8 flat top crane and a new "Horizon" cabin.

The J165.8 has a maximum capacity of eight tonnes and has boom lengths from 30 to 60 metres extended in five metre increments with a maximum load at the tip of 1.92 tonnes. The counter jib is short at 12.9 metres and it has a freestanding height of 53.10 metres when mounted on a 1.75 metre tower. Maximum line speed is 177 metres per minute. Its design optimises the weight of the components, facilitating quick and efficient assembly even in congested areas. It also incorporates innovative technologies such as micro speed, progressive rotation, and Smartlink ensuring efficiency, safety and low environmental impact.

Unveiled two years ago, the 24 tonne Jaso J390 ‘Low Top’ tower crane is beginning to gain traction. Falcon Tower Cranes in the UK has taken the first four to arrive in the UK, as part of a deal which includes five Jaso J235.12 flat tops.

The J390 Low Top can be rigged with a jib length of between 30 and 75 metres at which point it has a jib tip capacity of 3.8 tonnes. Counter jib lengths range from 15.3 to 19.9 metres, while the maximum free standing height is just over 90 metres on a two metre wide tower. The 24 tonne capacity can be taken to a 15 metre radius, while the 65kW IP55 hoist provides lift speeds of up to 118 metres a minute.

The first four cranes were installed in Cardiff, Wales where they are helping build a new 35,000 square metre cancer hospital for Sacyr.

The new cranes have been equipped with the J390 Safety Pack which includes Safety PLCProgrammable Logic Controller - a pre-installed anti-collision system, a secondary clamp brake and multiple built-in safety sensors. Jaso announced its Low Top range in 2019, starting with the 64 tonne J1400 and now has seven models with capacities from 18 to 64 tonnes and jib lengths up to 80 metres. ■