3 minute read

CO VID-19 Some management factors to consider when ramping up for postpandemic commerce

Points to consider as manufacturing gets back to business.

BY JOE TERRETT, EDITOR

Advertisement

Manufacturers are getting back to business as COVID-19 restrictions are eased, but they are facing a changed environment. Although most provincial governments allowed manufacturers to continue operating during the pandemic, it has been a challenge: sales are down, liquidity has been disturbed, sources of supply were disrupted and there are workforce safety issues that differ from past practise and must be addressed.

The virus could and likely will come again, or some other peril will appear. If there’s anything positive about the coronavirus crisis, it has laser-focused the need for companies to have a strategy in place to deal with such risks.

Rosanna Lamanna, a partner with Toronto and Hamilton-based advisory firm Fuller Landau’s audit and accounting team, notes some general points all manufacturers should consider as they prepare for what comes next.

Production. “Consumer behaviour has changed, possibly permanently,” she says, noting shortages (such as toilet paper) have meant brand preferences were replaced in a heartbeat. “That could happen to other SKUs.”

Look at what you produce. Consider the business case for focusing on higher demand and higher volume items, or managing a variety of SKUs.

“Ensure the plant can handle an increase in volume and the supply chain is robust enough to support it,” she adds.

Safety measures. Companies operating through the pandemic will have made necessary investments in safety measures, such as personal protective equipment (PPE) and aligning the movement of people in the

Navigating the return to business. What’s

NEXT?

BRINGING OPERATIONS BACK UP TO SPEED plant. Those reopening after a for backups. Have a replacement shutdown can expect a cost and plan for lost suppliers. Look putting new safety measures in at how you manage supplier relaplace will delay production. tionships and whether to go with

A top consideration must be multiples for essential inputs. employee safety, and how that Also consider digital solutions fits in with production. How for logistics to ensure deliveries many workers are required on are timely and can be managed the production line, and should remotely. they work in pods rather than as floaters? Not everyone will Weaknesses exposed be needed onsite, all the time. Working from home. As noted, Think about various online tools not all team members in a manuand digital platforms to manage facturing operation need to be the offsite scenario. onsite. She observes there is a

Plexiglass and social disnow a stronger working from tancing will be a thing, as will home culture that will change stepped up sanitizing, cleaning hiring somewhat because it will regimes, and more frequent require people with different testing. skill sets. Online training will

Supply chains. The pandemic grow because it’s more efficient has exposed the weaknesses than gathering people in a room in supply chains too reliant on for a day or three. global sources. Lamanna says it’s Financing. It’s back to basics: important to revisit whether and/ she calls for more diligent or how much global sourcing still forecasting. In the past, commakes sense. panies may have erred on the

The pandemic and shortages side of optimism. “There needs have also shaken just-in-time to be more realism in forecaststrategies, pointing to the need ing and projections. Consider

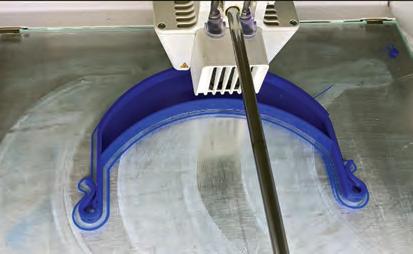

IMAGE: TANG90246 - STOCK.ADOBE.COM

new customers and how they’re operating. There will be casual, production and revenue forecasting, ideally daily, but at least weekly and worst-case scenario, monthly,” Lamanna says.

“If you don’t manage through this properly, it will hurt the bottom line. That hurts your opportunity to tell a good story about the business. There are only so many dollars to go around. Financial institutions are going to lend to viable companies.”

Despite the disruption, the pandemic has opened the door to opportunities that include producing new products (such as PPE), applying more flexible work arrangements, using online tools to deliver training and investing in digital platforms to meet business needs. And she warns companies should step up cybersecurity measures to head off an increase in fraud attempts. That means revisiting internal process and controls.

This is also a good time to engage in R&D, innovation and how to quickly bring new products to market. Revisit the type of people you hire and what they bring to the table. And Lamanna suggests partnering with other companies to drive the agenda and bring forward efficiencies to the plant floor. “It’s an opportunity to re-evaluate how things are done and how to do them better.”