3 minute read

Golorado millwork manufacturer adds pressure treating facility

GIINCE the early '70s Wigand elCorp. has used large quantities of pressure treated fire retardant wood products. As the applications for these products continued to grow, Emeric Wigand, Sr, president of the Colorado Springs, Co., corporation, saw wood treating as an area of growth and diversification for his company.

Emeric Wigand, who started the company in 1958 with two other people,stated, "The products we supply from our treating operation are truly an extension of the quality people have come to expect from our company."

In June of 1982, Wigand joined forces with the Osmose Wood Preserving Co. Osmose, a leading force in the treating industry, makes Flame Proof LHC fire retardant and Osmose K-33 wood preservative. Both products are among the most advanced formulations available.

December of 1982 marked the opening of Wigand's 12,000 square foot warehouse and custom engi- neered semi-automatic treating plant. The pressure treating facility was designed and installed by Osmose. This addition is the third expansion of the Wigand Corp. since it moved to Colorado Springs in 1978.

Quality control, on-time delivery and customer satisfaction have enabled them to provide materials for a $1.75 million bank headquarters in Dallas this year. Wigand also provided all interior millwork for the United Kingdom and Canada pavilions at Walt Disney's EPCOT Center in Florida. This installation totaled $2 million.

The corporation now occupies six acres in Colorado Springs. The site accommodates the treating plant and a72,W square foot millwork operation. Nearly 100 craftsmen produce architectural woodwork and cabinetry, using $1.5 million worth of advanced machines, tools, and equipment.

In treating materials with Osmose K-33 preservative and Flame Proof LHC, Wigand uses an advanc- ed vacuum pressure process to force the chemicals deep into the cellular structure of the wood.

Materials are loaded into a 6 x 52 foot cylindrical pressure vessel, the yearly capacity of which is 20 million board feet. A vacuum is created to draw air and moisture out of the wood, making the wood more susceptible to a liquid treatment. Next, either Flame Proof LHC or Osmose K-33. both water-borne solutions, is pumped into the vessel. After the treatment vessel is filled to capacity, the vacuum is released, and liquid pressure is applied up to 150 psi. In the closed environment of the pressure vessel, the only place the solution can go is deep into the wood cells.

A 50,000 square foot Unitemp dry kiln is then used to dry the Flame Proof LHC treated lumber and specific Osmose K-33 treated lumber such as the All Weather Wood Foundation material.

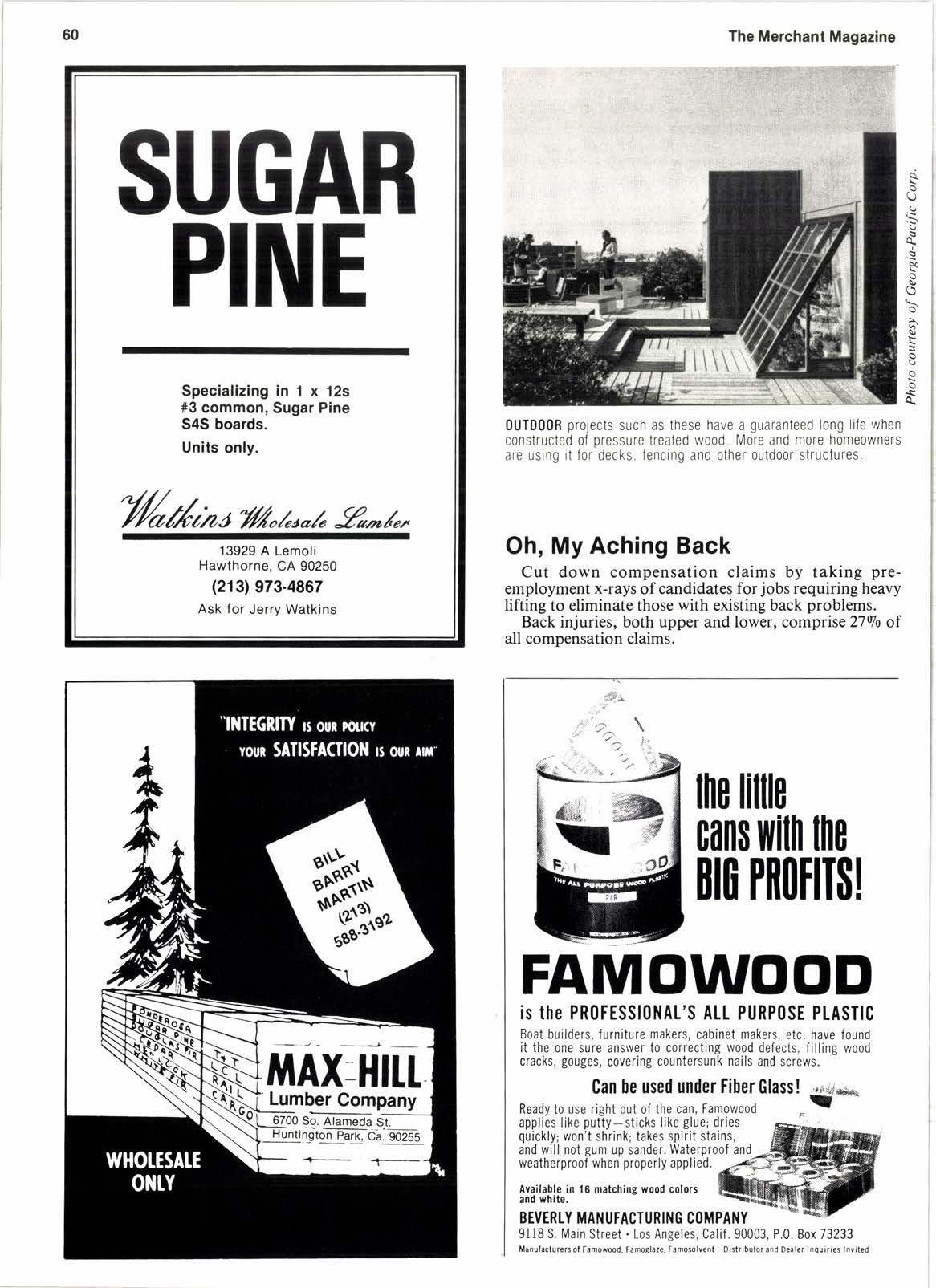

Osmose K-33 treated wood is used for a varietv of outdoor. above ground and ground contact structural and non-structural applications. Examples of uses include decking, fence boards, sills, furring strips, posts, landscape timbers, building poles, and All Weather Wood Foundations.

Flame Proof LHC produces a fire retardant treated wood that is better in appearance and performance than that produced by the old fire retardant formulations. Corrosion and hygroscopicity are substantially reduced. The material can be used for roof and floor trusses, beams, interior roof decks, architectural millwork, trim, paneling, interior

Story at a Glance

Treating plant added to serve growing Rocky Mountain area and to diverslfy company 100 work in large mlllwork operatlon strlct standards followed in treatlng program.

load bearing and non-load bearing partitions in homes, apartments, commercial. industrial and institutional buildings.

Wigand stresses tight quality control in all phases of its operations. All treating is done in strict accordance with American Wood Preservers Association (AWPA) specifications in addition to Osmose's stringent inhouse quality control program. Each piece is stamped with the American Wood Preservers Bureau (AWPB) quality mark.

All lumber and plywood treated with Flame Proof LHC will bear the Underwriters Laboratories(UL) certification as having a flame spread of not more than 25 in a burn test of 30 minutes duration.

Products treated with both Flame Proof LHC and Osmose K-33 are being sold by lumber dealers throughout Colorado as well as New Mexico, Wyoming, Kansas, Nebraska, and South Dakota.

In order to meet the demands of dealers, Wigand carries over a million board feet of lumber and plywood. This inventory includes coastal hemlock, Douglas fir, spruce-pine-fir, and Southern yellow pine dimension lumber, as well as Western CDX and AC plywood. Also stocked are Ponderosa pine and Southern yellow pine landscape and structural timbers. Wigand will also provide treating services only (TSO) to customers.

TIMBERS are loaded into the 6'x 52' 0smose pressure treating cylinder. (top right) A workman monitors the amount of chemical beino used in the semi-automatic treating plant.llower lett) Wigand operales a 50,000 sq. ft. Unitemp dry kiln. (lower right) A worker does a quality control burn test 0n Flame Proof LHC fire retardant.

With this inventory and the capacity of the treating plant, Wigand is able to fulfill all requests for treated materials within a maximum of two to three weeks.

In addition to treated inventory products, Wigand supplies dealers and millwork houses with surfaced hardwood lumber, both domestic

(Please turn to Page 66)