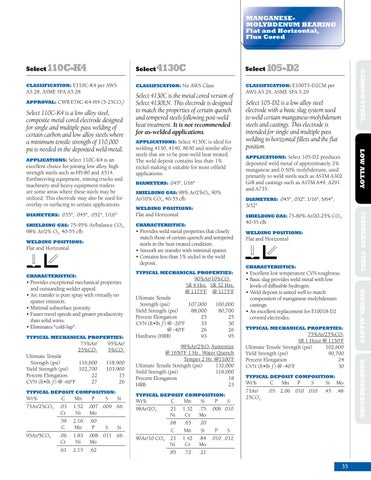

MANGANESEMOLYBDENUM BEARING Flat and Horizontal, Flux Cored

110C-K4

Select

E110C-K4 per AWS A5.28, ASME SFA A5.28

CLASSIFICATION: APPROVAL:

CWB E76C-K4-H4 (5-25CO2)

Select 110C-K4 is an excellent choice for joining low alloy, high strength steels such as HY-80 and A514. Earthmoving equipment, mining trucks and machinery and heavy equipment trailers are some areas where these steels may be utilized. This electrode may also be used for overlay or surfacing in certain applications. APPLICATIONS:

.035", .045", .052", 1/16"

75-95% Ar/balance CO2, 98% Ar/2% O2, 40-55 cfh SHIELDING GAS:

No AWS Class

Select 4130C is the metal cored version of Select 4130LN. This electrode is designed to match the properties of certain quench and tempered steels following post-weld heat treatment. It is not recommended for as-welded applications. APPLICATIONS: Select 4130C is ideal for welding 4130, 4140, 8630 and similar alloy steels that are to be post-weld heat treated. The weld deposit contains less than 1% nickel making it suitable for most oilfield applications. DIAMETERS: .045", 1/16" SHIELDING GAS: 98% Ar/2%O2, 90% Ar/10% CO2, 40-55 cfh

105-D2

E100T5-D2CM per AWS A5.29, ASME SFA 5.29

CLASSIFICATION:

Select 105-D2 is a low alloy steel electrode with a basic slag system used to weld certain manganese-molybdenum steels and castings. This electrode is intended for single and multiple pass welding in horizontal fillets and the flat position. APPLICATIONS: Select 105-D2 produces deposited weld metal of approximately 2% manganese and 0.50% molybdenum, used primarily to weld steels such as ASTM A302 GrB and castings such as ASTM A49, A291 and A735. DIAMETERS: .045", .052", 1/16", 5/64",

WELDING POSITIONS:

3/32"

Flat and Horizontal

SHIELDING GAS: 75-80% Ar/20-25% CO2,

40-55 cfh

CHARACTERISTICS:

CHARACTERISTICS:

TYPICAL MECHANICAL PROPERTIES: 90%Ar/10%CO2

• Excellent low temperature CVN toughness. • Basic slag provides weld metal with low levels of diffusible hydrogen. • Weld deposit is suited well to match composition of manganese-molybdenum castings. • An excellent replacement for E10018-D2 covered electrodes.

WELDING POSITIONS:

• Provides exceptional mechanical properties and outstanding welder appeal. • Arc transfer is pure spray with virtually no spatter emission. • Minimal subsurface porosity. • Faster travel speeds and greater productivity than solid wires. • Eliminates "cold-lap". TYPICAL MECHANICAL PROPERTIES:

75%Ar/ 25%CO2

95%Ar/ 5%CO2

116,600 102,700 22 27

118,900 103,900 15 26

TYPICAL DEPOSIT COMPOSITION:

Wt% 75Ar/25CO2 95Ar/5CO2

C .03 Cr .59 C .06 Cr .61

Mn P S 1.52 .007 .009 Ni Mo 2.16 .60 Mn P S 1.83 .008 .011 Ni Mo 2.15 .62

Si .66

Si .66

98%Ar/2%O2 Austentize @ 1650˚F 1 Hr., Water Quench Temper 2 Hr. @1100˚F Ultimate Tensile Strength (psi) 132,000 Yield Strength (psi) 118,000 Percent Elongation 18 HRB 23 TYPICAL DEPOSIT COMPOSITION:

Wt% 98Ar/2O2 90Ar/10 CO2

C .21 Ni .68 C .21 Ni .85

Mn 1.32 Cr .65 Mn 1.42 Cr .72

Si P S .75 .006 .010 Mo .20 Si P S .84 .010 .012 Mo .21

CHARACTERISTICS:

TYPICAL MECHANICAL PROPERTIES: 75%Ar/25%CO2

SR 1 Hour @ 1150˚F Ultimate Tensile Strength (psi) 102,600 Yield Strength (psi) 90,700 Percent Elongation 24 CVN (ft•lb ƒ) @ -40˚F 30 TYPICAL DEPOSIT COMPOSITION:

Wt% 75Ar/ 25CO2

C Mn P S .05 2.06 .010 .010

Si Mo .45 .48

35

HARDSURFACING

Ultimate Tensile Strength (psi) Yield Strength (psi) Percent Elongation CVN (ft•lb ƒ) @ -60˚F

SR 4 Hrs. SR 32 Hrs. @ 1175˚F @ 1175˚F Ultimate Tensile Strength (psi) 107,000 100,000 Yield Strength (psi) 88,000 80,700 Percent Elongation 25 25 CVN (ft•lb ƒ) @ -20˚F 33 30 @ -40˚F 26 26 Hardness (HRB) 93 95

Flat and Horizontal

NICKEL ALLOYS

WELDING POSITIONS:

Flat and Horizontal

• Provides weld metal properties that closely match those of certain quench and tempered steels in the heat treated condition. • Smooth arc transfer with minimal spatter. • Contains less than 1% nickel in the weld deposit.

STAINLESS STEEL

DIAMETERS:

CLASSIFICATION:

Select

LOW ALLOY

Select 110C-K4 is a low alloy steel, composite metal cored electrode designed for single and multiple pass welding of certain carbon and low alloy steels where a minimum tensile strength of 110,000 psi is needed in the deposited weld metal.

4130C

CARBON STEEL

Select