4 minute read

NLilIA Annuol Elects West Coocler Prerident Lumber Mcrnufocturers Pledged Coopercltion of Corpenters Union in Promotion of Wood Products

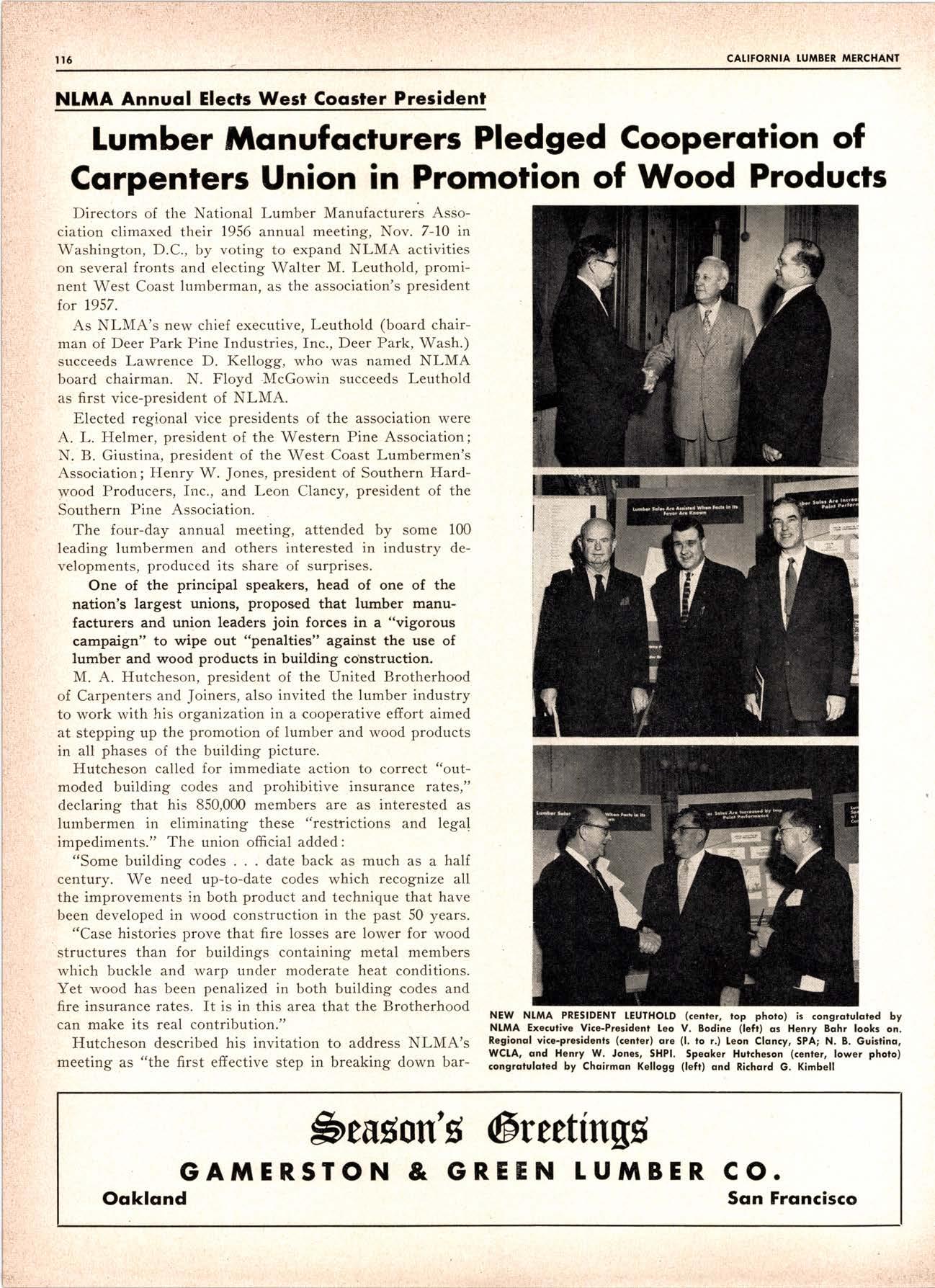

Directors of the National Lumber Manufacturers Association climaxed their 1956 annual meeting, Nov. 7-10 in Washington, D.C., by voting to expand NLMA activities on several fronts and electing Walter M. Leuthold, prominent West Coast lumberman, as the association's president lor 1957.

As NLMA's new chief executive, Leuthold (board chairman of Deer Park Pine Industries, fnc., Deer Park, Wash.) succeeds Lawrence D. Kellogg, who was named NLMA board chairman. N. Floyd l\4cGowin succeeds Leuthold as first vice-president of NLMA.

Elected regional vice presidents of the association were A. L. Helmer, president of the Western Pine Association; N. B. Giustina, president of the West Coast Lumbermen's Association; Henry W. Jones, president of Southern Hardwood Producers, fnc., and Leon Clancy, president of the Southern Pine Association.

The four-day annual meeting, attended by some 100 leading lumbermen and others interested in industry developments, produced its share of surprises.

One of the principal speakers, head of one of the nation's largest unions, proposed that lurnber manufacturers and union leaders join forces in a "vigorous campaign" to wipe out "penalties" against the use of lumber and wood products in building colrstruction.

M. A. Hutcheson, president of the United Brotherhood of Carpenters and Joiners, also invited the lumber industry to work with his organization in a cooperative effort aimed at stepping up the promotion of lumber and wood products in all phases of the building picture.

Hutcheson called for immediate action to correct "outmoded building codes and prohibitive insurance rates," declaring that his 850,000 members are as interested as lumbermen in eliminating these "resttictions and legal impediments." The union official added:

"Some building codes . . . date back as much as a half century. We need up-to-date codes which recognize all the improvements in both product and technique that have been developed in wood construction in the past 50 years.

"Case histories prove that fire losses are lower for wood structures than for buildings containing metal members which buckle and warp under moderate heat conditions. Yet wood has been penalized in both building codes and fire insurance rates. It is in this area that the Brotherhood can make its real contribution."

Hutcheson described his invitation to address NLMA's meeting as "the first effective step in breaking down bar- riers of communication" between lumber manufacturers and the carpenters' union.

Closer cooperation between these groups is a matter of "mutual survival," he insisted, and the end result should be "better technical improvement, a rise in productivity and greater consumption of wood products." NLMA directors authorized a special study to develop recommendations on the practicability of a national merchandising-advertising program. The study will be guided by a special merchandising committee to be composed. of representatives of NLMA's 16 federated associations. The committee was given discretion to instruct NLMA staff members to employ professional counsel for assistance in the study.

In a related development, NLMA's Public Relations committee decided to invite retail lumber groups and NLMA's 16 federated associations to view an audiovisual report on NLMA's national public relations activities in behalf of lumber and wood products. Other resolutions passed by the association's board of directors:

1. Authorized a survey of the trends in lumber demand, beginning with a study of lumber's use in home building.

2. Continued NLMA efforts to streamline lumber-handling methods.

3. Approved, as complete, an NLMA study of the effects of air conditioning on wood members in buildings. The association's directors were advised by NLMA's Products and Research committee that research to date indicates "air conditioning, of itself, will probably not result in a wood moisture condition above that which can be controlled by norrnal good construction practices."

4.- Discontinued NLMA publication of a Forest Products Research Guide in favor of a Research Inventory. The Forest Products Research Guide is a world-wide bibliography of technicai information developed over several years, while the Research Inventory is a year-to-year report on research being conducted in the U.S.

5. Continued an NLMA program to investigate promising research "leads."

6. Authorized tests and investigations to develop design criteria for random lengths of wood decking.

7. Approved proposed new research aimed at (1) reducing dimensional variations in wood, (2) developing new waterproof glues, and (3) developing minimum performance standards for end-glued structural lumber. However, the board decreed that actual work along these lines be delayed "until such time as funds can be provided." when you need your lumber todayl

8. aA.pproved several technical changes in the NLMA publication, National Design Specification for Stress-Grade Lumber and its Fastenings.

9. Pledged NLMA's cooperation with the Forest Products Research Society in a program designed to encourage more high school students to take college courses which will fit them for technical positions in the lumber and wood products industries. NLMA staff members will work with the Forest Products Research Society to improve the curricula of such'courses.

10. Scheduled NLMA's 1957 spring meeting for May 13-15 in Boston, Mass.

EFFICIENT IUTIABER CARGO HANDTING EXPERIENCED PERSONNET

XIODERN EQUIPIYIENT & FACILITIES

FAST TRUCK TOADING ASSURED

STORAGE AREA OVER IO 'VIILIION FEET

ADJACENI TO FREEWAYS FOR FAST TRANSPORT TO ATt SOUTHIAND CITIES

Just o lew reasons why you should CALL

CAII GEORGE DE BilTZ

FHONE tEttrilAl 3-5t0it or Zenith 35lO

Twelfih Morlite Plont Exponsion Adds 22,OOO Feet to Foctory

Marsh Wall Products, Inc., world's largest manufacturer of prefinished wall and ceiling paneling, this year constructed a plant addition which will increase the factory space by 22,0W square feet. With this addition, the total area of the Marsh buildings in Dover, Ohio, will be 230,000 square feet.

V. R. Marsh, executive vice-president and general manager of the company, in explaining the purpose of the expansion program, stated that the new factory space will accommodate new production facilities and provide increased storage for raw materials.

The recent introduction of several new products by the company, including Marlite Plank and Block and Korelock hollow-