Despite a challenging trading environment, Teignbridge Propellers wrapped up 2022 having recorded its best year ever, enjoying a 15% increase in turnover. On the back of those results, the company kicked off 2023 with a substantial reinvestment programme that will see both its physical and technological footprint increase to better serve its constantly growing demand. Richard Hagan met with Teignbridge Propellers’ Group MD Mark Phare to find out more.

Teignbridge Propellers, headquartered in Newton Abbot in the UK, is a specialist manufacturer of propellers and stern gear for commercial vessels, superyachts, leisure boats and the defence industry.

The company prides itself on its unmatched combination of engineering expertise and specialist manufacturing facilities that deliver some of the world’s most efficient, durable and high-quality propellers and stern gear systems.

Teignbridge Propellers’ investment programme kicked off at its Newton Abbot head office, where the company has invested in a new 600sqm warehouse.

The warehouse will provide secure storage for completed orders prior to delivery to customers. This new storage space will drive efficiency and shipping cost reductions, according to Teignbridge Propellers’ Group MD, Mark Phare: “While it’s true that most of our products spend their lives underwater and can cope with getting wet without rusting, the new warehouse will ensure that the packaging is kept safe, secure and dry.

“80 per cent of what we sell is exported, and in international shipping, the costs increase for wet boxes and packaging. We’re effectively then paying more to ship water around the world.

“Therefore, the new warehouse will make us more professional in the way that

we handle finished goods. It’s a relatively small investment, but it will deliver a significant advantage for us and our customers.”

A new factory is also under construction at the Newton Abbot site. The foundations for the new 1,500sqm facility were laid by early 2023, with the new factory’s expected completion date pegged at Q3 2023. The space will house Teignbridge Propellers’ new, extremely cutting-edge, robotic sand milling centre, as well as several other new machines.

“These developments demonstrate that we are continuing to reinvest profits into the business, ensuring the continued growth of our operations worldwide,” said Mr Phare.

In addition to its new warehouse building, Teignbridge Propellers has made a substantial investment into its manufacturing process with the purchase of two extremely high-tech new machines.

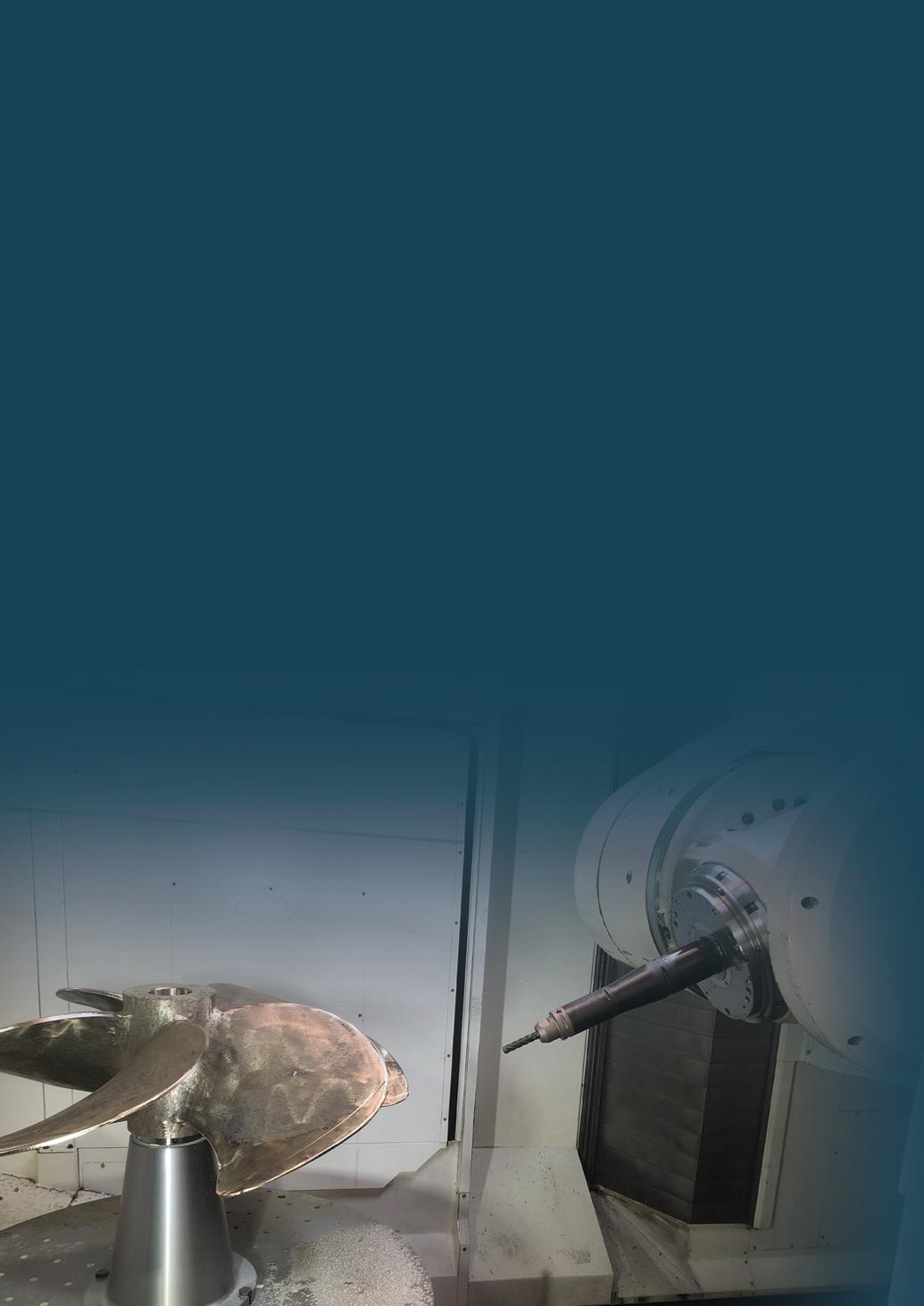

The first of these is a Tuscan LG38 propeller turning lathe. Purchased as a replacement for an existing, older machine, the new machine delivers a massive 400% output improvement over the model it replaces. “The LG38 delivers a significant production output increase for us, and consequently it is already far along into paying for itself,” Mr Phare noted.

The second machine is a Mazak Intergrex e-1600/V10 mill, with the capacity to fully machine propellers of up to 2.2 m in diameter, producing both the blade surface and the boss. “It machines our products to very high tolerance levels – within the thickness of a human hair,” said Mr Phare. “It produces a perfect propeller because there’s no human involvement in its production; its geometry is perfect, faithfully replicating the designer’s intended tolerances and design, with no v ari ations from one blade to the next.”

Purchased at a cost of approximately £1 million, the Mazak mill has revolutionised

both the quality of the product that Teignbridge Propellers offers and the quantity. “It’s a two-pallet system,” Mr Phare explained. “We can load two propellers for machining on a Friday afternoon and when we arrive on the Monday morning, we have two finished propellers.

“It also gives us a higher level of quality – particularly for customers seeking a small edge in performance, for example. The Mazak mill means we can offer guarantees in terms of better economy, lower noise or vibration. It means that we are able to supply a very high-end product to our customers.”

The Mazak mill has been such a success for Teignbridge Propellers that the company plans to buy at least one more during 2023.

In support of its strong customer base in Indonesia and its surrounds, Teignbridge Propellers has a brand-new factory in Batam, Indonesia. Located inside the Batam free trade zone, and only a short 40-minute ferry ride from Singapore, the new factory places Teignbridge Propellers in a strategic location right in the middle of the company’s most important Asian market.

The new facility will be equipped for manufacturing new build projects including shafts, couplings, stern tubes, rudder tubes, fabricated rudders and various other turned steel components. While cast components will provisionally still be shipped from Teignbridge Propellers’ Newton Abbot facility, the long-term plan is for the Batam facility to reach 50% of local content for products supplied to the Asian market, especially the Indonesian sector. The Batam factory will also provide robust after-sales support to its regional customers.

According to Mr Phare, the local market’s response to Teignbridge Propellers’ new presence in Batam has been enthusiastic: “We’ve received lots of feedback from the local shipyards and navy: they’re all excited about this opportunity. It puts us in a much stronger position in the region, with easy access to logistics networks and the nearly 100 shipyards on our doorstep. It’s an extremely good decision both for us and our customers.”

Looking forward, Teignbridge Propellers’ ongoing reinvestments into expanded capacity and new technologies are expected to bring an annual growth of approximately 20%.

Certainly, part of this growth will continue to come from sales of its best-selling product: high-performance propeller designs. Thanks to its high-tech Siemens STAR-CCM+ Computational Fluid Dynamics (CFD) software and hardware, Teignbridge Propellers is able to run 500 iterations of propeller design adjustments within only two days - a number that is far beyond the capabilities of a human.”

Through this process, we are able to rapidly achieve a propeller design that is optimum for the parameters we require –for example top speed, or fuel economy,” Mr Phare explained.

The company’s growing sales force will aid in its growth plans. It recently appointed a specialist sales manager for Northern Europe, who will be responsible for growing Teignbridge Propellers’ presence in the Benelux and German markets.

“It’s an exciting environment to be working in,” said Mr Phare, in conclusion. “Being in such a strong position, with our best year to date last year, and this year on track to reach our 20 per cent growth target. Meanwhile, purchasing new machines and gaining new technologies means that the future for Teignbridge Propellers is bright and we have everything to look forward to.”