4 minute read

Eye-opening experience

BY RENEE CLUFF

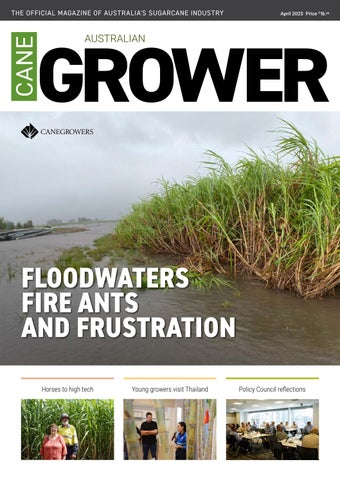

Emerging grower leaders from MSF Sugar mill areas recently took part in a study tour to Thailand.

Visits to farms, a fertiliser factory and a sugar mill which crushes 4-million tonnes of cane per year were among the highlights when Queensland growers toured the operations of MSF Sugar’s parent company, Mitr Phol Group, earlier this year.

25 farmers who supply Mulgrave, South Johnstone, and Tableland mills took part in the Thailand experience. MSF Sugar Senior Cane Supply Manager, Mick Ward, said it was targeted towards the next generation of industry leaders.

“We wanted to get some of the emerging leaders in the industry exposed to Mitr Phol Group’s operations,” he said. “The Thai sugar industry is going ahead in leaps and bounds and we wanted the young growers to get an idea of the size and scale of Mitr Phol’s group of companies to understand the broader picture at a global level.”

Innisfail grower Louis Fichera was among those to take part. He said he was amazed to learn about the scale of the group’s operations. “It gave us a better understanding of the sheer size of Mitr Phol,” he said. “I knew they were big but actually seeing it first-hand blew my mind.

“Everything becomes a product; refined sugar, energy, ethanol, fertiliser and they’ve funded and built a dam project to make productive land out of lowlying, marginal country and assist farmers with irrigation.

“They do listen and do a lot for their farmers in Thailand and you can look at it from a business perspective: they want to help in return for guaranteed supply.

“We need to be proud that our mills are backed by such a strong and committed company.”

The visitors travelled to the Mitr Phu Khiao Complex in Chaiyuphum Province, which is home to an ethanol plant and biopower station as well as Mitr Phu Khieo mill, which has capacity to crush 27,000 tonnes of cane per day.

Attendee Luke Calcagno, from the Cairns District, said they also toured an organic fertiliser facility, the Mitr Phol RDI (Research, Development and Innovation) Centre, a company farm and suppliers’ farms.

“The scale of the operation is what left an impression me,” Luke said. “Their mills are very modern, so while the average farmer’s operations may be less modern and precise than Australia’s, they are definitely ahead when it comes to milling. Everything’s automated.”

“I think the lack of red tape in Thailand really helps in this respect and they’re clearly willing to help the grower work towards increased productivity. In 1997, everything was hand harvested and what they’ve done in just under 30 years is incredible. They’ve learned from us and they’re growing better crops for it.

“Overall, the visit has given me confidence that the miller’s committed to us, it’s reassured me that the miller’s committed to the industry.”

Australian industry could learn from, including research breakthroughs in disease management. Louis was also impressed by Mitr Phol’s approach to human resources.

“They nurture their young employees,” he said. “A lot of the staff members were young and the company is always planning the next cohort coming through. They start training early to set their staff members up for their next positions, and that occurred in every part of the complex from the research facility to the mill.”

The Australian growers rounded out their study tour with a visit to the company’s headquarters in Bangkok before unwinding with a trip to the seaside town of Pattaya.