PRESERVATION UPDATE |

JESSICA LOMBARDO, EDITOR-IN-CHIEF

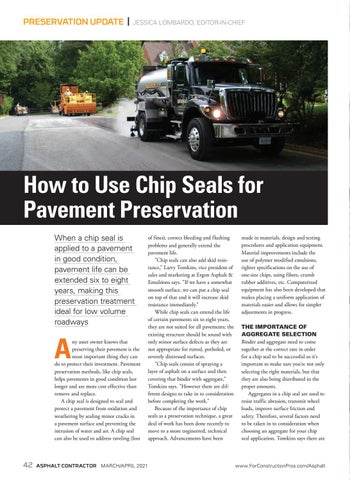

How to Use Chip Seals for Pavement Preservation When a chip seal is applied to a pavement in good condition, pavement life can be extended six to eight years, making this preservation treatment ideal for low volume roadways

A

ny asset owner knows that preserving their pavement is the most important thing they can do to protect their investment. Pavement preservation methods, like chip seals, helps pavements in good condition last longer and are more cost effective than remove and replace. A chip seal is designed to seal and protect a pavement from oxidation and weathering by sealing minor cracks in a pavement surface and preventing the intrusion of water and air. A chip seal can also be used to address raveling (loss

42

ASPHALT CONTRACTOR MARCH/APRIL 2021

ACON0321_42-47_PresChipSeals_JD.indd 42

of fines), correct bleeding and flushing problems and generally extend the pavement life. "Chip seals can also add skid resistance," Larry Tomkins, vice president of sales and marketing at Ergon Asphalt & Emulsions says. "If we have a somewhat smooth surface, we can put a chip seal on top of that and it will increase skid resistance immediately." While chip seals can extend the life of certain pavements six to eight years, they are not suited for all pavements; the existing structure should be sound with only minor surface defects as they are not appropriate for rutted, potholed, or severely distressed surfaces. "Chip seals consist of spraying a layer of asphalt on a surface and then covering that binder with aggregate," Tomkins says. "However there are different designs to take in to consideration before completing the work." Because of the importance of chip seals as a preservation technique, a great deal of work has been done recently to move to a more engineered, technical approach. Advancements have been

made in materials, design and testing procedures and application equipment. Material improvements include the use of polymer modified emulsions, tighter specifications on the use of one-size chips, using fibers, crumb rubber additives, etc. Computerized equipment has also been developed that makes placing a uniform application of materials easier and allows for simpler adjustments in progress. THE IMPORTANCE OF AGGREGATE SELECTION Binder and aggregate need to come together at the correct rate in order for a chip seal to be successful so it's important to make sure you're not only selecting the right materials, but that they are also being distributed in the proper amounts. Aggregates in a chip seal are used to resist traffic abrasion, transmit wheel loads, improve surface friction and safety. Therefore, several factors need to be taken in to consideration when choosing an aggregate for your chip seal application. Tomkins says there are

www.ForConstructionPros.com/Asphalt

3/9/21 10:17 AM