IV Produkt has been in operation since 1969, supplying first-class air handling units that are dependable and energy efficient. Senior Vice President of Sales and Marketing Europe Magnus Lind gave an overview of the company’s current capabilities. Report by Imogen Ward.

IN1991, IV Produkt developed a new business concept, focusing on the manufacture of sustainable products. “We committed to developing, manufacturing and selling environmentally friendly and energy efficient air handling units,” said Senior Vice President of Sales and Marketing Europe Magnus Lind. “Back in 1991, that was a bold statement and has effectively dictated how the company developed products ever since.”

For the past 54 years, Swedish-based IV Produkt has defined innovation with its groundbreakingly sustainable ventilation units. Now, with the development of its Easy Access units, IV Produkt is showing why it is worthy of its market leading position.

IV Produkt is fully committed to helping create a greener future, and work on reducing its scope one and two carbon emissions is well underway. Using a thirdparty assessment, IV Produkt recorded its scope one and two emissions, which were calculated at 0.21 tonnes of CO2 per million kronor of revenue.

“We are doing everything we can to reduce our impact,” said Mr Lind. “We looked at some of the emissions figures of our competitors and they are almost ten times higher. All aspects of the business are assessed to ensure we are doing the utmost. We currently rely on the district heating system – which uses waste product from the forestry industry – and buy electricity that is environmentally friendly”

IV Produkt noted that in order to help solve the current energy crisis, it needed to incorporate the UN 2030 Agenda into its plans. The company committed to three goals: good health and wellbeing, affordable and clean energy, and climate action.

“The European Commission stated that 40% of energy used goes into buildings,” said Mr Lind. “If, as a society, we could install more efficient air handling units in all these buildings, we could create potential savings equivalent to the total energy use for the country of Sweden. That’s a huge figure. The problem is the pace at which renovation is occurring. Currently, that figure is sitting at 1%, which means it will probably take about 100 years at the current pace, which would be too late.”

Whilst assessing the speculated time frame, IV Produkt worked hard to develop a time-saving solution. Thanks to the company’s impressive research and development department, the company developed the Easy Access concept.

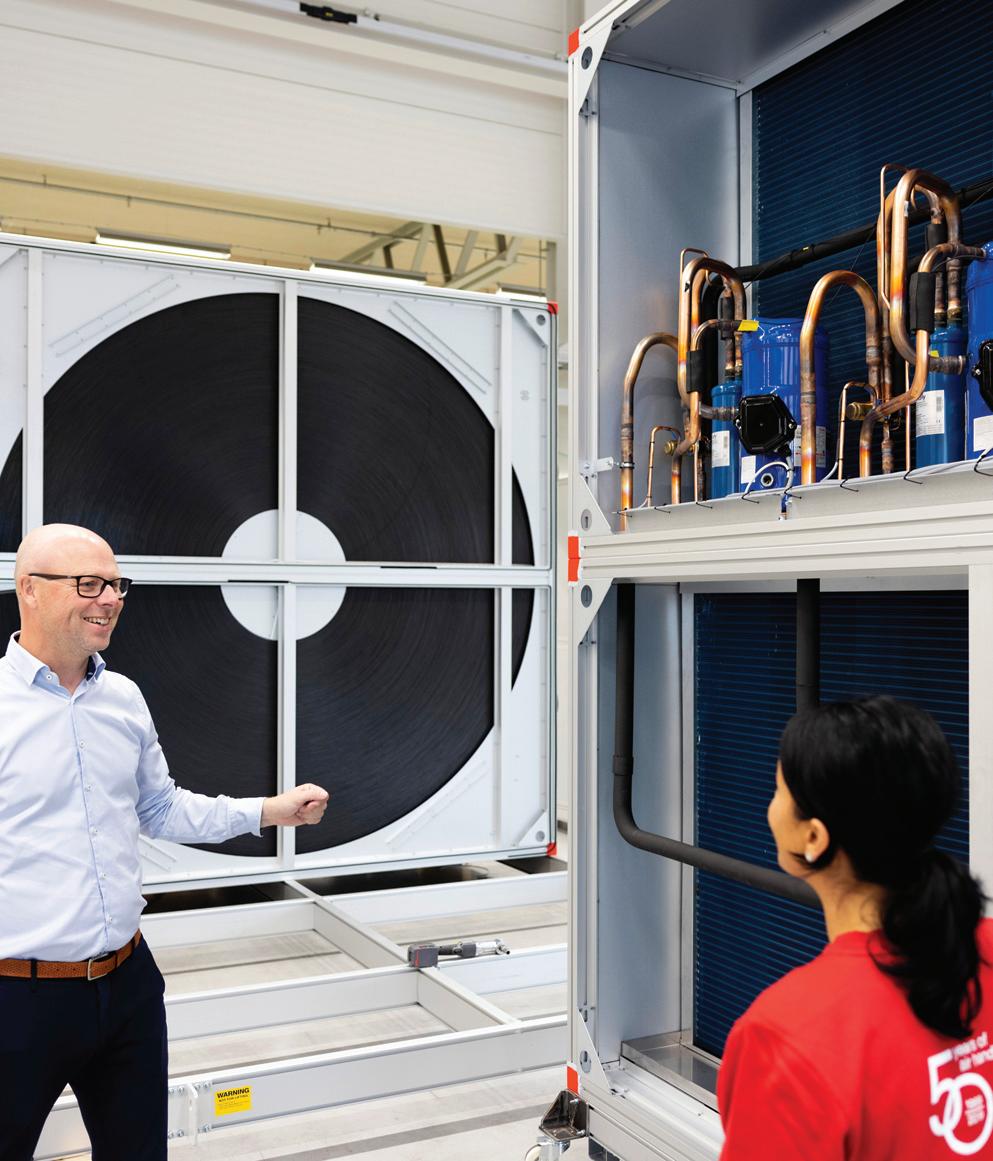

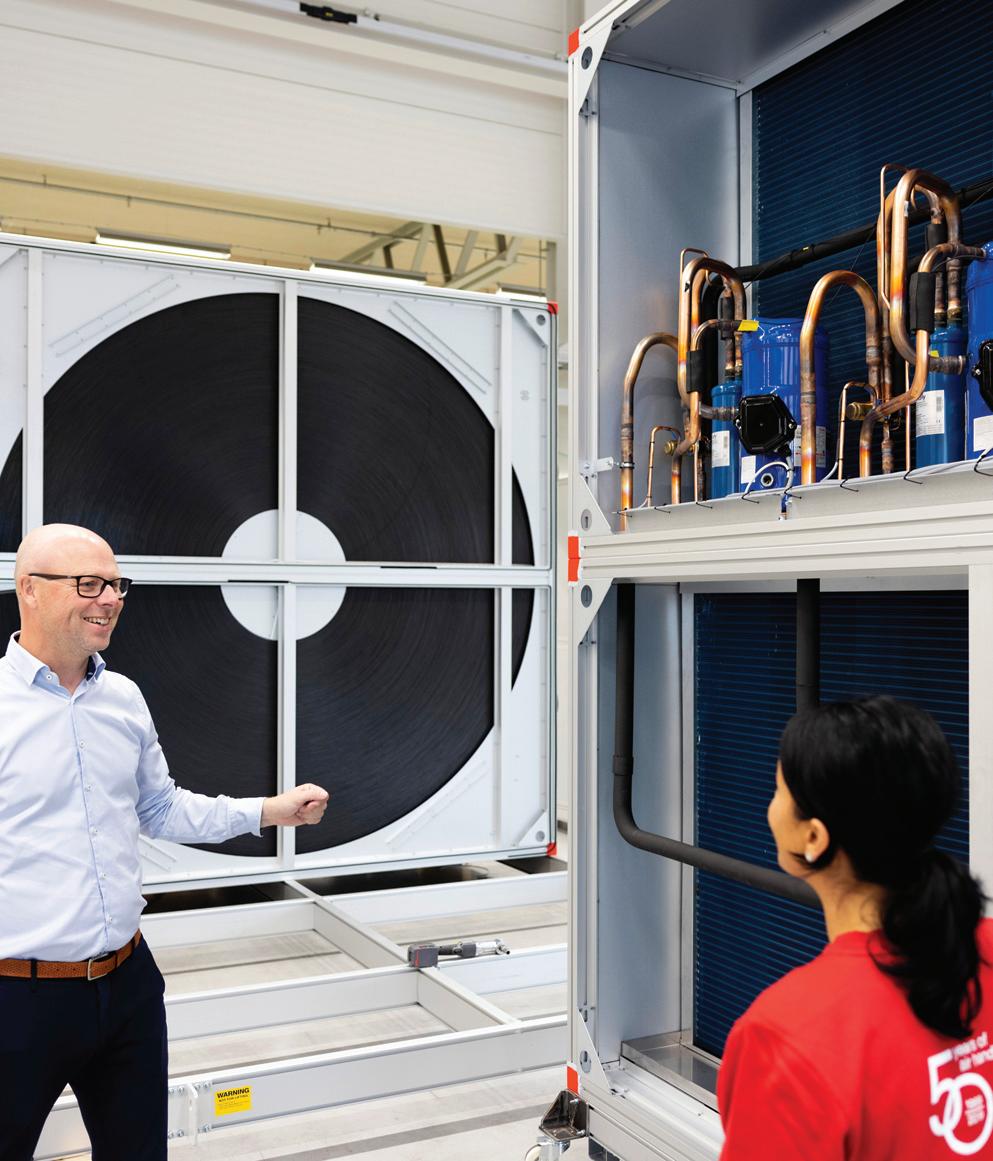

Easy Access was created as a solution to the limitations of old buildings. These buildings – some of which are listed – were not built to accommodate bulky air handling units, and demolition would be completely unviable, both from an economical and environmental standpoint. To solve this, IV Produkt developed tailor-made units which can be deconstructed for ease of transportation and installation.

“Realistically, most of the existing building stock is not going to be replaced: and why would we want that? Many of them are incredibly old and beautiful examples of historic architecture,” Mr Lind explained. “But, regardless, these buildings still need more efficient ventilation systems. That’s why we came up with Easy Access, which enables us to tailor the ventilation systems to the building.

“The units can be split into pieces, all of which fit through a standard 900mm by 2,030mm door. From a volume point of view, this concept covers most of our product range, up to 8 cubic metres per second.”

The adaptability and flexibility of this solution is unique to IV Produkt. Although other companies have attempted to replicate it, as far as Mr Lind is aware, no one

has even come to close to achieving this on such a big scale, with a product range of this size.

Due to the company’s extensive experience and the impressive capabilities of its R&D team, IV Produkt has extended this solution to more complex products.

This includes the cooling units and heat pumps, which are normally not easily split.

IV Produkt has successfully manufactured a heat recovery system that can be deconstructed (right down to the system’s internal rotary wheel). The company’s Easy Access concept was launched three years ago and has been providing customers with cost savings ever since.

Due to the complexity of these designs, IV Produkt has service engineers who ensure the products are installed and assembled correctly on the building site. These engineers receive practical training in IV Produkt’s competence centre at its facility in Sweden.

Over the past five years, IV Produkt has invested over €40 million into the development and expansion of its

Swedish facility. This included new production and storage facilities with a 5,500sqm floorspace enlargement and a brand-new innovation centre.

“We invested heavily into our facilities,” said Mr Lind.” At our metal processing centre, we are currently installing our third Salvagnini metal processing line. These machines are fully automated and cost approximately €3.5 million each. We are also looking at the possibility of further expanding our manufacturing and storage facilities, as this space has become critical over the past few years.

“Because of all the disruptions in material supplies, we have increased our stock quite dramatically. It’s unfortunate, because these delays disrupt the whole system, but we have tried our best to protect our customers from the impact of these delays.”

The company’s innovation centre is a large laboratory which enables the R&D team to develop a higher quantity of its quality-driven products. The centre has the latest technology to simulate winter and summer operating conditions all year round.

“It is a well-known fact that productivity drops as temperatures rise” Mr Lind said. “This is why we climatise our entire factory with our integrated cooling units and heatpumps; we can work just as efficiently on a hot summer’s day as if it were in the winter, retaining an optimum indoor temperature of 20 degrees.”

IV Produkt has been on a mission to maintain its market lead, whilst continuing to educate people on the importance of utilising environmentally friendly air handling units.

“Our goal all along has to been to increase our presence in the market and to have the capacity to manufacture more products that have a positive impact on the environment,” Mr Lind concluded. “When it comes

to commercial air handling units, we are number one in the whole Nordic region. We i ncreased our volume a lot last year, and we have plans to do the same this year.

“I used to work at a company that had a negative impact on the environment; now, working at IV Produkt, I can see what a difference our products accomplish. Imagine the impact we could have if more people understood the positive change our products can make. The potential is enormous.” n