3 minute read

S.M. Peyghambarzadeha, S.H. Hashemabadib,*, M. Seifi Jamnania, S.M. Improving the cooling performance of automobile radiator with Al2O3/water

Review on Enhancement of Radiator Efficiency using Nanotechnology

Swapnil Shimpi 1 , Socrates Temburne 2 , Gunjan Firake 3 , Kapil Deshmukh 4 , Prof. A. S. Tumane 5 1, 2, 3, 4, 5 Mechanical Engineering Department, PES Modern College of Engineering, Savitribai Phule Pune University, Maharashtra, India

Advertisement

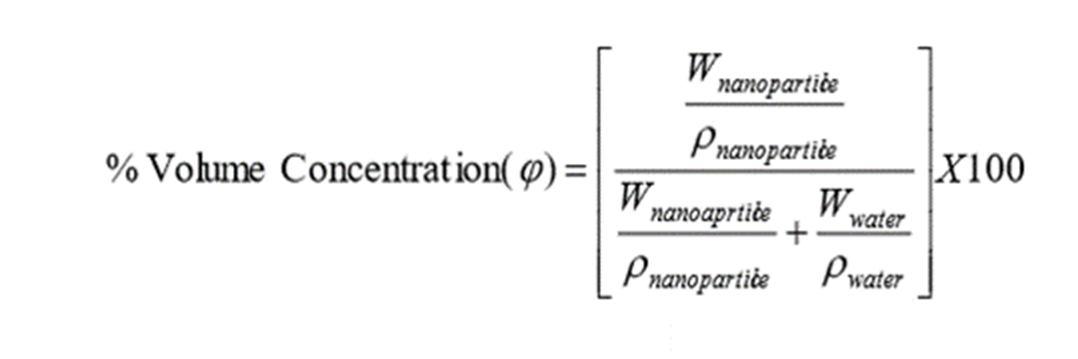

Abstract: The main function of a radiator in an automobile is to cool it’s engine. This cooling action is executed by radiator via cooling fluid, which we know as coolant. This coolant is responsible for heat dissipation from the internal combustion engines to outside of the vehicle. But this is what the problem is- “coolant”- the coolants which are used nowadays have comparatively lower thermal conductivity and it leads to overheating of vehicles, which ultimately facilitates subsequent operational and environmental problems. We know the modus operandi of convection heat transfer which is used to cool the circulating fluid which is a mixture of water and anti-freezing material like Ethylene Glycol with some additives. This is where improving the heat transfer characteristics of coolant is obligatory and we propose the use of novel heat transfer fluid called 'Nanofluid' which incorporates the use of Nanoparticles in preparation of coolant. This paper reviews the use of Al 2 O 3 based nanofluid prepared my combination of several methods studied through extensive research and various researchers predict that it exhibits better heat transfer capability to that of normal coolant. This nanofluid improves the effectiveness of a radiator and facilitates in increased heat dissipation out of the vehicle. Keywords: Al 2 O 3 Nanofluid, Coolant, Radiator, Heat Dissipation, Effectiveness, Nanotechnology

I. INTRODUCTION

Al 2 O 3 based Nanofluids are a relatively new type of fluids which involves a base fluid with nanosized particles suspended inside them. These nanoparticles or metal oxide, increase conduction and convection coefficients, allowing for more heat dissipation out of the coolant. While reviewing the literature related to this topic we witnessed that there has been many developments recently which have made the nanofluids more stable to be used as coolant. Notably in past ten we have witnessed substantial growth in research on nanofluids. In this review, papers listed in reputed national and international journals are only considered. The following study initiate to be captivated on fusion, preparation, characterization and flexibility of diverse nanofluids to various industrial and commercial applications. Various papers published in the past period of ten years belong to nanofluids and we observed that this publication rate should be of intense interest among the scientific community on the nanofluids research. We have put an effort to combine the research accessible in this topic on usage of nanofluids in radiator to improve its heat transfer capability, and recognized experiments that offer concentrated viewpoint on this topic and for its future activities in research on nanofluid. Important topic from few literature are gathered into segments and put forth in tabular format for better comprehension.

Sr. No 1 Title Of Paper Performance Analysis And Design Of Automobile Radiator (2017)

Design And Analysis Of Radiator (2017)

II. LITERATURE REVIEW

Conclusion Aluminum is most common material used in manufacturing of radiator. Aluminum decreases the overall weight of radiator. There are many advantage of circular cross section of radiator like increased heat transfer of fluid to surrounding, also the circular cross section has fewer perimeters. Various cross section like rectangular have problem of stress concentration while it is eliminate in circular cross section tubed radiator. Manufacturing of circular shape is easy. Material requirement for circular tubed cross section radiator is less and thus the overall cost of product decreases. In this paper comparison between Aluminum and Copper alloy radiator model is carried out. The copper radiator has higher temperate drop than aluminum radiator. But the Aluminum radiator is much economical than copper radiator. Aluminum radiator model is better for low cost & low weight and exhibit better corrosion resistance.