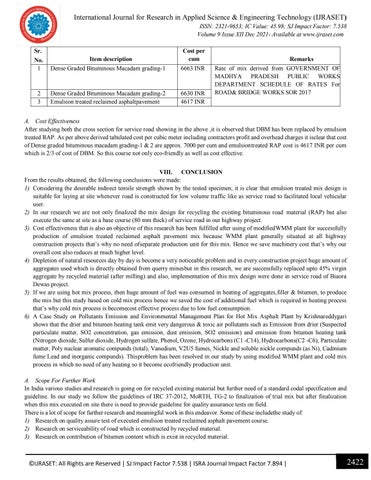

International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 9 Issue XII Dec 2021- Available at www.ijraset.com Sr. Item description

Cost per cum

No. 1

Dense Graded Bituminous Macadam grading-1

6663 INR

2 3

Dense Graded Bituminous Macadam grading-2 Emulsion treated reclaimed asphaltpavement

6630 INR 4617 INR

Remarks Rate of mix derived from GOVERNMENT OF MADHYA PRADESH PUBLIC WORKS DEPARTMENT SCHEDULE OF RATES For ROAD& BRIDGE WORKS SOR 2017

A. Cost Effectiveness After studying both the cross section for service road showing in the above ,it is observed that DBM has been replaced by emulsion treated RAP. As per above derived tabulated cost per cubic meter including contractors profit and overhead charges it isclear that cost of Dense graded bituminous macadam grading-1 & 2 are approx. 7000 per cum and emulsion treated RAP cost is 4617 INR per cum which is 2/3 of cost of DBM. So this course not only eco-friendly as well as cost effective. VIII. CONCLUSION From the results obtained, the following conclusions were made: 1) Considering the desirable indirect tensile strength shown by the tested specimen, it is clear that emulsion treated mix design is suitable for laying at site whenever road is constructed for low volume traffic like as service road to facilitated local vehicular user. 2) In our research we are not only finalized the mix design for recycling the existing bituminous road material (RAP) but also execute the same at site as a base course (80 mm thick) of service road in our highway project. 3) Cost effectiveness that is also an objective of this research has been fulfilled after using of modified WMM plant for successfully production of emulsion treated reclaimed asphalt pavement mix because WMM plant generally situated at all highway construction projects that’s why no need of separate production unit for this mix. Hence we save machinery cost that’s why our overall cost also reduces at much higher level. 4) Depletion of natural resources day by day is become a very noticeable problem and in every construction project huge amount of aggregates used which is directly obtained from querry mines but in this research, we are successfully replaced upto 45% virgin aggregate by recycled material (after milling) and also, implementation of this mix design were done in service road of Biaora Dewas project. 5) If we are using hot mix process, then huge amount of fuel was consumed in heating of aggregates, filler & bitumen, to produce the mix but this study based on cold mix process hence we saved the cost of additional fuel which is required in heating process that’s why cold mix process is becomecost effective process due to low fuel consumption. 6) A Case Study on Pollutants Emission and Environmental Management Plan for Hot Mix Asphalt Plant by Krishnareddygari shows that the drier and bitumen heating tank emit very dangerous & toxic air pollutants such as Emission from drier (Suspected particulate matter, SO2 concentration, gas emission, dust emission, SO2 emission) and emission from bitumen heating tank (Nitrogen dioxide, Sulfur dioxide, Hydrogen sulfate, Phenol, Ozone, Hydrocarbons (C1 -C14), Hydrocarbons(C2 -C6), Particulate matter, Poly nuclear aromatic compunds (total), Vanedium, V2U5 fumes, Nickle and soluble nickle compunds (as Ni), Cadmium fume Lead and inorganic compunds). This problem has been resolved in our study by using modified WMM plant and cold mix process in which no need of any heating so it become ecofriendly production unit. A. Scope For Further Work In India various studies and research is going on for recycled existing material but further need of a standard codal specification and guideline. In our study we follow the guidelines of IRC 37-2012, MoRTH, TG-2 to finalization of trial mix but after finalization when this mix executed on site there is need to provide guideline for quality assurance tests on field. There is a lot of scope for further research and meaningful work in this endeavor. Some of these includethe study of: 1) Research on quality assure test of executed emulsion treated reclaimed asphalt pavement course. 2) Research on serviceability of road which is constructed by recycled material. 3) Research on contribution of bitumen content which is exist in recycled material.

©IJRASET: All Rights are Reserved | SJ Impact Factor 7.538 | ISRA Journal Impact Factor 7.894 |

2422