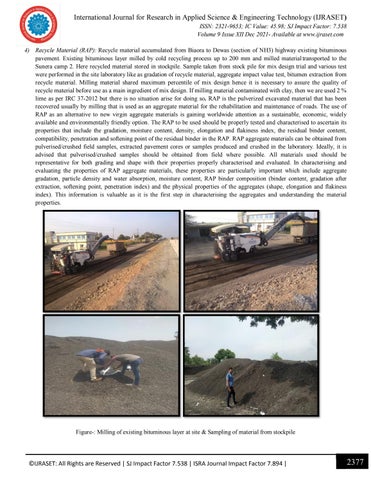

International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 9 Issue XII Dec 2021- Available at www.ijraset.com 4) Recycle Material (RAP): Recycle material accumulated from Biaora to Dewas (section of NH3) highway existing bituminous pavement. Existing bituminous layer milled by cold recycling process up to 200 mm and milled material transported to the Sunera camp 2. Here recycled material stored in stockpile. Sample taken from stock pile for mix design trial and various test were performed in the site laboratory like as gradation of recycle material, aggregate impact value test, bitumen extraction from recycle material. Milling material shared maximum percentile of mix design hence it is necessary to assure the quality of recycle material before use as a main ingredient of mix design. If milling material contaminated with clay, then we are used 2 % lime as per IRC 37-2012 but there is no situation arise for doing so. RAP is the pulverized excavated material that has been recovered usually by milling that is used as an aggregate material for the rehabilitation and maintenance of roads. The use of RAP as an alternative to new virgin aggregate materials is gaining worldwide attention as a sustainable, economic, widely available and environmentally friendly option. The RAP to be used should be properly tested and characterised to ascertain its properties that include the gradation, moisture content, density, elongation and flakiness index, the residual binder content, compatibility, penetration and softening point of the residual binder in the RAP. RAP aggregate materials can be obtained from pulverised/crushed field samples, extracted pavement cores or samples produced and crushed in the laboratory. Ideally, it is advised that pulverised/crushed samples should be obtained from field where possible. All materials used should be representative for both grading and shape with their properties properly characterised and evaluated. In characterising and evaluating the properties of RAP aggregate materials, these properties are particularly important which include aggregate gradation, particle density and water absorption, moisture content, RAP binder composition (binder content, gradation after extraction, softening point, penetration index) and the physical properties of the aggregates (shape, elongation and flakiness index). This information is valuable as it is the first step in characterising the aggregates and understanding the material properties.

Figure-: Milling of existing bituminous layer at site & Sampling of material from stockpile

©IJRASET: All Rights are Reserved | SJ Impact Factor 7.538 | ISRA Journal Impact Factor 7.894 |

2377