8 minute read

PERSPECTIVES

Insights on Industry’s Digital Transformation Leaders

By David Miller, Senior Technical Writer

Connected industrial technologies that make use of artifi cial intelligence (AI) and data analytics are becoming more prevalent and being used to address issues ranging from labor shortages and supply chain disruptions to climate change, according to ARC Advisory Group. Looking across the companies recognized in the report, ARC notes that no single indicator appears to be universally correlated with the companies’ digital transformation approach. However, certain factors do seem to be correlated with the success of digital transformation initiatives. Notably, the most successful companies have adopted digital technologies in response to specifi c external market signals, problems, or disruptions. When these narrow, well-defi ned issues motivated change, businesses saw far more positive results, according to ARC. Here are highlights from the ARC report on the strategic digital transformation approaches of the top 10 companies.

The top 10

Tesla: When Tesla seeks to automate a new internal process, it attempts to do so as e ectively as possible from the start, rather than engaging in multiple, subsequent revisions. ARC explains, “Their business model is built on the tenet that the vehicles are more like interactive computers with wheels, leading to the creation of an intelligent data platform and connected ecosystem, enabling Tesla to learn from and serve its customers. This is an example of a company that is comfortable with digital transformation and adapts to business challenges with greater ease.”

Intel: Digital transformation initiatives focused on connectivity have allowed Intel to run its semiconductor manufacturing process 24 hours a day, seven days a week, 365 days a year. Intel focuses primarily on connecting data insights with engineers who can solve specifi c problems, rather than merely maximizing data extraction. Digital twins and simulations also play a large role in optimizing factory output. In particular, Intel’s deployment of Internet of Things (IoT) technologies and predictive analytics at scale have decreased the company’s time to market, improved resource utilization, increased yields, and reduced costs.

BMW Group: BMW emphasizes its digital transformation on data analytics, intelligent logistics, and additive manufacturing—not just for prototyping, but mass production to create parts for customized vehicles. “By additively manufacturing metal and polymer parts at various points in the process chain and di erent sites across the global network, BMW has transformed its production processes,” ARC says.

Johnson and Johnson: The digital strategy at Johnson and Johnson includes cross-functional partnerships and development of a new culture around digital tools such as the use of artifi cial intelligence (AI) in product development, additive manufacturing, IoT connectivity, and automated order fulfi llment. The company primarily uses IoT connectivity to track and trace products throughout its entire supply chain—from suppliers to hospitals. Having IoT access to information in real-time allows Johnson and Johnson’s quality assurance procedures to manage the temperature of vaccines or other medical substances, regardless of where they are located at any given moment. 3M: Currently, the company has connected 240 plants and distribution centers to monitor the fl ow of products. Previously, 3M allowed individual facilities to operate autonomously using a localized subsidiary structure. Its digital transformation e orts have allowed it to achieve greater alignment and standardization across its plants. 3M is also using an AI platform to develop and deploy applications related to predictive healthcare and supply chain analytics.

Eli Lilly: Safety and quality receive special notice in Eli Lily’s digital transformation. For instance, the company has reduced ergonomic risks to employees by deploying robots to lift heavy boxes. In addition, real-time analytics have replaced after-the-fact testing to improve the e ciency of the company’s quality assurance procedures.

Deere and Company: Digitalization has been used by John Deere to achieve more dynamic logistics and production planning, improve the visibility and accuracy of materials throughout its global supply chain, and deliver customized user instructions in real-time. The company has also increased its investment in 5G to aid in the greater adoption of edge computing, autonomous devices, real-time location systems, asset tracking, inventory management, wearables, and robotics.

Procter and Gamble: A multi-cloud data strategy and a “culture of data” to inform business decisions are at the core of Procter and Gamble’s digitalization e orts. The company sees data and algorithms as key tools for constructively altering how it operates. Among the goals of Procter and Gamble’s digital transformation strategy are: Greater collaboration among employees; evolution of new products; improved production systems; supply chain and distribution optimization; and better customer relations.

Volkswagen: At Volkswagen, the use of robotics to replace human labor for ergonomically challenging assembly tasks has been a major focus. The company also uses computer vision to increase manufacturing e ciency at its factories. Vision sensors are used to gather optical data, which is then evaluated using AI technology capable of recognizing, processing, and analyzing images. According to Volkswagen, this has resulted in signifi cant reductions in energy use.

Nestlé: The digital transformation strategy at Nestle is known as Vision2Life and has four priorities: Bring value to those who receive IT services; operate as a single global IT team with pockets of local expertise; interlock product management with business stakeholders; and make IT a technology differentiator. Technologies adopted by Nestle include analytics, AI, and e-business. In addition, all of the company’s factories are equipped with collaborative robots. Everyone from procurement, manufacturing, sales, and marketing are involved in the company’s digital transformation process, which is focused on increasing product innovation, capacity, and availability of goods while decreasing costs.

See ARC’s full Industrial Digital Transformation Top 25 report here.

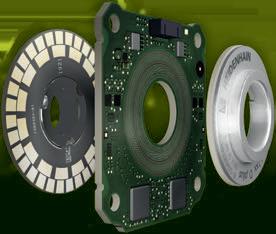

The KCI 120Dplus Dual Encoder High-Accuracy Robot Motion

The new KCI 120 Dplus dual encoder from HEIDENHAIN combines motor feedback and position measurement in a single compact rotary encoder. Both benefits can be applied to every robot axis, correcting inaccuracies such as gearbox backlash and work-induced reaction forces. The HEIDENHAIN KCI 120 Dplus thereby turns a typical articulated robot into a high-accuracy manufacturing system and dependable cobot.

Contact us today for details!

HEIDENHAIN CORPORATION, 333 East State Parkway, Schaumburg, IL 60173 847-490-1191 www.heidenhain.us

4 Ways to Ensure Your Data Lake Doesn’t Become a Data Swamp

David Greenfield, Director of Content/Editor-in-Chief

If your company is involved in a full-fl edged Smart Manufacturing, Industry 4.0, or other digital transformation initiative, you’ve likely encountered the term “data lake.” A data lake is essentially a place to store all the data collected from your operations. In a data lake, the data stored there can be structured or unstructured.

No prior processing is required for the data to be stored in a data lake.

Because all kinds of data can be stored in a data lake, these data storage sites hold high potential to provide guidance on matters you might not yet consider to be important. According to Amazon

Web Services, having di erent data types stored in a central repository means that you can apply numerous types of analytics, such as SQL queries, Big

Data analytics, full text search, real-time analytics, and machine learning to uncover new insights.

But, just like that junk drawer in your house was meant to store needed items that don’t quite fi t elsewhere, it can easily become a catch-all depository for things you should have already thrown away. In a similar fashion, a data lake can become a data swamp.

Data lakes can also become data swamps when users need special development or technical skills to access and use the data, says Niki Driessen, chief architect at TrendMiner, a supplier of data analytics technology for the processing industries. “Currently, data lakes are becoming increasingly important to process industries that capture and store immense amounts of sensor-generated time-series data,” he explains. “To make data lakes work for time-series data, it is important to understand that [these kinds of] data cannot just be dumped into the lake with the expectation of extracting its value.” To avoid having your data lake became a data swamp that obscures the value of your time-series data, Driessen advises taking the following steps: 1.Provide the required metadata. “There is no standard data lake tool or single platform that an organization can use to magically solve data lake issues such as data mapping and correlating,” says Driessen. “To ease data ingestion (for eventual analysis of time-series data), organizations must provide the required metadata—which includes data lineage, data structure, data age, and other metadata that provides common attributes or properties that link the data together.” 2. Connecting analytics to the data lake. Though no single standard exists to solve the data lake issues Driessen notes in the point above, there are common aspects of data storage packages from many di erent vendors that can help. One of these is a query abstraction layer. “This is a tool or component in an organization’s data lake that allows for writing standard SQL language queries against the data,” Driessen notes. “It also means that any tool that has support for standard ODBC or JDBC connectivity can be used to connect to the to the data lake.” 3. Data lake performance. Because data lakes typically use inexpensive block storage with a massive storage capacity, fast access to stored data is not guaranteed. This is a problem when working with advanced industrial analytics, as users expect the data to be where they need it and be able to access it as fast as possible. It can be problematic for all an organization’s data to be “sitting in one huge fi le in the data lake, as this structure is highly ine cient for extracting data,” Driessen says. The good news is that such issues can be corrected with the use of columnar fi le formats, which allow users to read data columns that are only needed for a specifi c case. “Since the entire fi le would not have to be read, less data is loaded, resulting in faster response times,” he adds. 4. Data partitioning. Another practice recommended by Driessen to improve data lake performance is partitioning. Here, data is arranged in folder-like structures by key properties, time, or a combination of the two. Driessen says this practice splits all available data into much smaller fi les, allowing users to drill down to specifi c data sets without having to transfer as much data. This translates into less time required to process the data or query against it.

Learn how to make sense of the industrial analytics market.