3 minute read

How lumber moves from ship to shore

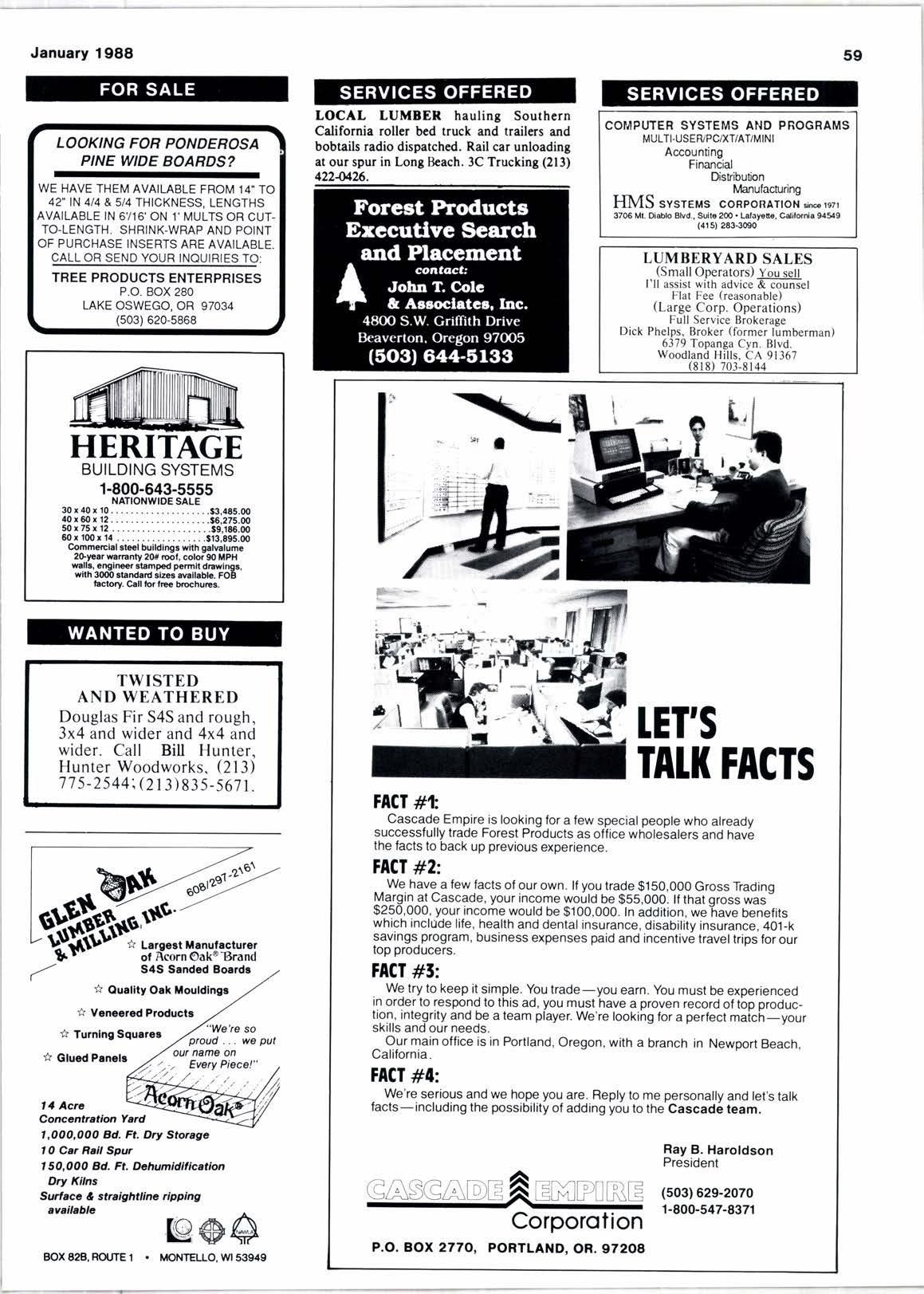

I UMBER HANDLING. The L words conjure up the image of a crew of men stacking tens of thousands of pieces of lumber, one piece at a time, onto a truck destined for the yard. And, actually, that was just the way the service was performed when Guerero Lumber Handling, Inc,, Long Beach, Ca., first began operations in 1931.

The nature of the business has changed dramatically throughout the years. Handstacking has long been replaced by bundle-toting forklifts, but the demand remains for Frank A. Guerero's service in Long Beach and Los Angeles harbors.

Frank Guerero's father started the business 57 years ago. Back then, it usually required about eight to ten handlers at the dock to meet the ship. Frank joined the company after he got out of the service in 1953. Father was getting out of the business as son and the age of automation settled in. Soon the full crew had been replaced by a single lift driver and an assistant.

Their day begins with the arrival of a steamship, often Greek or Korean in name, with hardwoods from a faraway port. The steamship company hires a group of longshoremen, which hold the legal right to unload the foreign vessels. They stack the lumber on the open dock and Guerero works with the customs broker for permission to receive the lumber. He checks the identity and condition of the wood before loading it onto his truck and hauling it, most often, to the final customer.

"Nowadays, we usually won't deliver the bundles of hardwoods to the yards," says Guerero. "Most of the importers just have a desk and an ollice, so we use our own trucks to deliver their orders direct to their customers."

Because they don't have the facilities to stock the lumber on site, many companies will order exactly the amount needed from the supplier. Others, usually in order to keep a steady relationship with suppliers, may try to sell the shipment while it's on the water. But by the time the wood is unloaded onto the dock, importers have only a few days to let it sit. After that, Guerero must ship the unsold lumber to a public warehouse. last choice since the

Story at a Glance

How dockside lumber handling has changed.. what's involved in offloading both hardwood and softwoods... what a professional handler does and why it is important.

backlog of bundles hurts everyone ver has no idea what he's picking up. - supplier, importer and handler. Many times I've seen them deliver "At certain times of the season, the wrong material. we ship more to the warehouses than "We also make sure the mill at other times," says Guerero. didn't ship the wrong material. Just "When the stock market crashed a last month, a company had ordered I couple months ago, lots of custo- x 12 meranti. On the docks we noted mers backed off on their orders. I x 10 had been sent in from MalayThey wanted to wait and see, and we sia. which the customer didn't want. ended up shipping a lot of lumber to It could have been delivered clear the warehouses." back to the East Coast before anvone

The docks are open to the public, though, so companies can - and a number (especially with smaller shipments) do - attempt to pick up and deliver their lumber without Guerero. But the problems they encounter are often not worth the trouble. Waiting for the stevedores to unload your shipment, dealing with detailed paperwork, having your own truck, hiring someone to load the truck, and securing a forklift at the dock are among the inconveniences for the infrequent handler.

In addition to availability, companies such as Guerero's also offer experience. "People trust us," he says. "They know that we know the difference between various species of hardwoods. A typical freight dri- llETAIIEl| else discovered the error," says Guerero.

He is also familiar with the various markings companies use to identify each load. The ends of boards may be painted half red and half white, or painted white with a red dot. Other importers merely have the company name, initials or logo stenciled on the bundle, or have a simple code applied. For example, a bundle stamped Russwood B-14 would identify a Russell Stadelman & Co. shipment of hardwood plywood.

The handler must also carefully check the shipment for damages. Guerero explains: "ln loading and unloading the cargo, about 100/o of it may get scuffed, gouged or dropped. The bundle may break open and you'll have pieces adrift everywhere. After they restack the bundle, we'll have to have a piece count and check the lumber's condition."

He must also note damages that may have been incurred when the wood was initially loaded onto the ship or perhaps tossed about on the

(Please turn to pagc 57)