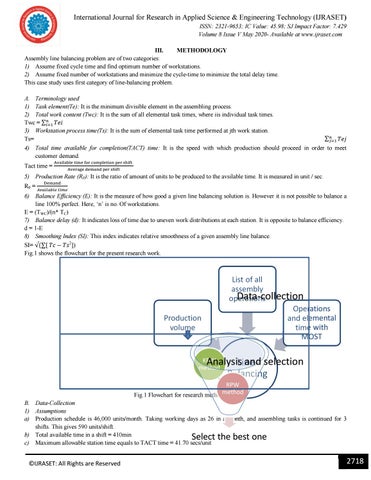

International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 7.429 Volume 8 Issue V May 2020- Available at www.ijraset.com III. METHODOLOGY Assembly line balancing problem are of two categories: 1) Assume fixed cycle time and find optimum number of workstations. 2) Assume fixed number of workstations and minimize the cycle-time to minimize the total delay time. This case study uses first category of line-balancing problem. A. Terminology used 1) Task element(Te): It is the minimum divisible element in the assembling process. 2) Total work content (Twc): It is the sum of all elemental task times, where iis individual task times. Twc = ∑ 3) Workstation process time(Ts): It is the sum of elemental task time performed at jth work station. ∑ Ts= 4) Total time available for completion(TACT) time: It is the speed with which production should proceed in order to meet customer demand. Tact time = 5) Production Rate (RP): It is the ratio of amount of units to be produced to the avsilable time. It is measured in unit / sec. RP = 6) Balance Efficiency (E): It is the measure of how good a given line balancing solution is. However it is not possible to balance a line 100% perfect. Here, ‘n’ is no. Of workstations. E = (TWC)/(n* TC) 7) Balance delay (d): It indicates loss of time due to uneven work distributions at each station. It is opposite to balance efficiency. d = 1-E 8) Smoothing Index (SI): This index indicates relative smoothness of a given assembly line balance. SI= √(∑[ − 2]) Fig.1 shows the flowchart for the present research work.

List of all assembly Data-collection operations Operations and elemental time with MOST

Production volume

AnalysisLineand selection

KBW method

Balancing

RPW method Fig.1 Flowchart for research methodology B. Data-Collection 1) Assumptions a) Production schedule is 46,000 units/month. Taking working days as 26 in a month, and assembling tasks is continued for 3 shifts. This gives 590 units/shift. b) Total available time in a shift = 410min Select the best one c) Maximum allowable station time equals to TACT time = 41.70 secs/unit

©IJRASET: All Rights are Reserved

2718